It is no wonder then we have progressed far enough to be able to 3D print with metals. It’s not only the thermoplastic but a wide range of material is made available for 3D printing.

However, you may have to think of the right 3D printing process when choosing the material, you wish to 3D print with.

Not every 3D printer will work with all the materials available. Especially when thinking of printing with Titanium, you must take all the precautions you can.

There is a separate league of Titanium 3D printer for working with this specific metal. And, you must select the right printing process if you wish to accomplish a project using Titanium.

Whatever the 3D printing aim is, if it involves titanium, you are bound to act in the right direction. Or, you may have to put a lot at stake.

Without making it sound so difficult for you, let us dive into the details of the topic. First of all, Titanium additive manufacturing isn’t for beginners.

Nor it is for offices or home use. The use of titanium shines within industries. And, there are understandable reasons for the same. Understanding the various nooks and corners of the technology will keep you all packed up.

If you are looking for a metal that is very strong yet precise enough to be able to get the intricate details smoothly, you are talking about titanium.

There is thermoplastic available with different metal combinations, ranging from 50% to 85% of the stake, it won’t get you the results even close to what titanium alone can.

This is where all the doubts end and you choose titanium 3D printing to give more flexibility to your projects.

A Brief Description About Titanium

Before we go talking about titanium 3D printer, let’s just get to know the miracle metal a little closer. Titanium is a combination of strength and delicacy.

Titanium can bond with other elements by sharing its electron, and with some ions, it can even get charged electrically. Titanium can be found in all those applications where a considerable amount of force is required.

Do you know that Titanium is the hardest known metal on the earth? Not just that, it is also the best when considering the ratio of strength to weight.

All these qualities make the metal best for a variety of applications and within different niches. From automobile to entertainment to aerospace, every industry enjoys playing around with this metal.

The best part is that the metal isn’t as susceptible to corrosion that most of the metals are. Plus, it features a high melting temperature, even more than most of the metals we usually 3D print with.

All these reasons are sure enough to make titanium unique and well accountable when lightweight material resilience is what you need.

It is the best choice for all sophisticated applications. Let’s not wander too far. The example is very close by. Titanium is the best suit for biomedical implants.

Although there have been quite some exciting advanced in the synthetic polymers, nothing comes closer to titanium when its about prosthetic needs.

But, isn’t it important also to know which titanium 3D printer could get the best results justifying the benefits of the miracle metal? It sure is.

We must find out the best 3D Printing process, the best 3D printer as well as other details connected with titanium powder 3D printing.

How to Work with Titanium 3D Printing?

Titanium, as we know, owns the highest strength to its collar. Hence, it does require more consideration alongside with specialized preparation than any other metal alloy.

This is due to its unique physical properties that come along with the metal. You cannot use titanium with thermoplastic combination and use it as a filament spool for creating models at home. On the contrary, you will require lasers to tame the metal as you want.

And, not just any laser for that matter. You would require a high power laser to wrangle the metal in your designs. You must look for a Direct Metal Laser Sintering (DMLS) 3D printer.

When working with DMLS 3D printers, you do not have to worry about the design part. This is because most of the 3D Designing applications are compatible with a titanium 3D printer.

In fact, you can choose the one that is easier for you to handle or the one you are used to working with.

Above all, these 3D printers work with the same extension of files as the usual FDM 3D Printers. So, you do not have to think much about the output of the design files as well.

What is Different Then?

The game changes when you start building the 3D model out of the DMLS machine. In other words, the 3D printing process is completely different from the usual desktop printers.

It does the same job of creating the 3D models from the 3D files, but the process differs. And, it starts right from the time you plan to feed the 3D file to the titanium 3D printer.

Instead of connecting your 3D printer to the computer, you need to upload the 3D design directly to the titanium 3D printer.

Once you have the design inside the memory of the 3D printer, it’s time for the optic lasers to act. These sinters the titanium powder together to create the end product.

This laser directs to the special chamber, a part of the DMLS machine. There is a platform inside the chamber responsible for dispensing the material into layers.

The job of the laser is to melt the titanium from powder form to the liquid substitute. The liquid takes shape with the help of the blade.

