Working with 3D printers comes with its own part of challenges. Especially when it stops working. And, you are unable to find ways to recover it.

There could be many reasons for your 3D printer to not perform as expected. However, looking for the right signs would help you determine the solution.

You can repair a 3D printer if you know how to troubleshoot the problem. It could be a minor issue or a major one when you will have to order parts of your 3D Printer to make it work again.

However, whatever the case it would be, you would certainly learn a lot about fixing these devices.

For some, the troubleshooting is fun as well. Finding out what is messing with the normal operation of the 3D printer is enthralling for many users.

Also, there are users who feel frustrated to go through those repeated steps time again when stuck at a certain point.

But, the process for correcting the problem is highly rewarding, if one gets to the right cause of the error. Moreover, you can save a huge amount that you may be spending on someone helping you repair a 3D printer.

How Can I Fix My 3D Printer?

As mentioned, there could be many reasons for your stuck 3D printer. Here are a few of the usual causes that can apply the brake to your day to day operation with a 3D Printer.

And, the steps you can use to ensure these problems are rectified at the earliest, without needing someone to come over and check the problem.

3D Printer Not Turning On

So, here is the problem that can happen to anyone. This could be because of a minor problem like a loose connection or something major that couldn’t be corrected at home.

However, finding the reason before seeking help could save you from the meaningless expenditure. What if it is just a loose connection? So, why not try your hands first and then take the right call?

Being said that, there would be steps that are so simple that you might find them unnecessary. But do not skip them, or you may not be able to find the fault.

Start with checking the connections. Trust this, many times, a lot of users forget to connect something and then spend the entire day trying to look for a probable reason.

You may be working around dozens of wires. In such a cluster, forgetting to connect a few isn’t a surprise. Everyone does that once in a while.

However, not realizing that sooner is something unusual. So, ensure you have connected every wire and the 3D printer switch is turned on. Later, try turning off and turning on the switch to find if there is any unusual sound that the printer is making.

If this step does not work, it is better to check the power socket you are using to connect your 3D printer. I told you, this may be overkill, but its important to ensure that everything is working.

You cannot treat stomach aches with medicines for headaches. Try connecting a mobile charger or some other device to check the power socket.

Moving forward, it is time to check the cable you are using to connect your 3D Printer. If there is any device that fits in your 3D Printer cable, this is the time to utilize it.

Connect the cable to that device and see if it is turning on. If it does, your power cable isn’t faulty. If it does not, you know what to do. Get a new power cable. That’s it.

Check for the fuse, if cable seems fine. It could be a blown fuse. Try replacing it and checking it again. If there is a problem with a short circuit, you may lose another fuse, but you know what to fix.

Things seem fine till here, use a multimeter to check the switch. If the power supply is able to provide enough voltage for running your 3D printer? In most cases, the above steps would resolve the problem.

If not, you may need an expert to help you out with the problem.

The Screen Interface Won’t Turn Up

Here, by default, the first step would be checking if the 3D printer is plugged in and powered on. You can follow the same steps above to make sure the power is running through the cables of your 3D printer. If that seems okay, you need to check a few other things.

Look for the connectors and wires connecting the screen to the 3D Printer. Turn of your 3D Printer, make the connections secure and firm.

Turn on the printer and check for the screen, if it turns on or not. The next thing would be to check the power signal reaching your control board.

You can use Multimeters and Oscilloscopes to verify the same. However, you must be cautious when using these tools. If this also does not signal anything, you may have to replace the control board of the screen interface connected to the 3D printer.

