3D printing is used for creating 3D objects from a digital file. The process involves various step and a part can be printed using one of the various 3D printing processes.

From designing the model to the post-processing of objects, a lot of things happen in between. So, how does a 3D printer work? This question has been growing rapidly since this technology has taken the front seat.

Discovered in the 80s, 3D printing wasn’t very popular among consumers. The technology was focused on building prototypes for industrial use.

However, as its application grew, the demand for learning and involving the technology into various businesses and for personal use surged.

Today, 3D printing is being utilized for more applications that one can think about. And, the applications are growing exponentially.

From toys for kids to parts for airplanes are possible with the use of 3D Printing.

There are examples of people printing houses using this technology at a cheaper rate. Isn’t that fascinating? It sure is.

And, that is the reason why many people around the world are looking forward to learning about this amazing technology of 3D printing where a simple file, when uploaded in a printer, can produce real objects that can be touched and used.

To understand how does a 3D printer works, it is important to know about the technology called additive manufacturing on which the 3D printers are based.

What is Additive Manufacturing?

There are many technologies we have come across so far when talking about the manufacturing industry.

From mining to welding to many other traditional processes, we have reached to additive manufacturing.

You must have heard about CNC machines that use subtractive manufacturing for making objects.

In subtractive manufacturing, large material is cut and shaped to the desired design with the help of tube lasers.

While this can be easy to understand, additive manufacturing is a completely opposite process.

Instead of subtracting from the original material, the layers of material are added one over another to form parts.

It follows the addition of materials and finally produces the final part. There are many methods involved in additive manufacturing, also known as 3D printing technology.

One can create flexible to strongest parts using this technology. Hence, it can be termed as one of the revolutionary inventions equally important as the invention of broadbands or mobile phones is termed.

Additive manufacturing has made many things possible that weren’t before.

It is possible to build objects that are not at all possible by any other manufacturing methods.

3D Printing Steps: How Does a 3D Printer Work?

