Since technology has reached incredible heights, there is no doubt that it is able to create novel and intricate structures of premium quality. One of the massively growing inventions is 3D printing, among many others like surgical instruments and jewelry.

This technology allows its users to make economical prototypes and metal parts. 3D printing is being applied in major industries like entertainment, architecture, education, aerospace, medicine, manufacturing, and the field of art and graphic design.

Industries and people who benefit from 3D printing are widely contributing to the economy while making their own lives better. If a person owns a 3D printing business, they would not need to work 9 to 5 in an office; they can set up their business at home and work for on-demand or freelance projects. Anyone can learn how to 3D print through online tutorials or taking up relevant courses.

3D printing websites also have ready-made 3D models that you can download for free and start printing straight away. 3D printing can also be enjoyed as a hobby and as an outlet for innovation and creativity.

One of the most essential reasons why 3D printing is becoming so mainstream is because it does not harm the environment in any way. The materials and composites used for 3D printing are recyclable. It does not require labor and can be managed by just one person. In addition, it does not produce any chemicals and harmful fumes.

Modern 3D printing techniques produce results in a relatively lesser time than traditional printing methods that used to take weeks to print. Modern techniques only take a few minutes or hours depending on the build volume of the prints. 3D printing has harbored job opportunities, creativity, innovation, and made production a lot easier in many industries.

What Is 3D Printing And How Does It Work?

3D printers involve the use of laser beams that liquefy 20 to 60-micron layers of overlapping metal powder, which allows designers to fashion complex shapes and details that may not be possible with conventional production methods.

Using CAD (computer-aided design) software, 3D printers are able to print out models that you have designed according to your preferences.

