3D Printing With Metal

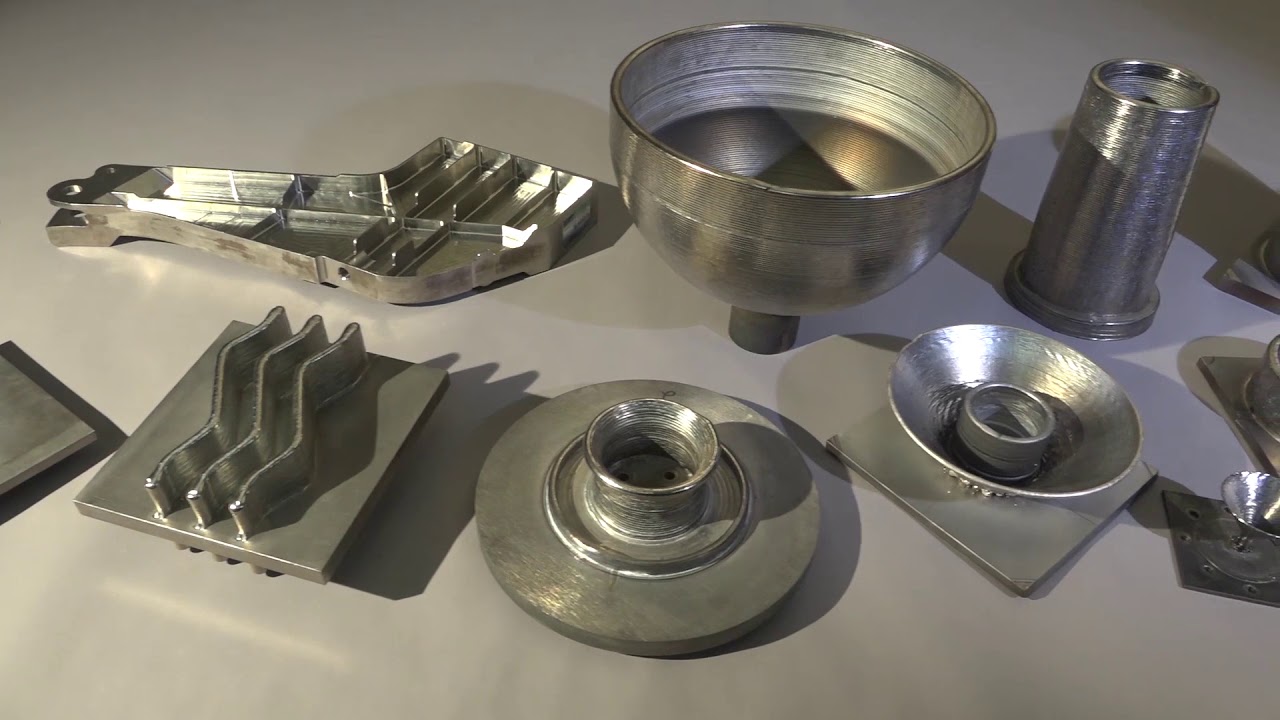

The first thing that comes to mind when thinking about additive manufacturing for industrial and business applications is 3D printing with metal.

Metal 3D printing is a catchall term for several technology families. Simply put, metal 3D printing refers to any technology that creates metal objects layer by layer through sintering, melting, and welding with metal.

Metal 3D printing is one of the most heavily invested in and fastest-growing manufacturing technologies. Nowadays, it is not only used in conjunction with other manufacturing technologies, but it is also capable of producing prototypes and finished products on its own.

In some cases, 3D-printed metal objects perform just as well as machined parts. It is primarily used in prototyping, aerospace, mechanical engineering, specific tools, and other applications.

3D Printing In Aluminum

Aluminum is a lightweight alloy with high flexibility, good strength, and mind-boggling thermal properties. Because of these properties, it has become the primary metal used in 3D printing.

Aluminum 3D printers are used in biomedical, automotive, and aerospace applications like no other metal 3D printer. Aluminum’s core strength is its ability to be molded and used for functional prototypes.

This metal material’s remarkable properties make it an excellent choice for high-performance functional parts that are subjected to high loads. Aluminum alloys are also appropriate for engine parts, manufacturing tools, and specific heat exchanger and outdoor applications.

