As we go on finding which 3D printer would suit us better, we keep struggling between the two of the most popular 3D printing processes: FDM and SLA.

These two processes have been the most used ones among the consumers and are being upgraded every now and then for providing even better results.

It is important to understand what each of the processes entails before jumping to compare FDM vs SLA 3D printers. Both processes are highly specific and have their own benefits and limitations.

What is FDM 3D Printing Process?

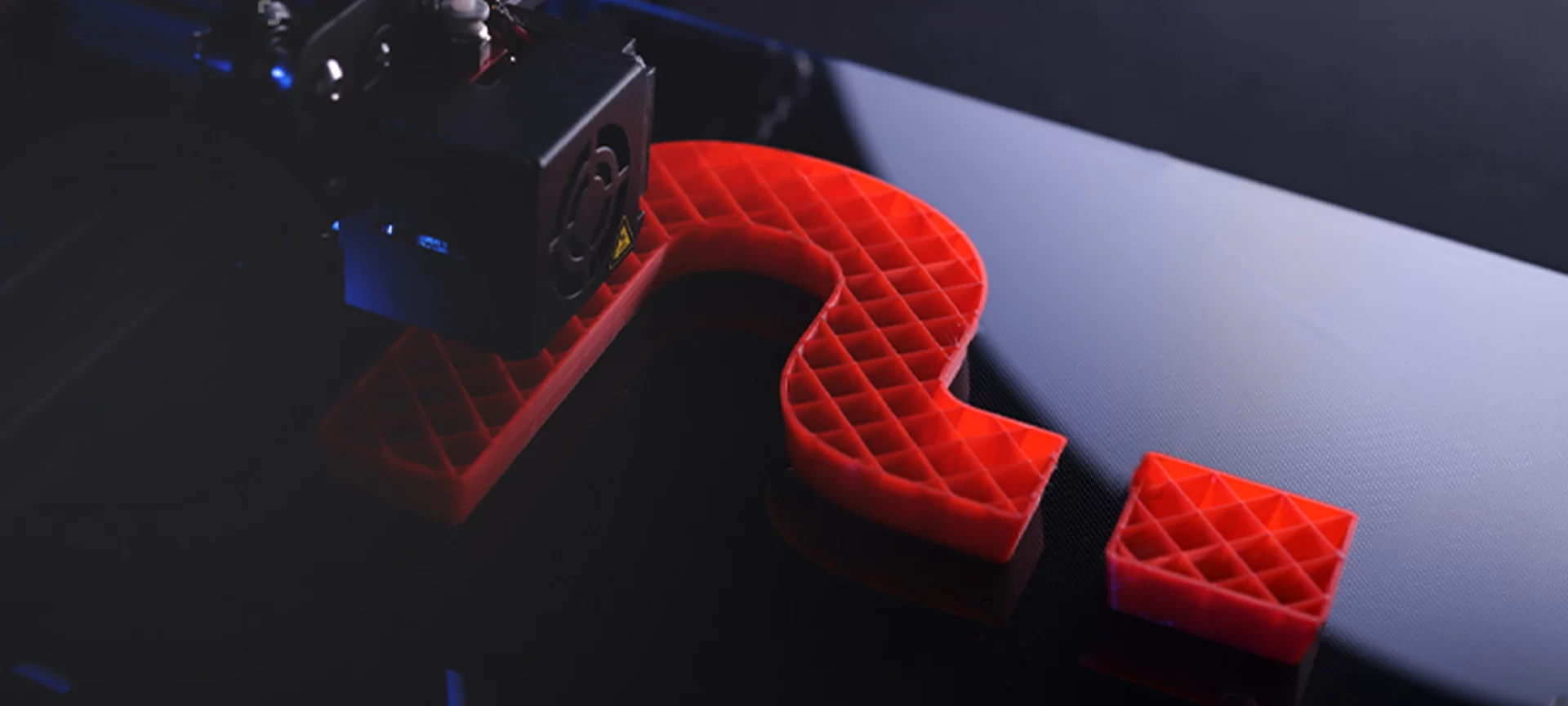

FDM which is an abbreviation for Fused Deposition Modeling, is the most common 3D printing process among consumers.