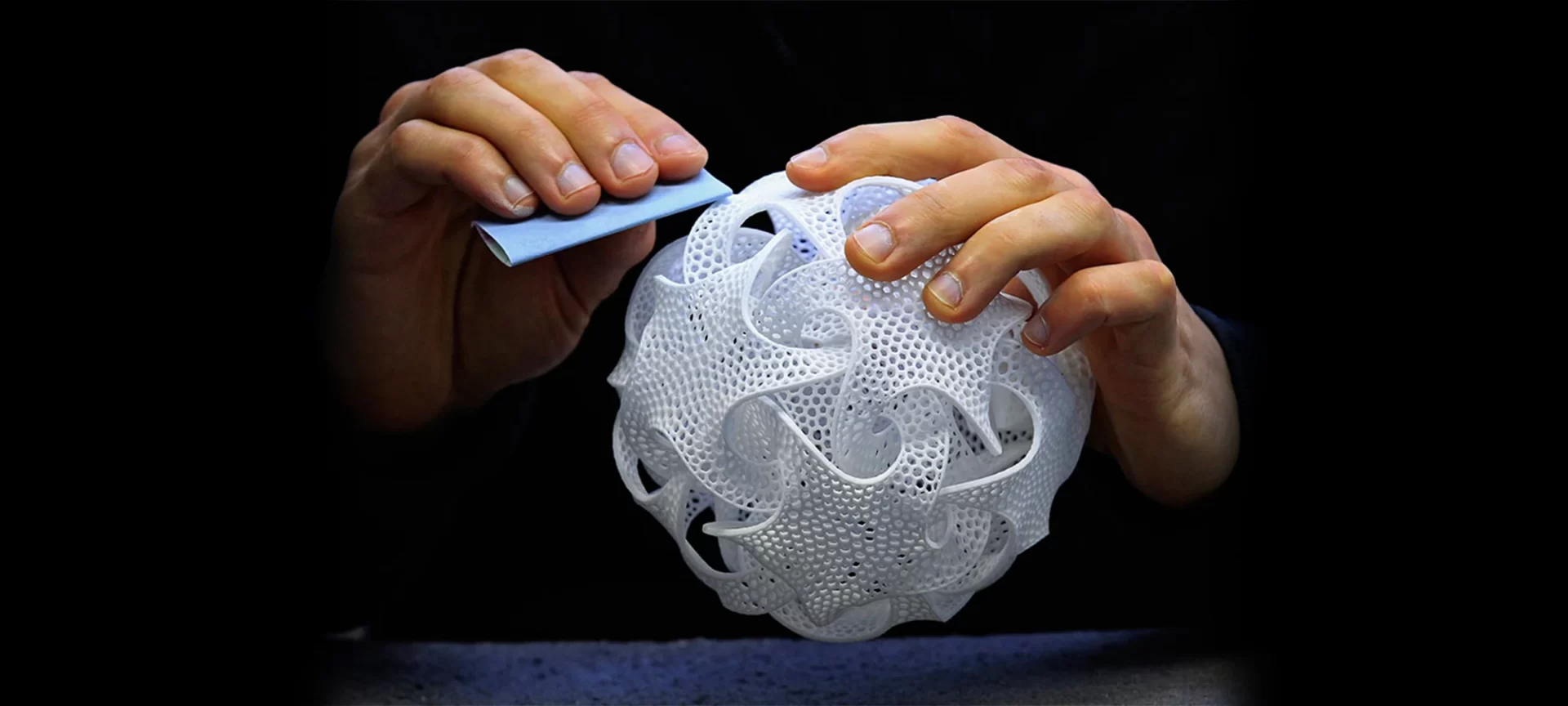

Sometimes sanding is also carried out; it depends on the surface finish required. Finishing is important for your product to look unblemished and intact.

It gives your printed part a refined look and makes it visually pleasing, and allows you to detect errors or imperfections after printing that you might ignore otherwise. A post-processed part is ready for display or for sale and shows off your skills.

There are 3D printers that are bigger in size than the other which may require more space due to their build size. These are used for producing bigger objects and must be kept preferably in a warehouse and may require expertise.

Other printers are smaller in size and are lightweight, and can be kept at home or in the office. These printers can print small 3D objects in very little time.

Waterproofing Your 3D Prints

By waterproofing your prints, you are able to prevent your parts from water damage; which means that water can neither enter nor escape through. If your printed parts are susceptible to humidity and rain, you may want to waterproof them.

Waterproofing 3D prints may be a bit hard, but it is not impossible. Since FDM 3D printers produce filaments one layer at a time, small spaces can occur naturally between the layers. These little gaps can make the process of waterproofing hard, but there are many easy solutions for that.

Below we have mentioned some waterproofing techniques that can be life-saving for you.