The material is suitable for both prototyping and manufacturing. The quality of 3D-printed aluminum parts is comparable to that of synthetic parts.

The material is suitable for both prototyping and manufacturing. The quality of parts 3D printed in aluminum is comparable to that of CNC-manufactured parts.

In general, aluminum 3D printers can also print with other common metals like titanium, stainless steel, and so on. This is in light of the numerous options that metal 3D printing is known to provide its users.

Advantages:

- 3D printers can produce complex information much faster than conventional manufacturing methods.

- In contrast to traditional manufacturing processes, the cost is lower.

- It is possible to construct specific artifacts with very limited data, depending on the technology used.

- It is possible to 3D print info in assembly and saves time and money as a result.

- The more complicated the form, the lighter the part can be without losing power. That is why 3D printed parts in the aerospace industry are so common.

- Metal 3D printing almost never wastes products.

Disadvantages:

- The cost of powdered metal is much higher than the cost of “regular” raw metal.

- For normal items, the rate of output is relatively slow.

- Metal 3D printers are not cheap.

- Surface finishing and post-processing are often needed.

- As compared to CNC machining, tolerance and accuracy are normally lower.

- In certain cases, additional heat treatment is needed to reduce the 3D-printed object’s inner stress.

Comparison Chart

| Name | Link | Nomination | Rating |

|---|---|---|---|

| EOS M 100 | Productivity | 9 | |

| Desktop Metal Studio System | User-Friendly | 8.6 | |

| Additec uPrinter | Reliability | 7.1 | |

| Digital Metal DM P2500 | High precision | 9 | |

| Markforged Metal X | Safe to use | 10 | |

| 3D Systems ProX 800 | Easy to use | 8.1 | |

| Sciaky EBAM 300 | Speed | 8.6 | |

| SLM 500 HL | High Volume Printing | 9.5 | |

| Velo3D Sapphire | Reliability | 8 | |

| SISMA Evemet 200 | Durable | 9 |

List Of Top Aluminum 3D Printers

EOS M 100

|

The EOS M100 3D Printer is a highly productive Aluminum 3D printer designed for the additive manufacturing of delicate metal parts, particularly in medical technology.

EOS’s website has far too much information taken from it in terms of learning about 3D printing, printers, printing materials, and even specifying if you want to print from their printers without purchasing them!

Uses:

- The EOS M 100 boasts the power stability of a 200-watt fiber laser, which the company claims ensures optimal and consistent processing.

- The printer can construct on a 100 mm diameter construction platform.

- Because the EOS M 100 has a modular structure, post-processing, cleaning, and setting up the printer takes less time than it does in other printers.

- The EOS M 100 employs a Yb-fiber laser to cure the 3D-printed part.

- This printer’s construction volume is 100 mm * 95 mm.

- The software that EOS recommends for use with this 3D printer is called EOS 3D Print2.

- A separate success stories tab details which printer was used in which industry to generate what!

- If you intend to be an EOS customer, there is a lot to look at and learn from on the website.

- The website is far too lengthy. As a result, if you are not used to navigating properly, you may become disoriented!

Desktop Metal Studio System

|

The Desktop Metal production system should be your first choice if you want to print with multiple 3D printing materials and large build volumes without sacrificing quality.

Its proprietary dividing binder jetting technology yields parts of world-class quality and functional prototypes that can replace any object produced using traditional manufacturing methods.

Uses:

- The use of a uniform print bed aids in the production of fully dense, high-quality parts capable of performing the most demanding applications. This Aluminum printer’s native resolution is stated to be 1200 * 1200 dpi with a layer height of 50 micrometers.

- The company claims that by using low-cost metal injection molding, it can deliver per-part costs competitive with traditional mass-production techniques.

- The Desktop Metal Production System can print 10000 parts per day, which is incredible.

- Desktop Metal is able to provide robust repeatability in this production system by utilizing anti-ballistic technology, print bar redundancy, and live optical bed inspection.

- This production system can print anything from stainless steel to reactive metals like titanium and other high-performance alloys.

- The Production System’s print bar has 16384 nozzles capable of jetting 1.5 billion drops per second.

- Parts of excellent quality

- The cost per part is competitive.