Because of its versatility and affordability, the FDM 3D printers are highly used among home users and beginners as well. FDM 3D printers work by depositing layers of plastic on the build surface, each later at a time.

The material used in FDM printers is mostly made of thermoplastic. These plastic filaments are fed to the print head through a hot extruder.

The temperature of the extruder is maintained that is slightly more than the melting point of the filament. This melted filament is then placed by the print head on the build plate, layer by layer. The process continues until the task isn’t accomplished.

The best part about the FDM printers is that they are available in the most affordable price range. Hence, making it easier for users to buy them. For every group of users, there is a budget FDM printer. You can get it for as little as $150.

How Does FDM Printers Work?

The first step when working with an FDM printer is to create a 3D file. The most common extensions are STL or OBJ.

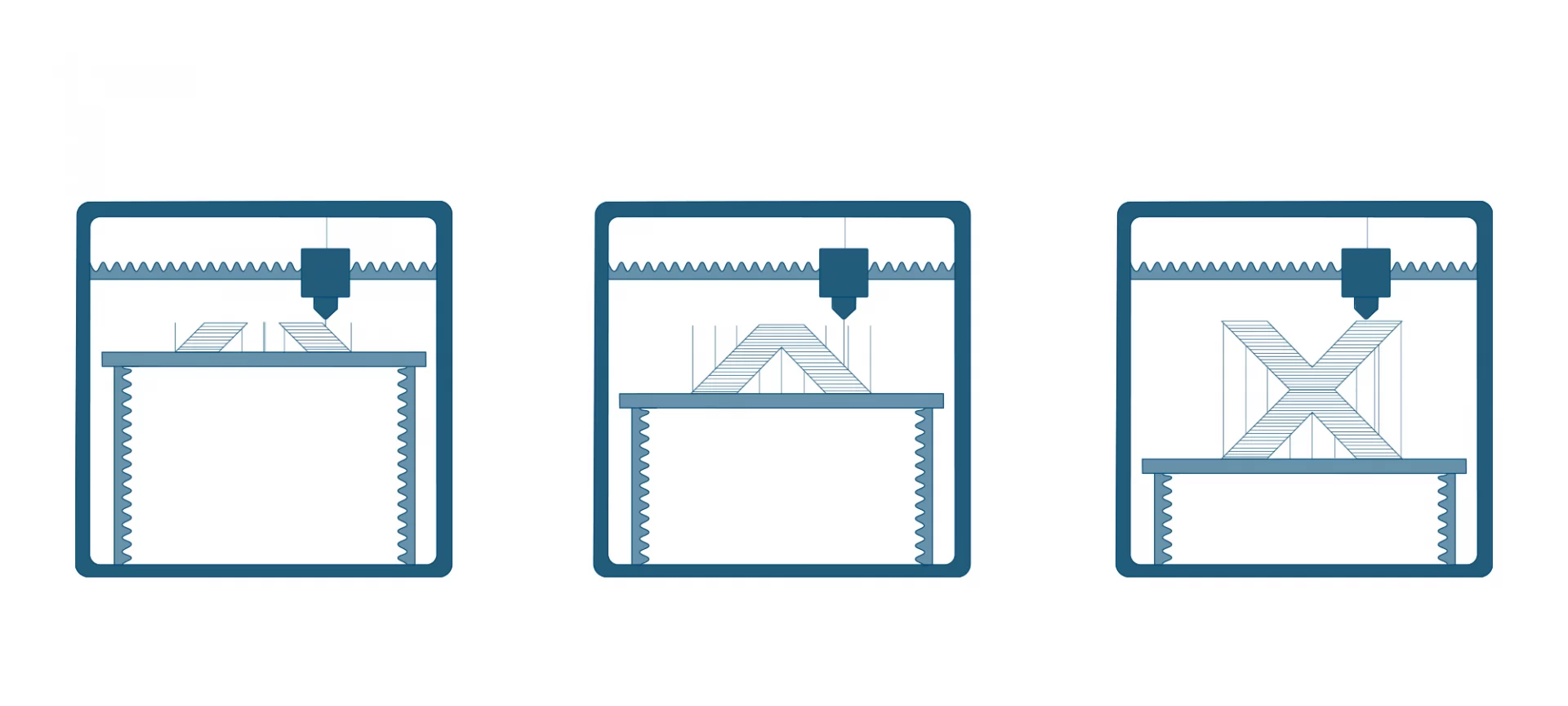

This 3D file contains the direction to slice the object into layers and process it further through the printer to create the final 3D print. The slicer program is used to slice the 3D objects and find the optimum settings for the model.

There are different resolutions one can choose for printing these models. The lower the layer height, the higher is the resolution.

Apart from the 3D file, the printer also needs material to print the model. These FDM 3D printers use plastic filaments which melts when heated up to a designated temperature.

Hence, can be pushed to the extruder, and finally out of the print head. There are many types of filaments available currently for users. The plastic is combined with other materials for realizing the diverse properties of the final object.

Using the instructions from the 3D file, the extruder lays down the layers, one by one. The different layers bond together as they fuse. And, finishes the job when the object is ready to be used.

What is the SLA 3D Printing Process?