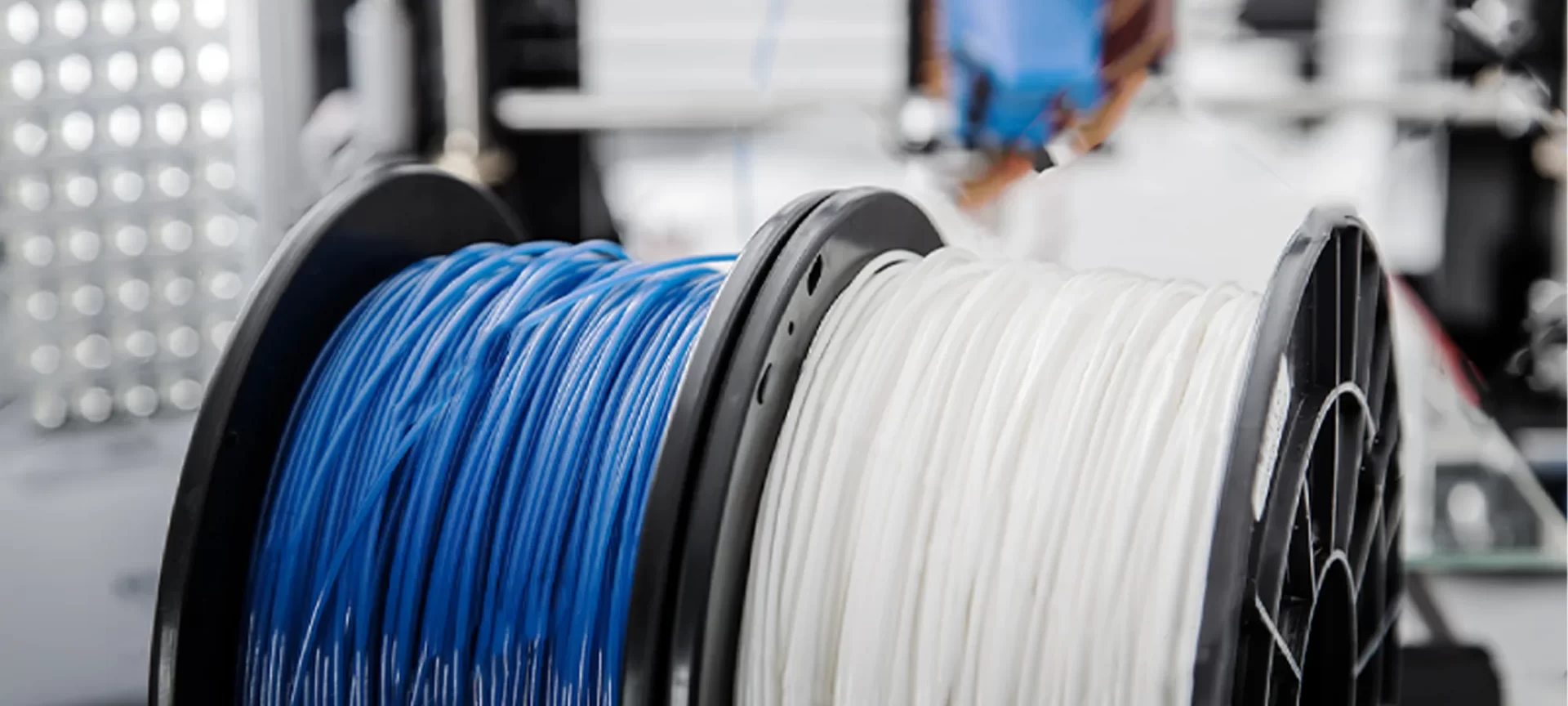

Select Water-Resistant or Waterproof Materials

There are some 3D printing filaments you can choose from that are waterproof. If you only need to create water-resistant prints, you can work with these materials without a lot of post-processing that will make them waterproof. However, if you want a waterproof print, you can use these materials with the techniques mentioned below:

PP

A thermoplastic filament called PP is usually chosen to create bottles, food packaging, and containers. It is a lightweight 3D filament, but it is hydrophobic which means it repels water.

PP is also very resistant to other substances like aggressive chemicals such as acids, organic solvents, and alkali. However, it is also quite flexible and heat resistant.

PP GF30

PP GF30 is waterproof, and also resists highly aggressive environments like UV, high heat, and chemicals, the only difference between PP and pp gf30 being that is the extra 30% glass fiber that is inserted into the filament.

This glass fiber filling enables PP GF30 to become water-resistant and lightweight while also making it rigid and strong. This is why PP GF30 is usually utilized in the aerospace and automotive industry.

PET-G

Consider choosing PET-G (Polyethylene terephthalate glycol-modified) for watertight prints. It is a water-resistant 3D filament and resists strong water and moisture as well. It is also very easily printable.

Usually, PET-G is used to waterproof materials like liquid-filled containers or beverage containers. It is impact-resistant and quite flexible too.