- Repeatability is unrivaled in the industry.

- Compatible with various materials

- Not for small business

Additec uPrinter

|

The Additec μPrinter is an industrial desktop Aluminum 3D printer manufactured by Additec, a company with headquarters in the United States and Germany.

The Printer is suitable for cladding and repair applications, as well as research and development, in addition to freeform 3D printing. The technology used by Additec is known as Laser Metal Deposition (LMD).

Uses:

- The ability of this printer to process commercial welding wire is a unique feature, implying that materials widely available anywhere in the world starting at less than $10 per kg can be 3D printed.

- Powder feeders are also available as an option for users who want to use metal powder materials.

- The Additec μPrinter is made up of three different laser diodes, each rated at 200 watts. And those pen-like structures were diodes.

- Consist of an inert chamber for an optimal 3D printing environment free of particles and with active temperature management.

- To create 3D metal parts, this entry-level metal 3D printer employs a type of DED (Directed Energy Deposition) 3D printing technology.

- The company has provided its users with a complete idea to compare with other technologies on the market.

- It can print with both powder and wire.

- In terms of an upgrade, the company allows you to customize your printer to your specific needs.

- There are not many images of parts or functional prototypes created with this printer.

Digital Metal DM P2500

|

Digital Metal, a Höganäs Group company, produces the DM P2500 professional Aluminum 3D printer (Sweden). Digital Metal began as a manufacturer of metal powder.

This 3D printer is ideal for serial production as well as end-of-life part customization in the aerospace, fashion, medical, dental, and automotive industries.

Uses:

- This printer employs high-precision binder jetting technology.

- The DM P2500 has a resolution of 0.035 mm. This enables medical-grade surface smoothness and quality (Ra6).

- It uses Binder jetting technology that allows users to reuse loose powder material, which contributes to environmental sustainability. As a result, there is significantly less waste than with other additive manufacturing techniques.

- The DM P2500 prints without the use of any support structures. And this actually lengthens your overall print time, especially if you are doing a lot of them.

- Printing takes place at room temperature.

- No images that can give you an idea of the quality to expect

Markforged Metal X

|

This 3D printer features an enclosed heated build chamber, and it can print with a wide range of materials. Moreover, this machine features ADAM printing technology and uses extrusion for metal printing.

Uses:

- According to the website, the printer does not even require an operator. As a result, the Metal X is both safe and affordable.

- The motion system in the majority of industrial-grade 3D printers is operated on rails, which ensures that the inner travel of the material with which you want to 3D print a part or functional prototype is safe and intact.

- Metal FFF, which stands for fused filament fabrication, is the printing process used by this printer.

- The printer measures 575 mm in width, 467 mm in depth, and 1120 mm in height.

- The MarkForged Metal X incorporates a 3D scanning unit capable of 1-micron measurement accuracy and 50-micron 3D scanning resolution for quality control.

- The entire system of Wash-1, Sinter-1, and 2 is a huge plus for the printer.

- The printers operate without the use of a separate powder binding system, which reduces post-processing of parts and thus increases print speed.

- Because there are no images of parts or functional prototypes, you have to judge the printer’s print quality based on the claimed layer resolution range.

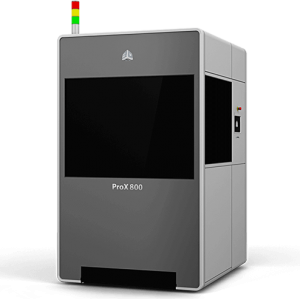

3D Systems ProX 800

|

This Aluminum printer is designed for professionals and industrialists in the field, and it can provide unbeatable quality parts and functional prototypes for major industries.

The printer system, which is equipped with the most recent print head technology, can produce real parts ten times faster than other 3D printers.

The machine is versatile and adaptable, and it can be used to produce precision parts with high dimensional accuracy.

Uses:

- ProX 800 is one of the few printers that can deliver part accuracy and surface quality in large parts and functional prototypes simultaneously.

- The ProX 800 is a printer that is compatible with a wide range of materials.

- This printer allows you to quickly change your printing material, allowing you to resume printing as soon as possible.

- The overall operating ergonomics of the ProX 800 are designed to be user-friendly.