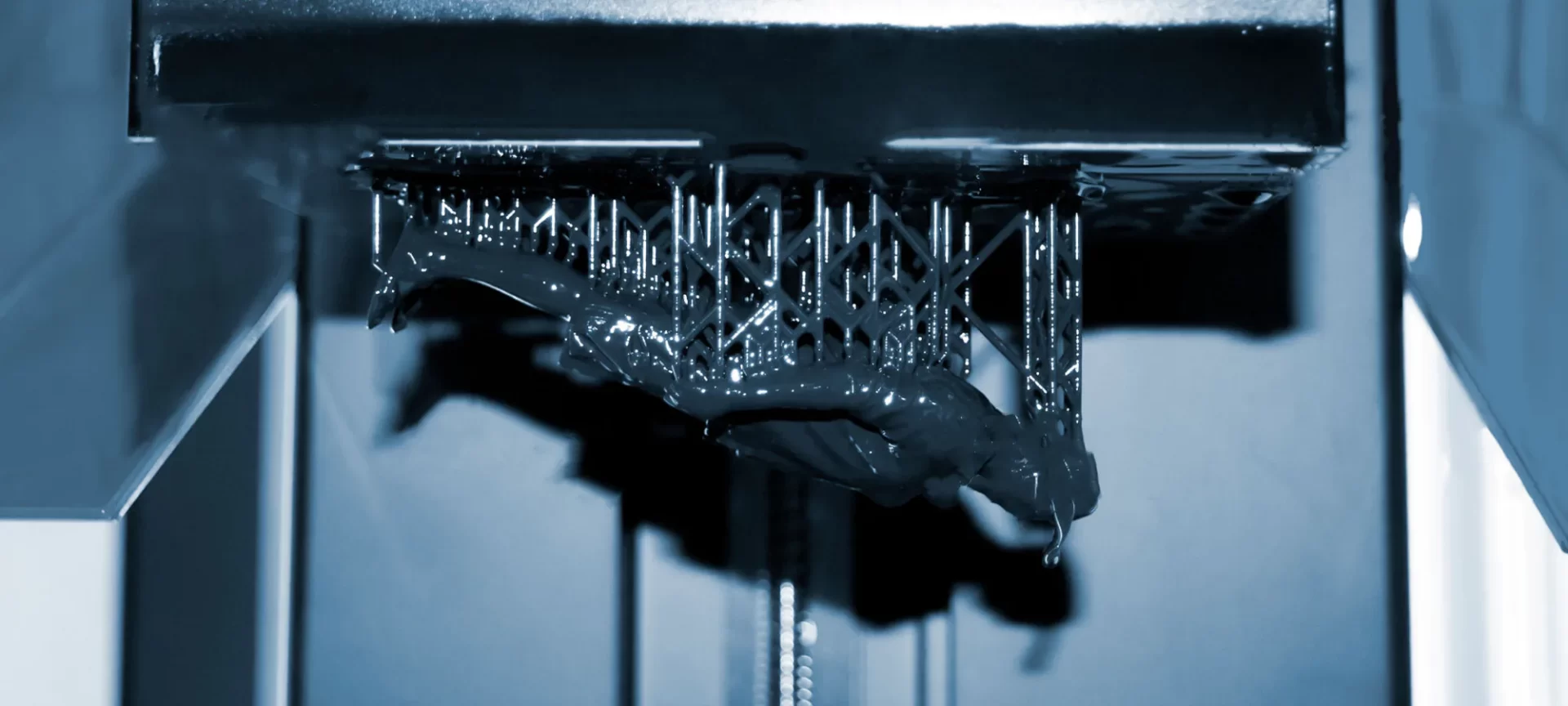

Stereolithography or simply SLA is another additive manufacturing method and the oldest one too. This also uses the layer by layer technology to build the final object. However, the models aren’t built by depositing melted plastic.

However, SLA uses a curable photopolymer. This photopolymer is a liquid resin that hardens when exposed to the UV light. This process is known as the curing of the resin.

