Every year, 3D printing keeps on innovating with various technological advances and new technology. 3D printing allows you to print out unique and complex structures. Each 3D printer comes with features that allow you to print with high precision and accuracy.

3D printing can be used in many industries including jewelry, medical, dental, manufacturing, and so on. With the help of 3D printing, you can create different kinds of models.

3D printers come in a range of sizes. In today’s world, you can easily access any type of printer that you require. If you require a printer for industrial production, you should be looking at the best large-scale 3D printers.

This guide lists the best large-scale 3D printers. Each printer has been tried and tested by our experts as we list down the pros and cons for each printer. Check them out below:

What Is 3D Printing And How Does It Work?

Making use of additive manufacturing technology, you can use 3D printing to produce 3D models. Each 3D printer comes with three axes. The XY axes are responsible for the 2D imaging while the Z-axis adds the third dimension.

3D printers are going to take over in the future, as they are convenient and easy to use. With 3D printing, you can print out anything ranging from toys to large-scale industrial models.

What Are The Benefits and Uses Of Large Scale3D Printers?

When it comes to large-scale printing 3D printing, there are many advantages.

Firstly, a large-scale 3D printer provides you with ample space to create large-scale models. These printers are suitable for industrial use and manufacturing.

Apart from offering a large printing volume, these printers offer other benefits, including an increased production rate. An increased production rate allows for your company to flourish.

Most large-scale 3D printers are fast and do not require much printing time as compare to traditional methods of production. Large-scale printing also helps cut production costs by using materials that are less expensive.

Another benefit of 3D printers is that they offer high-quality results with great detailing on the model. 3D printers are capable of printing out intricate to highly complex geometries.

When it comes to large-scale 3D printers, there is no limitation on the size and shape of your model. They also eliminate manufacturing issues, like inefficient workflows while maintaining print quality and print speed.

With so many benefits of having a large-scale 3D printer, you really need to invest in one.

Comparison Chart

| Name | Link | Nomination | Overall Rating |

|---|---|---|---|

| Creality Ender 5 Plus | Highly Reliable | 9.4 | |

| Tronxy X5SA-500 Pro | Most Affordable | 9.3 | |

| 3D Systems Fab Pro 1000 | Entry-Level | 9.1 | |

| Formlabs Form 3 | Most Advanced | 9.3 | |

| BigRep PRO | Editor’s Pick | 9.8 | |

| Cosine Additive AM1 | Extraordinarily Efficient | 9.7 | |

| BLB Industries The Box Small | Innovative Design | 9.6 | |

| Modix Big 60 V3 | Made for Professional Use | 9.2 | |

| gCreate gMax 2 | Extremely Reliable | 9.1 | |

| Raise3D Pro 2 Plus | Most Effective | 8.9 |

Recommendations of Grade 3D Printers

Creality Ender 5 Plus

Known for creating complex internal geometries and impossible designs, this large-scale 3D printer is an ideal option for those looking for high print quality.

Offering a build volume of 350 mm x 350 mm x 400 mm, the Creality Ender 5 Plus is a great option for those who want to print out large-scale models.

The printer comes within an affordable price range while not compromising on any of its features or performance.

The Ender 5 Plus comes with numerous automatic features including a bed-leveling probe. The printer also has sensors that help detect the number of filaments and notifies users when it needs to be refilled.

The printer has a solid and stable structure that allows for consistent printing which offers a high print resolution with high printing speed.

Offering a layer build volume and numerous other features, a large-scale 3D printer is a choice for many.

Uses:

- Ideal for prototyping

- Recommended for use in Professional settings

- Even works well in small-scale industries

- Does not require much assembly

- Can be connected to other devices over the internet

- Smooth and effortless operation

- Capable of printing large components

- Offers multiple material support

- Tubing for filament needs better routing

Tronxy X5SA-500 Pro

If you are looking for a printer that consistently produces superb quality output, then this large scale3D printer is your best option.

