Did you know that the SLA 3D printing is capable of producing highly accurate parts with high resolution? Apart from the unique 3D printing process involved in the technology, the credit also goes to the material used for printing parts with SLA 3D printers.

SLA material, with time, has also revolutionized. Today, you can find a variety of stereolithography materials, giving wings to different applications and their possibilities. The technology is no more limited to rapid prototyping but can help companies create end parts as well.

The article outlines some of the most commonly used SLA materials and their different properties that make them suitable for particular applications.

SLA technology is one of the oldest one and has found a lot of acclaim from experts around the world. With time, the development around the material has also exponentially raised. These days, you have a handful of options.

What is SLA Material?

Before we proceed to find out the different materials used in SLA 3D printing, let us know the basics of the technology. And, how the SLA material is utilized to create end parts.

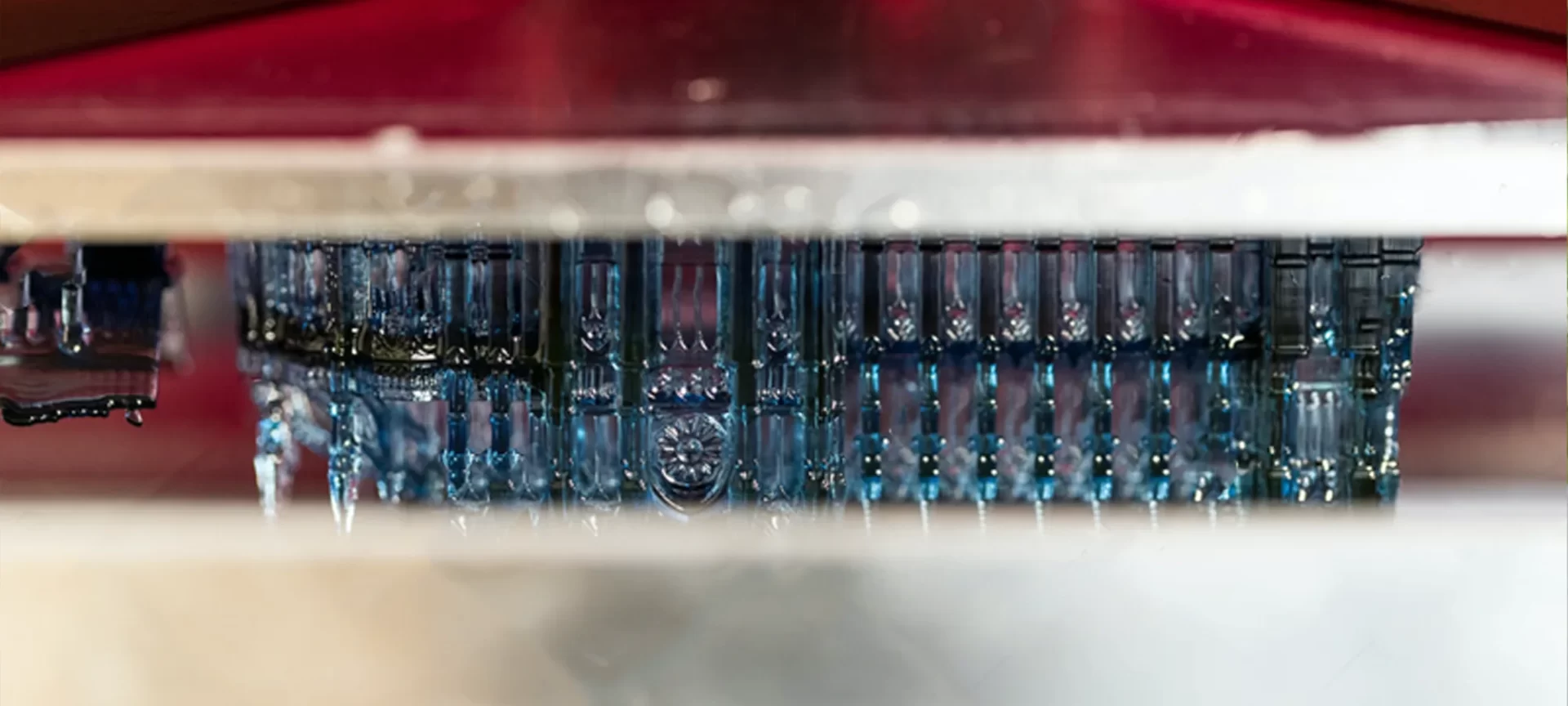

SLA 3D printing involves the use of UV laser for curing photosensitive liquid resin. After the exposure of the laser, the liquid resin hardens and the process is known as photopolymerization.

