As technology keeps advancing, you get better accessibility. Resin printing brought about a positive change in our lives. With the introduction of large resin 3D printers, we benefit from optimized production processes.

The printers produce industrial-quality models at an efficient speed. These printers are now widely available for use.

This article describes some of the best and efficient large 3D resin printers that you can buy. Each printer has been tried and tested by our experts to ensure value for money.

What is a Large Resin 3D Printer?

Resin 3D printers offer a high level of detail while printing. The way a resin 3D printer works depends on the technology included in the printer.

A resin 3D printer can use multiple technologies, such as SLA, DLP, or LCD to cure the liquid resin. The printer uses these technologies to create crisp and high-resolution models at a high speed.

These technologies, however, do differ in the way they cure UV resin. SLA technology employs UV laser and galvanometers that cure resin selectively.

DLP 3D printing uses a projector to cure resin while LCD technology uses an LCD screen to solidify resin.

Uses of a Large Resin 3D Printer

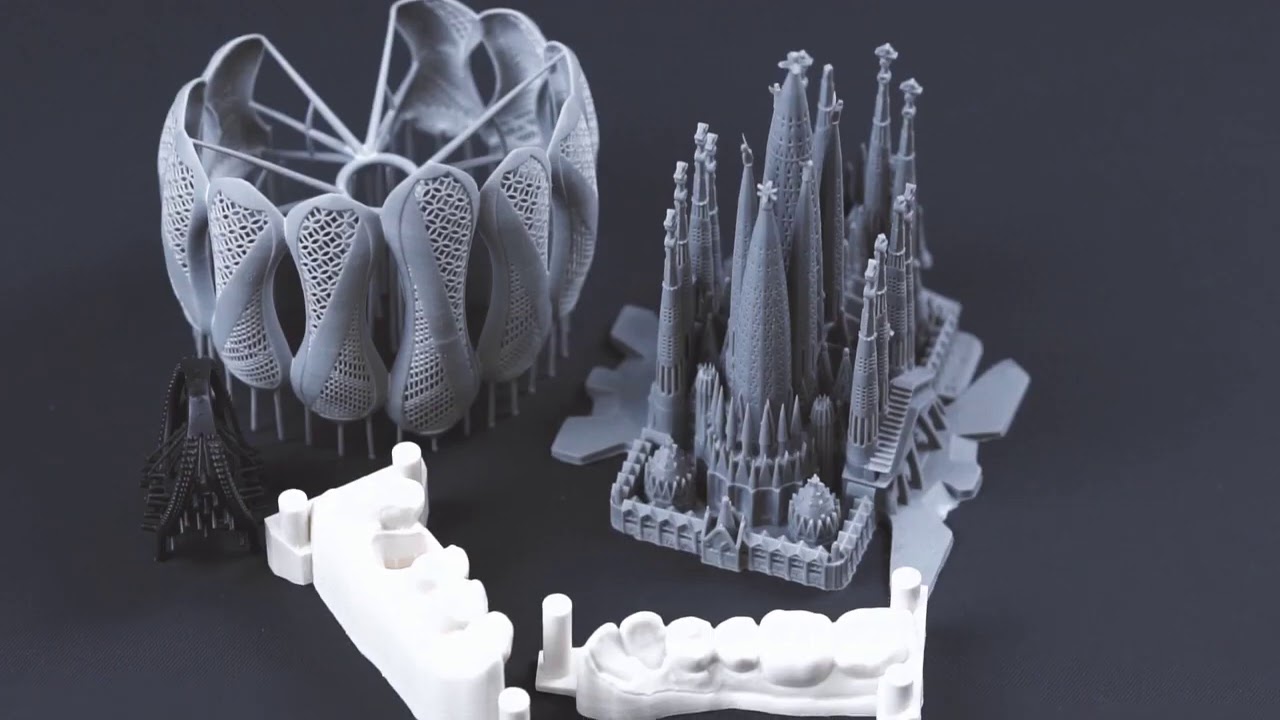

A large resin 3D printer can have multiple uses. These machines are ideal for high-precision prototyping. Having a liquid 3D printer at your disposal accelerates innovation.

A large resin 3D printer allows you to transform your ideas into models. The printer is typically used for the following purposes:

Medicinal and Dental Tools

Medical and dental processes require complicated tools. A large resin 3D printer allows you to produce consistent and accurate high-quality tools for each stage of the process.

The printer allows you to work on tools and devices that you can customize according to the individual needs of each patient.

You can be innovative thanks to 3D printing. Moreover, you will also save time with high-speed printing, which helps you lower costs as well.