Do not worry. It may sound complicated. However, the best part is that the machine would take care of the entire process that happens inside the titanium 3D printer. After you have transferred the 3D file to the machine, your task ends and the machine starts working.

What 3D Printing Processes Work with Titanium?

What do you expect from a technology that is consistently progressing? We do have other 3D printing processes that can 3D Print with titanium.

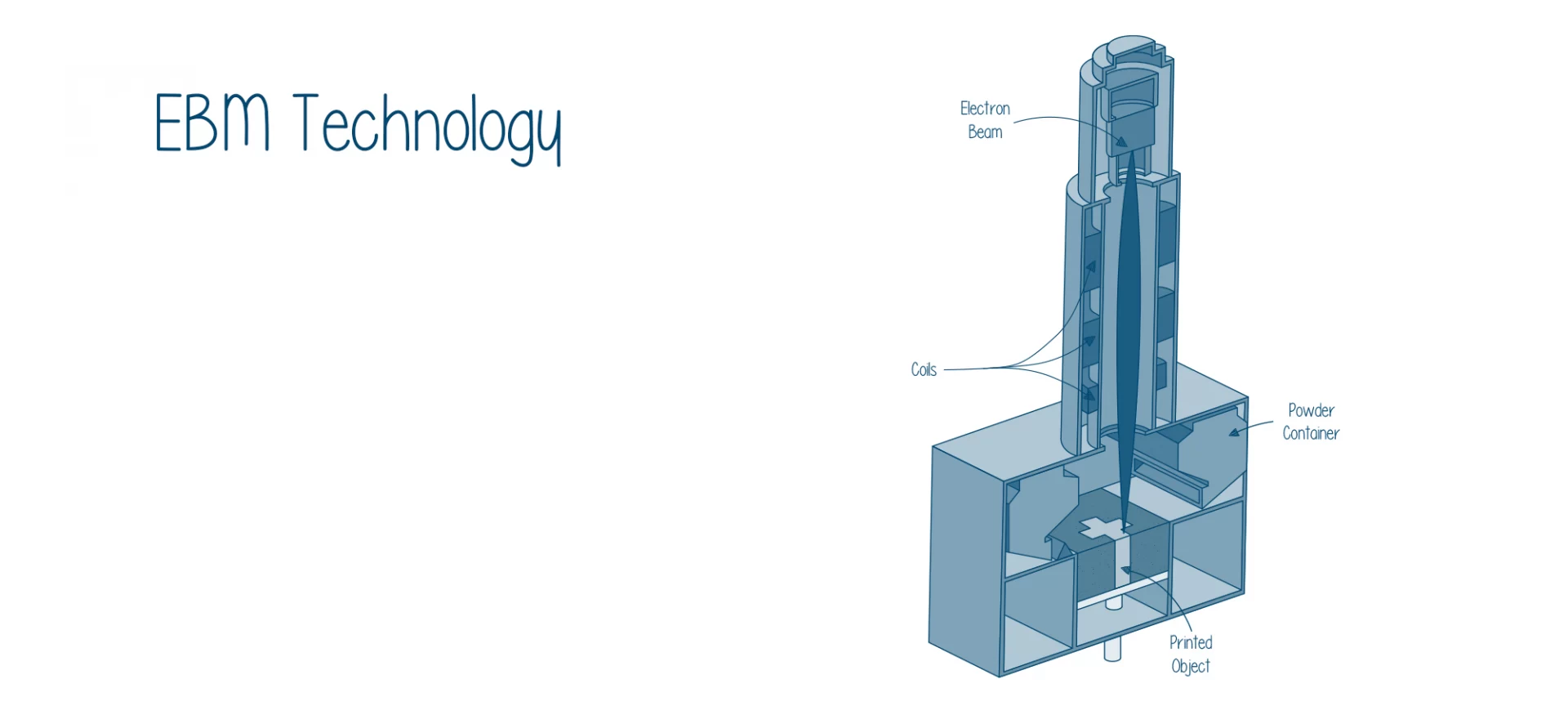

Electronic Beam Melting (EBM) 3D Printing

EBM is another 3D printing process that has been gaining a lot of attention from experts in 3D printing. Only by looking at the names of both these technologies you can find out the major difference between the two. Yes, it is the power source.

