With regards to the auto business, there have been a lot of advancements. With different brands surfacing recently, the competition within the automotive industry has risen significantly.

Hence, companies are trying every hack to ensure they are ahead of the others. In order to do that, businesses are inclining towards additive manufacturing technology for better and faster results. Yes, we can 3D print cars. This isn’t just a far-fetched dream but already happening.

3D printing is an incredible advancement that may reshape our future. It is fast and environmentally friendly.

While NASA plans to use 3D printers along with space missions, auto manufacturers intend to solve some more grounded tasks like speeding up the car manufacturing process, building durable and light bodies, and decreasing the number of auto parts altogether.

Slowly but surely Let’s have a look at some of the most beautiful 3D printed cars out there that will stay in the history books for sure.

3D Print Cars – Live Examples

As discussed before, there are a few companies that have tried their luck with 3D printing to manufacture cars.

Some have focused on adding accessories using the technology and others have chosen to create a majority of the interiors and exteriors with the help of 3D printing.

So, if you are interested to find out those few 3D printed cars already operational, here is the desired list for the same.

Blade from Divergent 3D

Credit: 3dprintingindustry.com

Credit: 3dprintingindustry.com

The success of this USA-based company has been widely recognized by media and investors in the past few years, if closing a $23 million investment deal is any indication of achievement.

The blade is the first supercar on the planet to be worked by the utilization of a 3D printing innovation.

This auto was built by the use of a patented mill technology where 3D-printed aluminum parts connect carbon fiber tubes to enhance the durability of the chassis.

This means that the strong chassis of this supercar is 90% Lighter than those of the rest of the supercars out there.

In September 2016, Divergent established a partnership with a big car manufacturer Pacho, which marked the beginning of a new era of strong unions between autos and 3D printing companies.

It is still unknown to what extent the cooperation will develop. And whether we will see 3D printed divergent visual supercars being sold by the end of this decade.

Light Cocoon from EDAG

Credit: motortrend.com

Credit: motortrend.com

It is no more a dream to 3D print cars. The German engineering company EDAG is quite ambitious, to say the least, as it is set on changing the way cars are being built to date.

Light Cocoon is a follow-up to Genesis, which was this company’s first attempt to create a 3D-printed auto body.

The external shell of the cocoon is made of durable water-resistant, ultra-slim texture that is drawn over the 3D printed car body made of polymer, the outfit for this car was designed in cooperation with a famous German manufacturer of sport cloth, Jack wolfskin.

The fabric weighs mere 19 grams for every square meter. The use of fabrics for the outer surface looks exotic, but creators from EDAG are convinced that this approach will be a success.

Automobiles of the future won’t require an expensive paint booth, and the minor bodywork will be simplified to replacing a piece of fabric.

Also, with the introduction of self-healing polymer composites, cracks and dents on your car will be a problem of the past.

Soulmate from EDAG

Credit: autohub.de

Credit: autohub.de

A soulmate is the latest development from EDAG that was introduced in 2016. This vehicle idea was planned in collaboration with the German organization Bosch and brought about the formation of an inconceivably wonderful lightweight vehicle with highlights of associated versatility.

The outer shell of the soulmate reminds us about the earlier prototype of the company, Light Cocoon, this car exoskeleton, was built with the intensive use of 3d printed technologies, in both chassis and body.

Since our nature always tries to improve things for the highest efficiency, the creators chose to use a web-like frame for increased structural integrity, and additional lightness.

This frame is led by LED lights from the inside to highlight the bionic shell and communicate with the outside world.

Bosch’s input in the concept was the extension of soulmates internet connectivity. It will receive full access to online services and smartphone apps.

The infotainment system is implemented by the use of multiple touch screens displays and interactive surfaces, so we can easily conclude that EDAG has successfully turned a car into a light 3D printed smartphone.

Strati from Local Motors

Credit: redbull.com

Credit: redbull.com

This is the world’s first 3d printed car that runs on electricity. Strati was created as a partnership project between Local Motors and Oak Ridge National Lab.

It took 244 hours to print this car and it consists of roughly 227 layers and 50 main parts, which is much less in comparison to 6000 parts of traditional autos.

It has fully recyclable black ABS plastic. Carbon fiber was used as the building material for Strati, and the only not printed parts are the motor, battery, power train, tires, and wheels.

This lightweight 1800 car is brought into motion by the permanent magnet electric motor that can accelerate the roadster to the top speed of 40 miles per hour.

The company expects to launch the car into production someday with a price tag between 18 to $30,000, depending on the setup.

LM3D Swim from Local Motors

Credit: cnet.com

Credit: cnet.com

If anyone doubted Local Motors’ ambitions to deliver a commercial version of its first 3D printed car Strati, they were wrong.

LM3D Is a street-legal four-seater, which parts are 75% printed using big area additive manufacturing technology. This model is made from a blend of 80% recyclable ABS plastic and 20% carbon fiber.

However, Local Motors are trying to test new compounds in order to create a viable manufacturing process to print 90% of E-cars, almost all the body panels, and even chassis, were 3d printed, but as before and probably for a long time ahead.

The powertrain and batteries are still made the conventional way. The company is planning on establishing long-term relations with software and electronics giants as ABM and Siemens, to develop new ways of connecting, monitoring, and optimizing the driving experience. This vehicle is available for purchase at around $50000.

Lotus 340R

Credit: supercarnostalgia.com

Credit: supercarnostalgia.com

Many cars with low production numbers, which were sold prior to 2002 and are in great demand for spare parts.