Gifts and Toys

With a large resin 3D printer, you can print customized and personalized gifts for your loved ones. You can modify designs to your preference.

Using a 3D printer, you can print toys as well as kitchenware, with a variety of products in between, including high-quality jewelry.

3D Printer for Education and Entertainment

3D printing can be a technical but fun process that allows you to experiment with various designs. You do not have to limit your imagination and can try out any idea with 3D printing.

You can also use this multifunctional tool for different purposes, including research and immersive learning, in a wide variety of fields.

Comparison Chart

| Name | Link | Nomination | Overall Rating |

|---|---|---|---|

| 3D Systems ProX 950 | Editor’s Choice | 9.8 | |

| Formlabs Form 3 | Strong and Practical | 9.5 | |

| EnvisionTEC D4K Pro | Most Functional | 9.5 | |

| Uniz Slash Plus | Most Reliable | 9.3 | |

| UnionTech RS Pro 800 | Best Value | 9.2 | |

| DWS XPro S | Premium Pick | 9.6 | |

| Peopoly Phenom | Best Budget | 9.0 | |

| Photocentric LC Precision 1.5 | Strong and Durable | 9.7 | |

| B9 Creations B9 Core 550 | Best Usage | 9.1 | |

| Asiga MAX | Strong and Sturdy | 9.8 |

List of large Resin 3D Printers

3D Systems ProX 950

|

3D Systems’ ProX 950 printer is truly the best in its league. The large resin 3D printer offers high-speed, accuracy, and a large format.

This model is the greenest large resin 3D printer available today. The printer uses revolutionary parts to help you take on multiple design projects.

The ProX 950 functions with the latest PolyRay™ print head technology. The printer can manufacture models at a speed that is 10 times greater than an average 3D printer.

With high performance, the machine is ideal for demanding projects, such as medical devices, industry, or even aerospace.

The ProX 950 is extremely flexible and versatile in its function. This large resin 3D printer produces models with high precision without compromising feature details.

Salient Features:

- High material efficiency uses less than a third of the material required with other printers, which helps you to save money

- Meets injection model accuracy with its high precision

- High-resolution printing

- Uses a wide range of functional materials for prototyping and production

- With multiple features, this large resin 3D printer is a top pick for industrial production.

- Delivers consistent and reliable production

- Quiet operation

- Easy resin loading feature

- Large build volume for mass production

- High functioning software

- Resin fill-ups can be expensive

Formlabs Form 3

|

Formlabs Form 3 is a stellar large resin 3D printer, hugely popular in the manufacturing world owing to its professional prowess.

Magnificent on the outside, the inside of the printer houses SLA technology based on Low Force Stereolithography. This technology results in superior texture objects.

Form 3 has a build volume of 145 x 145 x 185 mm, which allows it to cater to high consumer needs. The large resin 3D printer employs a large 5.5-inch touchscreen for a hassle-free user interface.

With a range between 25 to 300 microns, the printer offers accurate printing in high resolution.

Salient Features:

- Allows real-time monitoring and cartridge sensors to the introduction of a new form of resin

- The closed compartment body makes it a safe choice

- Supports a wide range of printing materials

- An advanced form of SLA, known as Low Force Stereolithography

- Closed body for added safety

- Can support multiple users and printers at a time

- Great quality prints at fast speeds

- Expensive

EnvisionTEC D4K Pro

|

EnvisionTEC D4K Pro is one of the best large resin 3D printers in the league. The printer has a build volume of 148 x 83 x 110 mm, which allows it to produce large items.

Its key features include high print speed without compromising the quality of the prototype. The D4K Pro is compatible with all kinds of castable resins, including PIC100, WIC100G, QView, and more

Though it’s an expensive industrial 3D printer, the D4K Pro has several useful features.

Salient Features:

- The build platform ensures high-quality 3D printing for a variety of materials

- D4K Pro can produce models with an accuracy of up to 25 microns in the XY resolution, and 1 micron on the Z-axis.

- The closed compartment body makes it a safe choice

- Supports a wide range of printing materials

- Allows for mass production with repeatable designs

- High print resolution

- Accurate designs

- Easy to set up and handle

- User-friendly interface

- Not ideal for use at home

Uniz Slash Plus

|

Known for its high-speed resin printing, the Uniz Slash Plus is one of the best large resin 3D printers available today, with LCD Stereolithography to produce high-quality3D prints.

The printer has a large build volume of 192 x 120 x 200 mm, which makes it ideal for large-scale projects. The printer has a high XY resolution of 75µm with an accuracy of ±20µm.

With the Uniz smart support technology, the printer offers a high printing speed that can reach up to 20mm/hour. This 3D printer also has a durable resin vat floor that can last for 1,000 3D printing hours.