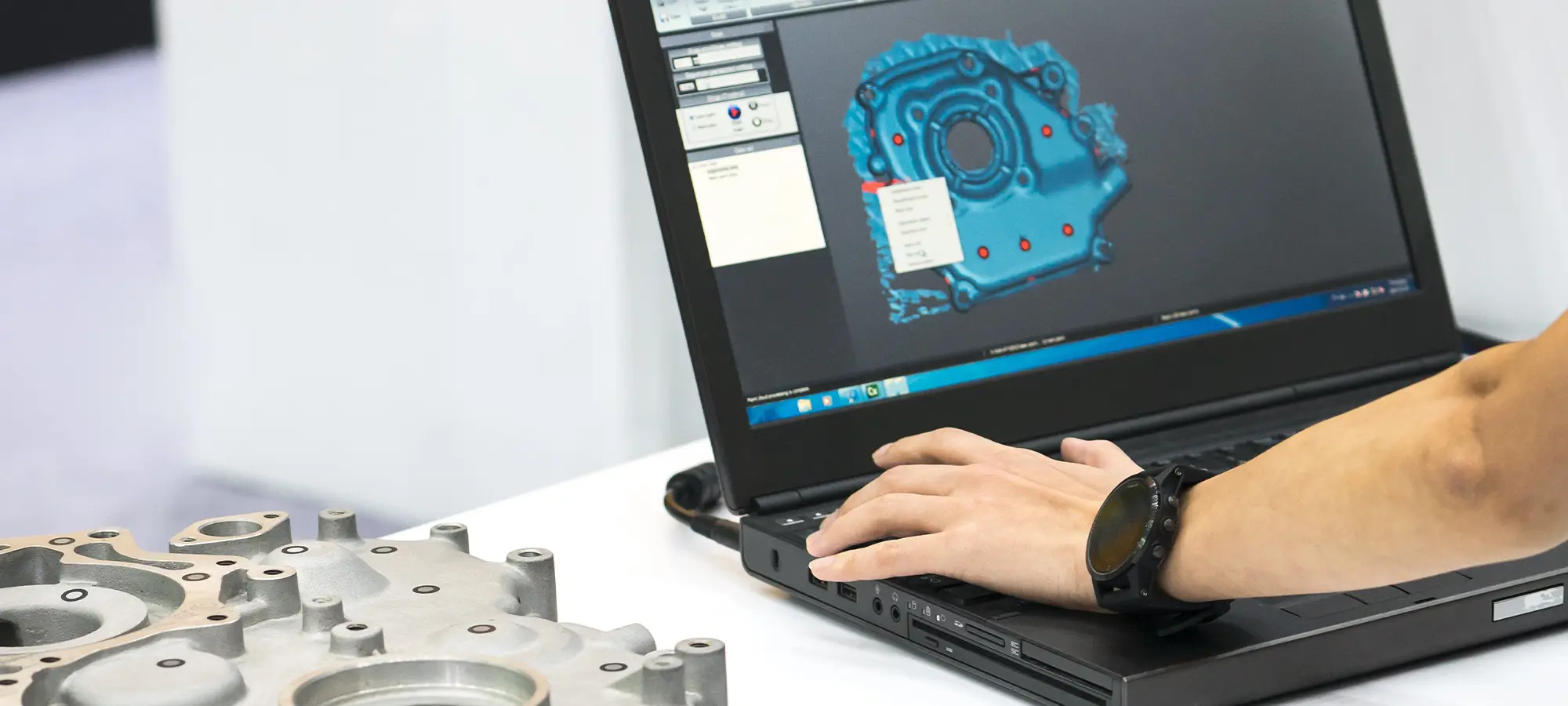

3D printing starts with the creation of a digital file using 3D modeling software.

There are many 3D models available online and one can download the STL file without a need to actually working on it. Once that is done, you scale your model and 3D print it using a 3D printer.

Step 1: Creating a 3D Model

This is the first step for any 3D printing job. If you do not have a file or a model to start with, you won’t be able to print a 3D object.

As stated, you can choose to build one yourself or you can try the ones available to be downloaded directly from the online repository. This may save time, but won’t be unique.

If you wish to print something that is in your mind, you must learn how to create 3D models using various software available.

Some are even free to use. You can anytime start learning using free versions with basic functionalities.

Once you know the trick, anytime convert your subscription to the paid version. It will also help you know which software you are comfortable with.

Once the file is ready, you can jump to the next step.