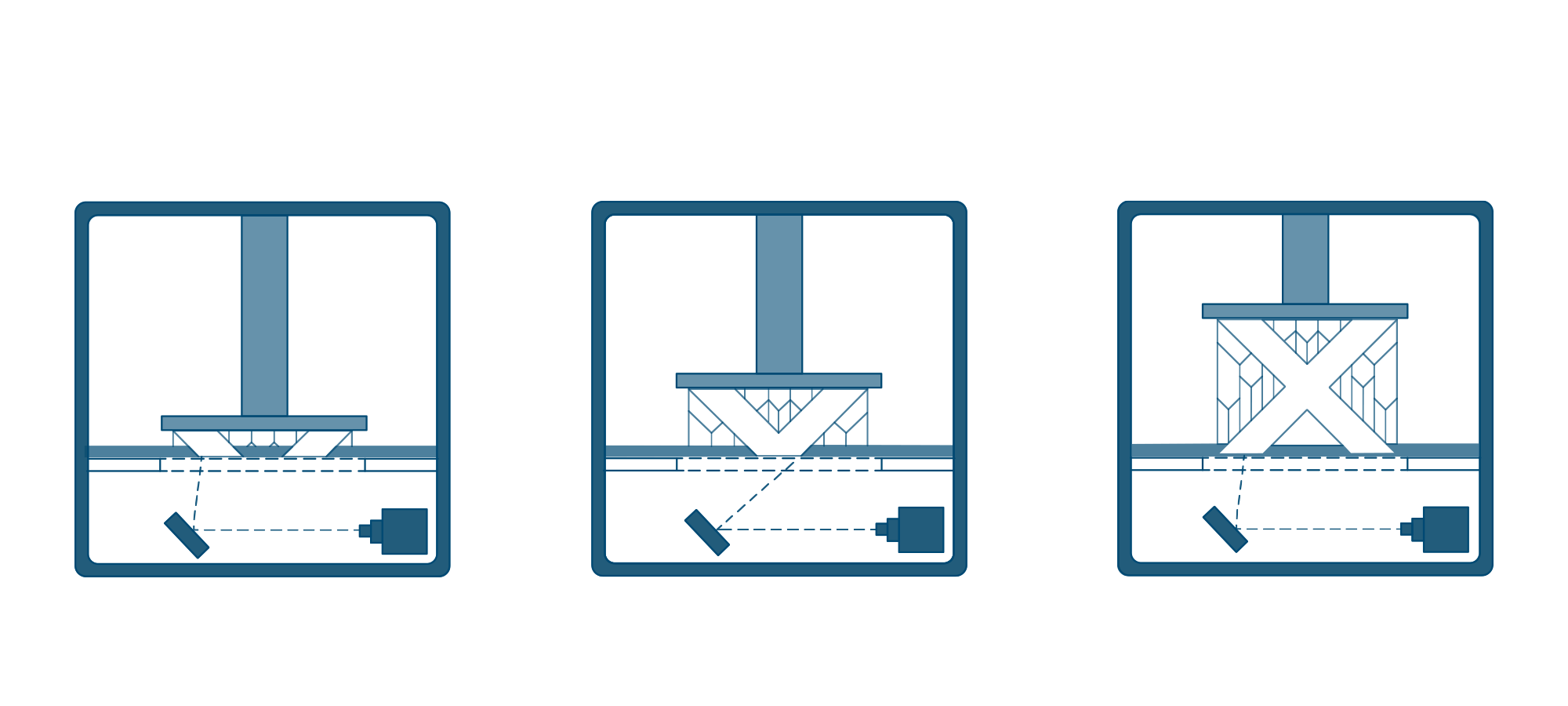

Also, one of the major differences between SLA and FDM printers is that the SLA printers usually print models from top to bottom instead of printing from bottom to top as it happens in FDM printers. This is the reason why the build platform lifts the model upwards.

The light source used to cure the resin is either a digital projector or a laser. The printers using a digital projector are termed under the Digital Light Processing (DLP) method. The DLP models are faster than the laser models.

In terms of pricing, the SLA 3D printers are expensive than the FDM printers. And, there is a limited choice for the budget-friendly SLA 3D printers. That is why the SLA Printers are mostly used in the professional setup.

How do SLA 3D Printers work?

It is really interesting to watch the models being printed by the SLA 3D printers. Even in this method, one requires a 3D file.

An SLA 3D printer makes use of the most complex 3D file which tells the printer where it must aim the laser. The SLA 3D printers are equipped with a base to build on the 3D parts. This base moves upward, slowly rising out of the liquid resin.

Although the technology works layer by layer, there is a huge difference in the properties of 3D objects printing from FDM machines. In the SLA method, the layers bond at the chemical level.

However, in FDM 3D printers, the objects bond together via the usual melting of filaments. Hence, SLA 3D printers are capable of producing more uniform designs.

What Are The Differences Between FDM And SLA 3D Printers?

From appearances to the mechanical properties, a lot of things are different among the objects printed from these two methods. Want to know about the major differences between FDM vs SLA 3D printers, here is what you should look for.

The Colour and Material Choices

Usually, an FDM 3D printer utilizes PLA or ABS filament. There are other types of filaments available too. Such as nylon, TPU, PVA, and few other PLA blends.

The PLA blends are available with wood, ceramics, carbon fiber, and few other choices. Users can also print with different colors of filaments as the color choices are huge.

Among the FDM printers, the capabilities for supporting different filaments vary widely. Some work with one or two filaments, mostly PLA and ABS and others support multiple filaments as well including most from the list.

Also, there are printers that only support proprietary filaments. And some offer an open system to choose filaments from other brands too. Different filaments produce different end results in terms of texture, stiffness and many other properties.

When talking about the SLA printers, the material choices remain limited for users. Resins are available in a limited number of choices and mostly the SLA printers run on proprietary resins.

Hence, cannot be used with resins available with other brands, further restricting the choice for users. Not just that, the color choice is also very less.

One of the most popular companies, Formlabs, only offers four colors: black, white, grey and clear. However, specialized resins are very precise and offer high durability, heat resistance, and other crucial features. Hence, can be used for industrial applications.

