3D printing has started impacting different crucial niches and the medical industry is not indifferent to the change. The technology has emerged to become one of the most revolutionary innovations around.

The advancements around 3D printing are not ceasing to impress and new milestones are making headway to find better alternatives for already existing solutions.

While we have not even recovered from the surprise of 3D printed gadgets and décor items, 3D printed body parts made us completely awestruck.

Think about a technology that could help you get an artificial bone printed in a matter of hours and transplanted on the same day.

If you are thinking we are overreacting, why don’t you look at the stats that show how 3D printing is getting stronger.

Not only used for rapid prototyping, but also capable of creating end products. And now, 3D printed human organs. One thing is for sure, the journey still remains unexplored.

We much expect to find more inventions in the coming time. But we must cherish the progress we have made so far. The technology does have brought great change to the medical science niche.

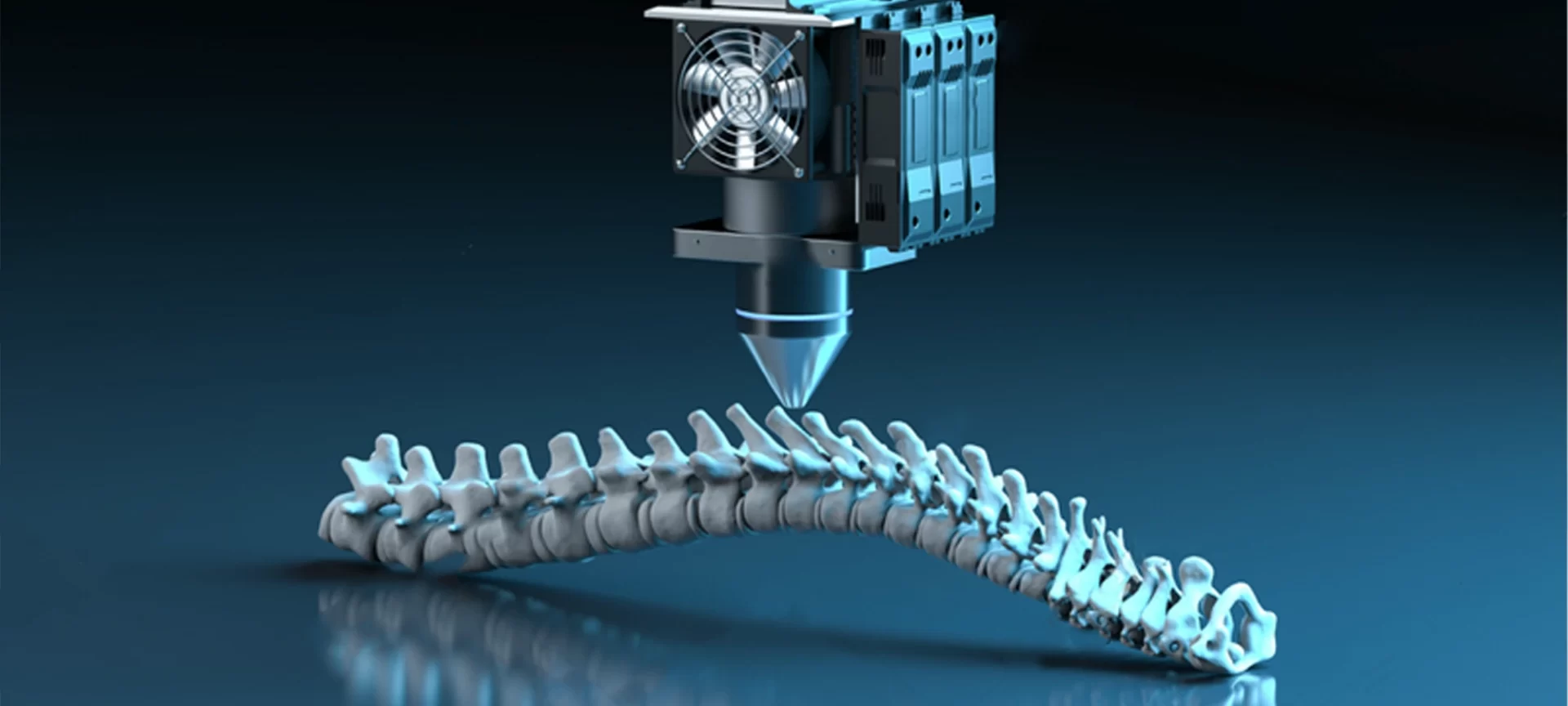

What is bioprinting? It refers to the process of using 3D printers for creating bodily structures such as bones and skin, one layer at a time, using biomaterial.

