Nothing seems to be falling in place if you are stuck at one point when hassling with an uncooperative 3D printer.

Either it’s about messed up thermoplastic or a complex extruder assembly, every slight to the big problem coming in between the print process gets us completely disappointed.

Starting as a beginner and reaching the league of experts isn’t easy when it comes to 3D printing. Hence, you must take each step slowly to ensure you learn as much as possible with every mistake.

The same goes for the 3D printer nozzle cleaning. You cannot just skip through this step. Many people often feel that these smaller challenges wouldn’t make much difference.

But that’s not true. Ask those who constantly have to go through the trouble of unclogging nozzles.

That is why, in this article, we will not only figure out the easiest way to unclog 3D printer nozzles but try not to get into that trouble in the first place.

There are various issues associated with 3D printer clogged nozzles and you would rather like to keep those at bay, as far as possible.

So, preventive measures should always be the first way to tackle the problem. We would later come back on the topic: How to clean 3D printer nozzles? However, first, let’s find out ways to keep these little components free of residues.

How to Prevent Clogging of Nozzle?

It is not an unusual problem for those working with 3D printers. Especially with beginners who often struggle to keep up with the nozzle clogging, only because of sheer ignorance to work that in place.

Most of the starters learn this the hard way. They first get into the problem inviting troubles such as stringing or no extrusion at all. Later, they try to clean the nozzles, again forgetting to prevent that from happening again.

Yep, that true. Some people take numerous times to realize that preventing the nozzle from clogging should be the best way to go about it.

And, not cleaning it after it is already clogged. It may happen that the nozzle may still clog after taking preventive measures, but the chances would be very slim.

Understanding that fact, one must follow the right direction in order to become a professional without missing out on the crucial routine for taking care of nozzles.

Prefer Cleaning the Nozzle When Changing Filaments

You may be printing with different filaments. In such a case, the extruding temperature may differ. Think about introducing a filament with a lower melting temperature after working with a filament with a slightly higher melting point.

While you may be adjusting the temperature to suit the needs of new filament, the prior one, if stuck inside, won’t melt at all. It would stay stubborn, clogging your nozzle and not letting you 3D print correctly.

This is one of the most common reasons for a clogged nozzle. The leftover filament tends to make the entire 3D print go haywire.

The good news is that you can get rid of the entire leftover even when it does not come off after pulling out the filament. You just need to push it inside with the help of more filament while it comes out of the nozzle end.

Is Your Filament Dust Free

The dust particles covering your filament would go inside the extruder along with your material while you feed it inside.

After burning, these particles will stay inside rather than leaving the nozzle end. Over time, these burnt particles will accumulate together to form a hard plug.

You must note that the filaments are free from dust when shipped by the manufacturer. If you can maintain the same quality of material until you use it for 3D printing, you can avoid the problem from happening.

You can use airtight containers or bags to store these filaments. Plus, you can also use desiccant to keep the dust away.

Ensure to Set the Optimal Height of the Nozzle

Do you know that the incorrectly set height of the nozzle from the build plate could surge the problem of clogging as well?

So, what exactly happens when we keep the nozzle too close or too far from the build plate.

When the nozzle is set too far, the filament cooling will happen before it would set on the bed, hence, resulting in poor first layer adhesion. Ultimately making your print fail in the later stages.

On the other hand, if the nozzle is spaced too close, it will restrict the correct flow of the material from the nozzle. This is also termed as retrograde extrusion.

In this case, the filament is unable to maintain proper flow and end up jamming the nozzle ends. It will also hamper the build quality of your 3D print. Ruining the entire effort, you just put in.

Set the Right Nozzle Temperature While 3D Printing

You will not like to get into the mess that this ignorance can create. Not setting the nozzle at the recommended temperature is one of the biggest mistakes you can make.

This is because the 3D printer nozzle cleaning is unimaginably difficult when happens due to improper nozzle temperature.

As you know that the diameter of the nozzle is usually smaller than that of filament, it becomes very crucial to melt the filament completely before it gets ready to leave the nozzle.

Or else, the nozzle won’t be able to extrude the filament at all. The filament will cool down just before leaving the nozzle due to lower temperatures.

