3D scanning has provided a lot of perks to many industries by easing the workflow and saving cost and effort efficiently. It is no wonder why t e technology has already reached a huge number of users from around the world.

Hence, the number of companies offering a 3D laser scanner has also multiplied. This has made it difficult to choose the one that could be best for your specific application.

So, what is 3D laser scanning? And, how is it helping businesses to cater to a different application? These questions are very common these days. Those who have not yet tried 3D scanning are trying to understand the nuances of opportunities 3D scanning offers.

3D laser scanners can help create 3D models of parts and objects without even touching them. It does so with the help of a projected laser. The coordinates of different points are noted and the 3D model is prepared based on these dimensions.

While it may sound like a job that could be completed with a press of a button, it is not. There is no 3D scanner that is completely automated. One needs to put effort to learn to operate 3D scanners. Hence, choosing the right 3D laser scanner becomes even more crucial.

Moreover, there are differences between the output file in terms of quality, resolution and lot other factors. The 3D laser scanner designed by different brands possesses its own limitations and challenges.

Some could be best at accuracy and others may get the work accomplished faster. Based on your preferences, it would be easy to find out which 3D scanner would best fit your needs.

What to Expect When Buying a 3D Laser Scanner?

Credit: Artec3D

Credit: Artec3D

3D scanners make life easier by employing easy processing and hassle-free technology. With only a few trails, one can master its operation. However, there are certain things one must expect when planning to buy a 3D scanner.

Because you may have to search a bit longer, it may seem like a daunting task. Every 3D scanner has its own strength. For example, some can scan tiny objects highlighting finer details and some can scan from quite considerate distances. Some are mobile and usually, a handheld device and others are stationary 3D scanners.

You can select the brand that better serves your expectations. For this, you may have to compare between brands. You can do that by visiting different stores and asking them to showcase the results of scans using the 3D scanners available.

Depending on what companies say won’t be a wise idea. Who would talk bad about their own product? So, referring to online reviews may also be a great aid when finalizing the choice.

Whichever 3D scanner you choose, you must look for the brand that provides the best support. You would be needing that from time to time. If you are looking for the lowest price, it may not get you the best quality. If your job requires precision, your budget must be flexible enough. 3D laser scanner price won’t be cheap if you are looking for a device that could be utilized for high-end applications.

Do not expect the 3D scanner to change the entire workflow in a day. Because it takes time to understand how the device works, you may have to wait until you realize what all you can accomplish using a 3D scanner.

Criteria for Choosing a 3D Laser Scanner

The job is not completed yet. You must check for certain criteria before finalizing your decision about which 3D laser scanner to choose. Depending on these factors, you would be able to visualize the device that best fits your specific application.

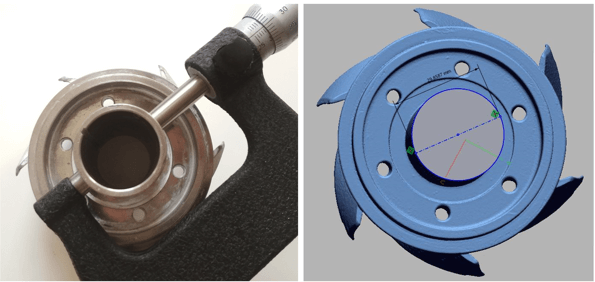

Accuracy

Credit: Artec3D

Credit: Artec3D

Do you require a 3D scanner for gathering the details of the parts for making key decisions for your company? If that is so, accuracy is the topmost priority for your 3D scanner. Slightest miscalculation of dimension could get you into trouble. Accuracy becomes directly proportional to the precision significance.

To ensure that the highest accuracy is achieved, one must calibrate the 3D scanner. The manufacturers of the 3D scanners do calibrate the device before selling it to the users for the highest accuracy, some of the options of 3D laser scanner offer onsite calibration as well.

In other words, users can tweak the accuracy settings from time to time, depending on the nature of the application, hence realizing the best results. By manual adjustment, one does not have to depend on the calibration setting the manufacturer of the device has done. Hence, allowing freedom over the 3D scanner performance.

If you are expecting high accuracy, you must take professional 3D scanners into consideration. The price would be on a higher-end, but the results would certainly justify the cost. To find out what is the accuracy of the device, you can check the specks of the 3D scanner.

Speed

Credit: Artec3D

Credit: Artec3D

While different 3D scanner technology has its own terminology to calculate the speed of the 3D scanner based on it, 3D laser scanner speed is assessed by the number of points it can capture in a single second. A laser 3D scanner can scan millions of points in one second. As the number of points increases, the speed increases too.

