It is amazing how modern science is exceptionally saving and improving lives. Currently, 3D printing is transforming the world of healthcare experts who play the main role of assisting their patients in miraculous ways.

3D printing’s future in the field of medicine is promising and growing exponentially. Opportunities for limitless innovations and creativity are being observed due to its continuous development in medical research and its practical implications.

What is 3D Printing?

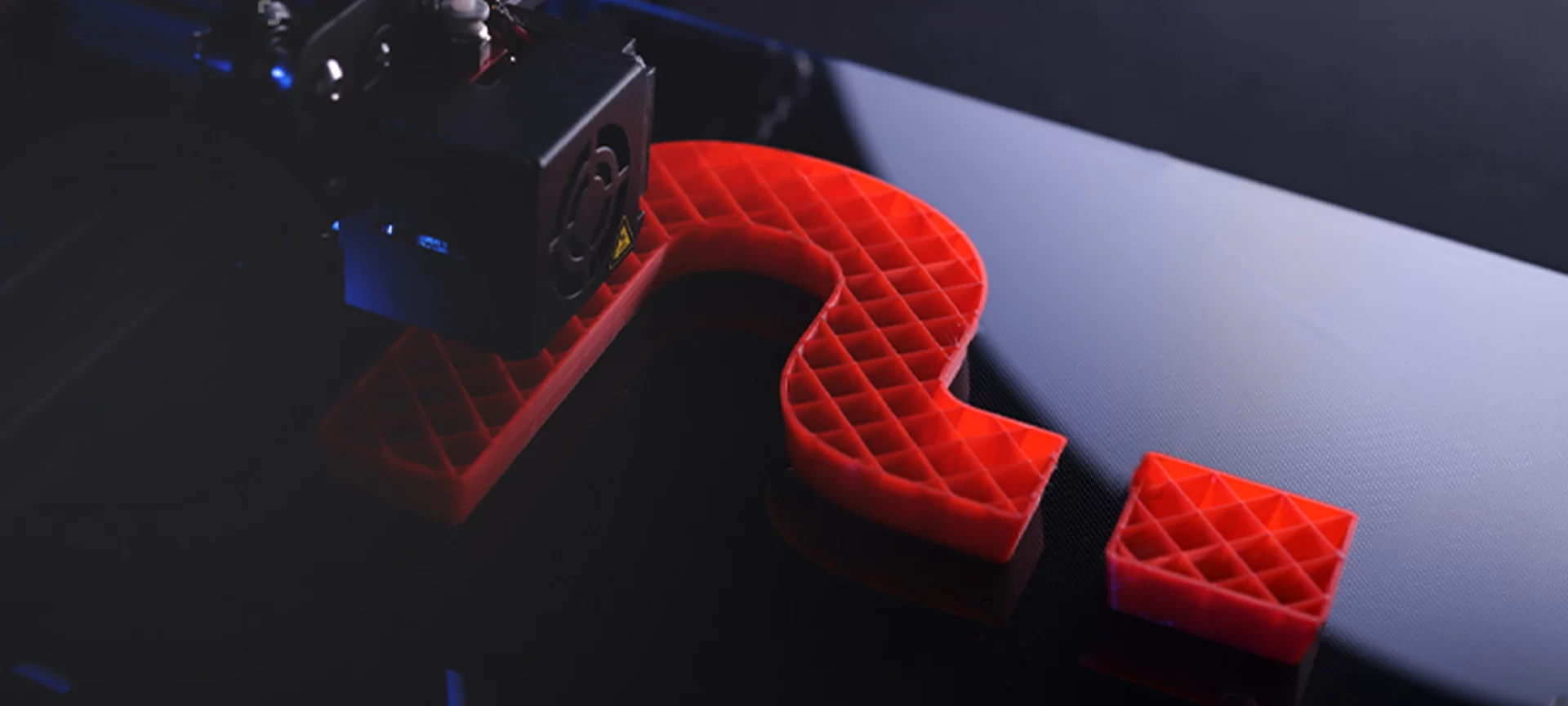

3D printing allows you to produce different objects via digital files. It works in the same way as paper printers, instead, it uses materials like fibers, plastic, resin, and heated metal to produce a living object by using specialized 3D modeling software.

The software allows 3D designers to tailor any object they imagined and it produces customized medical instruments in a short time and through a fairly easy process.

Gradually, 3D printing, also referred to as additive manufacturing, has been drastically changing and bettering medicine from the beginning of the century, just like its impact on so many other industries, from cars, graphic designing, to clothing.

It is not surprising because it is a time-saving and cost-efficient solution to create bespoke products.

Before 3D Printed Prosthetics Were Introduced

One in 1,900 children in the US face a limb reduction deficit. The total number of people who require prosthetics around the world is around 30 million. These problems are mostly observed in poorer countries where there are not enough opportunities to find proper and modern healthcare facilities.

Issues such as time and money prevail and people may need to travel very long distances, and upon arrival, it takes almost a weeklong process to assess the patient’s requisites and make a prosthetic, and it takes additional time to fit it. Most of them cannot stay away from their family and peers for too long, and some cannot live a day without earning for food and other necessities.

