Every 3D printer comes along with a build surface. However, not all of these surfaces provide satisfying results. Some are good at first layer adhesion and others fail to meet the expectations.

Hence, it becomes really daunting to come up with the right selection. Every print surface has its pros and cons and one must choose according to one’s priorities.

If the question is about the excellent adhesion, this guide would help you make an informed decision. The article elaborates on the different types of build surfaces available and helps you choose the best 3D printer bed surface depending on your application.

But before we proceed, let us find out why bed surfaces are so important for 3D printing applications.

Why is The Build Plate so Important?

When 3D printing, the first layer matters the most and that is the reason why you would find plenty of articles and guides written about the same.

When failing to perfect the first layer, users can get into a lot of trouble, as worse as failed prints. The first layer indicates the quality of the rest of the print, hence it is very important.

The first layer can let you decide if proceeding with the print would be beneficial or just a waste of time and material.

And, that is the reason, build plate is considered one of the most important parts of a 3D printer.

Can you ever think of printing without a build plate? No, you cannot. And, how well the first layer is created would highly depend on the characteristics of your build plate.

These build surfaces come in different variations. These have varying surfaces along with different thermal characteristics as well as varying price tags.

There are two major jobs of a print surface. One is to provide a flat surface for the first layer to come up clean after printing.

A flat surface also helps in supporting the later surfaces dependent on the bottom layer, providing it complete space coverage.

The other important task of the build plate is to provide an adhesive surface in order to keep the filament stuck in one space. It creates a temporary bonding between the first layer and the build surface.

In other words, the build plat provides a space for 3D designs to take proper and designated shape. It is very important to find the best 3D printer bed surface for your needs.

Or else, you would never be able to realize the maximum benefits of 3D printing. Also, you can get yourself into a long list of problems such as warping, shrinking, failed prints and so on.

However, it is important to note that buying the best 3D printer bed surface is not the ultimate solution for all the challenges related to 3D printing.

There are other factors that play the part such as the setting of the extruder height, the printing temperature, and many others. In short, 3D printing involves tweaking as well as adjusting different settings available with your 3D printer to come up with the best accuracy.

Which is the Best 3D Printer Bed Surface?

While it is not impossible to answer the question, there are few great choices that you can choose from.

With the evolution of desktop 3D printers, there has been a huge development in every area of 3D printing. From better adhesion to ease of use, researchers have given attention to every nook and corner.

Considering all these perks, here are a few choices that are best in their own way.