Hence, clogging the ends of the nozzle. As mentioned before, this jam is one of the difficult ones to tackle.

So, it is better you keep tabs of the temperature you are setting for your nozzle. It must be the recommended temperature for the filament you are using or feeding to the extruder.

How Do You Clean a 3D Printer Nozzle?

We have already learned about the ways to keep your nozzle away from clogging. But when it’s about 3D printing, you cannot leave any stone unturned and any tip unrehearsed.

You must also know the tricks for 3D printer nozzle cleaning. That is when you would actually learn how to tackle the problem completely.

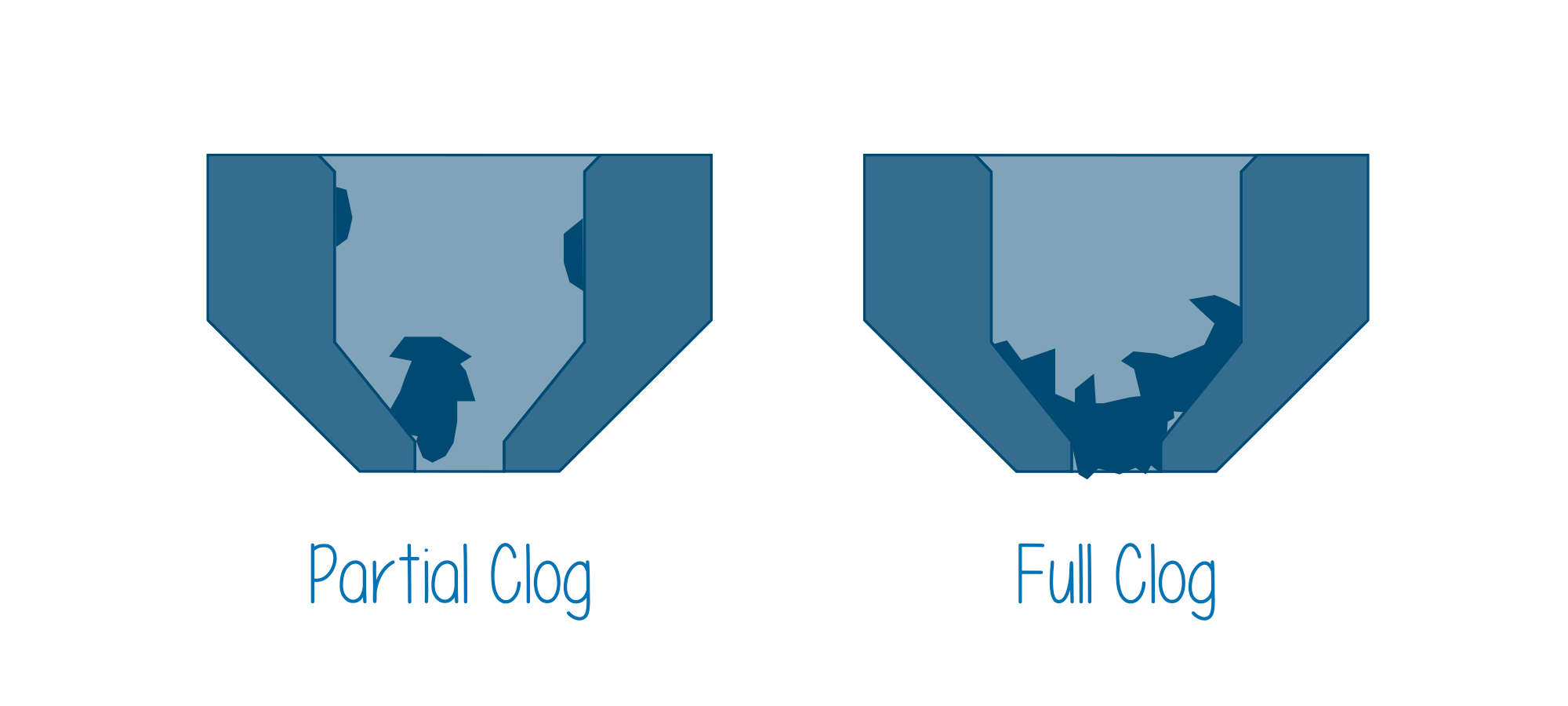

The tricks and plans for 3D printer nozzle cleaning will depend on the severity of the jam. You may try one of the listed ways when encountered with such a problem.

