- All

- Favorite

- Popular

- Most rated

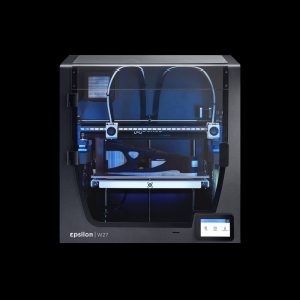

PROS:

- Huge build volume.

- Independent dual extrusion system.

- High-quality parts and functional prototypes are assured.

- Excellent print speed in batch production.

CONS:

- Difficult post-processing.

- The enclosed print chamber makes the printer susceptible to a lot of maintenance.

PROS:

- Independent dual extrusion system.

- Passively heated build chamber.

- Enclosed body.

- Safety filter.

- Huge build volume.

CONS:

- Post-processing of the part or functional prototype manufactured on the printer is difficult than it is in an open-bodied 3D printer.

PROS:

- Excellent in batch production.

- Produces high-quality parts and functional prototypes.

- Independent dual extrusion system.

- Huge print volume.

CONS:

- Difficulty in post-processing of parts and functional prototypes because of the enclosed build chamber.

PROS:

- Printing in five different modes.

- A storage capacity that has no moisture.

- Huge build volume.

- High-quality parts and functional prototypes.

- HEPA as well as Carbon filter ensuring completely safe part or functional prototypes.

CONS:

- Enclosed chamber.

- Difficult post-processing.

PROS:

- Works of different modes.

- Can produce parts with large build volumes.

- Wireless printing.

CONS:

- Closed print chambers are known for giving a difficult time to the user while post-processing.

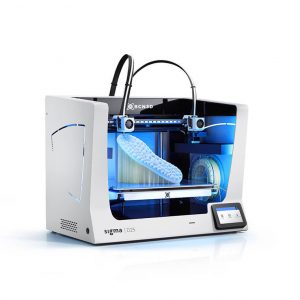

PROS:

- The printer is comprehensive yet simple calibration is magically possible.

- Sigma R 19's print performance is like no other in a similar price range.

- The modes duplication and mirror amplifies your productivity.

- The hotend level correction which is meant to be done mechanically is made easy by the manufacturer's edge in this printer's design.

- The printer does not require enough maintenance in the longer-term because it comes with guides and accessories to support you.

CONS:

- When it comes to filament, the printer is known to produce a lot of waste.

- You need a lot of adhesives while using the printer for the prints of the parts or functional prototype to stick to the print bed.

- Although the manufacturer boasts about the dual extrusion printing done by the printer, the reality is, it works slow.

- A scrap of the final part or functional prototype can escape into the display screen of the printer causing damage.

- During the printing process, the Sigma R19 is noisy.

Show next