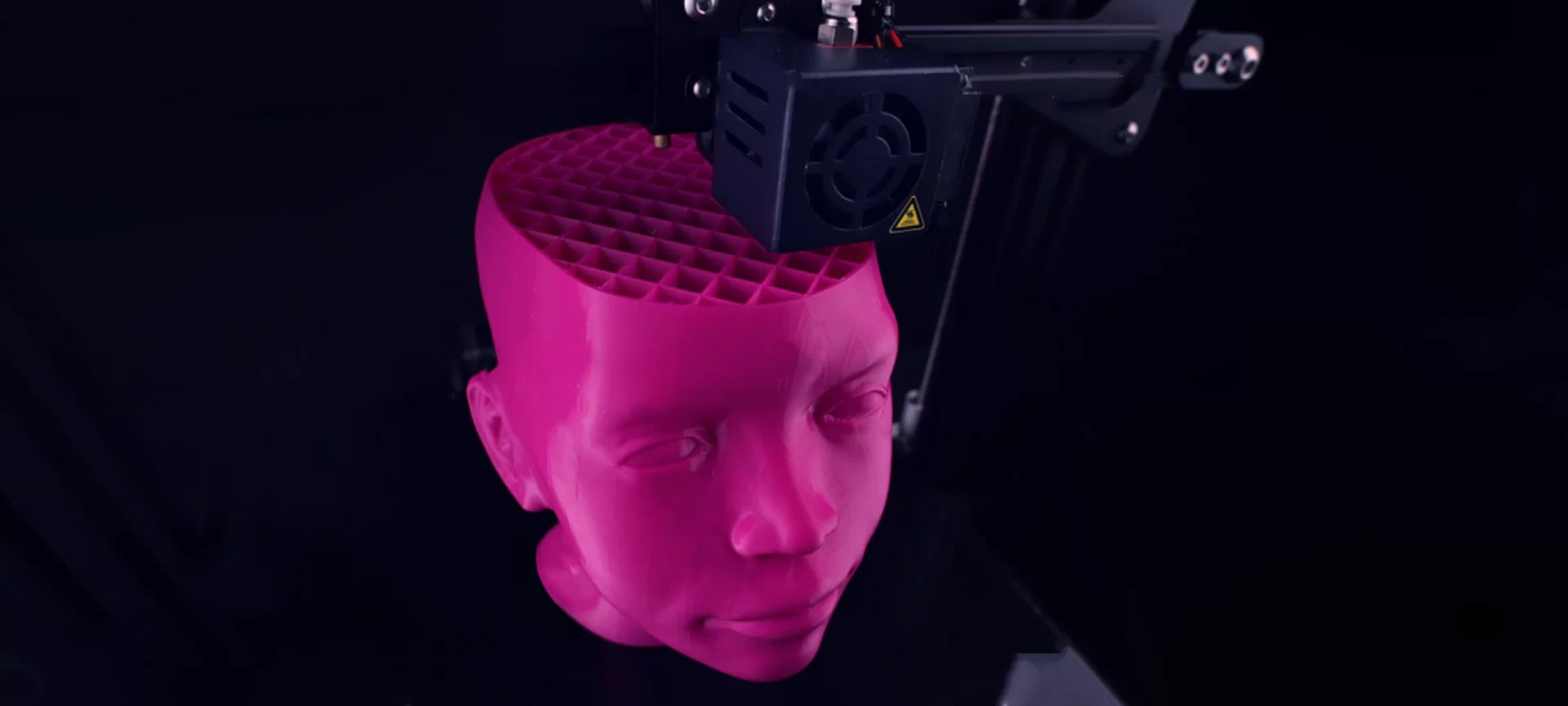

Step 2: Printing Using 3D Printer

Printer: Makerbot Replicator+

Printer: Makerbot Replicator+

There are many 3D printers that allow you to directly feed the CAD, STL or OBJ file into its memory.

However, with few other options, you will have to slice the design before feeding it to the printer. Slicing involves dividing of design into various horizontal sections and layers.

After which the design becomes ready to be printed. However, before proceeding, you must determine the material that would be best for your printing. Materials come with different finishes and mechanical properties.

Choosing the one best for your printing would lead to the best results. You can choose between various materials used in 3D printing such as resin, sand, PLA, ceramics, metals, biomaterials, glass, textiles, food, etc. Further, you can move to the last step of 3D printing.

