Every technology has its own ups and downs. 3D printing is no different. Since its development, the technology has been a matter of debate.

Either it’s the usage of the machine or the accessibility, there have been one or the other thing making 3D Printing the center of discussion.

The only difference is that in the past, technology was discussed among industrial applications. Now, even the consumers and end-users are constantly sharing views about 3D Printing technologies.

And, as much as its advantages are obvious, disadvantages of 3D printing are also talked loudly among enthusiasts and makers. This is all because everyone who has ever come across a 3D printer knows about its immense potential.

Researchers and developers are always trying to come up with new solutions to minimize the issues with the old ones. And, the industry is growing at a fast rate.

Today, 3D printing is a part of a huge industrial population as well as sitting strongly beside consumers from various sectors.

There is no way one can ignore the benefits it poses. However, one must be aware of the challenges too. Hence, being able to make the most of the technology that is highly promising and likely to stay for as long as we exist.

Advantages and Disadvantages of 3D Printing

What is 3D Printing? As we have been discussing two different sides of the technology, it is important to glance over a little bit on the definition of 3D Printing as well.

3D printing is an additive manufacturing process where an object is created one layer at a time. With the help of 3D printers, based on different printing processes, one layer is set and the next one is laid over it.

There are different materials used for the process. Hence, it is capable of providing varying results with different properties of parts and products.

However, there are many other things that come into play when measuring the value of technology over traditional methods. In some areas, the technology does make a huge contribution, however, there are those areas as well, where it does not fit the application.

Let us explore the different categories and areas that define how beneficial technology is or for which tasks it won’t be suitable at all.

Speed

As we know, speed is an important factor to define the capability of a machine. Speed measures how fast a given task would be completed from design to its completion.

Did you know that 3D printing was once termed as Rapid Prototyping? The name suggests that it is capable of speeding the prototyping job and it is.

Using Rapid Prototyping, users can design and develop parts in the minimum time possible and complete the testing process at the earliest. Not just that, in case of changes to the design, the modifications can be done in no time without impacting the manufacturing speed.

Prototyping isn’t a day’s job, and it used to take weeks and months for testing new parts. The problem was even worse when the modifications came into the picture.

However, after the introduction of 3D printing, the task has become faster. Businesses are now able to develop the parts in house, without needing a service center for the same.

Or, they can opt for that as well, if needed. Still, the job would be faster. In other words, the entire process of prototyping from start to finish is now possible in days.

This was about prototyping. If we talk about the desktop 3D Printers and their contribution to making jobs of makers and hobbyists easier and faster, you would find a lot of benefits.

Enthusiasts now can make anything they want and create any design they like. 3D printing has helped in reducing the lead times.

This means that one does not need to wait for outsourcing complex manufacturing jobs. One can turn their house into a workshop and can do anything that they want to with minimum to no help needed from outside.

This does not mean that 3D printing has got no limitations in terms of speed. In 3D printing, as explained before, the manufacturing happens each layer at a time.

This means that there is a fixed time for the preparation of each layer. And, fixed time for each part. So, considering the same design and size, every part would take the same time.

On the other hand, with injection molding, mass production could be made faster. Once the initial time needed for creating suitable tools and molds is invested, the entire manufacturing process can be automated for mass production, significantly reducing the time.

This means that 3D printing technology is great for single or small production runs. However, the disadvantages of 3D printing lie when it is measured against the traditional methods for carrying mass production of the same design parts.

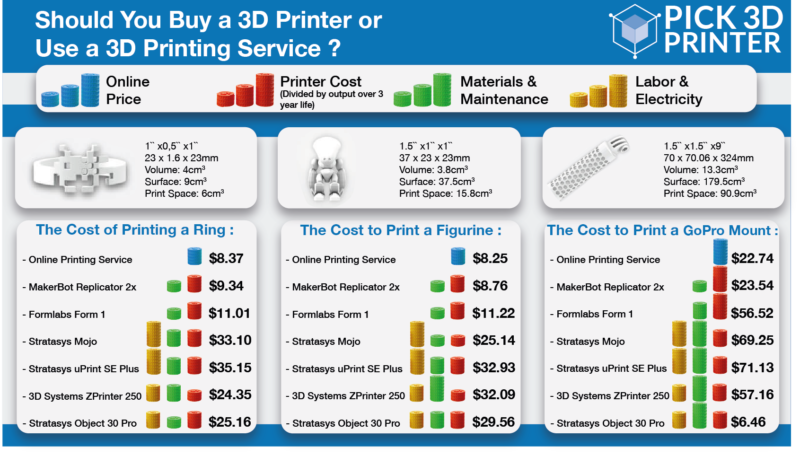

Cost

Cost calculates the average funding required for producing a single model. As already explained, using 3D printing one can significantly reduce the time for developing a single unique prototype.