One uses lasers and the other makes use of an electron beam. Both these 3D printing process can work with titanium otherwise.

EBM produces higher energy output from DMLS. And, there are various other advantages too. You can expect an EBM machine to produce fewer internal defects with way better fatigue properties that that of DMLS machines.

These also result in minimal to no waste material. Plus, all the excess titanium powder is recyclable.

On the contrary, DMLS can help achieve finer layer thickness. It can produce a minimum of 20–40 μm. Whereas, through the EBM titanium 3D printer, users can get to 50–70 μm layer thickness.

Hence, DMLS can produce a better and smoother surface finish. And, this is the major reason why DMLS is still chosen over EBM in most of the cases.

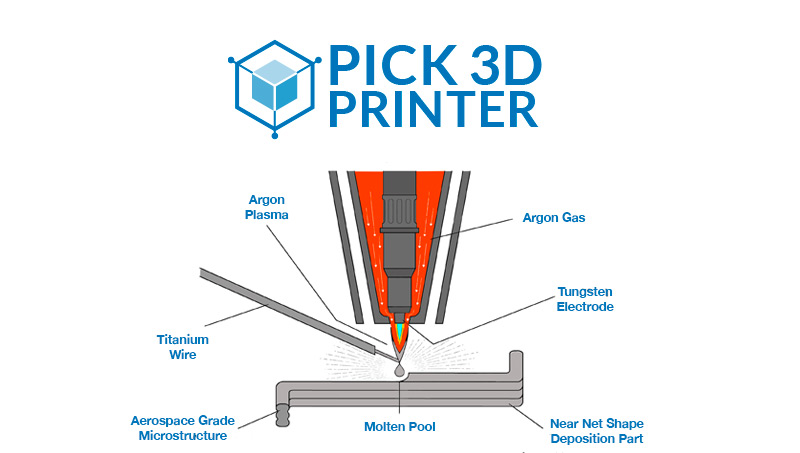

Rapid Plasma Deposition (RPD)

There is one more approach for getting a clean 3D model with a titanium 3D printer. An approach introduced by Norsk Titanium. And, the process is known as Rapid Plasma Deposition (RPD).

So, what happens in RPD? It starts with melting a titanium wire to build layers of 3 to 4 mm in height and 8 to 12 mm in width. The entire process takes place inside a chamber which is covered with an atmosphere of inert argon gas.

The RPD produces comparatively rough surfaces when compared to DMLS or EBM. But it could work faster, close to 50 to 100 times in comparison to the powder-based 3D printing. As per the creators, the production process when monitored 600 times per second, can produce high standards of consistency.

And, the machine can build larger volume parts. Making itself one of the major entries in the world of 3D printing. However, the journey is still long.

To replace DMLS with any other technology won’t be that easier. To date, the best titanium 3D printer is the one working on the DMLS 3D printing process.

Pros and Cons of Titanium 3D Printer

You must be all excited about 3D print with titanium. So, here is what you must expect of the metal. Learn about both sides of the coin and take decisions wisely.

- 3D printing with titanium isn’t an easy process. However, the good news is that after owning the right titanium 3D printer, all you have to worry about is the 3D design.