However, these numbers are for references and the results may vary depending on the distance of the object, its size, surface quality, etc.

Those who work on a tight schedule and must complete the job within the timeline could actually make use of such scanners that provide high speed. Using a high-speed 3D scanner, one can quickly scan objects and expedite the process and workflow with ease. If your project is large and has a huge budget, a speedy 3D scanner would help complete the same on time and with the best results.

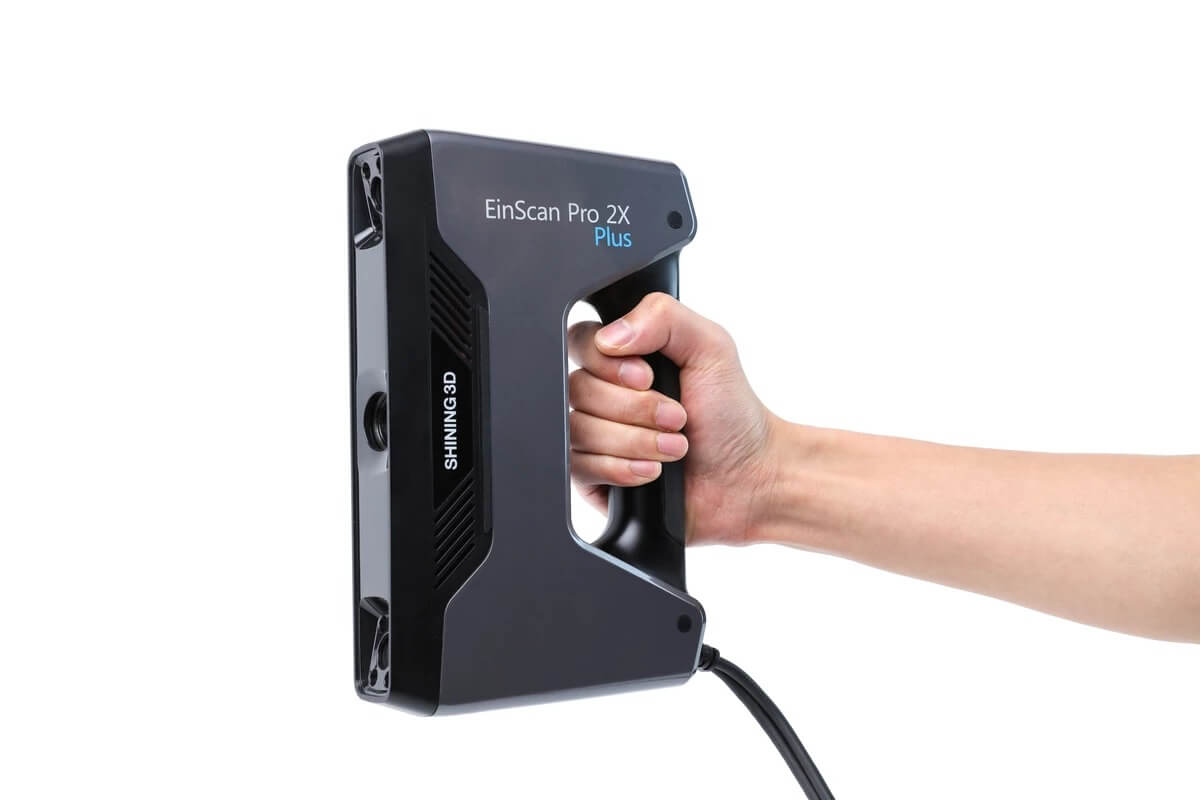

Portability and Ease of Use

Scanner: EinScan Pro 2X Plus

Scanner: EinScan Pro 2X Plus

Assessing portability is also very important. As mentioned before, there are two categories of 3D scanner based on portability: Handheld 3D scanner and Stationary 3D scanner. Both have their own strengths and weaknesses.

The stationary 3D scanners are capable of scanning large objects with ease and in the fastest time possible. On the other end, a handheld 3D scanner is perfect when scanning tricky angles and different turns of the object difficult to reach. By offering freedom of control to the user, the handheld device is a much more flexible solution. However, the speed isn’t as competitive as the one provided by stationary 3D scanners.

There are other things to consider when choosing between these two choices. Do you work in a controlled environment or you need a lot of traveling? If your scanning happens out in the field, you may not like stationary 3D scanners.