Because the materials are created with varying combinations of the monomers, oligomers, photoinitiators, as well as many other additives, the end part may reflect varied characteristics.

This is a boon as we can fill these materials as and when required to produce parts with varying mechanical and thermal properties. However, the SLA materials do have few limitations apart from the benefits it entails.

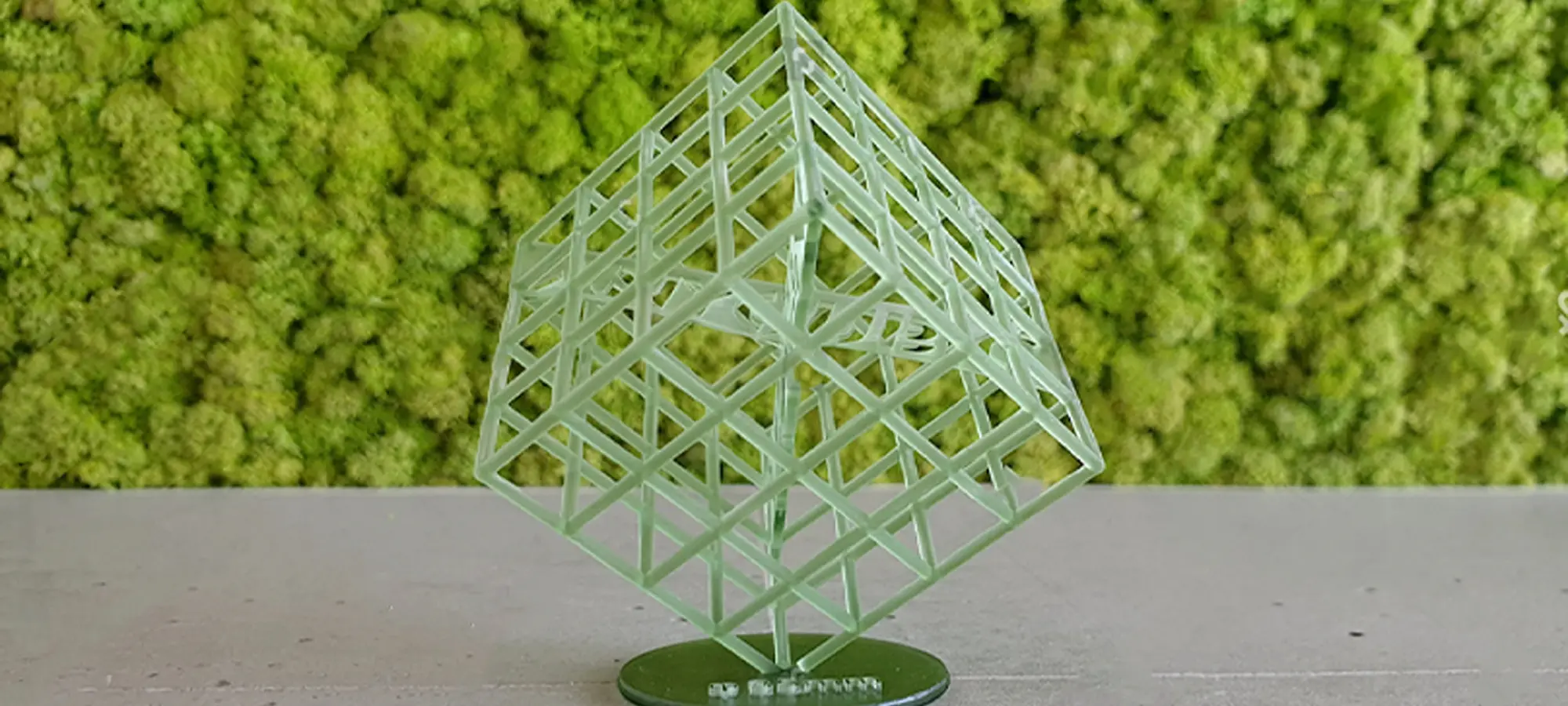

When talking about the pros, the materials exhibit properties like smoothness, and better surface finish. These are capable of producing finer features with great details.