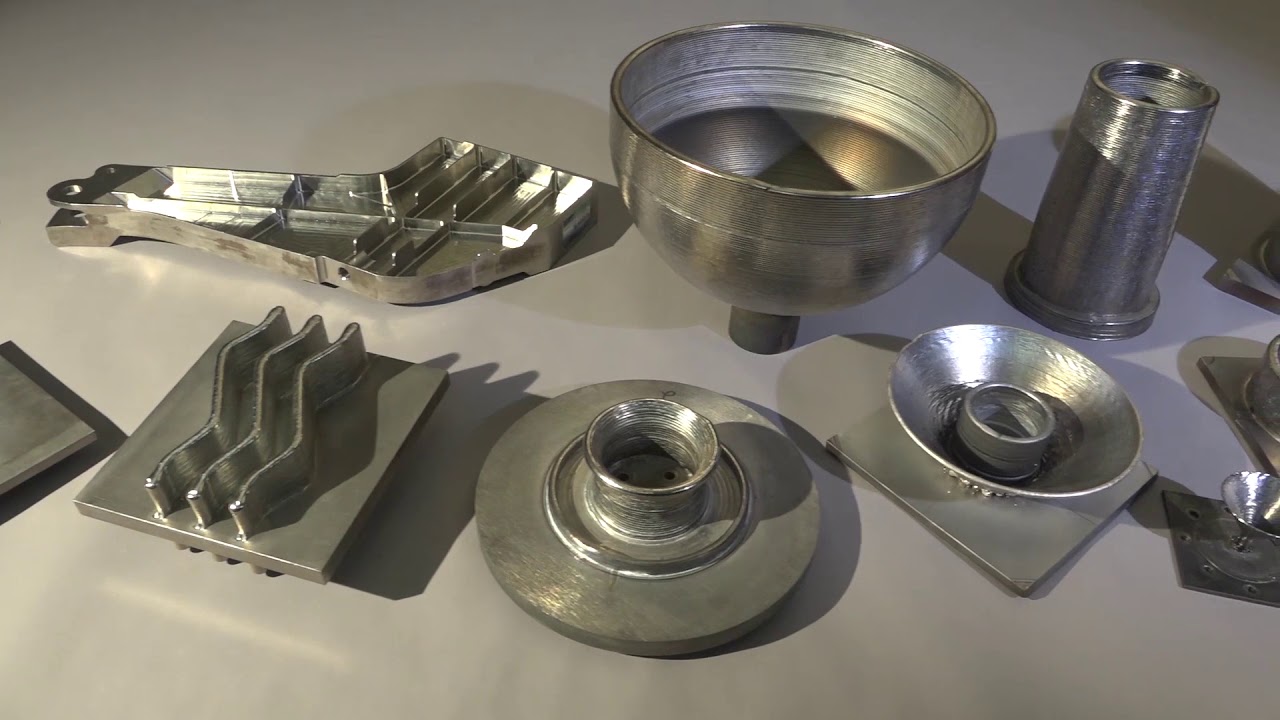

- The model’s creation will happen inside the machine itself. Plus, the titanium is a great metal for printing prototypes.

- DMLS machines do not require any other tooling equipment to finish the printing job. Hence, without worrying about the post-processing, you can get your models ready as soon as they come out of the 3D printer. It does save a lot of time and effort.

- DMLS, as mentioned before, is capable of getting the most intricate details printed with the highest perfection. Hence, you can depend on a titanium 3D printer to produce complex details and prototypes that are difficult to create with traditional methods.

- You can produce the tiniest details. The kind of parts we are talking about are usually required by a number of crucial niches. From dental to the aerospace and a lot many other industries. Small and intricate parts with the amazing finish are easily achievable using titanium.

- The replication of designs and change in the prototypes is cost-effective when using titanium 3D printers.

- The titanium 3D printer cost makes it completely impossible for everyone to own the machine. Hence, the usage is limited to large scale industries.

- The machines aren’t equipped to print larger models. You can only create small to medium 3D parts using these machines.

- DMLS machines often go wrong with its z-axis when compared with the desktop 3D printers. However, if you find something in the middle of the print, you must stop the process to readjust the settings and start over.

- Surface imperfections are rather invisible because of the precision the machine has got. However, this can later create issues if you are working the parts for a multistep manufacturing process.

Recommendations of Titanium 3D Printer

Here are a few recommendations you must check out:

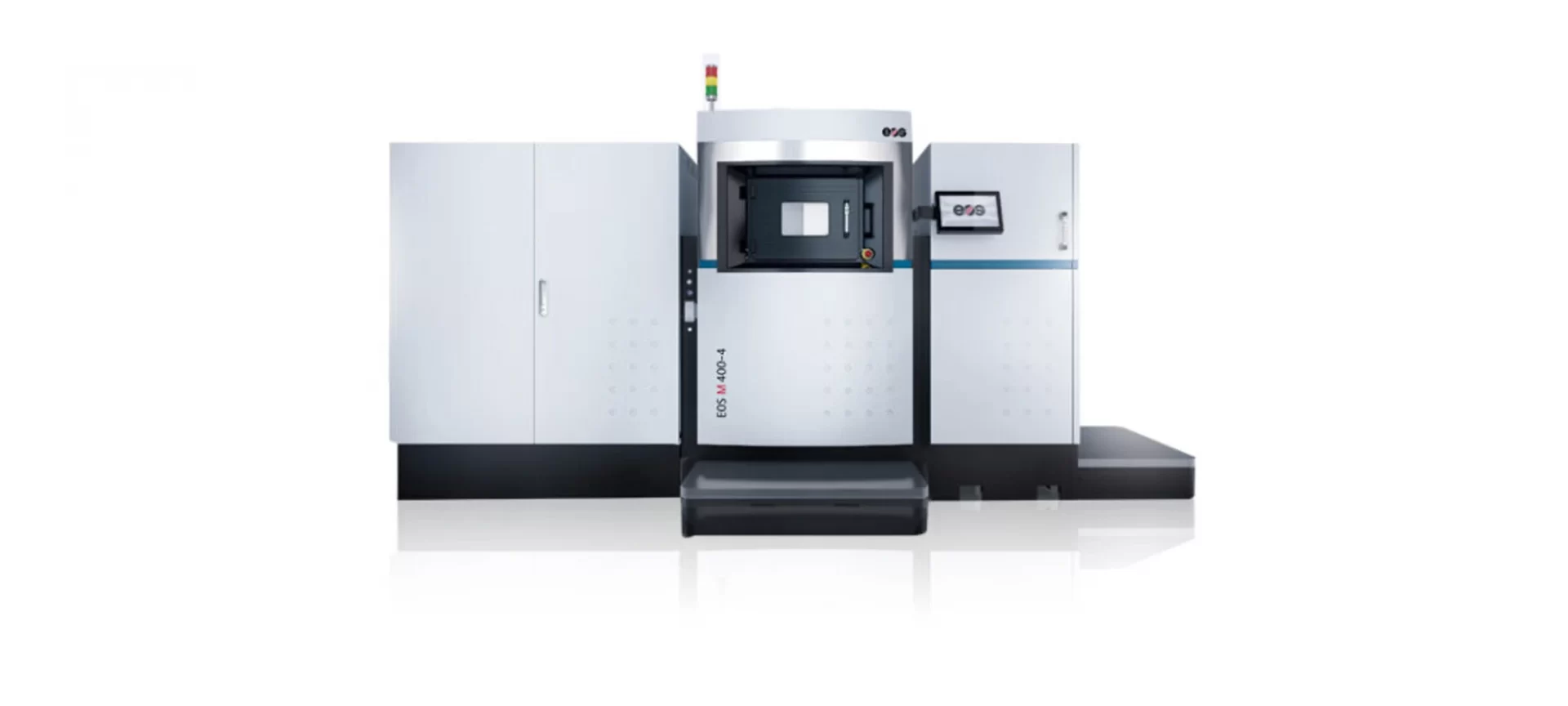

M400 By EOS

The 3D printer is a DMLS machine. It was designed by a German manufacturer, EOS. As you would expect, the printer is for industrial use. This printer makes use of fiber lasers.

The laser is responsible for melting and later fusing the fine metal powder particles together to build layers upon layer. You can achieve highly intricate details with the help of this 3D printer. Hence, it is used for many applications.

Sciaky EBAM 300

This 3D Printer is based on EBM technology. The EBAM 300 is one of the most popular printers today. It is capable of creating a 10-foot long titanium aircraft structure. And, the job can be completed at a rate of fifteen pounds of metal per hour. Hence, the project will take not more than 48 hours.

The EBAM 300 can produce over ten feet longer structures with titanium. This is the longest structure by far possible to create through a titanium 3D Printer.

|

The Conclusion

Titanium is for sure one of the best metals for various applications. But to tame the metal, you must choose the best titanium 3D Printer that can take care of your design and justify it in the best possible way.

Also, you must understand the different factors that would act together to bring the best model into reality. After assessing all those parameters, you can only think of getting the right 3D Printer for your specific need.