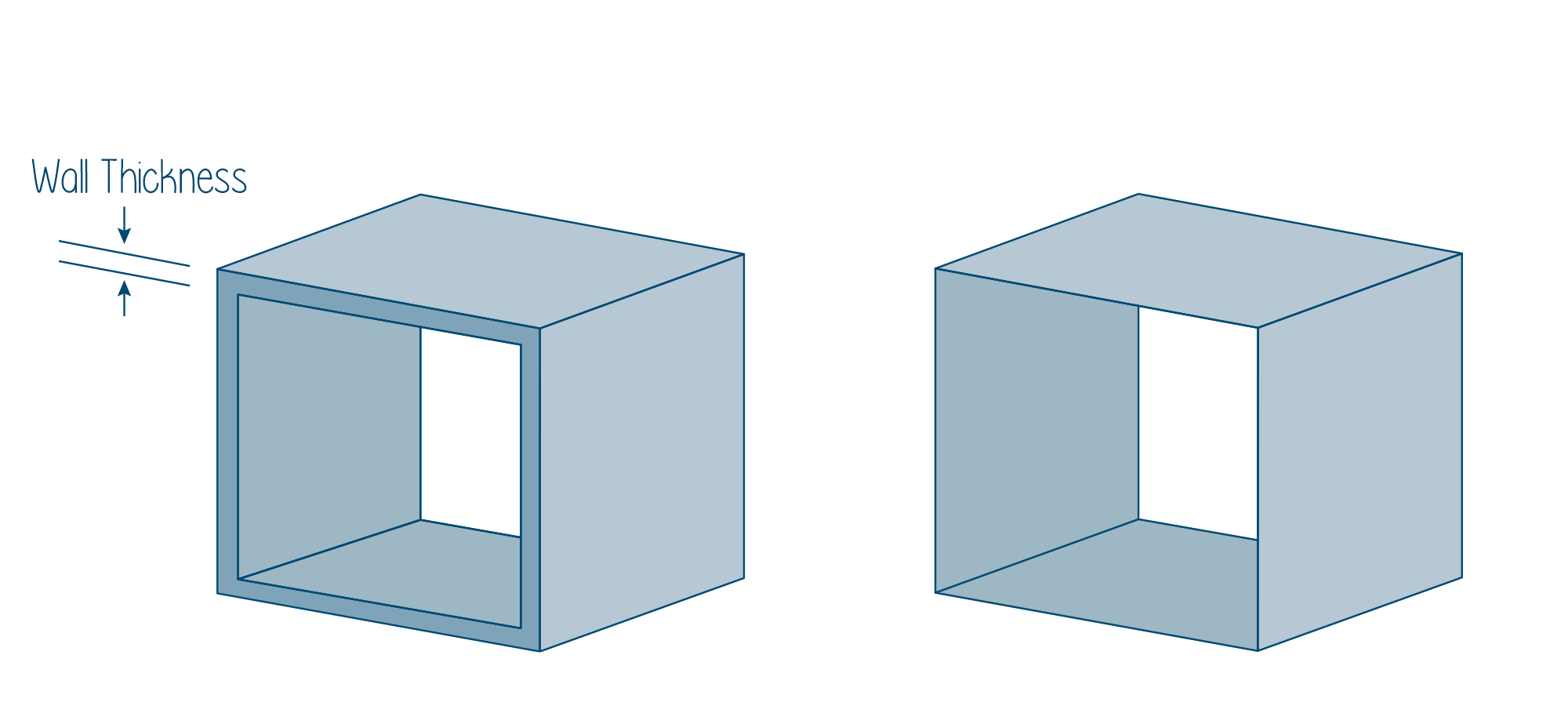

Print Thicker Layers

You can waterproof your 3D prints using various easy techniques, one of them being printing thicker layers. Printing moderately thick layers can decrease the chances of leaking by lessening the interfaces to print.

The fewer the interfaces, the lower the risk of leakage you face. You can add an extra 150 mm to decrease interfaces to your layers. Using a wider extruder to print can allow you to print thicker layers.

