3D printing has become a trend. The thought of printing anything that you can design into CAD files is really enthralling. Apart from industrialists and entrepreneurs, a lot of enthusiasts and hobbyists are also following the trend.

The online communities are surging and the awareness is spreading like a wildfire. However, there are still a few limitations of 3D printing that make it difficult to reach masses.

With lots of things to 3D print, individuals usually feel intimidated by the way this technology works. There is a huge number of courses online, but would that knowledge justify the investment of a few hundred dollars on something that we haven’t tried for real.

The questions are numerous and the answers are limited. We do know that the technology is made simpler with passing time, however, have we reached that stage where we can call 3D printing technology, a technology for all?

The limitations of 3D printing can be few, but still hold a lot of importance in giving this technology ahead away into normal households.

Trying to put some light on the same side of the story, here are a few limitations that are usually not talked about a lot, but exist anyway.

Limitations of 3D Printing

We have been talking about a lot of things we can accomplish by a 3D printer.

But the information wouldn’t be complete without talking about the challenges one can face when shifting the gears from traditional manufacturing to 3D printing.

Outlining 10 of the major limitations that are being worked upon by the experts would give you a better stance to decide for yourself.

Consumes a Lot of Energy for Operation

You may not have been told about this before. But you would certainly like to know about the additional cost that 3D printing would put on your shoulders.

We have been witnessing how the electricity cost has turned out against our favor from the last couple of years. With no sign to slow down, companies keep trying to implement strategies and measures to reduce the amount spent on electricity bills.

If you have been struggling to bring your expenses down, 3D printing would make your fight even difficult.

According to the researches made on the technology, it has been found that energy consumption with 3D printing is 100 times more than the power consumed by traditional manufacturing.

We may agree to the fact that 3D printing is a step towards a greener planet by facilitating reusable materials such as plastic.

However, it would also be true to quote it as two steps backward, by consuming non-renewable energy for its operation. Hence, the only way to get past the limitation is to use 3D printing for small batch productions.

The 3D Printer is Costly

If you are thinking of starting a manufacturing firm and have a limited budget to afford machines, to begin with, you may not like the huge cost associated with 3D printers.

Only one machine can cost you ranging from a hundred to thousands of dollars. Not just that, the software and material requirement would come as an extra cost.

That is why you may not see many businesses reaping the advantage of 3D printing even after 40 years of its invention.

There is a simple calculation to do. If you have a large order, your cost would be higher. However, for small products can be printed at a cheaper cost.

If you are up for buying a consumer 3D printer, you may get it for less money. But, why pay extra for a few items by investing in material cost and electricity bill, when you can get that at a lower cost from the market.

Unless you want to learn or want to create unique designs, you may end up repenting over your decision of buying a 3D printer.

3D Printing Requires Skilled Users for Operation

You may have read that 3D printing is easy as compared to the traditional methods which are completely true.

However, there are certain skills that must be learned before you go on printing your first 3D printed object. It may not be as user-friendly as being told or as you perceive it to be.

You must know how to work with CAD files and learn about some hardware settings of 3D printers before beginning to 3D print.

Consider it Slow for Mass Production

The new 3D printers are being introduced and this limitation of 3D printer is being worked upon.

However, the fact is that mass production would eat up time when compared with traditional manufacturing.

Also, the time will depend on the complexity of the design, the size of the product and a lot of other parameters. Some 3D printing processes even require a lot of post-processing steps. If not done properly, it can even destroy the objects 3D printed.

If your 3D printing service center is too busy with orders, you may expect it to deliver yours after a week or even more.

3D Printing Can be Used for Piracy

We all know that piracy is a huge setback of businesses. Copying one design and selling it for a lower price can throw the actual manufacturer out of the business. 3D printing is making it even easier. All you need to copy design is the blueprint of the file.

Once you have the 3D design, you can print as many 3D parts as you please. And, anyone can do that. Moreover, with technology aggressively reaching more people, the cases of patent violation could become a huge problem.

The problem is deeper than one can imagine. As the blueprints are accessed through a shared repository, differentiating between the pirated ones and non-pirated ones wouldn’t be easy, hence, difficult to fight.