The process is very precise and takes into account a lot of details. The cells are taken from the patients who need the transplant.

These stem cells are cultivated to form a bioink, used for 3D printers to create body organs. So, let’s have deeper information about what technology is supposed to do or is already doing.

A shift from 3D Printing to Bioprinting

Bioprinting originated from 3D printing. As we all know, 3D printing is about joining different layers to create an entire model, bioprinting organs take place in the same fashion.

3D printing started with one focus to expedite the rapid prototyping process. It stayed that wat for quite long years.

However, in the last few years, the advancements have proved to be revolutionary. It has been recognized as one of the most innovative ways of manufacturing being able to impact huge industrial sectors.

From car parts to surgical tools, all these applications are no more news. These have already kept individuals busy for long now. These days the flash news is the utilization of the technology in the transplant of a human organ.

In the medical industry, doctors and researchers are already using 3D printing for many purposes. From 3D printing surgical instruments to dental implants, are all happening from quite a few years now.

However, not the next milestone is to complete the tests already happening around the world to bring bioprinting at the forefront of transplanting human organs.

For instance, the heart valves of humans are already being 3D printed using different 3D printing technologies.

As of now, the transplant has not done on humans, but the promising future awaits us all. There likely would be significant advancements soon in the field of 3D printed body parts.

Bioprinting’s emergence is a result of innovations happening around 3D printing which is progressing from rapid prototyping to engineering parts involving biological components. This not only involves human tissues but vaccines and much more.

Can Body Parts Be 3D Printed?

While the possibilities are yet to be defined, here is what we have come to acknowledge. Let’s have a look at the biggest breakthroughs in medical history.

Bones

Bones replacements are done in huge numbers across the globe. Hence, the invention by a team from Swansea University in the UK provided huge aid to the process.

Through their bioprinting process, one can generate an artificial bone matrix with the use of durable as well as a regenerative biomaterial.

As of now, medical professionals use bone grafting to treat complex bone fractures. It is a surgical process that involves replacing damaged bones with cement molded materials.

However, this process isn’t completely satisfactory as it has few limitations such as insufficient mechanical integrity. Also, the synthetic transplanted bones do not offer regeneration of bone tissues.

With printed bones, one can 3D print the accurate bone structure replacing the damaged part. The biomaterial used is not only durable but regenerative as well. It is made with agarose, gelatine, collagen alginate, polycaprolactone and calcium phosphate.

Plus, the material can fuse with the natural bones with time. Hence, replacing with the actual bone over time.

Cornea

Yes, the cornea can be 3D printed as well. This may have seemed like a farfetched dream for researchers, it is now already under testing.

The invention goes to the kitty of a group of researchers from South Korea. This prototype has been printed using biocompatible decellularized corneal stroma along with the stem cells.

The aim of the team is to improve the innovation to make it available as a concrete alternative for corneas surgeries pertaining to cataracts and other eye complications.

It would replace the need for the donor while making the cornea 3D printed with the help of this emerging technology.

The doctors also make use of artificial corneas. These are created with recombinant collagen such as a synthetic polymer. The problem is that these couldn’t be properly infused into the eye, making it impossible to stay transparent once the surgery is over.

On the contrary, 3D printed corneas copy the lattice pattern of collagen fibrils with respect to the natural corneas.

This can be achieved using the stress generated due to the 3D printing process through the frictional force.

Hence, researchers were able to regulate the design of the pattern in which the fibrils were printed. Hence, these can closely match the structure of the actual cornea of humans.

