What does a DLP 3D printing process mean? Before leaping forward to understand what resin would better suit your printing project with DLP printers, we must understand the process first.

A DLP 3D printer is most likely an SLA 3D printer with one major difference. While SLA uses lasers to cure resins, in DLP, the digital light projector screen is used to generate light source. Because of which the speed also increases when working with DLP.

On one hand, SLA uses point to point technique to cure resins, DLP uses a one-layer flash technique that cures all the points simultaneously, present in that single layer, making the process faster.

Although this could sound like a great alternative, there does remain a limitation. DLP technology cannot be used for creating detailed parts as it is possible with best resin 3d printers.

Moreover, the 2D images are projected on the resin surface area in the pixel forms. These when converted into a 3D part, changes into voxels. These voxels are rectangular in shape, hence, they end up giving parts the boxy surface finish.

The good news is that one can get rid of these problems by involving correct post-processing methods. And, choosing the right 3D printing material (in this case, its resin) which forms the base of every 3D project.

What is Resin?

Unlike filaments used for FDM printers, resins are not available in solid form. Rather, they come in a liquid solution. The resin liquid comprises of different monomers and oligomers.

These are short carbon atom chains which may contain a few functional groups. These do not change when left like this on their own. To make functional parts, one must connect these monomers and oligomers to create longer chains.

This resin then converts into hard-plastic material which is what we require for our 3D projects.

This is where the role of light source comes in. With the help of a light source (light projector in case of DLP), the photo-polymerization takes place.

During this process, with a minor charge imbalance in the molecules of monomers and oligomers, the ends of these short chains start to connect with each other forming longer chains.

The best part about printing with resin is that the layer adhesion does not become an issue as it is with FDM parts.

The reason that not all the charged ends subsidize within the printing of a single layer, these tend to connect with the next layer in progress, providing bonding between different layers. This helps in providing great tensile strength to the parts when printed with the help of resins.

What Qualities to Look for in Resins?

A lot of things depend on the choice of resin. When you are printing using a DLP 3D printer, you may have to ensure the limitations are less of a concern.

This can be handled hugely with the help of the resin selection process. Depending on the properties of your resins, your end parts would demonstrate great differences in terms of their physical and mechanical properties.

If you know what you are looking for in your end models, you would be in a better position to select the right resin based on their properties.

As resins are very specialized products and work best in their field of excellence, you may not be able to use the same resin for two different jobs.

So, what are the things you must look for? Here are a few parameters that will assist you to judge the resin based on what you want to print.

Are You Looking for Durable Parts?

This would very much answer your first concern. Many of you may know that the parts printed with DLP are brittle and prone to crack when hit hard.

In spite of the strong layer adhesion, this property isn’t avoidable. These are not tough and could break easily.

Getting a durable print is not that easy when it comes to print with resins. However, this is no more a dream.

Many companies have come up with engineering resins. By exhibiting high tensile strength, these types of resins can produce tough parts without any problem.

So, if you are building functional parts such as hinges, you may use the one that is engineered for toughness. Another way to achieve this is by using a flexible resin. These resins can change their shape or elongate a little to save them from shattering apart.

Used especially for snap fits and other similar applications, these options are very durable.

Resin Providing Rubber Like Properties

Technological advancements have brought us too far. We have been working hard to leave limitations behind and come up with solutions that could change the way we 3D print.

With similar intentions, flexibility has been introduced to resins in an altogether fascinating way.

These resins flaunt lower tensile modulus and exhibit higher elongation alongside higher impact resistance.

Just remember, printing with these resins isn’t easy. Due to extreme softness, you may require extensive support structures.

Want to Print Transparent Parts?

It is completely possible with the DLP process using photosensitive resins. With the help of special resins, the properties close to glass appearance can be achieved without any doubt.

However, you must realize that the mechanical properties of the parts would remain the same as it’s with standard resins.

Looking for High-Quality Surface Finish?

Those who are acquainted with 3D printing would know that smoothness is not associated with parts printed with DLP printers.

However, there are companies that claim to provide some special resins that can get you the desired finish. There are some that even can be used for printing highly accurate parts with minimal shrinkage.

Want Resin for Medical Application?

DLP printers are also used for medical applications such as printing prosthetics, and equipment. These can be used for creating surgical guides, dental retainers, hard splints, and orthodontic implants as well.

However, not every resin can get the result that these applications require. Hence, using specialty resins that must maintain their chemical and structural stability during the continued and extended contact with open wounds, sensitive skin or bodily fluids is very important.

They must not break easily and can be used for longer periods. There are many other properties such as thermal stability that these resins must possess in order to provide desired results.

Recommendation of Best 3D Resin for DLP Printer

Resins are expensive and a liter of resin can range from $50 to $200. There are many companies that are providing special resins to ensure that the applications are served to its best.

If you are looking for the DLP resin, you can find it at Ameralabs. The company offers a variety of 3D resins for DLP printers.