One more thing to consider when figuring out the portability of a 3D scanner. Does it run on an internal source only or can work on external sources as well? This would be highly beneficial when you are working with a handheld device and do not have a power source nearby to plug the 3D scanner too.

Portability decides the kind of 3D scanner you must choose. Similarly, ease of use comes hand in hand. If you are going to use your device most often, you just need an option that can provide the best results with minimum efforts. In such a case a portable 3D scanner would really be helpful when reaching the difficult regions. However, speed would also matter.

A 3D scanner capturing objects quickly would help you move on to the next project. It will save time and money and would let you work with restricted timelines.

Resolution

Credit: Artec3D

Many may not be able to pick the difference between accuracy and resolution. However, these two are completely apart. Accuracy measures the actual degree of correctness in terms of dimension, size etc. However, the resolution is based on the distance between any of the given points of a 3D model. Resolution is specified by microns or millimeters.

A 3D scanner with the least distance between the points is capable of providing the best resolution. This will highlight the details finely. The high-resolution 3D laser scanner can be utilized for a variety of purposes. And, especially where the resolution matters most. For example, reverse engineering, VR, animation, forensics, quality control, jewelry designing, and many others.

A high-resolution 3D scanner is capable of producing models with clear views and perfect appearance.

However, before choosing a high-resolution 3D scanner, one must understand the challenges it brings with itself. A high-resolution 3D scanner is heavier and it takes more time to complete the scan. When it is about printing a 3D model later, using a 3D printer, a high-resolution 3D model would make the process slow. Also, users with computers that aren’t equipped with the latest technology, and hence, are less powerful, would experience problems working with high-resolution 3D models.

One can go for a low-resolution 3D scanner when one needs fast processing time. The resolution settings must be used correctly in order to get the desired 3D model.

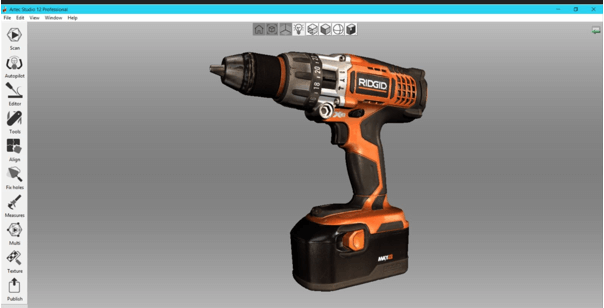

Software Updates

Credit: Artec3D

Credit: Artec3D

If you have forgotten that the software is the reason why 3D scanners are doing its job, you must revise your assessment strategy. The software makes things happen and 3D scanner’s capabilities depend on how good is the software the 3D scanner uses. Because of the software, the 3D scanner manufacturers are able to introduce new features to the already existing technology.

A powerful packed software would be able to capture objects of distinct sizes with ease without compromising on the output result. These applications are sometimes difficult to manage and few are highly user-friendly. Even the novice can operate the easy to learn the software.

Few of the companies offer post-processing software that could do wonders when utilized to its optimum use. Hence, you must take into consideration the scanner and the software before you choose the right 3D laser scanner.

One more thing you must note when checking the software of the 3D scanner. Do not forget to verify is the manufacturer of the 3D scanner is engaged in continually improving the features of the software and releasing the update for its existing users. This is very crucial. Because technology is progressive, you must expect it to become better than it is now.

When that happens, most of the changes would be handled by updating the software. In case, your manufacturer does not provide you the flexibility of updating the software, your 3D scanner may become outdated after a few years of use.

Who would like to spend on a 3D scanner after every few years? No one would. Hence, to check the same is a must for those looking for a long term use of an expensive device. No one pays thousands of dollars for something that they may stop using after a couple of months.

The Conclusion

While it is not easy, to sum up, the criteria in a few headings, these are the ones that matter the most. Apart from the above factors, one must measure the maintenance cost of the device, size of the parts one wants to scan, how many applications one caters and many others.

Simply by focusing on the needs of the 3D scanner, one can select the one that ticks most of the right boxes. When said that, it is also true that none of the 3D scanners would stand best at all your considerations. You may have to compromise in a few areas that are not much important.

However, whichever you choose, it is certain that the 3D laser scanner would be a great addition to your business workflow. By using a 3D scanner, you would be able to enhance your output as well as scale your business. Being able to complete a greater number of projects, you can increase your profit.

A 3D laser scanner is capable of many great things. And, your company can utilize every bit of it. By choosing the one that meets the set standards of your business, you can unveil huge potential that seemed far away.