While on the other hand, the traditional methods are better suited for mass production of finished parts.

In terms of cost, 3D printing does make sense for very small runs. These machines are expensive and one would not require more than one or two machines for carrying production on a smaller scale.

Also, the material wastage is less in 3D Printing, making it a viable choice for small scale production when it comes to cost.

When looking from the traditional manufacturing perspective, defining cost would mostly depend on the scale of production. Mass production will consume less energy for creating larger objects.

The cost of creating the required tools is often higher and the wastage is more too. However, when combined with the speed of manufacturing, the initial investment would be sufficient and balance the overall production cost.

Hence, making traditional manufacturing a better choice for mass production when compared with 3D printing.

Flexibility

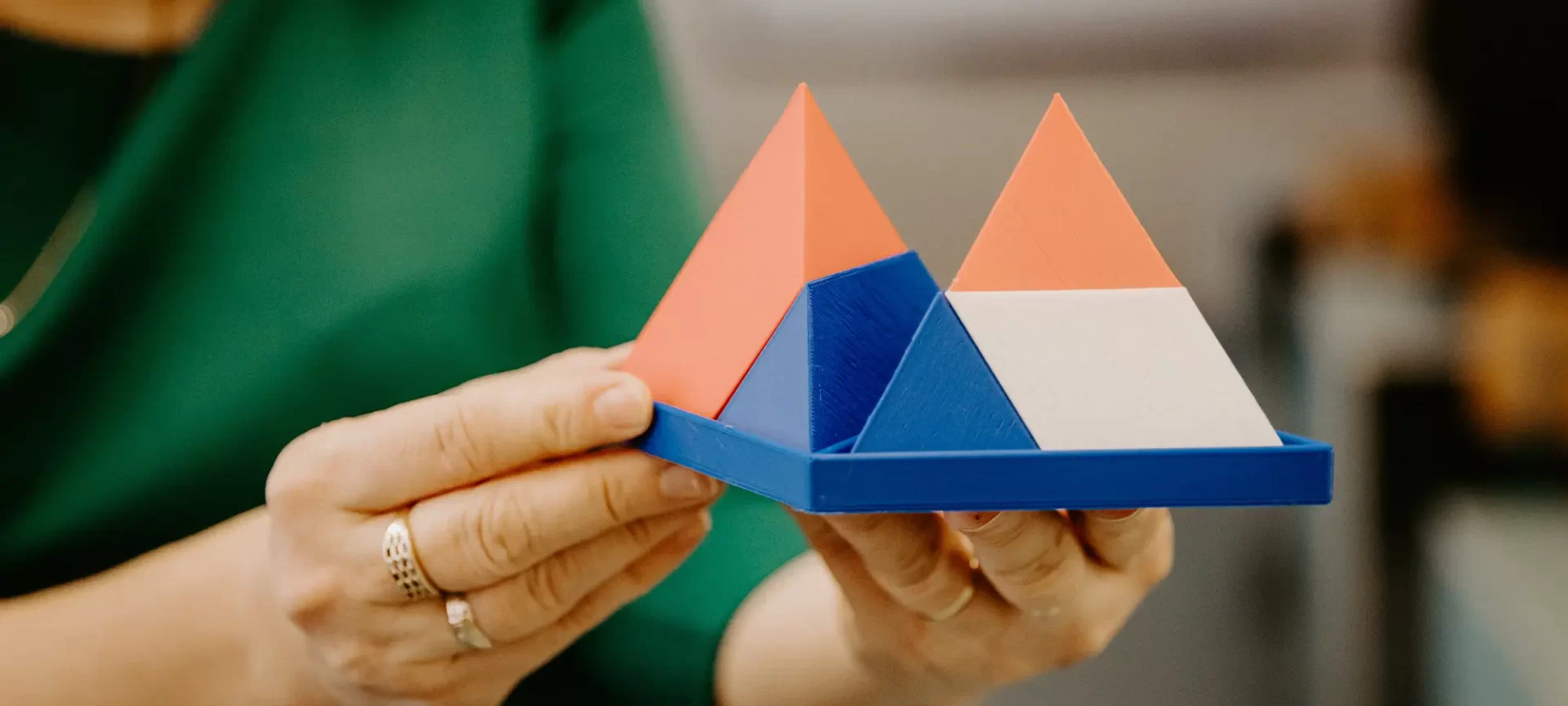

This is where 3D Printing takes over all the credit. This is one of the major advantages of 3D printing which is impossible for traditional methods to surpass. 3D printing provides flexibility to create anything that can fit inside the printer’s build space.

When considering the conventional methods, one would need to design the tools and molds every time a new part design would need to be carved.

This is not the case with 3D printing. One can just load the 3D design and the printer would make it possible. With very little effort, one can come up with new parts and modifications in the design.

Not just that, it is even possible to build complex designs using 3D printing that is not possible to be created with any other methods available to the human race.

Talk about hollow infill patterns or finer geometries, 3D printing can make it possible. However, traditional methods would fail in doing so. Also, users can combine different materials and colors to come up with mixed textures and internal properties of the model.

It has also given end-users with not much knowledge of the technology to try their hands with easy to use design applications and make changes to the existing designs for their personalized products.