Featuring a build volume of 500 mm x 500 mm x 600 mm, the Tronxy X5SA-500 Pro allows for large-scale print production. This printer has a lot to offer in terms of its advanced and innovative features.

This affordable printer does not compromise on its features as it has a fixed dual-stepper-driven bed, which maintains consistent temperature and allows for detailed layer-by-layer printing.

The Titan-style extruder allows for advanced 3D printing. This printer has sensors that detect when the printing material runs out. The printer also has a resume function for when there is a power outage.

Among other notable features, the Tronxy X5SA-500 Pro has a high compatibility for various devices offering remote operation to the users

This printer offers the best speed and the best print quality on a large scale. You should definitely consider it while buying large-scale 3D printers.

Uses:

- This printer is suitable to print a range of models and prototypes

- Ideal for professional use

- Industries such as automobile, ceramics

- Practical and functional design

- Ensures creation of large parts due to large build volume

- Can be connected to other devices over the internet

- Print cores keep their temperature maintained

- Not ideal for beginners or first-timers

3D Systems FabPro 1000

|

If you are looking for an industrial-scale 3D printer that also offers high print quality, then FabPro 1000 is an option that you should definitely consider.

Offering a build volume of 125 mm x 70 mm x 120 mm, this printer offers effortless printing.

The printer has an enclosed chamber for printing that helps maintain a consistent printing environment inside. The printer comes fully assembled and has a plug and print design.

The FabPro 1000 has a heated printed bed that maintains its temperature. You can also take off the model easily after it is done processing.

The printer offers a wide range of layer resolution of a minimum of 30mm. The print speed is also 45% faster than its competitors.

The FabPro 1000 is compatible with a wide range of resins. It can also be connected to various devices over the internet, which allows for remote operation. Its wide touch screen is not only intuitive but also user-friendly.

Uses:

- Used for delicate and bulky geometries

- Ideal for future design and development

- Useful in jewelry sector for investment casting

- Dentists can use it for dental models

- Consistent Printing

- Simple operating process

- Offers support for multiple materials

- Industry competitive speed

- Requires post-process curing

Formlabs Form 3

|

If you are someone who requires large-scaled 3D models, then you need to get a large-scale 3D printer like Formlabs Form 3.

Offering a large build volume, this printer comes with upgraded features that make it a reliable option.

Built in an enclosed frame, the printer offers a safe working environment and helps prevent the release of harmful fumes into your workspace as well.

The closed design is able to protect the laser and optic heads from dust and other particles that can be damaging.

The printer uses low Force Stereolithography technology, which essentially utilizes less force while it is conducting layer-by-layer printing. Layer-by-layer printing helps with the detailing of intricate designs.

Uses:

- Models require no post-processing

- Used in industries such as the manufacture

- Ideal for use in professional settings

- Ensures support free prints

- Can be operated remotely

- Compatible with a wide range of print material

- Large printing space

- Might not be beginner-friendly

- Pricier option

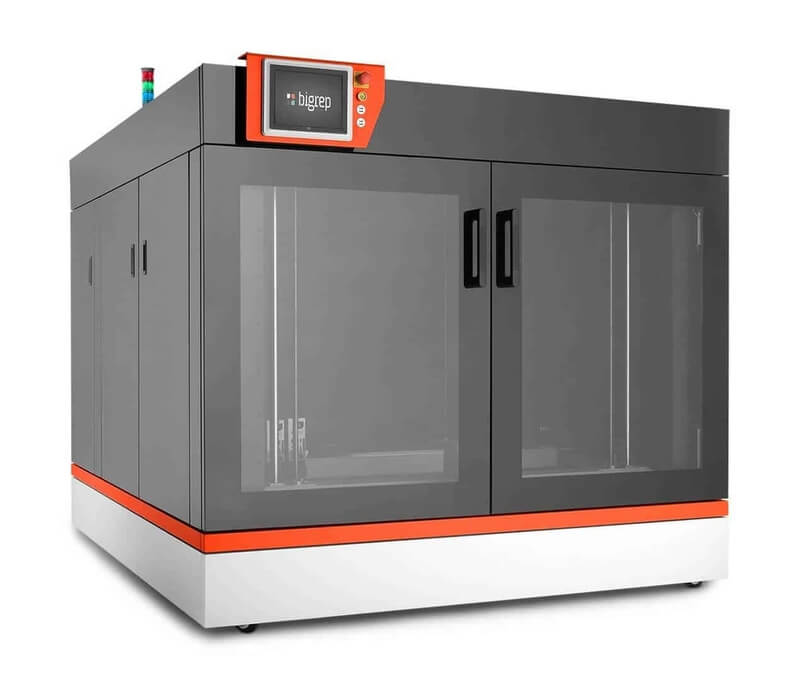

BigRep PRO

The BigRep Pro is a large-scale 3D printer designed especially for industrial use. The printer is capable of handling larger prints with its impressive build volume of 1080 mm x 980 mm x 960.

Apart from a greater build, the printer also offers a high resolution that lies between the ranges of 0.1 mm to 1.6 mm. Equipped with great features, this model is truly one of the best large-scale 3D printers.

The BigRep Pro comes with a dual extruder capable of supporting multiple materials, including soluble supports. Maintaining its high-performing capabilities throughout the printing process, this printer comes with an enclosed chamber.

The chamber is humidity and temperature controlled to provide an ideal printing environment that remains consistent throughout. Apart from this, the printer also has an insulated filament cabinet that helps keep the filament secure.

This large-scale 3D printer comes with ease of use. The highly intuitive user touchscreen is responsive and helps maintain and customize the printing settings easily.

The printer also comes with various automatic features such as bed leveling and calibration. The printer itself has a solid and stable structure that results in error-free printing while the frontal glass door helps you monitor the printing process easier.

Metering Extruder Technology (MXT) is a unique feature of this printer, which comes with a thoroughly designed extruder system. Together, this results in feeding, melting, and extrusion of the filament. The CNC control system provides the power for this printer to function.

Uses:

- Software-controlled workflow means that every stage of the process is fully automated

- Can be used for professional prototyping of highly detailed models

- Large scale modeling for industrial use

- The sensitive and responsive touchscreen interface

- Exemplary printing results

- Reliable printing

- Ideal for mass production

- Connectivity with other devices over the internet

- Can be noisy

Cosine Additive AM1

Manufacture by Cosine Additive, the AM1 is an FDM large-scale 3D printer. This printer offers an impressive build space of 1100 mm x 850 mm x 850 mm, which is capable and powerful enough to make large-scale items.

Sized at 1753 x 1474 x 1855 mm, the printer occupies a large space and is ideal for industrial use. The printer comes with a dual extruder that allows you to work with different filaments. You can also use two different colored filaments to create two-tone models.

The printer also comes with a palette extrusion system used for injection molding. The system helps create a blend of polymers and lets you produce a wide variety of models and prototypes.

The AM1’s high-temperature extruder can reach a temperature of 500 degrees Celsius and the heated bed helps maintain that temperature consistently.

With a high-temperature environment, models are produced with great adhesion, eliminating the risk of errors or failed printing.

With an enclosed chamber, maintenance of temperature is made easier while the release of harmful gases is also prevented. The printer nozzles are swappable.

Among its numerous features, this large-scale printer also offers an easy operation with its 23 inches touchscreen.

The touchscreen has an intuitive interface, which makes printing hassle-free. This powerful printer also comes with a built-in camera for monitoring purposes.