Glass

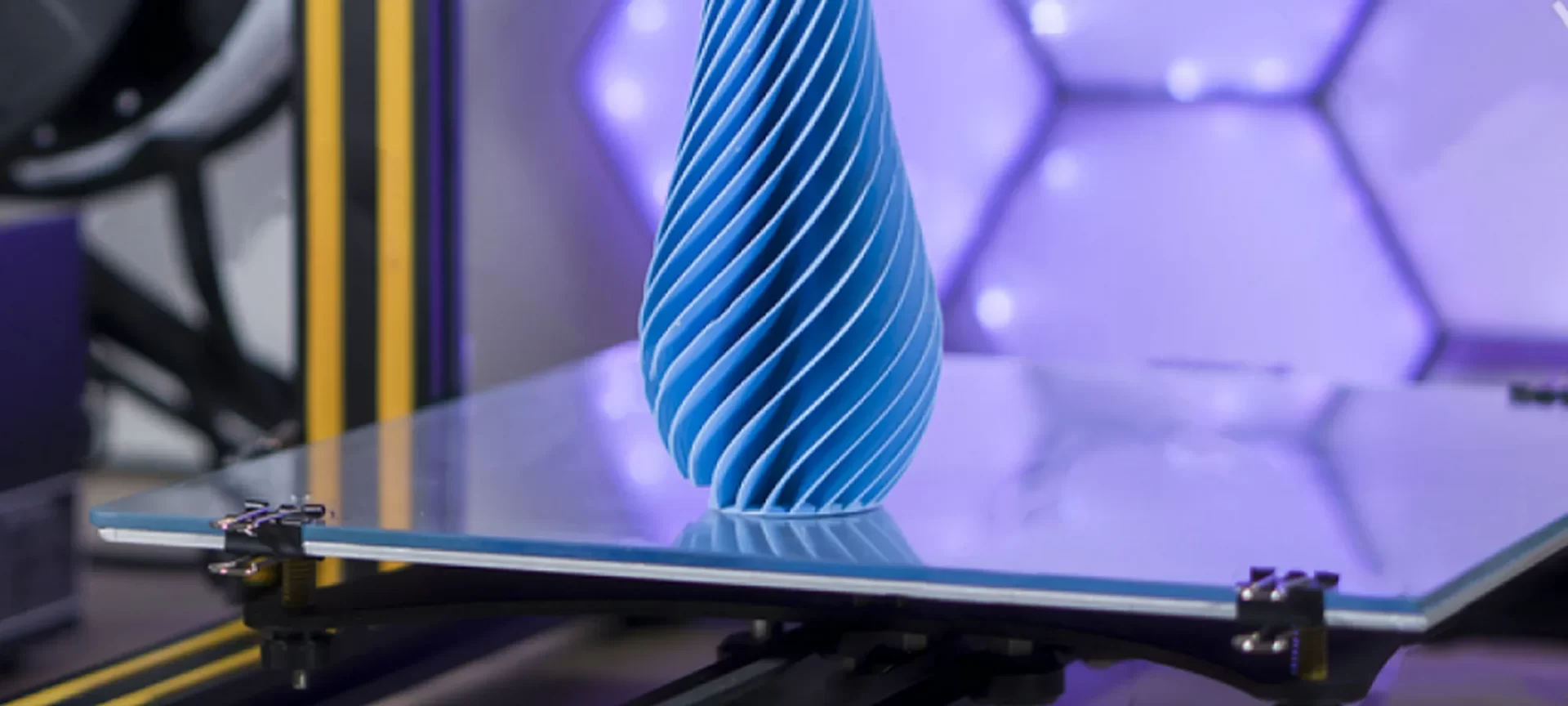

The glass build surface is one of the most popular choices, being the simple and easy to use option. It is used widely among the 3D printing community for many reasons.

First of all, Glass is extremely stiff. This means that it can result in a perfectly flat surface is created with precision. Moreover, it would not warp with time. Hence, providing a flatter and solid space to carry on the 3D printing process.

The other important factor that makes glass so popular is that it has low thermal conductivity. Because of this, the glass surface does not heat easily, hence, spreading the heat evenly across the print bed.

To make the most of this option, one must use an adhesive to get the best results with the first layer creation. You can use a glue stick, painter’s tape, or even a few varieties of hairspray.

The glass surface, when paired with hairspray, has been known for providing a highly smooth first layer finish.

However, to bring fragile, the glass surface must be handled by care when trying to manually separate the prints out of the bed.