Problems of Traditional Prosthetics

Current prosthetics require inserting the limb into a silicone sleeve and they need straps to hold it in properly.

The traditional procedure of producing a custom fitting prosthetic uses the method of covering the stump in plaster to make a reverse mold, before allowing it to dry out.

After that, the reverse mold needs to be filled with more plaster, and leave it to rest so it can harden. Then a socket can be created from this that can fit after more modifications for precision to the bone on the stump.

This process is tedious and takes almost a week and lots of care to avoid tender areas or nerves. If this is not enough, there are costs to meet. The custom-made pieces are made of acrylics, polyurethane, and polypropylene, and a pylon created of either aluminum or carbon fiber.

These materials are far from cheap and the point that they are not mass-produced but created as a one-off further exacerbates the situation. A traditional prosthetics costs between $1,800 and $8,000, and needs replacement after every five years, with children needing replacements within two years.

3D Printed Prosthetics as the Solution

Instead of spending a week with an expert to precisely fashion a prosthetic, a 3D scanner can do all of this work in just 15 minutes, and the scans can be disseminated around the world and 3D printed in seconds.

Furthermore, 3D printed prosthetics can be tailored in different catchy colors to match the skin tones of patients for less than $30.

Upon creating the 3D prosthetic designs, the STL files can be stored forever. For example, if a child gets a prosthetic arm and outgrows it, you can use the file to scale up the arm using the original file and print a new arm.

Are 3D Printed Prosthetics Changing Lives for Amputees?

Advantages of 3D printed prosthetics

Apart from speedy printing, there are various other advantages of 3D printed prosthetics that secure the future. When someone loses a limb, their lives are affected in every aspect; family, work lives, and social lives all are disrupted.

Routine functions like troubles in balancing, ergonomics, and center of gravity that result from sizable weight are diminished. Prosthetics printed with the aid of 3D printing weigh the same as the average limb of any child or adult, which restores balance and provides support to the spine.

3D printing is now successfully being used in knee replacements including jaw surgeries. 3D bioprinting and 3D printed organs are now the future, leading to 3D printed kidneys and hearts. They are cost-effective and take less time to make and can be tailor-made according to the patients’ needs, saving lives and improving their living conditions.

Professionals have made 3D-printed skin for individuals dealing with burns, damage to limbs and organs, as well as those who require implants.

This rapidly developing technology has produce 60m customized hearing-aid shells and ear molds, and on a daily, it is creating countless dental crowns and bridges from digital scans of teeth, by taking the place of traditional wax modeling methods that have been applied for centuries.

Knee replacement and jaw surgeries are being done using surgical guides that are 3D printed on the machines.

A number of companies like the Xponential Works portfolio company Unyq are taking full advantage of generative design and additive manufacturing to come up with a new radical approach to prosthetics keeping in mind both form and functionality.

Many other organizations and companies are paying significant attention to the world’s most needy amputees in places that are short of medical infrastructure or resources, which limits their capacity to produce prosthetics on a large scale.

Many different 3D printed prosthetics hands have been made and one of the most well-known of these is Phoenix Hand. They are used for various functions that meet the needs of each individual’s aesthetic requirements and disability.

Creating prosthetics has always required specialization. An orthoptist’s main responsibility is to design and make fit the prosthetics according to the needs of the patient.

With the help of 3D printing, this field has reached amazing heights, enabling orthoptists to produce amazing customized prosthetics with immense precision.

They fit extremely well, are very comfortable, and improve quality of life by digital color-matching and synthetic skin coverings to make them less apparent.

Here are a few of the Most Intriguing Models

Phoenix Hand

Credit: myminifactory

Credit: myminifactory

There are three versions of this model. This device works with a functional wrist, using the palm to press with sufficient force. The user has to close their fingers when flexing the wrist for the device to work.

Knick Finger

Credit: thingiverse

Credit: thingiverse

The Knick Finger is an interesting development, which will enable people who are missing fingers to restore function. They do not have to use the entire hand, but rather this device can be customized to each finger. 3D printing allows the makers to design the device specifically for each patient.

Conclusion

Apart from the use of 3D printing in industrial, architectural, art, educational, and entertainment areas, 3D printing is now providing better living conditions and solutions for amputees and people with other conditions that result in limb reduction or loss. It is now the first choice for health care practitioners due to its cost-effective and time-saving properties.

The Fact that 3D-printed prosthetics can be fashioned according to a person’s needs and preferences, prosthetics serve the functions of real limbs and can be designed to make you look like a superhero!

Already there are functional 3D printed prosthetics in the market that are more advanced than in 3D bioprinting where much of the research is currently theoretical.

Attempts are being made to produce prosthetics with 3D printing that closely resemble the feel and texture of a real human hand. It was produced in a material known as Filaflex, and it looked realistic. It seems like there are promising possibilities for a bright future in 3D printed prosthetics.

As 3D printing keeps growing in the field of medicine, we can look forward to 3D printed organs and endless possibilities for the deprived as well. Setting up 3D printers in many countries will save lives and spread happiness.