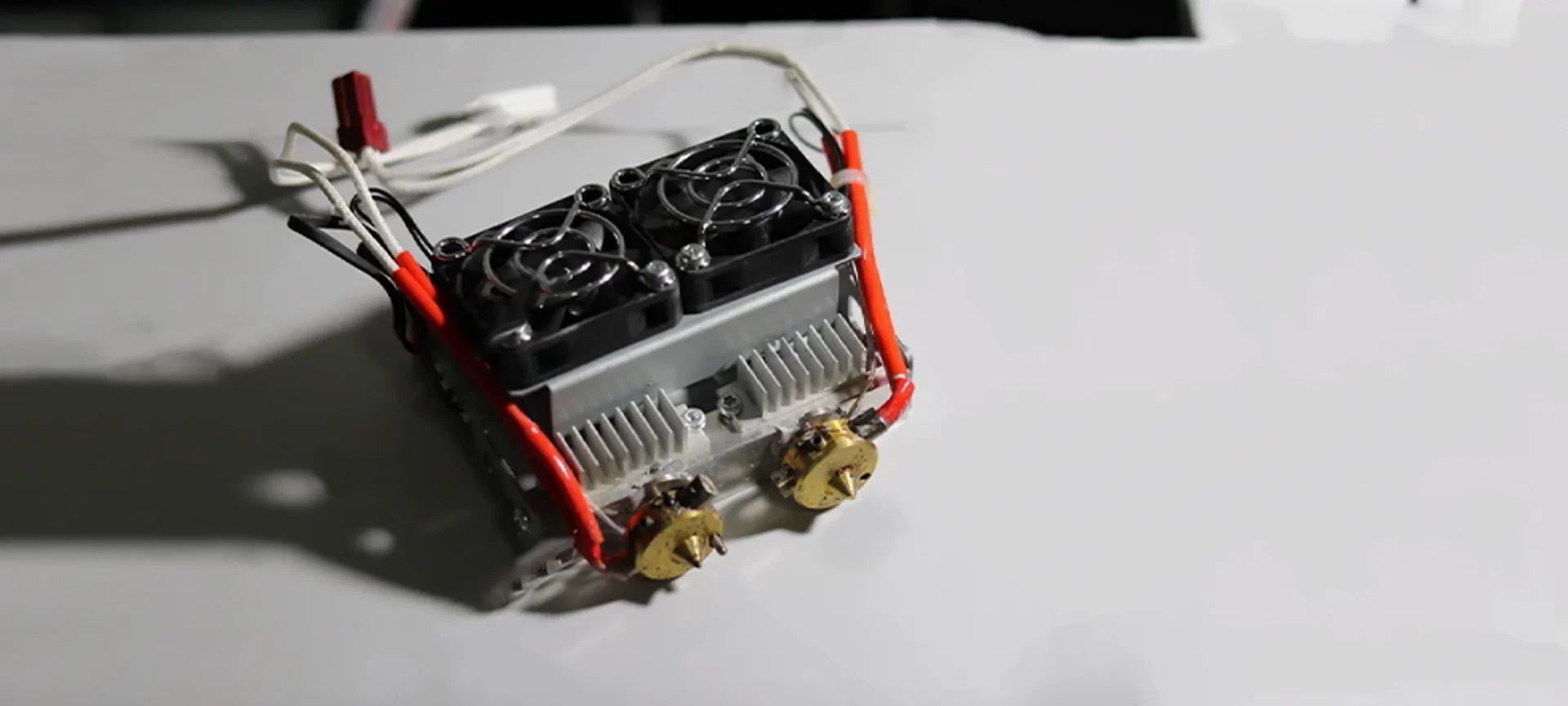

The nozzle is not Heating

In this case, you will have to work out by manually heating the nozzle. The information would be available on your printer setup guide.

This is often put as ‘preheat’. If that isn’t the case, you may need to check the heating element is connected to the control board. This rarely is the case. So, mostly, you will have to change the heating element.

The same applies to the problem when the bed won’t heat up. You can follow the same steps as illustrated for nozzle problem.