Uses:

- Lets you to work with a variety of material and produce all kinds of models and prototypes

- Capable of printing building parts or spare parts

- Ideal for industrial use

- Offers fast production

- Compatible with multiple filaments

- Reliable printing

- The bed is leveled automatically

- Pricey option

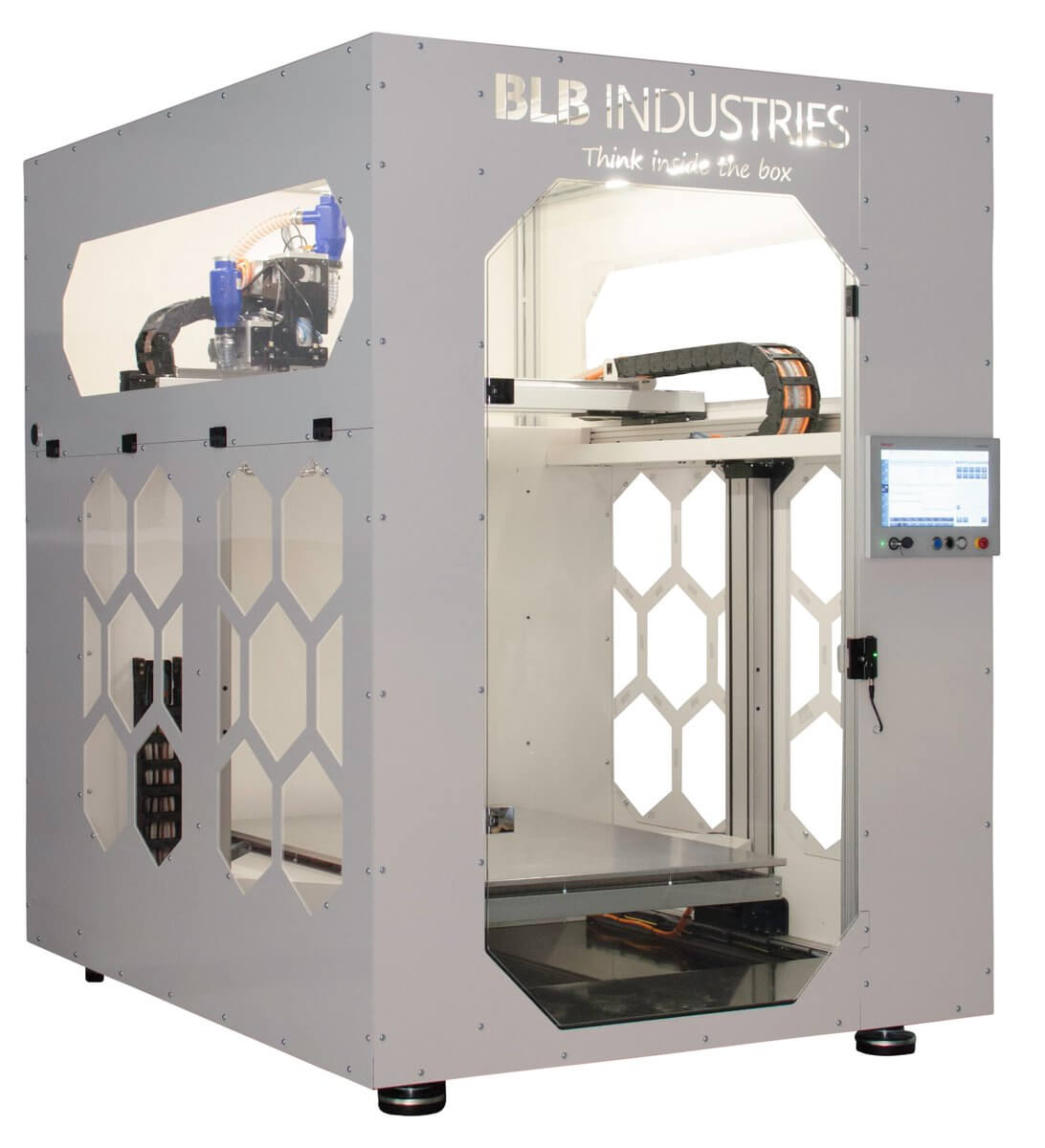

BLB Industries The Box Small

If you are looking for a large-scale 3D printer, then you should be looking at the BLB Industries The Box Small printer. This professional 3D printer comes with a build volume of 1500 mm x 1000 mm x 1000 mm.