- Its maximum build envelope measures 650 mm * 750 mm * 550 mm. It also operates with the highest precision and accuracy thanks to interchangeable material delivery modules.

- Materials can be easily changed.

- A solution from a single source

- Because of the integration, it is simple to use.

- High-quality components and functional prototypes

- A management system that is integrated

- Parts and functional prototypes are used on a large scale.

- The price of this printer is out of reach for many people.

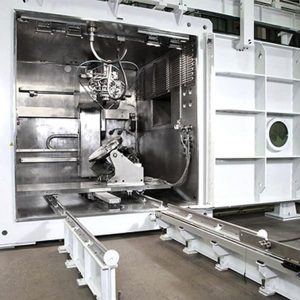

Sciaky EBAM 300

|

The EBAM 300 features a welding gun for depositing metal layers, which is unlike most other printers on the market. If you are looking for a beast of a machine, you can opt for this model.

Uses:

- The print speed of the Sciaky EBAM 300 is 7 to 25 lbs., or 3.18 to 11.14 metal per hour. The print speed can be adjusted depending on the part or functional prototype that you want to create.

- Sciaky EBAM 300 guarantees an 80 percent reduction in material costs. Because of their rarity, the raw materials used in electron beam technology are frequently expensive metals. As a result, they are out of the ordinary price range.

- IRISS Closed-Loop Control Technology, a patented suite of sensors, software logic, and CNC controls, is used by the machine. IRISS continuously monitors key metal deposition parameters in order to make real-time adjustments to the deposition inputs.

- The highest build volume is available in the shortest amount of time.

- Best print quality

- The cost of this printer may be a major deterrent to purchasing it.

SLM 500 HL

|

Among many SLM 3D printers, the SLM 500 HL stands out for its quality and ease of use. This machine is best suited for those involved in the large-scale production of medium-sized parts.

Whereas the SLM 500 HL is the market’s fastest and most compact 3D printing machine. The company claims that the SLM 500 HL is one of the best printers they have ever created.

Uses:

- The SLM 500 HL is packed with features to help industries and high-end 3D printing applications run smoothly.

- The 3D printer is specifically designed to reduce operational costs while also providing operational safety.

- The finished build cylinder can be removed from the machine using the SLM 500 HL.

- Twin laser optics are used in SLM 3D printers.

- This 3D printer is built with an open system design.

- The SLM 500 employs a patented closed-loop transport system for powdered metal.

- If you have worked with an SLM 3D printer, you are probably aware of the issues with removing soot from the process chambers.

- The machine includes extensive process monitoring modules.

- Twin 400W or 700W fiber lasers are included.

- Application of quad overlapping laser processing

- Powder material handling in a closed-loop

- Availability of Integrating lasers both independently and in parallel

- Reduced manufacturing costs for high-volume metal parts and simultaneously, time-saving material

- Gas flow and recirculation have been improved.

- Improved Printing Speed

- Open software architecture and system parameters that can be changed

- Printing medium-sized parts are restricted.

- Support removal necessitates post-processing.

- Individual or business use is not possible.

Velo3D Sapphire

|

The Velo3D Sapphire is a high-volume Aluminum 3D printer manufactured by Velo3D, a US-based company. This large metal additive manufacturing system is intended for serial production.

It is powder compatible with nickel-based alloys and has a build volume of 1 meter high. Intelligent Fusion, a proprietary 3D printing technology, is used in Sapphire to print complex geometries and overhangs. This printer is outfitted with two 1kW lasers.

Uses:

- This printer features in-situ calibration and process control, which ensures optimal quality each time.

- This 3D printer has a vertical axis of 1 meter, which makes it the tallest printer in its range.

- Features an enclosed chamber.

- Metal 3D printing almost never wastes material.

- Because of the more complicated forms, the part can be lighter in weight without sacrificing strength.

- Powdered metal is significantly more expensive than “regular” raw metal.

- For regular objects, the rate of production is relatively slow.

- Metal 3D printers are costly.

SISMA Evemet 200

SISMA’s EVEMET 200 is a metal 3D printer for industrial use. SISMA is an Italian 3D printer maker.