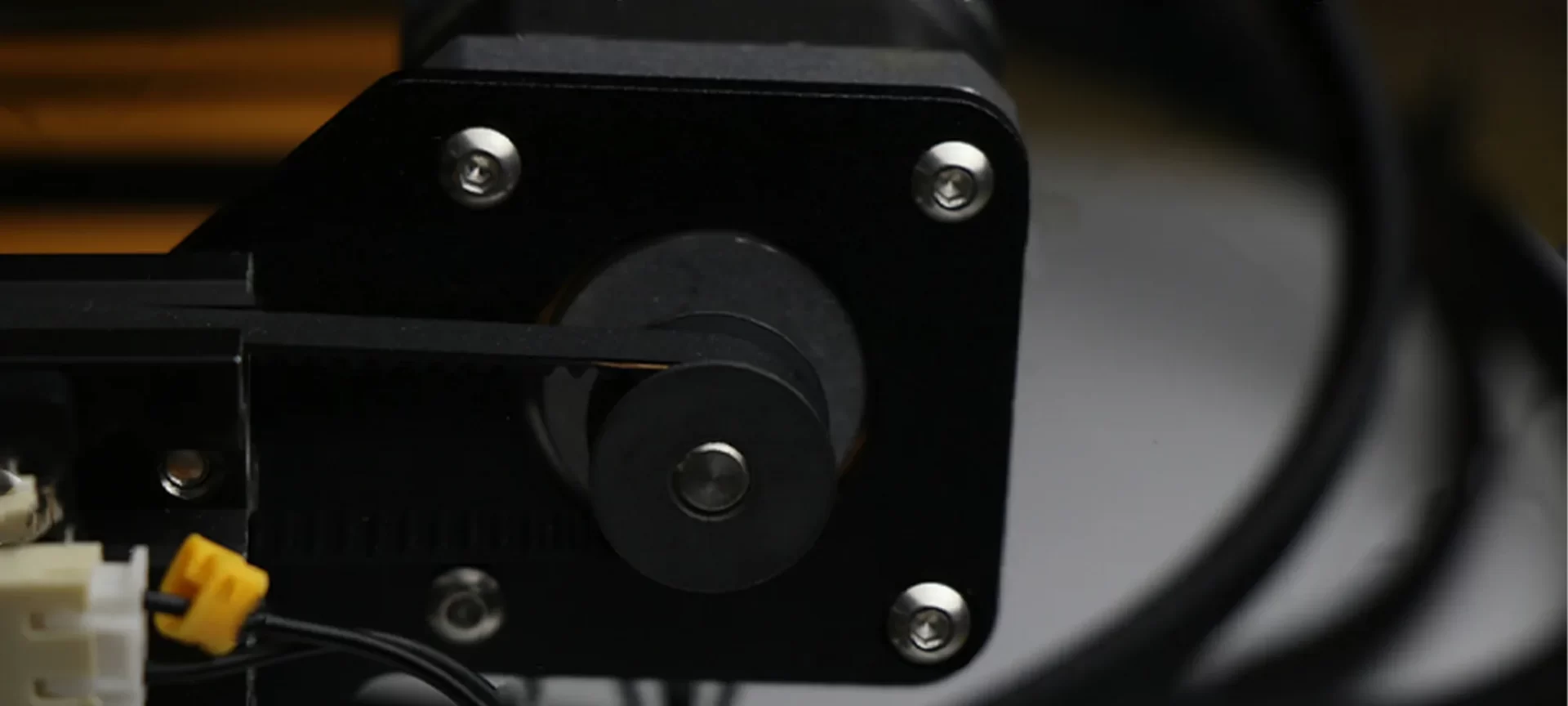

Stepper Motor(s) is a Problem

This isn’t something that one usually comes across. Hence, ensuring that the stepper motor is the problem must be the first step. If while working, one motor seems not to work, it could faulty.

However, if both the motors aren’t working, the chances for a motor problem is very slim. Check all the connections to the stepper motors.

From the component to the control board. Verify of the stepper motor driver is sending a proper signal and is working fine. If the driver is fine too, you must replace your stepper motor.