Harmful Gases Can Cause Health Issues

We all know that plastics when melted emit fumes which is dangerous for humans if inhaled in large amounts. Aren’t 3D printers are exposing us to the harmful emissions? The 3D printers used inside the closed doors of our houses are even more dangerous.

Researchers have discovered that carcinogenic particles may be introduced in the air during additive manufacturing.

These particles can settle in the bloodstream of users and can cause congestion in their breathing system. Hence, triggering cancer and various other harmful diseases.

There are 3D printing machines that come with HEPA filter but aren’t able to completely refine 100% of the fumes. Those that aren’t compliant with HEPA filters do not help at all. All the fumes generated are circulated inside the house or affect those working close to the machine.

Long term exposure can lead to problems that are still to be realized. It is important to take precautions and include necessary measures while working with 3D printers.

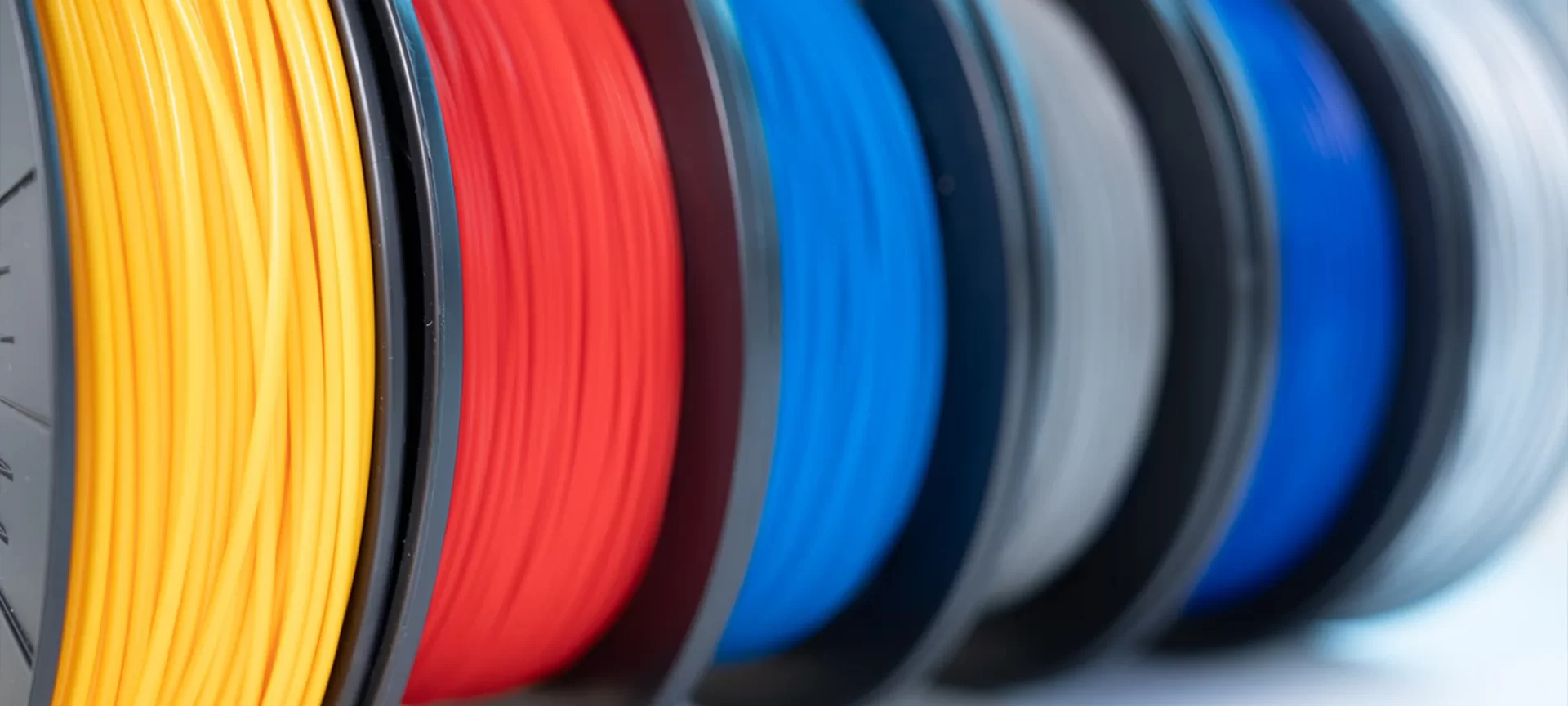

The Printing Materials are Limited

The limitation of 3D printing can be directly felt when unable to choose the desired material for printing. Although the number of material choices is increasing as the demand is growing, it is still far less than the ones available with traditional manufacturing.