3D Models Handling: Adhesion and Removal

The next big difference that lies between these two methods is the ease of handling the prints. In the case of an FDM printer, the main concern is the adhesion of the first layer of the model.

However, when it comes to the removal of these models from the print bed, it is relatively easy than the SLA printers.

Coming back to the SLA printers, adhesion is not an issue at all. However, the removal of the printed models isn’t as simple as it is with the FDM printers.

Often users struggle with the excess of resin left on the platform. These could be removed with the help of different tools such as a palette knife.

Moreover, the efforts are much more extensive. However, the developments are underway to make the removal process easy for SLA printers.

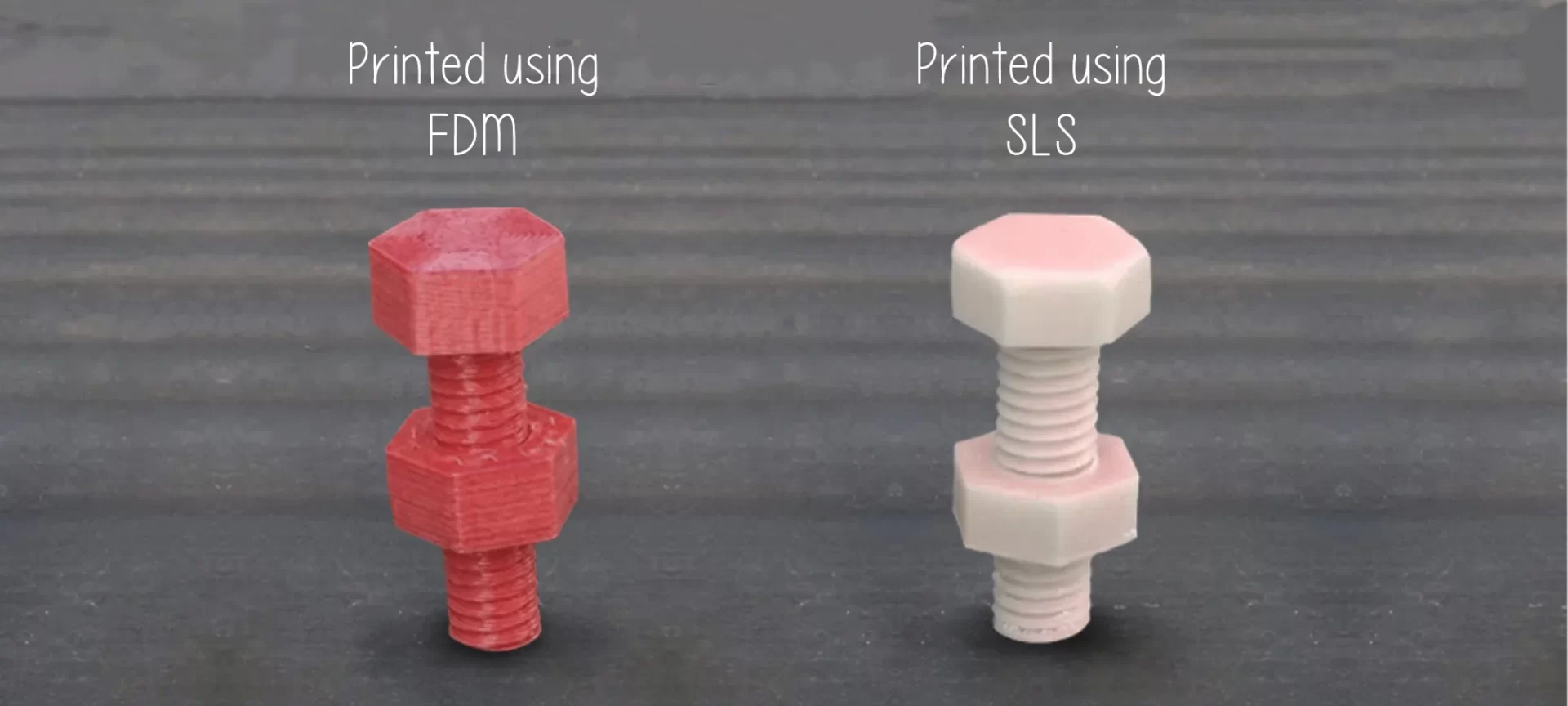

FDM vs SLA 3D Printer: Print Results

The FDM printer’s resolution and precision depend on the size of the nozzle and the movement of the extruder along the X/Y axis respectively.