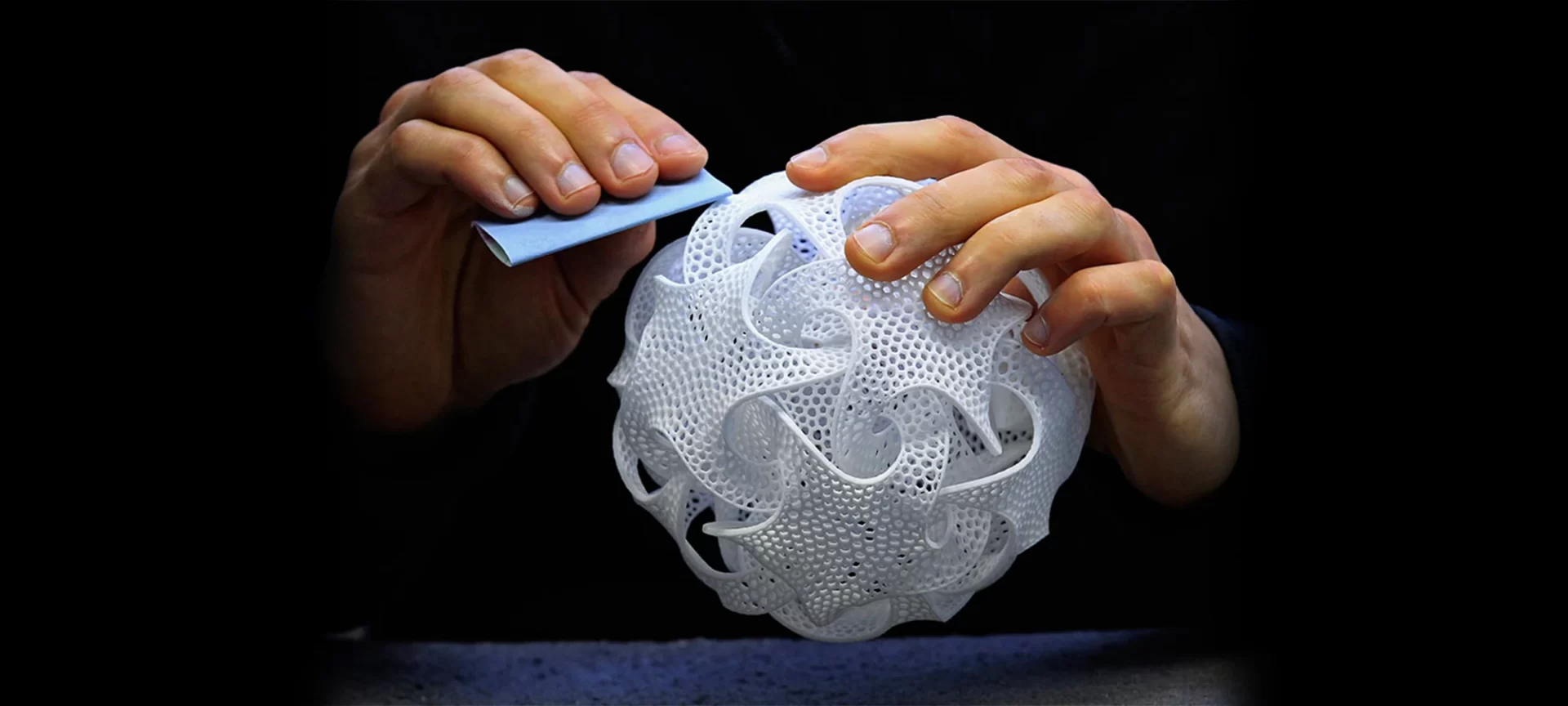

Step 3: Post Processing

Most of the time, the 3D printed parts are not ready for final use. It must go through some post-processing methods before it is ready to be delivered or used personally.

In those cases, you may have to work to remove the support, smoothen the surface, remove the powder and lot other works.

It may sound like a tough job, but it becomes easy as you start understanding which post-processing steps your part would need.

Different 3D Printing Processes

The technology that started with Stereolithography is now done using more than 10 processes around the world. The major processes used widely are as under:

Stereolithography:

The process involves the curing of photosensitive resin using a UV laser. This is the oldest method of all and especially used for rapid prototyping.