Cartilage

BioFAB3D, an Australian bio fabrication center have created a handheld cartilage printing device. They have named it BioPen.

The BioPen consists of stem cells. These stem cells are the result of the patient’s fat. These stem cells can help surgically implant the custom scaffolds of living material into misfunctioning joints.

As mentioned in the case of bone 3D printing, the cartilage is also capable of growing within the body.

As of now, the testing has been completed on sheep with success. And, the researchers are positive about making this innovation available for the regeneration of cartilage in humans sooner.

The technology would work simply by placing one layer of bioink at a time to create a complete structure when working on the joints.

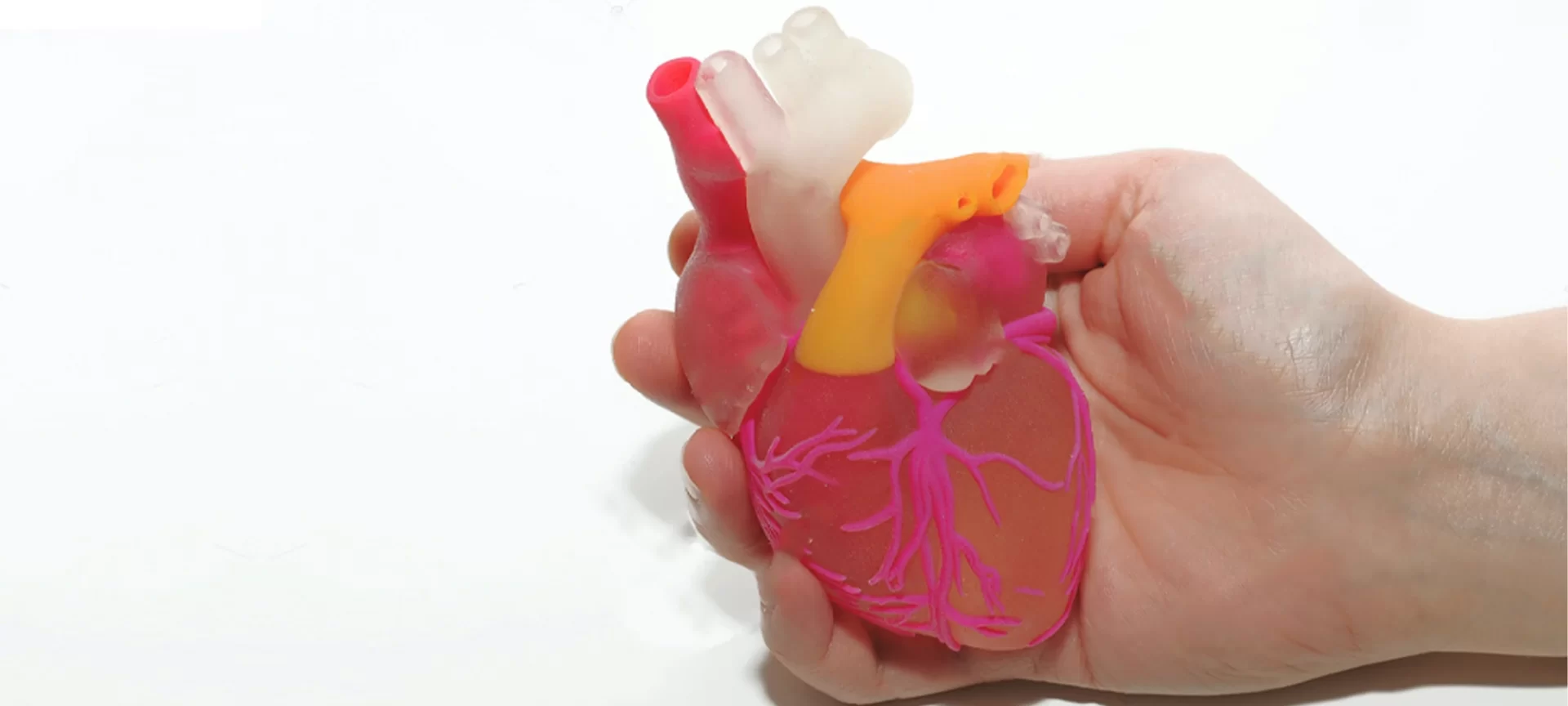

Heart

The American Friends of Tel Aviv University designed a fully-vascularised heart with the help of 3D printing technology. The researched used the donor’s fat tissue to accomplish the task.