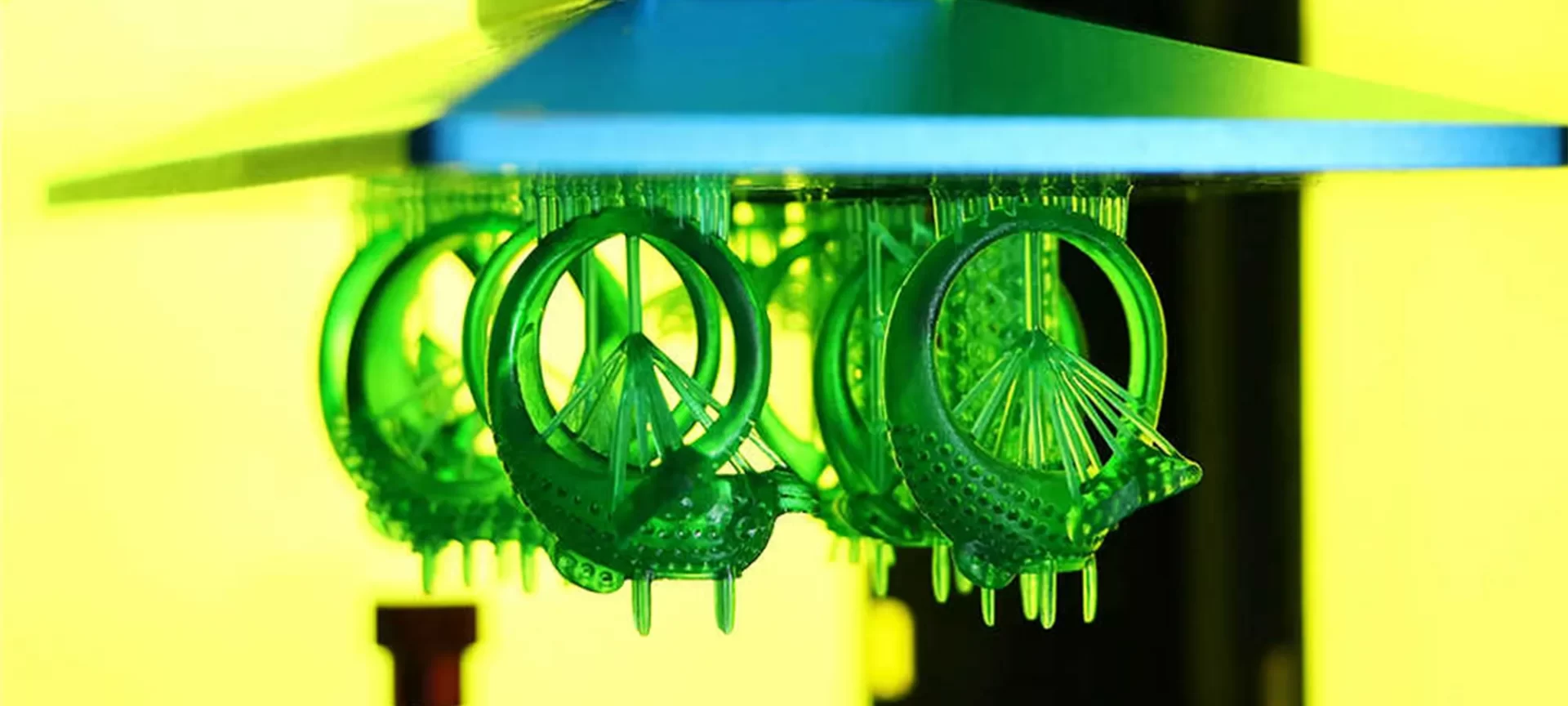

AMD-6 DLP SAMPLE

AMD-6 DLP SAMPLE

They have specialized resins that different tasks and exhibiting different properties. For example, the AMD-6 DLP resin is designed for advanced modeling and miniature 3D printing and IPR-12 DLP can help create amazing industrial prototypes.

These resins are affordable and worth every penny. You can use these resins for different applications and can 3D print stunning quality parts and models.

Why Ameralabs?

Selecting companies for buying resin is a tough job. You may be fascinated to buy the ones that are cheaper, however, depending on the criticality of your application, you must not compromise with the material you use for 3D printing.

And, Ameralabs in one of the few companies that provide you what you need at an affordable price.

Apart from selling high-quality 3D resins, the company provides great support by sharing great articles about 3D printing with resins.

You can find a lot of helpful materials available on their website. They do offer samples for resins you would like to try.

You can live chat with then using Facebook messenger for all your queries. The support team is helpful and very diligent.

The Conclusion

DLP 3D printers work with resin and provide huge benefits in terms of speed and affordability when compared to the SLA printers. Hence, choosing DLP over SLA won’t be a tough call if high precision isn’t that important.

And, to make the decision count, you must print with the best resin. Keeping costs into consideration and understanding that the material cost won’t be as cheap as it is with FDM filaments, you must decide accordingly.

Different resins have different properties. The mechanical and thermal properties decide what features the printed parts will own. Such as, resins must be assessed in terms of their tensile strength, elongation, tear strength, compression set, Thermal expansion, and lot others.

Depending on what you need, you can choose the one demonstrating the right properties.

Otherwise, even the best DLP 3D printer may not be able to get you the best quality prints. So, look for the resin that better serve your goals and print with that one only. You can definitely ask for samples from different companies and decide on the one with the best results. The more you experiment, the more likely you reach closer to the right resin.