Quality

Measuring how perfect a part is created isn’t very difficult. Only by looking at the parts, one can tell. In this category, 3D Printing falls miserably. 3D printing works on layers.

One layer is connected to the other. This means that there is an inherent weakness between these layers.

One can definitely bring in different measures to enhance the strength and overall quality, however, not every measure would suit all the designs, especially the complex ones.

Also, the layers are visible forming linings around the parts. This takes away the visual appeal of the parts. There are ways to improve the surface quality, however, it would take extra effort and time.

One can also decide to create parts using laser-based 3D printers embodying high-resolution settings.

But the process would take a very long time. Making the option infeasible anyway. Additionally, it will also add considerable production cost to the part production.

Accessibility

The accessibility of 3D printers was restricted to a few industries with high production budget a few years before. However, things have changed now. As we are progressing, new machines have come into the market.

An FDM 3D printer costs as less as $100. However, it is true that the machine is for single use and contains only the basic feature.

Those looking for a serious application, may invest around $1000 or $2000 and get a machine much capable of printing with two colors and materials. These machines are suited for professionals and enthusiasts.

However, when thinking of industries, a 3D printer would cost even more than $10,000. And, this is just the cost for one printer. A complete setup would need multiple such 3D printers.

Talking about injection modeling, one may have to spend around $50,000 for a complete setup. However, this does not include the tooling cost.

So, it is easy to infer that a 3D printer, although being costly, is still accessible to users as per their budget. These machines are available in different flavors and budgets, making it more accessible than traditional production methods.