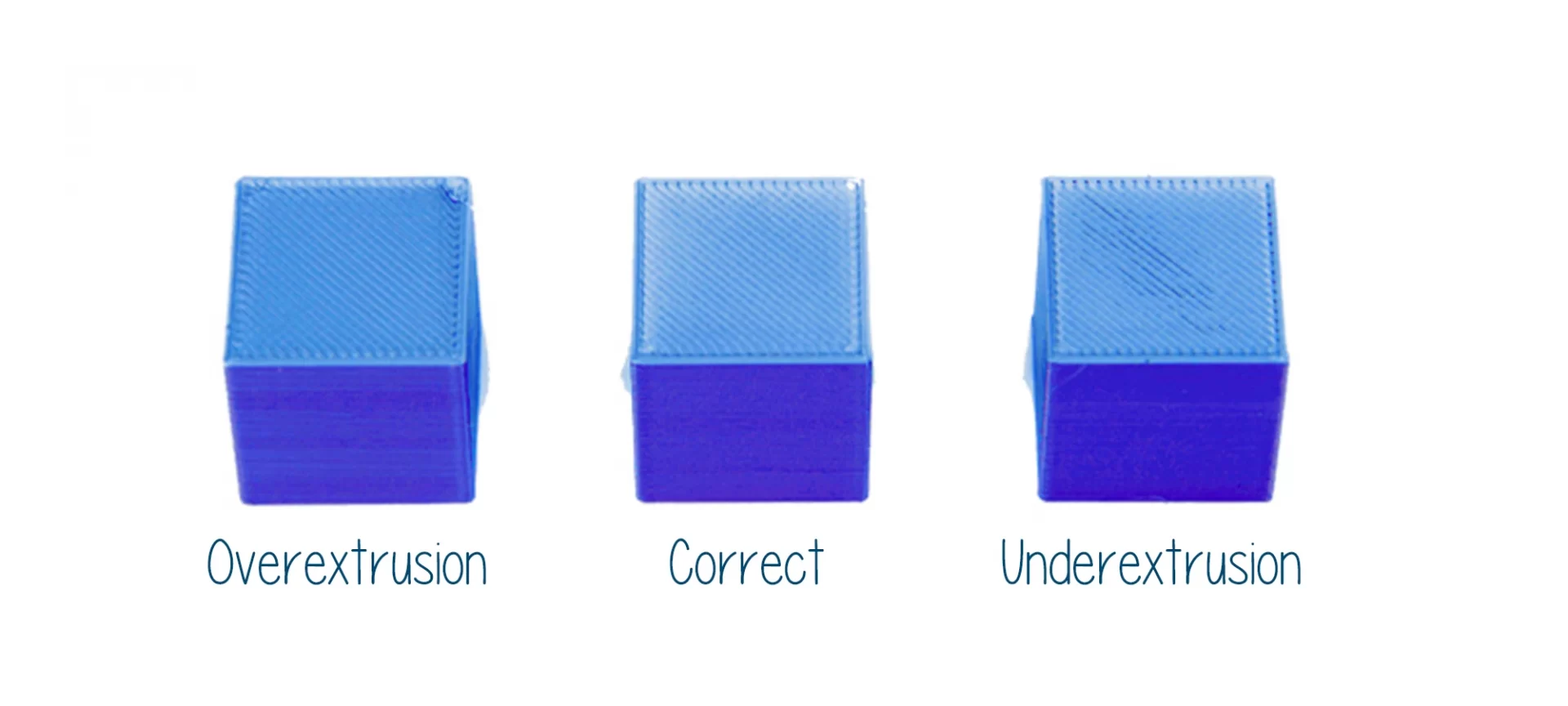

Over Extrude

Slightly over-extruding the filaments during the printing process can make prints waterproof. However, be wary that this technique will not work if you need sophisticated dimensions or are making an end-use product.

