We keep talking about the unbeatable capabilities of a 3D Printer that make it such a powerful machine. Often its ability to create parts that aren’t possible by any other methods is outlined when backing for its benefits.

Doesn’t that ring a bell? Amidst everything, can we 3D print a 3D printer when it is capable of printing almost everything? This question has become very common among 3D printing users.

And, there are companies that have come up with the self-replicating feature. According to the claims, it is believed that most of the parts of a 3D printer can be printed by itself. In other words, one can print a 3D printer itself.

This may seem like a very difficult task and it sure is. Those who have no idea about how to work with 3D printers and 3D design models may not be able to do it themselves.

Of all the information available online, the job is to create the printer itself. It does require experience. Without knowing in and out of what you are building, how are you going to accomplish it?

Hence, you can expect a lot of learning throughout the process. And, most of all, you would require a 3D printer to print a few parts by yourself.

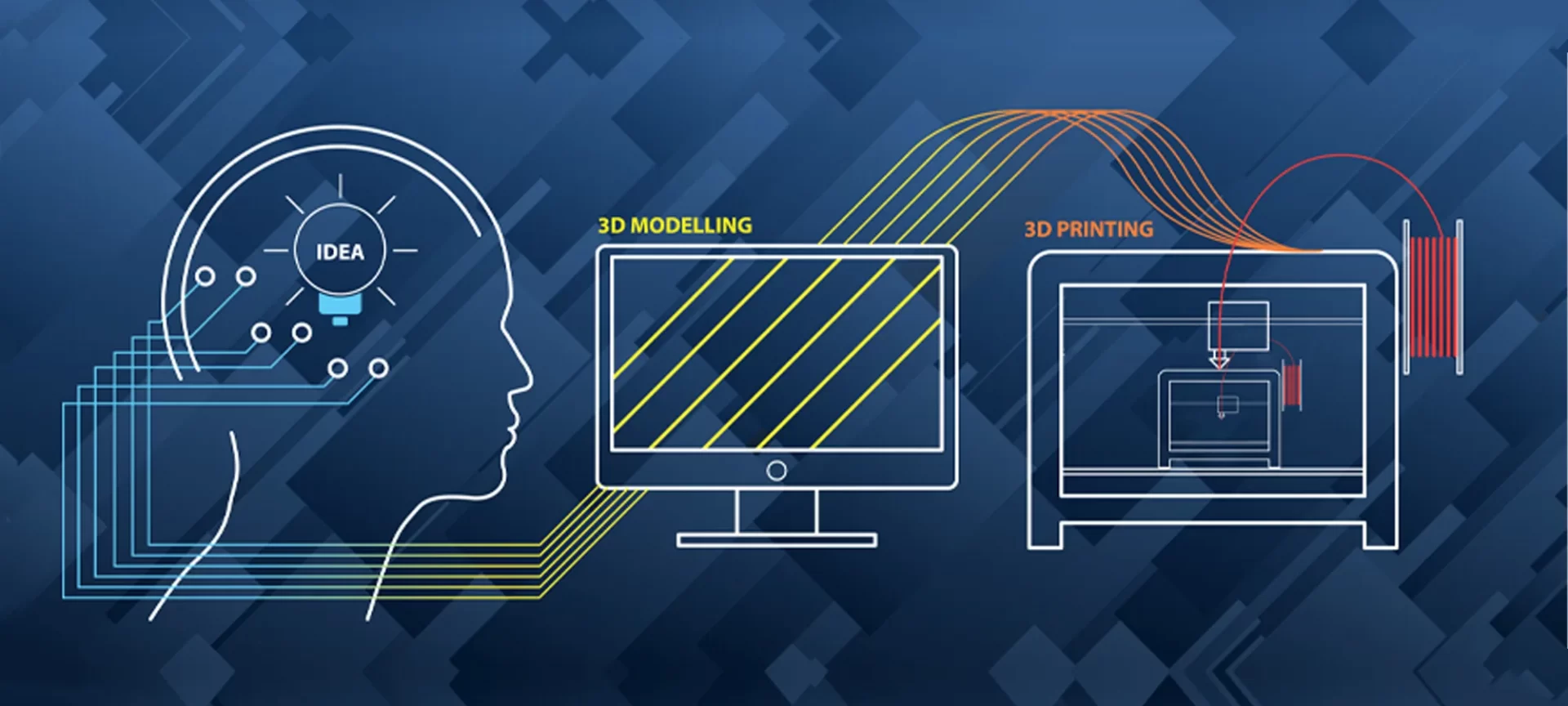

The step by step process involves an idea of how you can create a fully functioning 3D printer by using your experience and a lot of online help.

When to Decide to 3D Print a 3D Printer?

This question must be the roadblock to answer. If you have the option to buy a 3D printer, why on this earth would you decide to build a 3D printer?

Seeking an answer to this question would help you realize what you are in for. There could be many reasons, however, it must not be decided in the blink of an eye. There is a lot of things you must consider before you spend a lot on your project, more than the cost of a fully assembled 3D printer.

Hone Your Skills: Are you among those kinds of individuals who crave learning new skills and do not mind spending over it. Even if you are, you must understand that building a 3D printer won’t be easy. If you are ready to invest time and effort, you can do it.

DIY and Enthusiasts: There are few individuals who like to do it themselves. These enthusiasts are self-motivated and are ready to put their 100 percent in working for what they wish to achieve. If you are one of them, you can try your hands too.

If It Feels Expensive: Although not every time you would be able to build a 3D printer at a lesser expense. It may end up in failure which would rather be expensive.

I do not like to hold you back, however, it is important to consider every aspect when you are beginning to build a 3D printer. But it is true that you can build a 3D printer at a lesser price than what it is sold for in the market, if only you know the right tricks.