The Evemet 200 planned to better suit the manufacturing needs of the dental sector by also dealing with reactive metals has a maximum printing volume equal to a cylinder with a base diameter of 200 mm and a height of 200 mm and a total printing volume equivalent to a cylinder with a base diameter of 200 mm and a height of 200 mm.

Uses:

- A power-lading tank with a capacity of up to two and a half times the maximum printable volume is needed.

- With any form of metal power available on the market, in the print settings setup.

- Inside the printing chamber, a modern gas flow control device allows for optimum density around the entire working area without dirtying the laser safety lens.

- Two laser sources that are completely overlapping and operate together (full overlap).

- Laser pulse control functions are state-of-the-art, allowing for a better surface finish and less tension during the piece’s construction.

- The printing plate is preheated to + 200°C.

- Components and the manufacturing group are in charge of computing.

- Each of the two filter cartridges will print for up to 1000 hours.

- Without the need for an external discharge station, an integrated suction device transfers residual dust from the construction cylinder to the recovery container.

- A melt pool control device that analyses the laser beam and verifies the accuracy of the finished product

- External dust management system for automatic sieving through the EVEMET MULTIPLO station

- Supports other materials too.

- Individual or business use is not possible.

Frequently Asked Questions (FAQs)

What Is The Process Of 3D Printing Metal?

Metal 3D printing works similarly to plastic 3D printing in that metal content, such as powder or filament, is added layer by layer.

If you are using metal powder, each 0.05-millimeter layer is fused together with a laser or glued together with an inkjet to form a component. A metal component must be post-processed after printing.

What Types Of Metal 3D Printing Technologies Are There?

Yes, there are many, and they are all used depending on the properties your printed parts need. Selective Laser Melting (SLM), Electron Beam Melting (EBM), Direct Energy Deposition (DED), Binder Jetting, and Bound Powder Extrusion are the most common metals 3D printing technologies.

Are Metal 3D Printed Parts as Solid as Metal Parts That Have Been Produced Traditionally?

It depends on what you are comparing it to, as well as the 3D printing technology you are using. 3D printed metal pieces, on the other hand, can be just as solid as conventional metal components.

If you use Selective Laser Melting technology to 3D print pieces, they will have mechanical properties that are similar to casting.

In addition, depending on the technology used, the porosity of a 3D printed metal component will exceed 99.5 percent density.

How Much Detail Can You Get Out Of Metal 3D Printing?

Depending on the 3D printer and the final application, you can obtain a variety of resolutions. You will need high resolution if you want to print jewelry. If you are looking for a fast and dirty prototype, lower resolution is the way to go. You can print at a maximum resolution of 35 micrometers.

The minimum layer thickness (Z height) is around 35 micrometers, with a 50-micrometer X or Y resolution. The minimum thickness of the wall is around 150 micrometers.

Buying Guide

Materials for Metal 3D Printing

The most widely used material in metal 3D printing is aluminum, which is often used in alloy form. Aluminum is valuable because it is both resistant and light. It is primarily used in industries where weight reduction is important, such as aeronautics and automotive.

Steel is also widely used, especially in industrial settings. Steel has excellent mechanical properties and a smooth finish. As a result, it is the most commonly used metal in 3D printing.

There are also metals for medical applications, such as gallium and cobalt-chrome, as well as titanium, which has high corrosion resistance and biocompatibility.

Jewelry is made mostly of precious metals. Gold, silver, and bronze are all used for 3D printing to produce intricate pieces of jewelry, despite their high costs. However, the most difficult part comes at the end.

Applications for Metal 3D Printing

In industries such as aerospace and automotive, metal 3D printing is currently used to produce tool components and finished parts.

3D printing may be used to create aircraft parts or rocket motors, which saves weight and money.

Metal 3D printing has applications in the medical field, such as the creation of implants for analysis, especially in the dental field. Metal additive manufacturing can also be used to design boat propellers in the marine industry!

Conclusion

If you are looking to buy an aluminum printer or a metal printer in general, there are a few things you should keep in mind.

This is to ensure that the printer you are purchasing is the one you are looking for. The list of these fundamentals begins with build volume, layer resolution, and the technology used for 3D printing parts and prototypes. You can make a better decision by comparing these items to printers at the same price.

Aside from these features, you can compare the print speeds of two 3D printers as well as the materials, i.e., other than aluminum, with which you can print.