By over extruding the filament you will enable it to integrate better with the prior layers printed. If you are printing on very high heat, they can easily melt. Even though this is a strong waterproofing technique, it might affect the quality of the print.

Add More Perimeters

If you do not want to affect your print job by waterproofing, then you may choose to add more perimeters or shells around your model. This provides increased protection and space between your print and the water. By putting in approximately 4 to 6 shells will reduce leaking by making a strong border.

Print Less Complex Models

This might not be possible, but by creating less complex models you can waterproof your prints. The more complex the geometries, the higher is the chance of leakage.

Print designs that are made with sharp corners, overhangs, or complex details have more chances of error in regards to layer adhesion and gaps. If you can lessen the complexity of your designs, you can create a high waterproof model.

Material Selection

Few materials are more prone to deformation and chemical reactions than other materials, which can create non-waterproof parts. If your chosen material is reactive to water, your 3D print will deform if it contacts water or a humid environment. This is why you need to closely consider choosing the right material.

Materials

If you are going for FDM printing, you may want to work with three of these materials: PLA, ABS, and PETG. Let’s see how they can benefit you.

PLA might not be waterproof, but it does work fine if you are not suspecting it to hot water. It works well in cold water.

ABS is a great material for waterproof printing. Though the parts may crack or deform when cold, ABS’s waterproof traits last for a long time.

PETG is a refinement of PET that is usually used to make water bottles due to its excellent waterproofing properties. It has exceptional resistance to thermal properties. As long as you are performing other waterproofing techniques, PETG should be your best choice.

Food Safety

If you are opting to use a 3D printed part that may contact drinks or food you must use food-safe material like PP, ASA, PETG or ABS. prior to printing be sure that the producer of the filament has stated that it is in fact food-safe.