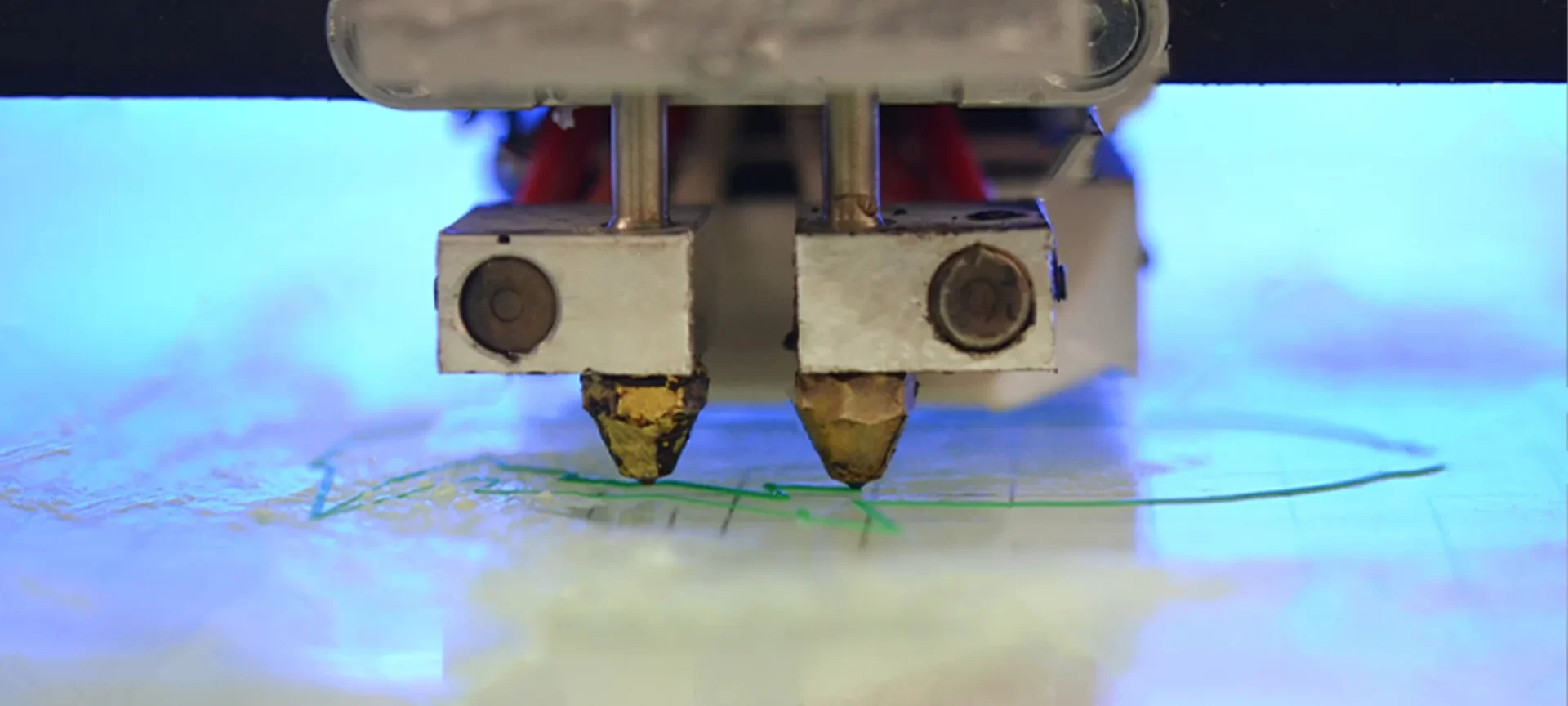

No Plastic or Very Little Plastic Coming Out or Nozzle

This could be because of a jammed nozzle. Or else, the nozzle is not able to attain a proper temperature. Check if the extruder’s stepper motor is working fine. In most of the cases, the reason is the first two problems.

More than Required Filament Extruded

Again is a huge problem and won’t let you print properly. The first thing to check is the calibration and the next one would be the extrusion multiplier setting.

Also, if you have changed the stepper motor recently, you can check for the drive gear and its diameter. If it’s different from the prior one, that could be raising the issue.

Or else, the settings of the steps per revolution may be different for the new stepper motor. You must check all these and find out what has gone wrong. In most cases, you would find the problem right away.

Problem Sticking the First Layer

A lot of users would have come across this problem. One of the most frustrating ones. Dealing with first layer adhesion is very irritating if it is creating a problem.

However, the good news is that the problem is easy to sort out. Try checking the slicer settings. A bit of tuning may help get the settings right.

Check the distance between the hot end and the build plate. Reducing the distance may help you find the solution. Or else, you may have to check for other things.

If the adhesion is not adequate, you can also choose to go with other options for enhancing the first layer adhesion. Such as painters’ tape. You can also rub glue stick or use hair spray on the build plate for better adhesion of print bed.

The Conclusion

A 3D printer is a complex design. However, not for those who are constantly working on it for different applications.

Knowing the machine better is very important if you are looking for a long-term association without inflating the operational or maintenance cost.

To be precise, you must know how to handle some of the breaks and knocks that come along the way when working with the 3D printer.

There could be many other problems too apart from the ones listed above. Such as jammed print bed, loose bolts or screws. And, many others. You can choose to give up or try harder until you find it to identify the problem.

Hence, try figuring out what could be the probable reason for the stuck 3D printer or for its unusual results.

Most of the time, the problem would be simple to resolve, just hidden somewhere and difficult to determine.

As soon as you know how to identify the correct reason, you would be able to repair the 3D printer on your own. Trust this, it would be self-rewarding and great learning.