Plus, they are highly stiff. On the flip side, these produce relatively brittle parts that lack flexibility. Plus, being photosensitive, these parts are not suitable for outdoor applications.

The exposure to UV rays could change their mechanical properties compromising their actual use. Moreover, these are prone to creep as well.

But as said before, the different resins showcase different properties. So, let us check in detail the various options and their unique properties.

What Are The Most Commonly Used SLA Materials?

We would discuss four major SLA materials used in this type of 3D printing technology.

Standard Resin

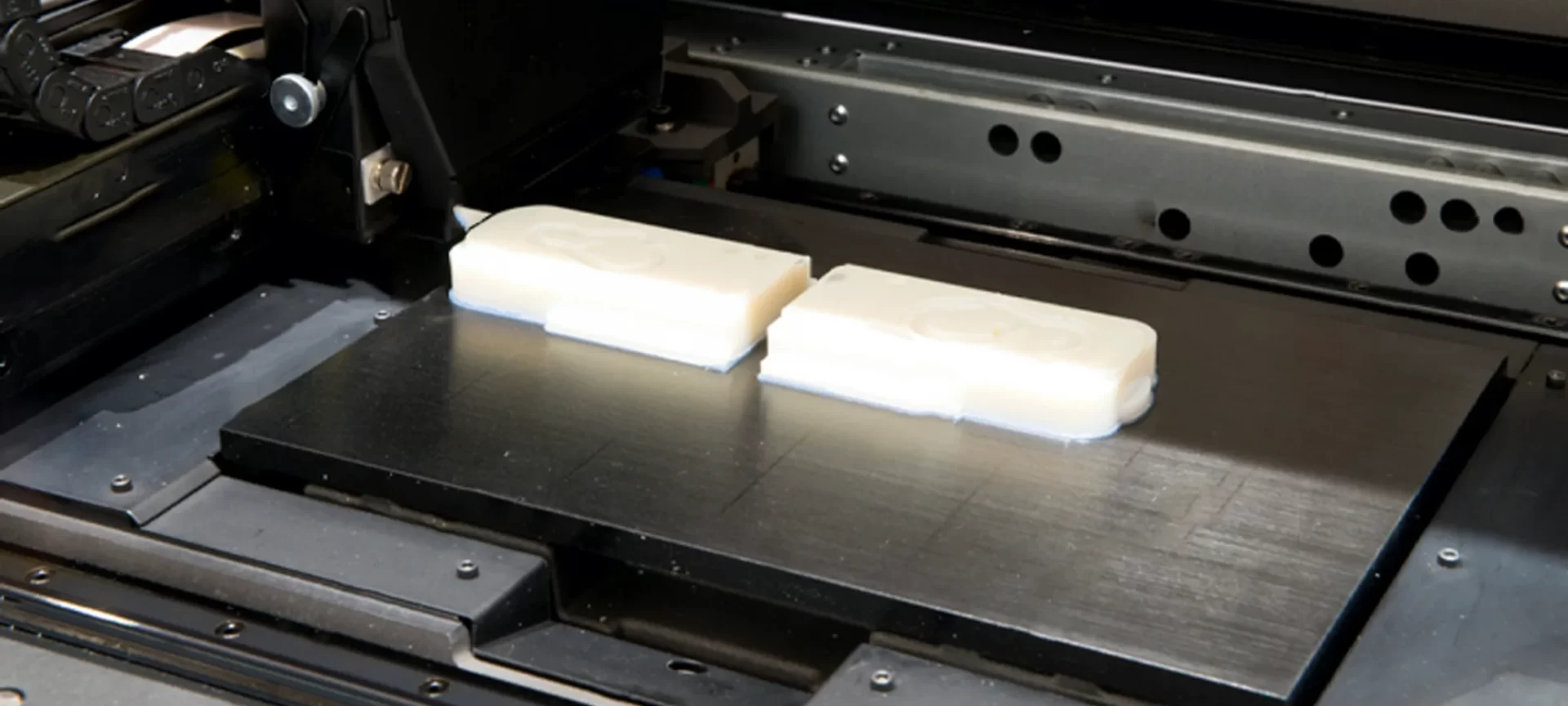

The parts printed with standard resins exhibit properties like high stiffness and amazing resolution. These provide a smooth injection molding-like finish.

These are the cheapest among all the resins used for SLA 3D printing. Hence, they are very useful for creating prototypes. These are also available in different colors.

This property also slightly affects the application of the materials. For instance, grey resin makes it easy to highlight the fine details, hence suited for applications that have such priority.

One the other hand, the white resin provides a smoother finish. So, you know when to use this alternative.

The SLA material offers affordability to the users. And, comes packed with the goodness of being accurate and precise with the details.

However, it is brittle and exhibits a lower impact strength. These are also aren’t very good at high temperature. The standard resins are used for rapid prototyping being economical as well as for art sculptures and more.

Clear Resin is also among the standard material utilized for SLA 3D printing. While it holds the same properties as that of the other standard resins, it can provide optical transparency when used after pre-processing.

Because of its transparency, you can use these for LED holders and many similar applications.

Engineered SLA Material

This specific choice accumulates a range of injection-molded plastics to ensure experts achieve wide options in terms of material properties.

Hence, making the 3D printed parts suitable for several applications. From prototyping to functional testing, to manufacturing and what not.

When trying to develop engineered resins, the materials undergo post-curing in exposure to the UV light. This is done to make the parts reach their maximum mechanical properties

Tough resin

Tough resin is one of the many types of engineered resins that was developed for making parts susceptible to high stress. The material can withstand the high strain.