There could be other reasons too. If you think you are ready to take the challenge, you are in. However, you must remember that there would be failed attempts which you must own and learn from it.

This would help in analyzing what went wrong and what different you must do to make the next one successful.

Steps to 3D Print a 3D Printer

Let’s get ready to print a 3D printer. You would need to spend a lot of time if this is the first time you are trying it. It may take weeks for you to complete the entire process. For some, it may take less time, depending on the kind of experience they have with 3D printing technology.

Start the Research

This is the first step and goes throughout the process of printing a 3D printer. You should never stop researching about various tricks and technological know-how when working around such progressive technology.

To start with, try to find an example that would help you find the basic structure of your device. Analyze what you can replicate and what enhancements you can add to the existing design. Currently, one can only 3D print FDM machines.

That too, in parts. So, you must read about every component in detail and get a clear idea of what every part is supposed to accomplish. For example, the basic universal parts, construction, design, engineering, tuning, and whatnot. You can carry your analysis in two steps.

Read About Your Favorite Model: Now, when I say favorite, remember to pick the one that is feasible to 3D print. You cannot go on marching into the most expensive ones with every best feature.

Select the one that you can build as a beginner. However, that does not mean to choose just any 3D printer. Look for the reputation that the machine holds. This would help you achieve a strong and robust base design for your 3D printer.

Add Enchantments to Make it Unique: Because you are doing so much work, won’t you like calling it yours or just a replica. If yes, be creative and find out what you can do to make it yours.

Yet again, do not introduce any major change. Or, you may not be able to fix the problems later. Go on adding a better print bed or an enhanced cooling system. And, call t his machine yours, ones it is ready to print another printer for you. Sounds fun, isn’t it?

Assemble Parts of 3D Printer

It is no surprise that you won’t be able to print everything all by yourself. You would require certain parts to be shipped by different vendors. Remember to order parts early as they may take time to arrive.

Make a list of all the small as well as major parts for designing the 3D printer. Missing any of it will only delay the process further. Keep referring to the online help and other useful websites that have related files and design guidelines.