These fat cells were cultured, however partially and later reprogrammed to generate heart cells. The heart structure consisted of fully functioning blood vessels, cells, ventricles, and chambers. The structure replicated the medical images taken from the donor’s actual heart.

Although the technology is still to be brought at the forefront, it does create a huge buzz around it. The testing is still under process.

A rabbit was tested but the researchers could not pump the blood through the heart. Hence, a lot of work still remains incomplete.

But the ongoing advancements are promising and hope to see a beating 3D printed heart sooner.

3D printed organs do seem to impact the overall medical facility as a whole. And, these inventions are just a small impression of what we can accomplish in the future.

Skin

This innovation has created huge hopes within patients with burnt cases. The research team at Wake Forest School of Medicine has come up with a 3D printer that could help replace traditional skin grafting surgery with a better alternative.

The printer can actually print skin cells directly on the burnt wound.

The traditional treatment is based on using the healthy skin of the patient to harvest the skin for burnt body parts. However, there are times when there are not many unburnt locations left in a patients’ body. Making skin grafting surgery nearly impossible.

However, when using a 3D printing technique, one only requires 10% of the size of the burnt cells to regenerate the entire section of burnt cells.

Using a scanner, doctors can check the depth as well as the size of the burnt wound. Using this data, the 3D printer can print dermic, hypodermic, as well as epidermic skin cells.

Bioprinting Organ Progress Categorized into Three Stages

As per the expert’s forecast, the 3D printed body parts would progress through three phases to become the future of the medical science industry.

Phase 1: The experts feel that from 2017 to 2020, the bioprinting organ will be in phase 1. In this phase, the 3D printed tissues and the models and structures based on them would be adopted for screening and testing purposes.

Phase 2: It would take another 5 years to progress. Starting from 2020, it would stretch till 2025. In this period, the bioprinted tissues would be used for surgical implantation. For example, in the process of bone fracture treatment or cartilage repair.

Phase 3: This is when the 3D printed body parts such as kidneys and other organs would be available for actual surgical transplantation. This would be possible only after 2025. However, once we reach this phase, we would be having a great help for those waiting for years for donors and ending without getting one.

How to Create 3D Printed Body Parts?

If you have created 3D parts, or have read about it, you must be knowing how the technology works. It models design in layers.

Each layer is added over the previous one. And, the process continues until the complete 3D design is translated into a 3D model.

The same goes for the creation of 3D printed body parts. You can expect it to work in the same way. Here is a step by step process of bioprinting organs.

Step 1: The first thing you would need a requirement. In other words, you must know what you are going to print. Either a bone structure or a prosthesis for covering the surgical defects.

Step 2: To create the design of the required 3D organ, you would first need to design the 3D file for the same. This must be in the form of an STL (Standard Tessellation Language) format. To create the file, you must use the digital file acquired from scanning. If that is not a possibility, you can also use manual design to create the STL file.

Step 3: As it is with the usual 3D printing, the STL file or other acceptable format for that matter is converted into G-code. This is done through slicer software.

Many 3D printers are equipped with a slicer software and the process happens on its own. However, some of these machines require a third party slicer software to accomplish the job.

In either case, you must generate the G-code because that is the only language the 3D printer understands. In this process, the 3D design is broken into different layers which would be later printed one at a time.

Step 4: These G-code instructions are fed to the 3D printers specifically designed to create 3D printed organs. The successive layers take the form of the 3D organ once the process executes successfully.

The Conclusion

3D printing has brought us a huge success in the medical field. Hopes are rising and soon we would be able to justify each of them.

However, with patience and continue progress, the 3D printed organ parts would be available for actual transplantation in coming future. We just need to be patient and positive about the progress taking around us.