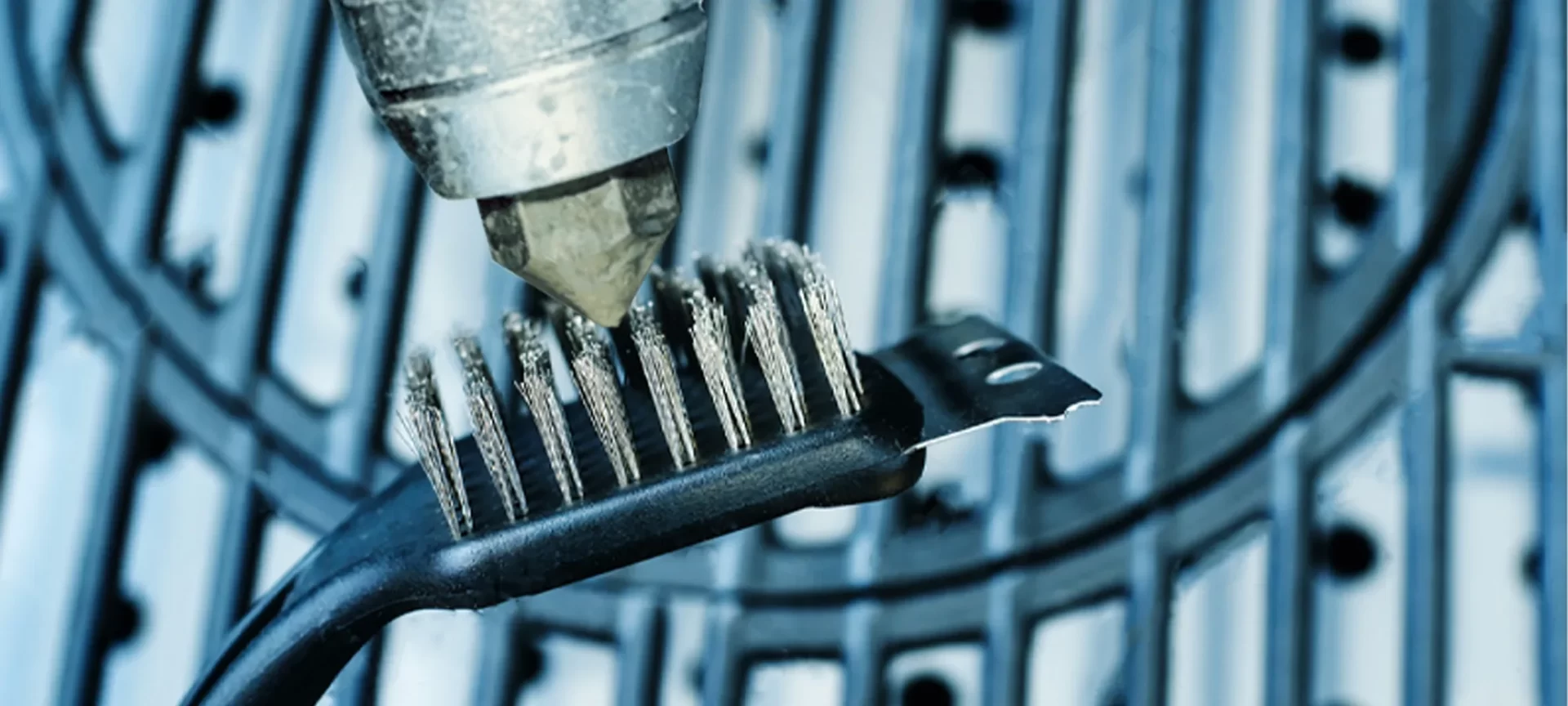

Brushing the Outside of the Clogged

As it would seem, this one if the easiest way to get rid of the clogged nozzle. All you have to do is clean the nozzle by brushing it from outside to dirt away from the residues if stuck in the ends. Do not forget to use the right brush for this job.