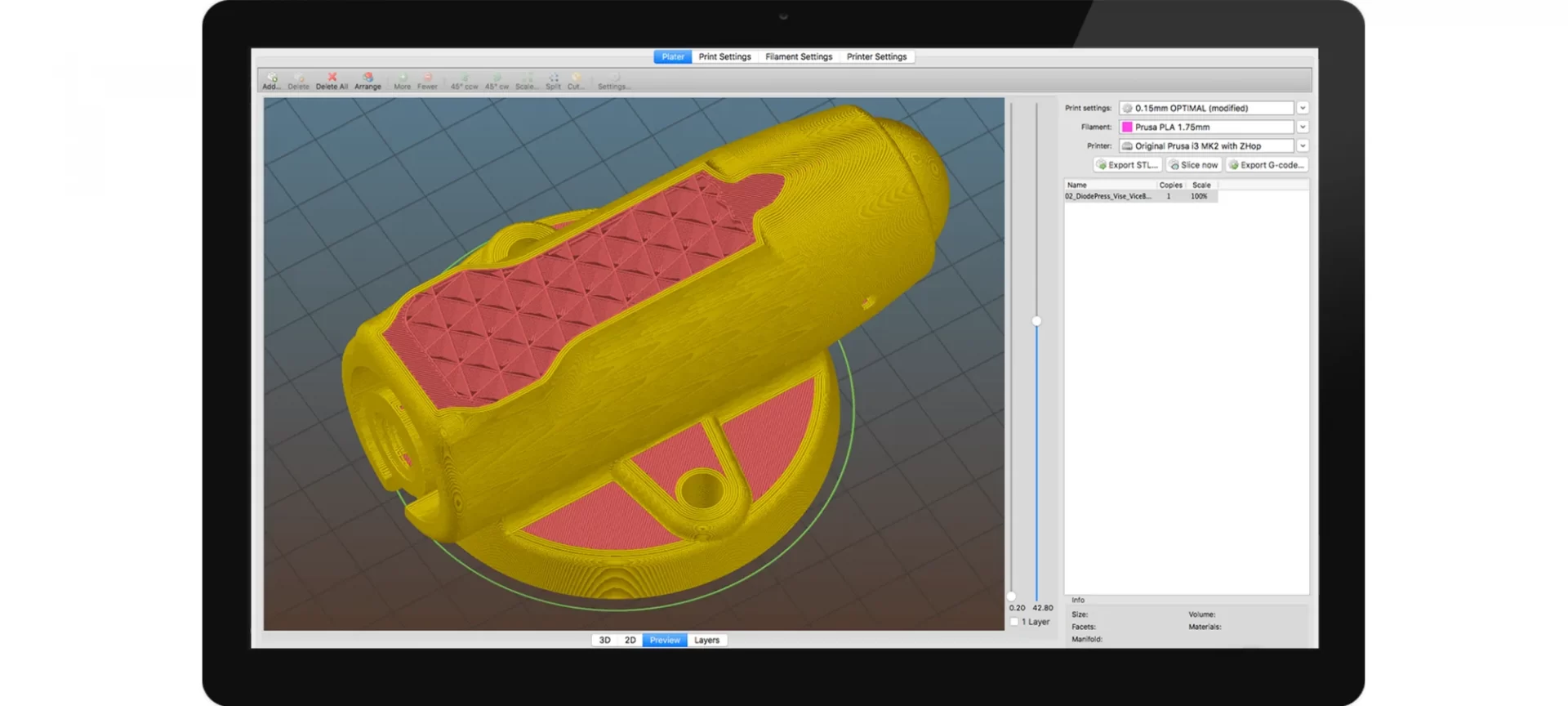

Slicer Settings

One of the major points you need to remember is whether your 3D prints are sliced with proper settings. Along with other things, settings make sure if your 3D printed part is full, tight, and protected which might affect how waterproof your part will be. Be wary that your slicer settings are extremely important in letting your 3D print to be waterproof as some models can be hard to waterproof as compared to others. Detailed and complex models are tougher to waterproof so make sure your modeling is simple.

Nozzle Size

This is not per se a slicer setting, but a wider nozzle really helps in waterproofing parts. Wider nozzle leads to thicker extrusion, which includes the shelling of a part. It does not matter how many there might be, but thicker shelling reduces the chances of your prints becoming thin and allowing them to form holes or gaps in them.