Sustainability

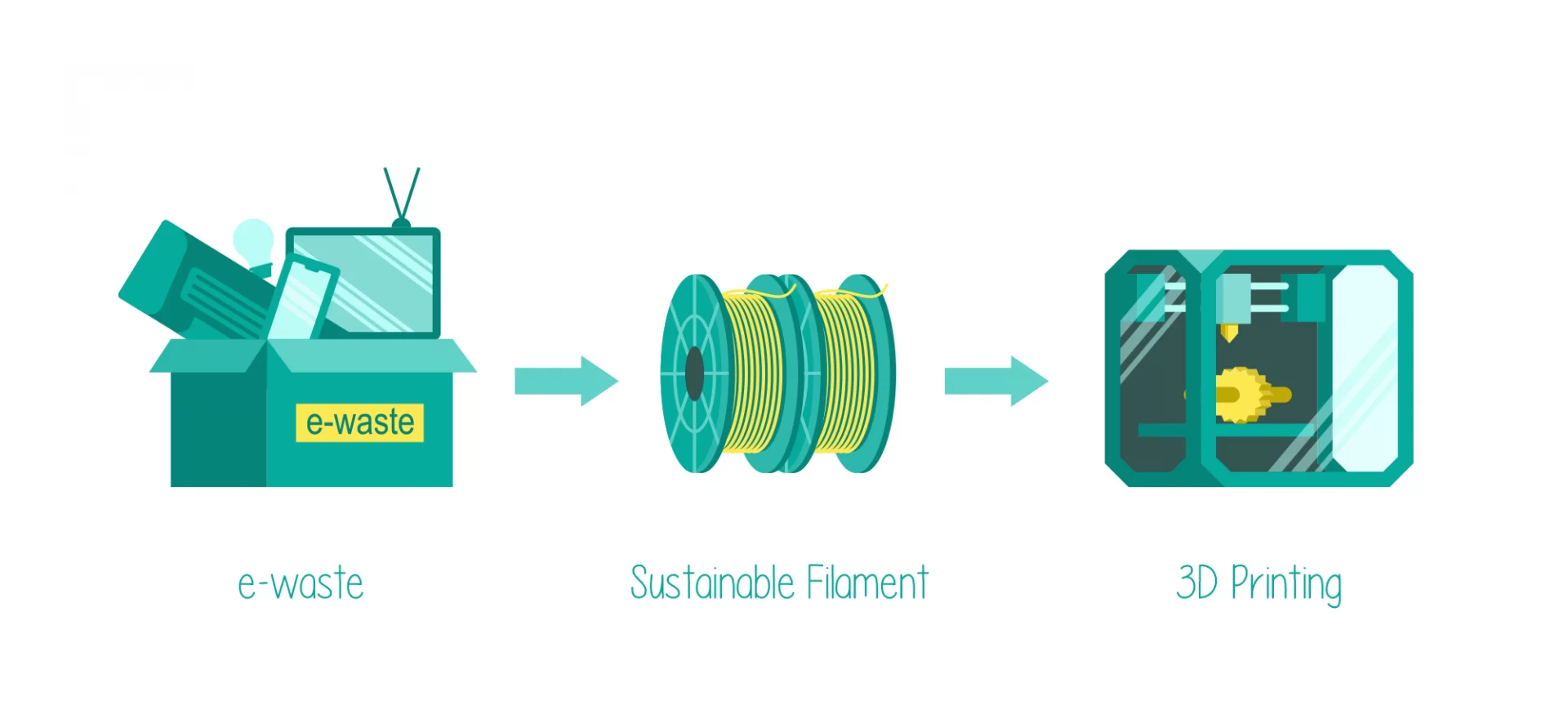

Sustainability helps us measure a rough estimate of the amount of waste generated for producing a single part. Also, it looks at the recycling ease of the part when compared to other methods.

Let us go back to the accessibility of the two production methods. 3D Printing being accessible to a larger section of society helps in eliminating the harmful impact of the shipping process that comes handy when outsourcing work for manufacturing.

Also, because the 3D printers are also for home use, one can set up the workspace inside their homes, not requiring a factory elsewhere. Hence, saving the environment immensely.

Moreover, when we talk about waste materials, 3D printing again wins the game. 3D printing is known for creating lesser waste material than traditional manufacturing.

Also, the majority of materials available for 3D printing can be recycled. Hence, making 3D printing a highly sustainable option.

However, the disadvantage of 3D printing does trail behind here as well. 3D printers need energy for running efficiently.

Also, when considering cost, 3D printing is still behind traditional manufacturing methods in terms of mass production.

This means that with time, the need for energy and power needed to operate the printer and for processing of recycling materials into a printable format would outpace its sustainability.

To be precise, when considering the need for saving renewable resources, traditional manufacturing would still be a sustainable option for mass production. Hence, making traditional methods better in terms of sustainability when compared with 3D printing technology.

The Conclusion

There are many ways to define the benefits and limitations that the technology entails. In different categories and considering different factors to measure the same, we get differing results.

It is impossible to choose one technology over others and completely eliminate the other one. From our discussion, it is completely lucid that both technologies have their own perks and limitations at the same time.

We cannot deny that 3D printing does make things easier and simpler. The technology has given us huge freedom of creativity and comes with many choices.

On the other hand, traditional manufacturing may lack a certain front, it does stay as a viable choice for mass production.

To sum things up, 3D printing advantages lies in its speed for smaller production, flexibility for creating impossible designs, the cost for setting a small business from home, and accessibility as per the usage and budget.

However, it does showcase some limitations. The disadvantages of 3D printing are also obvious.

From infeasible choice for limited budget mass production to less sustainable choice, make it a dicey option for many users. Hence, to make an informed decision, it is important to measure both sides of the technology.