Parts to Order:

Have a different list of parts that you need to order. Prepare the list and recheck it a number of times before you place the order. And, while you do so, remember the size of these parts you wish to order.

For example, if you are ordering a print bed, remember to order the one that fits your printer’s design. Even if the parts can be printed and are difficult to design, you can choose to order those. Or, you can try designing the complex parts first. If you do not succeed, you can order them later.

What Can You Make with a 3D Printer:

This probably is the next question? Make another list of parts that you wish to print from a 3D printer. When said that, you must arrange a 3D printer for completing the printing tasks.

If you already own a 3D printer, the job would be easier. However, if you do not own one, you can borrow it with someone. Or, if you are a student, and your college has one used for educational purposes, you can utilize that too.

The point here is, you must have a 3D printer handy because you would need it too often during the process. There would be some failed prints and at a time, you may need to print parts more than once just to get the desired result.

For finding designs, you can look for online free repositories. These contain parts for different 3D printers and also offer versatile designs. For example, you can find a lot of designs for the outer frame of your machine.

Design Parts Using Modeling Software

You may also choose to draw the designs on paper before you start designing these. Or, you can start right away. This again is the most difficult part of the entire routine.

Looking at each part for hours and trying to build the design with required modifications could take weeks of hard work. You may feel frustrated with a few failed attempts. However, experimenting with designs would help you attain the one that you wish for.

It is recommended that you choose the free options for designing these parts. If you already have the paid subscription of the software that you like using, go with that option. For beginners and first-time users, a free software would do the trick.

You can either use an existing design and make a few changes by importing it to the workspace. Or, you can build one from scratch. If you are a beginner, designing from scratch will only delay the printing process. So, choose wisely and decide what you are in for.

Print these parts using the 3D printer you already have. Ensure that the connecting parts are well fitted.

Assemble Parts Together

Once you are done printing the parts and the order has already arrived, it is time to put things together and complete the electronics. This is another difficult task that you must carry on with patience.

There is no way you are going to fix things in a day if this is your first time. Assembling parts together, even when using the pre-designed kits, is a tough task.

There would be times when you feel that the printed parts aren’t adjusting with the ordered parts. If that is so, it is better to print the specific part again. Instead of trying to fit it improperly. These things take time and would take days for you to solve the design pattern.

Carry on the assembly and calibration of the machine with proper detail. If necessary, you can join the online communities that are motivated in accomplishing such DIY tasks related to 3D printing technology. Users are usually very cooperative and queries are answered quickly.

Testing the 3D Printer

Last but not least. Before you carry the testing of your 3D printed 3D printer, you must ensure that the settings are perfectly done.

Once assured of the bed leveling and other settings, feed a small amount of filament and start printing. If you are convinced by the results, you have got a printer for yourself. If not, check where the problems are and try resolving the issue.

This won’t be very difficult as you have basic design ready. All you need to do is twig a few things here and there and test if the results are satisfactory. It may be time-consuming but once you have reached this phase, you are almost done.

You must keep a watch on the print results and analyze the first print closely to look for the problems.

The Conclusion

If you have reached this point, you must be patting your back. You should because it had been a hectic journey and you accomplished it with satisfactory results. In the process, you also got to learn a lot about 3D printing and the possibilities that the technology entails.

Building a 3D printer from scratch is a difficult job, you must have realized that by now. However, things get easier as you reach your goal.

There are a few things that you may note when planning to create your second printer. This time, you can go for a complex version as you have already understood the basic structure and different types of movement systems.

How about planning a closed frame? You may include this in the first design as well. Talking about the advanced options, you may go for the dual extruder next time.

Or, you can simply order one for yourself. The best part is that you completed the building of a 3D printer and it is working. The feeling to create designs for real by a 3D printer that you created yourself is completely different.

There is no comparison for such experience. And, now that you can 3D print a 3D printer, you are more than just a beginner.