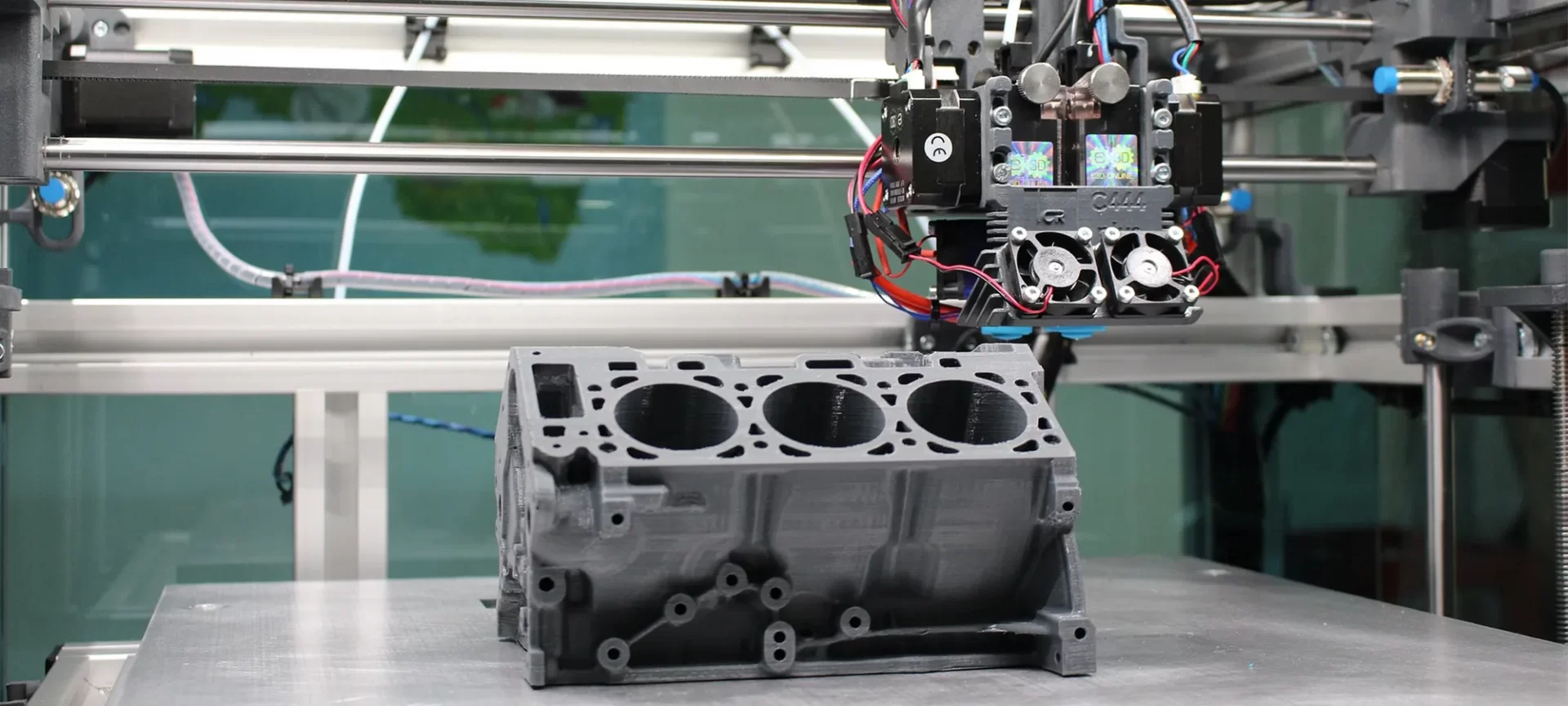

FDM (Fused Deposition Modeling):

This is the most widely used process and is the cheapest of all too. The 3D printer based on FDM is available for as little as $200 or even less.

The material is melted by the heated nozzle and is deposited on the build platform. Once the layer solidifies, the subsequent layer is deposited on the top and this goes on until the final part is printed.

One can even choose to buy the 3D printer with more than one head for multiple color options while 3D printing.

SLS (Selective Layer Sintering):

This technology is different from FDM, although used for printing with plastic material. The powdered material is deposited on the build platform.

This is then passed through the laser selectively melting and fabricating the powder together.

Once done, another layer of powdered material is deposited. The best part about SLS is that it does not need a support structure.

DLP (Digital Light Processing):

This is also done with photosensitive laser. However, instead of using a UV laser as used in Stereolithography, a laser projector is used.

Most of the process is similar to Stereolithography, however, involving some differences to be counted as an altogether different process.

DMLS (Direct Metal Laser Sintering):

If you are printing with metals, you may want to consider this process of 3D printing. The powdered metal is sintered using a laser power source.

The process is very much similar to SLS, however, is mainly used for printing metal parts. It works with high heat and cannot be used at home or for individual use.