There are other factors too that influence the precision of the printed part. The precision also depends on the layer’s bonding force.

Moreover, the lower layer may squeeze with the weight of the upper layers, resulting in many problems. For example, warping, shifting of layers, and others. These problems not only compromise the precision but end up harming the surface smoothness as well.

On the contrary, SLA printers do not have to worry about such issues. The bonding between layers is stronger and they are known for producing consistent results in terms of higher resolution.

These printers are highly accurate. The laser precision creates highly accurate models. The parts are smoother as well.

This is because of relatively less force applied during the printing of the model. In short, the SLA printer can produce many precise and smoother models as compared to the FDM printers. Hence, if you are looking forward to buying a highly precise machine, you should go with SLA printers.

Operational Cost

Apart from the filaments, FDM printers have other consumables as well. These are the nozzles. While one does not have to change the nozzle often, the cost mostly depends on the filament rolls. 1 kg of PLA filament costs around $25. The cost for specialized filaments is more and vary depending on which one you choose.

In the case of In SLA printers, resins are costly than the filaments. 1 liter of standard resin can cost somewhere between $ 80 to $150.

The resin tank can also be included in the list of consumables as one must replace the tank after printing with around 2-3 liters of resin. The cost of the resin would depend on the manufacturer and the model of the 3D printer. However, it stays between $40 to $80.

One must invest in build platforms from time to time. These would cost around $100.

Post Processing

The support removal takes equal efforts in both methods. FDM models can be fined tuned using fingers or a cutting tool.

Sanding is also helpful in smoothening of the surface produced by FDM printers. The soluble supports can easily be removed by placing the model inside the water. While in SLA models, the printed parts are immersed in isopropyl alcohol.

One thing must be noted. Parts created by FDM printers may not need support, depending on the design of the model. However, parts printed by SLA printers would always need support. So, post-processing cannot be skipped in the case of SLA 3D Printers.

Applications of FDM and SLA 3D Printers

Based on the properties of the parts produced by each of these methods, the applications vary for FDM and SLA 3D printers.

FDM Printers are Good for

- Home Use

- For learning purposes

- Rapid prototyping

- Printing low-cost models

- The best option for enthusiast and makers

- When Colorful prints are expected

- Applications where surface finish and precision take the back seat

SLA Printers are Good for

- When one wishes to create a smoother surface finish

- When print quality is the priority of the user. It would help in producing intricate details with exceptional results.

- When strength does not make much sense. The reason that the parts printed by SLA printers are prone to degrade when exposed to sunlight makes these models less durable at certain temperature conditions.

- Mass production in large scale industries

- Molds preparation

The Conclusion

The war between the SLA and FDM printer would never cease. You would find few inclined towards the SLA 3D printers and others finding FDM printers more value for money.

The reason lies in the goal of the users. Not every SLA 3D printer is best for every application and neither FDM printers can take care of every job with perfection.

These two printers are developed to do tasks differently. That is why they are categorized into two different 3D printing methods.

Before you go ahead and decide to buy an SLA 3D printer, you must know the limitations connected to it and the same goes for the FDM printers.

Also, assessing your needs and checking which one would be closet to your requirement would help you judge the situation better.

FDM vs SLA 3D printer, when this question pops in, you must look for your printing needs first. Both these methods are best in their own way.

While FDM printers offer low operational cost, the SLA Printers produce very detailed prints. Consider both sides of the coin before you make an informed decision. After all, these devices do not come cheap.