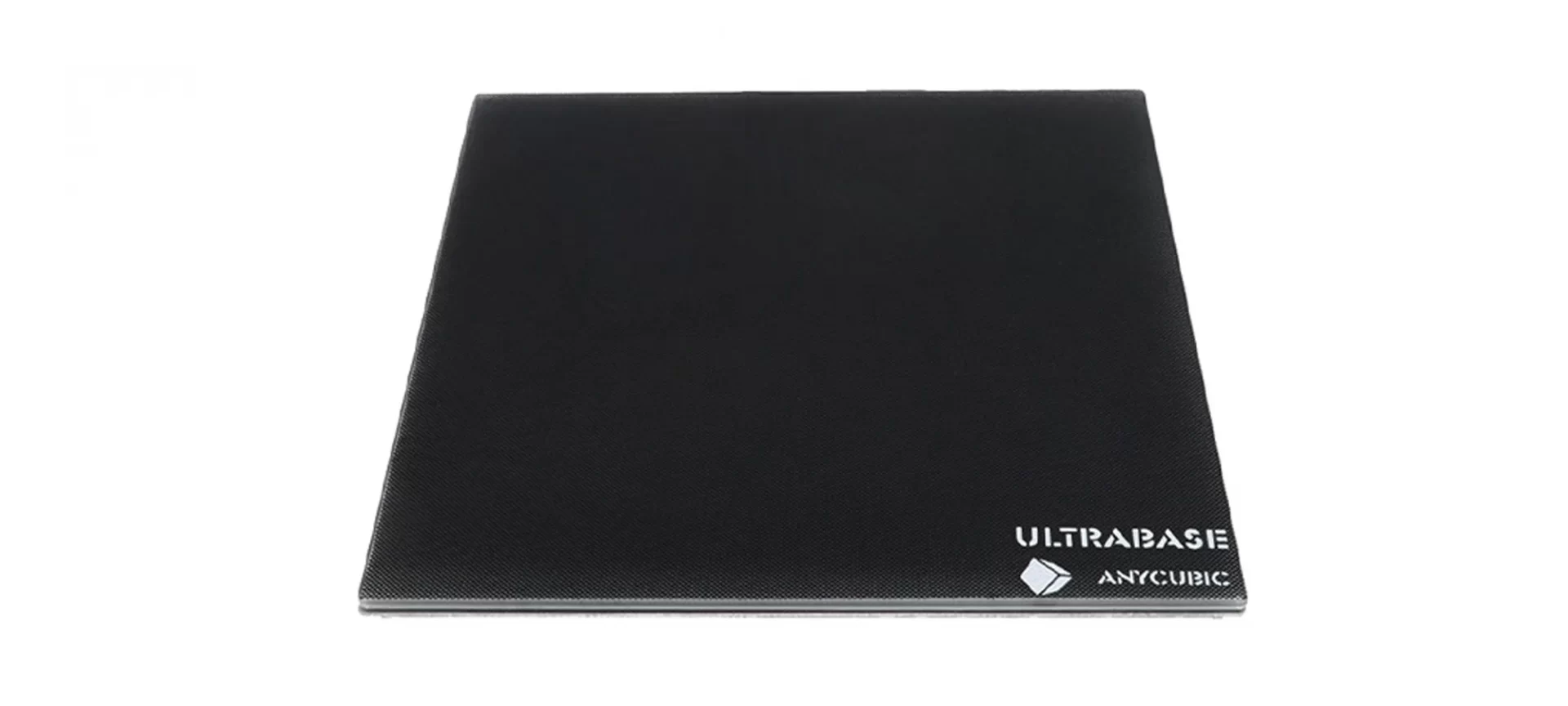

Anycubic Ultrabase

Anycubic Ultrabase is the next generation glass bed with a special structure of nanoparticles spread to the glass surface.

These nanoparticles attach to the print when hot and leave it loose when cooled. So, no hassle to manually remove the print from the surface after it completes.

Moreover, as the Ultrabase is attached to the glass surface, it does exhibit the important characteristics of the glass. Such as it is stiff, conductive as well as flat.

There is one major difference though. One must not expect the same level of smoothness that is achievable with glass when printing with the Ultrabase.

With Ultrabase, one is not required to add an adhesive which eliminates the need for one extra step. However, there is one major problem that comes handy with this option.

The built-in adhesive surface, with frequent use, can wear out over time. It can also be damaged because of careless use. Hence, needing a replacement more often than when using a glass surface. And, it would be expensive too for those who 3D print more often.

Aluminum

This again is the most common build surface used in 3D printers next to glass.

Although Aluminium is considered a great conductive metal, hence enabling the heat to reach uniformly throughout the build surface, the metal is susceptible to expanding under high temperatures.

And, we all know that sticking the first layer on an uneven surface is not easy.

However, the reason why Aluminium is widely used is because of its property to withstand rough methods that are included to remove the print from the bed.

Hence, can be used multiple times without needing a replacement. Making itself an affordable option. Also, Aluminium, as mentioned before, helps in distributing the heat evenly throughout the build surface which is necessary for uniform adhesion of the first layer.

BuildTak FlexPlate

Most of the users find it difficult to work with the fragile and still glass plate, hence, opting for a much flexible solution. If that is what you are looking for, here is the BuildTak FlexPlate.