EBM (Electron Beam Melting):

This process is also involved in printing with 3D metals. The powdered metal is deposited and the electron beams help melt the material.

The melted material fuses together forming the final part. This also happens in layers. The process only works with conductive metals to ensure the electron beams are reactive.

BJ (Binder Jetting):

BJ is also one of the most popular processes among those users who love to print in multiple colors.

The powdered material is deposited on the platform and the liquid binder and color us jetted over the material to bind it together and color it in the specific color.

What Can You Do with a 3D Printer?

This is a very important question when choosing the 3D printer. Apart from knowing how does a 3D printer works, it is also crucial to know its application. Or else, your 3D Printer may sit in a corner and you keep thinking what to do with it.

To avoid that from happening, here are few applications of the 3D printer to choose from.

Creating Prototypes:

Invested for the same purpose, rapid prototyping is still one of the major applications of 3D printing.

The prototypes are created using 3D printing which is then tested for moving forward with mass production.

These prototypes help in deciding if the design is correct and can be used further. Many industries come up with newer designs and before producing masses of the design, testing it beforehand avoids many risks.

Automotive:

The automotive niche is also involved in using rapid prototyping but is not limited to it.

The industry is also using 3D printing for manufacturing spare parts, jigs, tools and fixtures.

With the ease of on-demand manufacturing, the companies can manage with shorter stock levels and can build parts faster and cheaper when required with the help of 3D printing.

People are even able to restore their old cars using 3D printing. Mostly popular among enthusiasts who like to experiment with new things.

Aviation Industry:

How about 3D printing parts in one go that used to involve welding of 25 different parts together to form one part by using traditional methods.

Moreover, parts printed with 3D printing weigh 25% lesser and are much stronger than the ones manufactured by older methods.

The printing of fuel nozzle for aircraft was a breakthrough for the aviation industry. Reducing the budget of production of each aircraft with a huge margin, the industry is keen to find more applications than those that exist today.

Construction:

It is even to print buildings with 3D printing. It may sound like a dream to many, but it has already happened.

A company has been able to successfully complete it already. There is no staying away from the fact that there is a lot of other things 3D printing can do for construction companies, but constructing an entire building is something exceptional.

Products for Consumers:

A few years back, 3D printing wasn’t able to print in a larger volume. Hence, the usage was limited to fewer applications.

However, as the technology advanced and mass production became a part of the fun, consumer products were included in the manufacturing list.

One can print footwear, eyeglasses, jewelry, shoes, vases, and whatnot. You only need the right vision to think about what you can sell. If you have that edge of creativity, you can print almost everything. 3D printing has made that possible.

Healthcare Application:

You must have heard the news about implants done using 3D printing. Because this is being done widely for many purposes.

3D printing is capable of printing internal organs, few if not all. Who knows what can be possible in the future using 3D printing?

This technology is being used for manufacturing hearing aids, prosthetics and has a huge contribution to the dental field. Printing exact fitted molds and aligners and many other applications are possible with 3D printing.

The Conclusion

3D printing is a huge invention. Since the time it came into the picture, it has always intrigued experts in thinking beyond what we already know. It is only because the possibilities are unlimited.

The world of additive manufacturing is a complete world in itself with giving individuals an upper hand over traditional technologies.

These days, even the common man is eager to learn how does a 3D printer works. Isn’t that an achievement in itself?

People are becoming aware of the various advantages the technology holds. Users look forward to finding better opportunities as nothing seems impossible when it comes to 3D printing.

There was a time when 3D printing stayed stuffed inside the industries and not everyone knew about it.

Apart from those related to the field, 3D printing was almost inaccessible to the mass. However, as technology advanced and keep on advancing, the greater number of companies and individuals are becoming a part of this revolution.

So, asking the question: how does a 3D printer work isn’t uncommon. All you need is a determination to know about the technology and you can 3D print in no time.

Either at home or for business use, 3D printers are well equipped to solve problems of any complexity at length.