Based on FGF technology, the printer printers with granulates. The solid and sturdy printer has an aluminum structure with provides it with a stable structure for large-scale printing. This powerful printer comes with all kinds of advanced features and technologies.

Promising high-end results, this large-scale 3D printer comes with Rexroth linear motion modules. These modules are responsible for exceptional results and help maintains the requirements for a large-scale 3D printer.

This printer is compatible with multiple nozzle diameters that can be used to create all shapes and sizes of prototypes and models. The printer also has one of the fastest printing speeds in the industry.

It can print up to 6kgs per hour allowing you to save production time and increasing the amount of printing in a short time.

Among its many notable features, the printer also has a heated bed that maintains a consistent temperature for the adhesion of the models.

The build plate is flexible and allows for easy removal of the model once it is done processing. Unique to this printer, a water cooling system helps with the maintenance of the temperature.

In terms of operation, using this printer comes with ease due to its user-friendly interface. The printer can also be connected to various devices over the internet.

The main functioning software is called Simplify 3D slicing software that offers you many customization options.

Uses:

- Its innovative technology provides greater control over geometry and makes it ideal for use

- Useful in various industries such as automobile, aviation, construction, and so on

- Creates high-resolution models and intricate geometry designs

- Useful for mold printing and prototyping

- Offers a large build volume

- Has the fastest speed thus making it ideal for producing high-quality models

- Safe and easy to use

- Unique and useful features

- Heavy

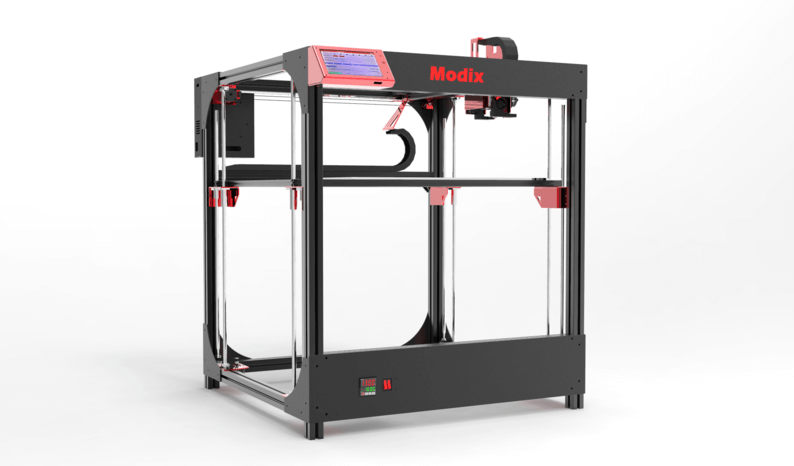

Modix Big 60 V3

Finding a balance between size and functionality, the Modix Big60 V3 is one of the best large-scale 3D printers that come with an impressive build volume of 600 mm x 600 mm x 660 mm.

The printer can support large-scale production. Among its most appealing functions, the printer comes with a removable build plate that makes it easy to remove the models after it has been processed.

The printer also offers an exceptional printing speed, which helps you save printing time.

The V3 also has an E3D high flow Volcano heater block that is extremely useful while printing. Apart from this, the printer is capable of automatic bed leveling and helps you save time and energy with its easy and effortless operation.

The printer has a Duet3D Wi-Fi-enabled main board that enables it to connect to multiple devices. Its dual-zone silicon heater for the print bed helps save power while performing efficient printing.

Reliability is its key feature, the V3 flex offers the best print volume among other printers while remaining upgradable as well.

Uses:

- Efficient production of prototypes

- Easy operation makes it ideal for beginner use

- Time-saving printing

- Resume print function

- Has a compact footprint

- Reliable printing

- Easy temperature maintenance

- Requires assembly

gCreate gMax 2

|

A renowned name in the market, gCreate gMax 2 is the best when it comes to large-scale 3D printers. This affordable machine is compact and travel-friendly.

The printer comes fully assembled and offers reliable, high-quality printing. With a solid structure, this 3D printer also offers consistency in its performance.