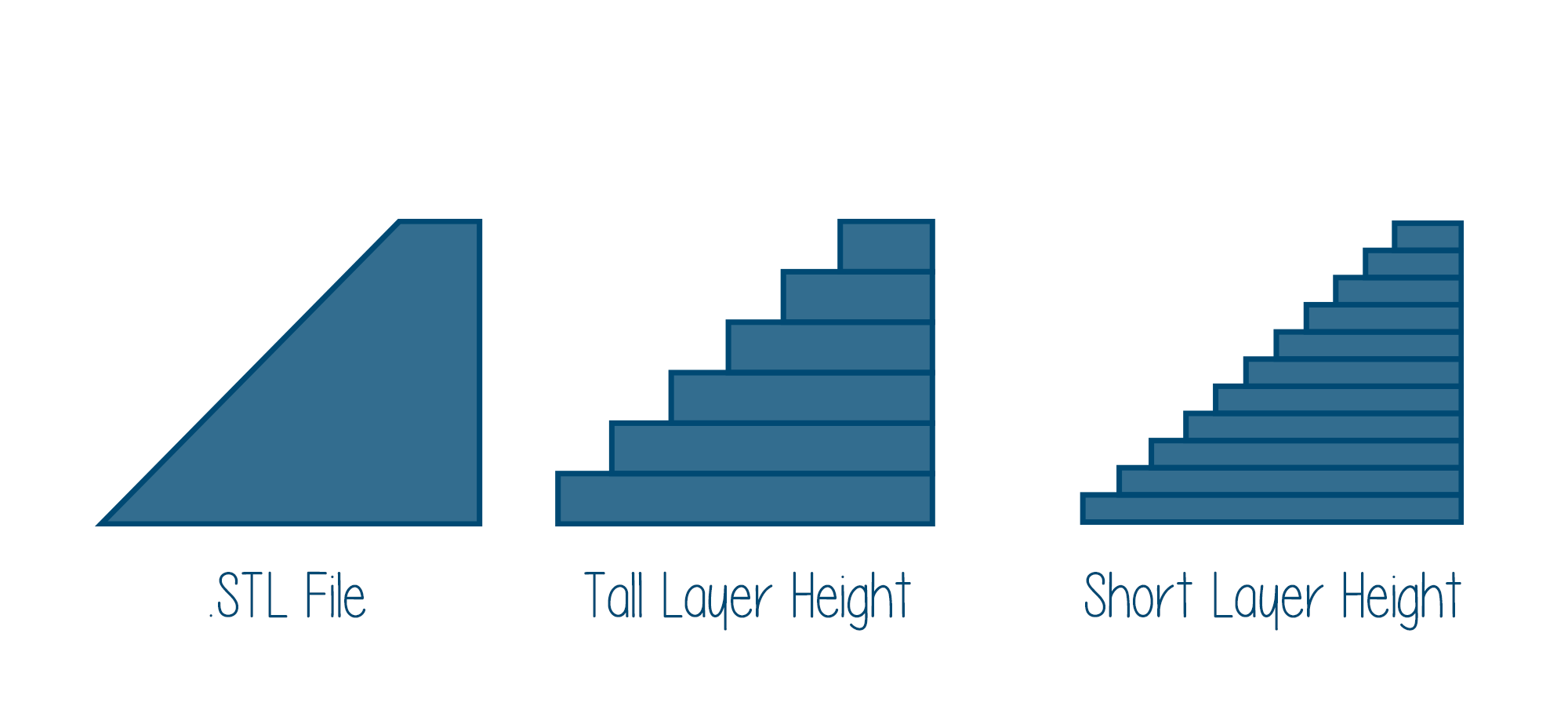

Layer Height

By opting for setting for higher layer height can refine the waterproofing properties by creating taller layers. This will result in your print containing fewer of them, which allows for lesser weak spots (i.e. layer lines) that might make your print susceptible to letting water in.

Post-Processing

One of the most important techniques of making a waterproof 3D printed part is post-processing. Smoothening your layer can result in great waterproof properties by blending layers and removing layer gaps by tightening the layer surrounding the part. Smoothing layers can be achieved in different ways. The main technique however is to put on a solvent to a soluble print. Few materials are soluble to particular chemicals like ABS dissolves with acetone.

- Acetone: One of the most preferred solvents for post-processing as acetone layer smoothing is compatible with many materials like HIPS, ABS, and PMMA, ASA, and polycarbonate filaments.

- Epoxy: Layering a print with epoxy resin will make it less vulnerable to water as it smoothes the 3D print’s layer lines.

- Wax: Waxing may be less usual but it does the waterproofing job well. It may not dissolve layers like acetone but does fill in the gaps present between layers.

Testing

After you have made a waterproof 3D printed part, you should make sure to test it as you will not always have a waterproof part. For testing your print, let it sit in slightly cold water and then remove it to dry for almost an hour. In case of any cracks or deformations, your part will fail to be waterproof.

Conclusion

3D printing takes your time, attention, and energy, and you want your end product to reflect your hard work and creativity. It is important for your finished product to look perfect and be flawless to avoid any errors. Post-processing is essential if you want your finished print job to be free of any imperfections and for them to look smooth and refined. It takes hard work to design and print an object and that makes it more important for you to work on the printed object to achieve desired results.

If you are selling your products, there is no room for mistakes and even if you are an artist or hobbyist, you want your 3D printed object to be exceptional. Printing a waterproof part gives it extra care and consideration and makes it desirable. You reduce any errors and make you or your customers satisfied, and you get to produce products with quality and consistency.