For the best cleaning, you must use a wire brush. This is capable enough to remove the stubborn plug caused due to accumulation of burnt material. Use the brush with brass thread. This would ensure that your nozzle does not tear away or get damaged.

This must be the first step every time you deal with a clogged nozzle. The reason why it is so important is that you can skip every other difficult trick if this one works in the first place.

Remember, that the brushing will only clean the nozzle tip. Hence, if the problem of clogging isn’t gone using this method, except that the jam is worse than you imagined. Being so easy to accomplish, you can actually include it as a part of the routine for maintenance.

Use a Pin to Clear the Jam

If the clogging isn’t too bad and you just need to remove a small amount of melted filament, you can make use of a pin. Or else, you can also use a small needle (acupuncture needles will do the trick).

The trick is easy to complete. You just need to heat the nozzle to a temperature that softens the clogged filament and not melt it completely.

Either you use a shotgun or a manage the temperature through hot end assembly, remember not to completely melt the clogged filament.

After this, you only need to push the clogged material out of the nozzle end using the tip of the needle.

Use Nylon Filament for Executing Cold Pull

As you already know, not all the stubborn jam can be removed using a needle or a brush.

In such cases, you would need an effective method for 3D printer nozzle cleaning. If you are looking for such an alternative, this is what you can do: Use the nylon filament to cold pull the jammed filament.

In this method, you will require to manually feed the filament through the nozzle. Hence, you must first dismantle the setup of the extruder to make that possible. Later, you need to heat the nozzle to about 250 °C. After it reaches this temperature, leave it for 5 minutes.

Although the best filament is Nylon for executing this method, you can also make use of ABS. To clean the nozzle, push the filament manually through the nozzle, keeping your push firm and gentle.

The clogged filament will melt completely at this temperature. Hence, it would come out of the nozzle end along with Nylon filament. You must keep extruding the filament until you stop seeing any other filament than nylon.

Again, leave the setup to cool down properly to reach the room temperature. We haven’t settled yet. You must again heat the nozzle to about 130 °C.

This will help soften the nylon filament instead of melting it completely. Pull the left-out material from the nozzle. The cold pull will help remove the leftover plug if any. Hence, ensuring the nozzle is completely free of dirt and residues.

If you think that the problem still persists, you can carry this method multiple times unless you are completely satisfied that the 3D printer nozzle cleaning is carried with success.

Remember, if the filament seems too hard to pull, you can further increase the temperature slightly to ensure it softens before the cold pull.

Clean the Nozzle in Acetone

This is one alternative that you only use when nothing else would work. The problem with this method is that it takes longer to complete as well as it may not work consistently for all filament types.

In this method, you must remove the nozzle from the extruder settings first. You can make use of socket wrench to do that. The method works best for ABS material.

You can soak the nozzle in the acetone for about 15-20 minutes. After the clogging leaves the nozzle, you can reinstall it back to the extruder. However, do not forget to wipe away any leftover acetone from the nozzle.

Very often, in case the clogging is because of a material that is not dissolvable in acetone, this method won’t work properly. You can still make use of a heat gun for melting the clog away.

The Conclusion

The clogged nozzle is the worst problem to encounter. A lot of professionals have talked about the stubborn jam that took hours to leave the nozzle end.

And, it becomes difficult to even more, if you keep ignoring the problem until it clogs the entire end, resulting in no filament extrusion condition.

Hence, the best way to take care of your nozzle is to keep it clean at all times. After every print, do not forget to clean your nozzle, if possible.

If that seems to be a tough job, at least, clean the nozzle after you switch between filaments. You sure can do this if you love your 3D printer and your passion to grow with the technology to create better models in the future.

Your mistakes must not disappoint you. But should encourage you to think better. When you feel stuck while 3D printer nozzle cleaning, breath and think of the problem that may have caused it.

You will know what to do. With time, you may never have to face this problem. Because you would learn how to maintain your nozzle and other components of the 3D printer. Isn’t it?