The printer can also be connected to multiple devices over Wi-Fi along with its user-friendly interface that makes it extremely easy to operate. The printer also has some sensors, which alert the user if any error occurs.

With a build volume of 457 mm x 457 mm x 609 mm, this massive machine allows for large-scale printing in numerous industries. The machine makes use of dual HIWIN linear rails to help provide support to the print bed.

This results in exceptional printing details. Printer features also include a dual extrusion print head, which results in a wide variety of prints. The Wi-Fi-enabled touch screen allows for easy operation.

Uses:

- The printer comes with pre-installed software which comes loaded with basic model designs

- Ideal for industrial use

- Simple in operation

- Reliable prints

- High-resolution printing

- Compatible with most printing material

- Open frame design

Raise3D Pro2 Plus

|

The Raise3D Pro2 Plus is known in the market for its build volume that is around 305 mm x 305 mm x 305 mm.

This large-scale 3D printer offers the best high-resolution 3D printing, which is capable of producing high-quality 3D prints.

Among many other features, the printer is known for its uncompromising high printing speed that helps save printing time.

The printer also has a heated bed that can be calibrated easily through an auto-calibration system, which means you will have less trouble leveling the bed.

The print bed and extruder nozzle have the ability to heat up to an extensive range of temperatures, making the printer compatible with a wide range of printing materials.

The printer software offers different controls, which makes printing simple.

Uses:

- Can be used to print detailed models such as jewelry, décor items, and much more

- Capable of industrial use

- Should be handled by professionals

- Reliable printing

- Wide material support

- Durable and long lasting structure

- Can be connected to other devices using Wi-Fi

- Can be noisy while printing multiple materials

Buyer’s Guide

Buying a large-scale 3D printer requires a lot of thought processes which is why the guide will help you decide which certain important factors you should keep in mind while choosing the right model.

Here is what you should consider:

- Print Quality: For good print quality, ensure that your printer offers a wide range of layer height and resolution. Carefully go through the machine specifications and make sure that it has all the attributes to guarantee your required accuracy and precision.

- Ease of Use: A large printer should be accessible for everyone to use which is why you should look for advanced features that are user-friendly. A user-friendly interface can help guide the user through every step and make large-scale production an easy process.

- Build Volume: This goes without saying but if you are looking for a large-scale 3D printer then look for the printer’s specifications carefully. Opt for a printer that is easy to handle while having a large printing volume at the same time.

- Speed: If you want to save time and increase the production rate, then look for high-speed printers. While most industrial printers offer high speed, ensure that none of these printers compromise on the print quality. A good printer offers high speed as well as delivering a smooth finish so that does not require any post-processing.

Frequently Asked Questions (FAQs)

What Materials Should You Use for 3D Printing?

The use of printing material depends on the compatibility of your printer. Most printers usually make use of materials PLA, resins, filaments, metals, ceramics, and so on.

Before buying a printer, see for its material compatibility and get one that best suits your needs.

Where Is Large Scale 3D Printing Mostly Used?

3D printing has been used in a vast number of industries including sectors such as aerospace, automotive industry, medical, jewelry, or even home use.

Every industry can benefit from the time, money, labor, and material savings that3D printing offers. A large-scale 3D printer allows users to be limitless in their creation.

Are Large Scale 3D Printers Too Expensive?

Yes, these printers can often only be afforded by large enterprises because of their high costs. However, numerous companies come with affordable options as well, making them ideal for small-scale use.

Conclusion

Within the market, you will find different options for large-scale 3D printers that offer a large build volume.

From the 3D printers reviewed above, we see many affordable options such as the gCreate gMax 2, which is cost-effective which offering detailed printing and large print volume at the same time.

The BigRep PRO is the best of the best as it proves to be the jack-of-all-trades with its multi-function capabilities and advanced engineered technology.

This large-scale 3D printer has a lot to offer including a large print volume. The device has all the qualities that an advanced 3D printer should have.

All these large scale3D printers have a unique selling point apart from their exceptional build volumes. I hope that this article helps you find what you are looking for.