The material is like ABS filament used for FDM 3D printing. It exhibits a tensile strength of 55.7 MPa as well as modulus of elasticity is 2.7 GPa, very close combat with ABS.

You can use the material for creating sturdy parts that are resistant to shatter. These resins do a wonderful job when used for creating functional prototypes as well.

Talking about the limitations, the material cannot fit into applications that require parts with wall thickness less than 1mm. The parts are brittle too as it is common among all SLA materials.

Tough resins are great for creating parts that require mechanical assembly.

Durable Resin

The material is created to copy the properties of PP (Polypropylene) used in FDM 3D printing. The parts produced are resistant to wear and tear. And, the resin also provides flexibility to the parts produced through SLA 3D printing.

Because of its properties, the material is suitable for applications that require high flexibility. It also provides low friction as well as a smooth surface finish. The material is widely used for applications such as snap fits and ball joints and various others.

When talking about the disadvantage of the durable resin, the first thing that comes to mind is its incapability to produce parts with wall thickness less than 1 mm. It also has low tensile strength, even lower than touch resins.

Heat Resistant SLA Material

As the same suggests, heat resistant resins are popular when accomplishing applications that require high thermal stability.

In other words, these materials are used for parts that need to operate at high temperatures. Moreover, these resins have considerably better heat deflection temperatures lying between 200-300°C, unlike tough and durable resin.

Hence, the SLA material is ideal for creating fixtures, casting tooling and various similar parts. In short, these materials could withstand high temperatures. Hence, you can decide on the application accordingly.

Similar to tough and durable resins, the material isn’t suitable for creating parts that require less than 1 mm wall thickness. Also, it is brittle as the other SLA materials tend to be.

However, the good news is that the temperature flexibility does provide experts with more options when it comes to the application of 3D printing.

Rubber-Like SLA Materials

The name says it all. The resin provides high elongation and is very flexible. That is why the material is utilized for parts that need to be bent or compressed.