As of now, plastic is the most widely used 3D printing material as it is cheap and easy to manage given the lower melting point.

Limited material choice makes it difficult to employ the use of 3D printing for a greater number of applications.

If one is printing with different materials, one may have to buy different 3D printers. As every printer supports a limited number of materials. A 3D printing process printing with metal would not print with plastics and vice versa.

Moreover, some 3D printers can only print with PLA when it comes to plastics. Some have the provision to print with different plastic materials.

The Textures and Color Printing Limitations

It would be incorrect to say that the multiple colors 3D printing is not possible. It sure is.

With new 3D printers and better technology introduction, there are many limitations of 3D printing that is being resolved with time. However, the solution hasn’t been able to impress everyone.

The textures and color options available with traditional manufacturing is still greater than what we achieve through 3D printing.

Users have to compromise in terms of color and the finished textures with 3D printing.

Or else, it must employ post-processing methods, which sometimes is too hectic and not even compatible with every 3D printing process to get the desired results.

Talking about the surface finish, one may be disappointed by the results of a few of the cheaper 3D printers. Even the costlier ones may not be able to provide the quality surface finish compared to the one achieved through other methods.

Again, printing with wood and ceramics is again a huge challenge.

The Limited Size of the 3D Printer

If you are working with a certain 3D printer, you are restricted to print objects with no larger size than allowed by the 3D printer build area.

You must confine your creativity to the size already defined for your 3D printing. These limitations of 3D Printing is highly felt within the small scale 3D printing service center.

These centers have to define the size of the orders they accept and reject those that are larger than the defined sizes.

Larger 3D printers are already at work, but not everyone can afford it. Even when able to get it by investing all the savings and loans, paying for the additional expenses would be completely impossible with limited budgets.

Although there has been a small room-sized house 3D printed by now, constructing a complex and multiple story buildings are still a challenge.

3D Printing Leading to Scarcity of Jobs

As we all know that automation has always been the biggest enemy of job security and so is for the manufacturing industry as well.

Job layoffs are a serious matter and every country’s government is concerned about the problem as much as the citizens are.

With automated technology, the need for labor force is decreasing exponentially. The manufacturing industry is one of the major industries that require labor on a larger scale. Think about a 3D printer that can be operated using 3-4 technicians.

Compare it with the traditional methods and manufacturing technologies that require dozens and hundreds of workers at the same time.

You would be able to calculate the disruption 3D printing is capable of causing. The technology is no doubt is helpful in eliminating human error hugely, however, taking away jobs from labors won’t be justified either.

This can cause a universal problem if industries start implementing 3D printing technologies for all its production jobs. Ultimately leading to economic crises.

The Conclusion

As the technology starts getting into people’s ears, the hype tries to hide the problems related to it. 3D printing is no different.

The major reason why the awareness about 3D printing took so long was because of the limitation of 3D printing that, more or less, still exists.

3D printing is definitely capable of accomplishing tasks that are not possible through any other methods.

But that does not make it eligible for making the disruptions that it is capable of. Researches are heading away to tap the benefit of the technology and control the problems to its best.

We have succeeded too. In terms of reachability, cost, accessibility, awareness, etc. And, we have to cross a long way too.

However, the way the technology has succeeded in impressing the mass, the results would be out sooner.

Not just the limitations of material and color options are worked upon, but studies are being carried to make the technology safe and economical.

Companies are coming up with better and smarter 3D printing machines. Manufacturers of 3D printers are stressing on safety and ease of use.

These can bring a lot of difference in the coming future. Leaving being the limitations of 3D printing, it will take time for 3D printing to completely eliminate traditional methods of manufacturing. The clock is already ticking and the change would be seen anytime from now on.