The FlexPlate consists of a unique system. It has magnets along with a removable spring plate made of steel. Hence, users can easily take out the prints by popping the models when printed through flexing the steel. That is why it is named as FlexPlate.

The major perk of the entire design is that the build plate can be removed and used interchangeably. Hence, letting users print models without waiting for the print surface to become ready for printing. A huge advantage for those printing in large production.

One must keep in mind to use the BuildTak brand adhesive stickers or PEI when working with this print surface. It is not at all recommended to print models directly on the print surface. You can also use painter’s tape or various other adhesive stickers.

However, there is one major challenge when using FlexPlate. The print surface needs a flat surface such as glass for installation. Or else, your prints will not stick properly to the surface, resulting in warping and other related issues.

Heated Bed or Non-Heated Bed?

Many 3D printing users have come up with this question from time to time. Why a heated bed is necessary for 3D printing?

These days, a heated bed is provided with most of the 3D printers even at an affordable price. This is because of the many advantages that the heated bed offers. However, you must understand that no one size fits all.

This means that the requirement to own a heated bed varies depending on the usage of your machine.

The heated bed helps prevent the warping of the first layer. It maintains uniform heating of the material, hence, eliminating the problems of uneven cooling. This further helps in reducing the warping of the first layer.

The print bed temperature is decided based on the melting point of the material in use. And, the value depends widely from one filament to another.

Some filaments do not even need a heated bed when printed such as PLA. On the other hand, ABS cannot be printed without a heated bed.

So, the question remains: Do I need a heated bed? If you are printing with PLA, you do not need a heated bed.

However, in the long run, when you may wish to print with more complex materials, your creation will be limited. Hence, it is recommended to get a heated bed even when you are printing only with PLA, as of now.

But, before you do that, here is what you must consider as well, the other side of the story. There is only one drawback associated with a heated bed.

The 3D printer equipped with a heated bed consumes additional power.

So, if you are not ready to pay extra bucks for a heated bed and add more expense to the monthly bills, you can also plan to install a 3D printer enclosure to keep the component hot. However, the results would vary.

What are The Different Types of Bed Additives?

There are quite a few options for enhancing the adhesion of the first layer.

Glue Sticks and Hairspray

Washable glue-sticks are the simplest and favorite of all when trying to attach the first layer to your bed. The best part is that the washable glue sticks can be applied directly to the print surface.

Either it’s a glass or aluminum build surface, you just need to scatter the glue over the build plate evenly to get the perfect adhesion.

And, it can be wiped off easily with the help of water. The best part is that the surface finish is very smooth. The same holds true for hairsprays.

The choice works well with most of the standard filaments and materials. However, may create problems when used with materials that are highly susceptible to warping such as ABS or polycarbonate.

Painter’s Tape

Painters tape can be applied directly to the glass as well as the aluminum plate. The painter’s tape has a rough surface on the top which provides the material different places to hold on to.

Hence, helping the first layer to stick firmly to the bed. The option is very useful in helping combat warping.

However, you may find very minor curling at the corners which are not noticeable at first sight. However, the surface finish is not as smooth as it is with glue stick or hairspray.

PEI

PEI is a better option than painter’s tape because of the rougher surface as compared to the painter’s tape. In other words, the option has a greater number of bumps which let filament hold on to the surface more easily.

Using PEI, you can print with even those materials that require a heated bed. The prints are easier to remove as well. And, the solution takes care of warping very well.

The Conclusion

Getting the first layer perfect is very important and essential for a successful overall print. One of the prerequisites to achieve the same is through a good printing bed.

This not only ensures the reliable adhesion of the first layer but would help combat problems such as warping as well as deformation.

Plus, getting a heated print bed would further increase the possibilities of 3D printing. When buying a 3D printer, the most common surfaces offered are glass and aluminum.

Hence, you must be prepared to use additional adessives to enhance the first layer bonding to the print surface. Hence, the best 3D printer bed surface combined with other favorable settings is a must to achieve accurate and expected results.