With low tensile modulus, it does provide more flexibility to the parts. You can create handles, and other flexible parts using this material.

Although many great things can be accomplished using Rubber-like resin, these do not completely possess the properties of rubber.

Moreover, you may have to use more than the usual amount of support to complete 3D printing using this material.

After being exposed to the sunlight, the properties start degrading with time. And, it is also not suited for parts that need to have less than 1mm of wall thickness.

Ceramic Filled Resin

To achieve the desired properties, the resin is mixed with glass or other choices of ceramic particles. This combination ends up providing rigid parts that are very stiff. Moreover, these tend to produce parts with a smoother surface finish.

The good news is that the material is great in terms of thermal stability. And, it is also highly heat resistant.

Plus, these exhibit a high modulus of elasticity and bring down the problem of lower creep, usually associated with standard resins a lot lower.

The best part is that the SLA material is suitable for parts with thin walls and finer details. However, it is brittle, even more than the tough and durable resins.

Also, it has a low impact strength. You can use the material for applications like tooling or molds, fixtures, and various others.

Dental SLA Materials

The dental and medical SLA resins have found their unique space in the application around the medical niche. These are specialized resins that are used for particular applications. These are engineered to provide specific characteristics and properties.

Class I Biocompatible

These resins are great at providing high precision to the 3D designs. Also, they offer a smoother surface finish. For these properties, the material is widely used for custom medical equipment.

This is because these parts can be steam-sterilized with the help of autoclave. Hence, the equipment 3D printed with class 1 biocompatible resin can be used directly during operation.

However, these parts aren’t very resistant to wear and tear and provide just a moderate resistance.

Class IIa Biocompatible

Unlike Class I biocompatible resin, these are not used for surgical guides but long term medical applications. These are engineered specifically for orthodontic use. These can stay in contact with the human body for more than a year.

If you are thinking about creating custom hard splints or even retainers, these are the choice you must use. Being highly resistant to fracture and wear, the material can stay unharmed for years to come.

Being highly accurate, these can even fit finer designs. However, with all the advantages, these do stay out of the budget for its expensive price.

Castable SLA Material

The castable SLA materials are developed to provide the jewelry industry with the best suited 3D material. To fit the material for jewelry making applications, it has been created to provide sharp details along with a smoother finish.

Plus, these would burn away easily without leaving any mess around. You won’t experience any ashes or residue when printing with these materials.

Using the Castable resin, experts can design the casts directly from the 3D files, making the work a lot easier for jewelry makers. Plus, it can accomplish designs that none of the traditional methods are equipped to do.

It provides flexibility to the creativity of designers. One can come up with any design and almost all those 3D files can be converted into jewelry of your choice.

However, these materials are not resistant to wear and tear which does not matter much as they are created to burn down anyway. You must go through post-processing steps to come to achieve the desired results.

The Conclusion

3D printing has come a long way. Not only the 3D printing technologies, but the variety of materials is also surging. Companies are coming up with new and better developments to stay competitive enough.

The battle to provide the best alternative is on. Hence, you may not have to worry about finding the right material ever. With so many options, you would be able to get the one that matches your 3D printing goals.

When it comes to SLA 3D printer material, you can opt for a variety of choices. Depending on what you would like to accomplish, you can choose the SLA resin that gives you the desired mechanical properties.

It may seem a bit difficult in the beginning. But once you start reading about the properties of different alternatives, you would get acquainted with their purpose of use.

The many great things that come along with 3D printing is already well known to everyone. With the addition of more variants of materials, these advantages are even becoming stronger.

Either it’s the small manufacturing unit or large scale business, 3D printing is getting smarter and powerful with passing time. Thanks to the selection of materials.

SLA 3D printers are capable of doing a lot of jobs providing the highest accuracy to the designs. And, the SLA materials fill in for the gaps they may exhibit.

Hence, you get an overall best experience when printing with this technology. You can work on functional prototypes, create end products and can astonish others with your creative designs.

The plethora of choices the niche provides is beyond imagination. You just need to think further and you may be able to find a better application of these materials.