It has an auto-calibration system, which means you will have less trouble leveling the bed. The print bed and extrusion nozzle can heat up to an extensive range of temperatures. This feature enables you to print with different kinds of materials.

The software allows you to make all the basic changes to your 3D model. You can move, rotate, zoom and add specific media to your prototype. Different controls are available from the control panel while it also provides the information while you print.

Salient Features::

- This printer comes with the Uniz software that is compatible with various devices, including Windows and Mac.

- The printer arrives assembled, so you can start printing right away.

- Durable product

- Easy to use.

- Unidirectional peel technology allows for above-average print quality

- Works with various types of resins for printing

- You can easily remove the finished products

- Solid frame structure

- You can print directly from a computer via Wi-FI

- No control screen

UnionTech RSPro 800

|

The Union Tech’s RS Pro 800 uses SLA technology for producing 3D prints of parts and functional prototypes. The printing technology has a powerful laser beam used to solidify resins layer by layer.

The printer has a build volume of 800 mm x 800 mm x 550 mm, which makes it ideal for producing large models.

The Pro 800 is a large resin 3D printer that also offers a minimum layer thickness of up to 0.05 mm.

The printer also has a closed-loop system that performs various functions, including regulating laser power, resin leveling, temperature maintenance, and so on. The printer has large build plate prints without warping.

The machine gives its users free control over the settings. You can even operate it remotely. The printer can print resins in various colors.

Salient Features:

- Allows you to operate the printer remotely

- The printer has a large granite build plate. The plate provides immense stability and flatness required for the printing process

- Automatic pump for resin refilling

- The Pro 800 is a first-rate printer, which is quite popular in manufacturing. Its ability to produce quality prints makes it one of a kind.

- Super accurate and precise

- Allows third party material use

- Easy to use, which makes it beginner-friendly

- Changeable resin mat

- Requires assembly

DWS X Pro S

|

DWS XPro S is a large resin 3D printer that offers a build volume of parts and functional prototypes in 300 x300 x 300 mm. The machine is ideal for industrial manufacturing.

It is compatible with a wide range of resins that you can use for casting, molding, functional prototypes, and more.

The machine uses SLA technology, using a laser beam to solidify resins into functional models. The X Pro S large resin 3D printer is a fully automated, all-in-one printer.

X Pro S can work with various materials including ABS, like polypropylene, rubber, and other transparent materials

Salient Features:

- Vertical production offers greater control to the users

- Uses the Nauta, DWS’ parametric software for scaling and copying models

- The software also predicts the amount of resin required for a prototype

- DWS X Pro S is a great option if you want to manufacture items

- High print resolution

- Accurate designs

- Easy to set up and handle

- User-friendly interface

- Low running and maintenance cost

- Accompanying products can be expensive

Peopoly Phenom

|

Peopoly Phenom is one of the best large resin 3D printers. In fact, it’s probably one of the biggest 3D printer models. The huge build volume of 0.8 x 6.1 x 15.8 inches of the printer is ideal for large format printing.

The Phenom uses UV LED technology instead of a laser. A grid of LEDs under the bed emits UV light, which means fewer moving parts and therefore limited complications.

However, there is also a risk of the UV light causing damage to the LCD screen, which is likely to occur after 400 hours of printing time.

This will occur after approximately 400 hours of print time. You can use the touchscreen to control different features and settings of the Phenom.

Salient Features:

- Uses ChiTuBox as a slicer, specifically designed to slice 3D models for use in SLA resin systems

- ChiTuBox offers a one-click function to hollow out a model

- Uses a fast technique to cure resin, which results in high-speed printing

- Excellent print quality

- User friendly with a responsive user interface

- The bed is easy to level

- Large print volume and formatting with its massive build volume

- The LCD screen may require replacement over time

Photocentric LC Precision 1.5

|

The Photocentric Liquid Crystal Precision 1.5 is a large resin 3D printer with a build volume of 121 × 68 × 160 mm.

The Precision 1.5 printer functions as a standalone unit with increased accuracy, a disposable vat system, and a user-friendly touchscreen.

The touchscreen allows you to control the settings and operate various functions on this large resin 3D printer.

The LC Precision 1.5 offers precise printing with high resolution. The layer thickness for the printer is 25 microns with an XY accuracy of 47 microns.

Unlike other printers, this printer has a dedicated part-washing unit, which you can use with a liquid resin cleaner.

With its advanced features, this printer is surely a steal.

Salient Features:

- The printer is compatible with a wide range of resins developed by Photocentric. This allows you to be flexible in terms of color and rendering

- If there is a power failure, the printer’s resume print function allows you to start from where you left off.

- The Photocentric software allows you to develop increasingly realistic details.

- Provides fast printing with accuracy

- Easy to assemble

- Decent build volume

- High-quality printing

- The print bed may need some improvement

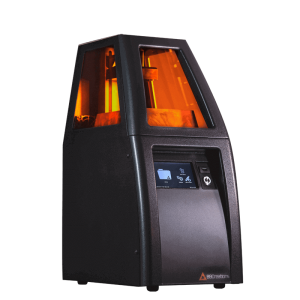

B9Creations B9 Core 550

|

The B9 Core Series model 550 3D printer is a large resin 3D printer that is fast, affordable, and well built. The printer allows you to design models directly from your computer.

The printer uses the B9 Core Series software with CAD technology. This printer is ideal for large-scale production, with a build volume of 96 x 54 x 127 mm and a 50-micron resolution.

The B9 Core 550 has precision-engineered technology that eliminates the need for functions, such as calibration, speed optimization, and so on.

You can connect the printer to various devices with Wi-Fi, USB, or Ethernet.

This machine is truly one of the best large resin 3D printers that you should consider.

Salient Features:

- Easy to use touchscreen user interface that performs various functions, including importing graphic and customizing your model

- Requires no maintenance or high-cost material

- Powered by an industrial LED light engine that enables fast printing

- Layer to layer printer that allows complex designing as well

- This machine is great for professional use.

- Quick layer curing time

- Simple, easy-to-use workflow

- Also offers Wi-Fi connectivity for easier control

- The build volume is not as large as other printers

Asiga MAX

|

Asiga makes 3D printers for dental applications. Their recent product, the Asiga MAX is a powerful large resin 3D printer, with DLP technology for detailed printing at high speed.

This technology allows you to make large products without sacrificing print quality. The LD3 has a build volume of around 119 × 67 × 75 mm.

The Asiga MAX allows you to experiment with third-party products so you can produce a wide range of products. This printer a well-rounded package for jewelers interested in working with 3D printing.

Salient Features:

- This printer features modern technology, such as a touchscreen and Wi-Fi. These features make for an easier operation.

- The 3D printer has a closed enclosure, which keeps the device dustproof.

- Easy to assemble and takes less than 30 minutes to put together

- The printer has high compatibility, as you can easily use it with any third party material

- Network compatibility through Wi-Fi, USB, and Ethernet cable

- Easy to assemble

- Compact footprint

- The printer bed heats up in 5 minutes

- Doesn’t have clear operating instructions

Buyer’s Guide

You need to weigh a range of options when selecting purchasing a large resin 3D printer, including:

- Speed: With high-speed printing, you can print many products in a limited time. In order to save time, select a printer that allows high printing speed without compromising the print quality to get the best possible results.

- Printing Quality: Select a large resin 3D printer aligned with the level of quality you require with your printing.

- User Interface: The quality of the interface can change your printing experience. A good user interface helps you save time while navigating through the settings with ease.

- Resolution: A high-resolution 3D printer allows you to create models with intricate details and designs. If you want detailed designs, you should look for a high-resolution printer.

- Build Volume: You have to consider the dimensions of your printer as well. A build plate is usually shaped as a square or rectangle. If you are a beginner, a small printer will be suitable. However, if you’re venturing into the manufacturing business, then you might need to look for a device with a larger build volume. All the printers mentioned above have a large build volume.

- Compatibility: A compatible printer allows you to work with different types of printing materials. With a wide range of material compatibility, you can produce unique designs and expand your creativity.

Frequently Asked Questions (FAQS)

Why Does Ventilation Matter While 3D Printing?

When your filament or resin heats up, it releases intense and reeking fumes, which may lead to irritation and headaches. Therefore, a properly ventilated room is necessary for 3D printing. However, some printers already have an enclosure or a fan, which will reduce your contact from the fume extraction.

What Is The Difference Between FDM And Resin Printing?

Resin printing offers better precision, smoother surface areas, and crisper details on small models. The FDM does not deliver the required smoothness or precision. However, resin printing can be complicated while FDM is relatively simpler.

Conclusion

There are different types of large resin 3D printers available. Each printer comes with unique features.

From the printers reviewed above, Unitech’s RS Pro is one of the most cost-effective large resin 3D printers with useful features.

The 3D Systems ProX 950 is a jack of all trades. The printer has multi-functional capabilities with advanced engineered technology.

All large resin 3D printers mentioned above are ideal for large-scale productions. With this guide, you can easily navigate through the available options and get yourself the best large resin 3D printer.