Since prior to that year, 3D solid modeling software hadn’t been used, but many companies are using 3D scanning and 3D printing technologies to give new lives to limited edition autos like the 1999 Lotus 340r.

More than 40 components were produced for this four-wheeler that came out in a very small volume of 340.

An ultra-precise blue light LED scanner and software from Geomatic capture were used to capture complex design points of this lotus and then transition models to the printer. Altogether it took 15 to 20 scans.

Among those, 60% 3D printed parts were the front hood, Rear Decklid, rear wing, and fenders. Laser stereolithography, Selective Laser Sintering, and Fused Deposition Modeling technologies were used in combination to create the scar from ABS plastic and reform GF material.

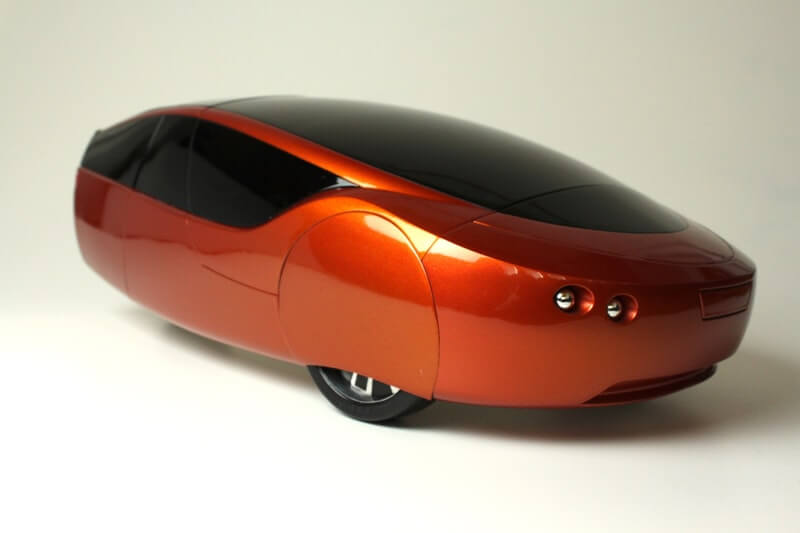

Nanyang Venture 8

Credit: newatlas.com

Credit: newatlas.com

This is a four-wheel concept electric microcar. It was designed for the competition sponsored by shell corporation Eco-Marathon in 2015, students from the College of Engineering from Nanyang Technological University were determined to demonstrate the visibility of use of the emerging 3D printing technology and making such large objects as cars.

The unique feature of Nanyang Eight, is that it has a specially designed chassis that could accommodate the upper body or cabin that is customized for the needs of an individual customer.

The idea is that in the future people will be able to create their own designs of ABS plastic car bodies from various templates that could be done 3D printed, and mounted on the strong carbon fiber chassis and the car will then reflect the personality of its owner.

Nanyang venture eight is powered by an electric motor that is juiced by lithium-ion batteries, which could be recharged to some extent by solar panels located on the roof. If university students were able to build this car in three months. Imagine what prospects are out there for the future 3D printed electric cars.

Urbee 2 from Kore Ecologic

Credit: frontiere.eu

Credit: frontiere.eu

To 3D print a car, you need attention to every detail. And, Kore Ecologic has done it too well. A company of enthusiasts who funded their project of the greenest automobile in the world through Kickstarter. Their automobile or v2 is a hybrid that wasted 1100 pounds.

It is brought into motion by a powertrain that consists of two electric motors with 16 horsepower each, and one cylinder combustion engine that runs in biofuel.

The max speed of this car is 70 mph, and it can cope with 40 miles range on pure electric charge. 60% of exterior and interior parts of Urbee were 3d printed, and its incredible design gives the car an outstanding aerodynamic resistance coefficient of 0.149

Honda Micro Commuter

Credit: newatlas.com

Credit: newatlas.com

It is a tiny car that was presented by Honda in 2016 and is the first 3D printed model from this manufacturer.

It has the name micro commuter, and it was produced for Toe Shyama, a Japanese company that makes cookies and plans to put the car to use.

Honda cooperated with the 3D printing start-up, Koduku Inc, and the total development process took about two months.

The only non-3D printed parts of this electric vehicle are the chassis and the power train. The Honda motorcycles division participated in the creation of a frame.

So underneath those 3d printed panels. Micro has pipes that give it a lightweight, yet strong structure, a large battery that is built into the floor of this vehicle allows up to 50 miles range and also, there was the possibility to install two extenders, next to the driver’s seat, that will each allow 10 extra miles of driving.

This fully operational automobile will start delivering cookies from toe Shyama in the nearest future.

Shelby Cobra

Credit: motorauthority.com

Credit: motorauthority.com

This iconic for the history of the American automobile industry car was built by the US Department of Energy to demonstrate the abilities of efficient modern 3D printing technologies and popularize low emission driving.

Shelby Cobra is a classic sports car that was manufactured 50 years ago. But it received a new 3D printed body that was built by the use of a big area additive manufacturing machine from Cincinnati, Inc.

Overall, it took 24 hours to print all the necessary parts made from 80% ABS plastic and 20% carbon fiber mix. Printing speed was 500 to 1000 times faster than a regular desktop 3D printer.

This automobile was equipped with a new hybrid powertrain that consists of an electric motor, batteries, and fuel cells with a weight of 1900 pounds.

This two-seater is 75% 3d printed, and it currently serves as the ambassador of this technology around the US by traveling to different exhibitions.

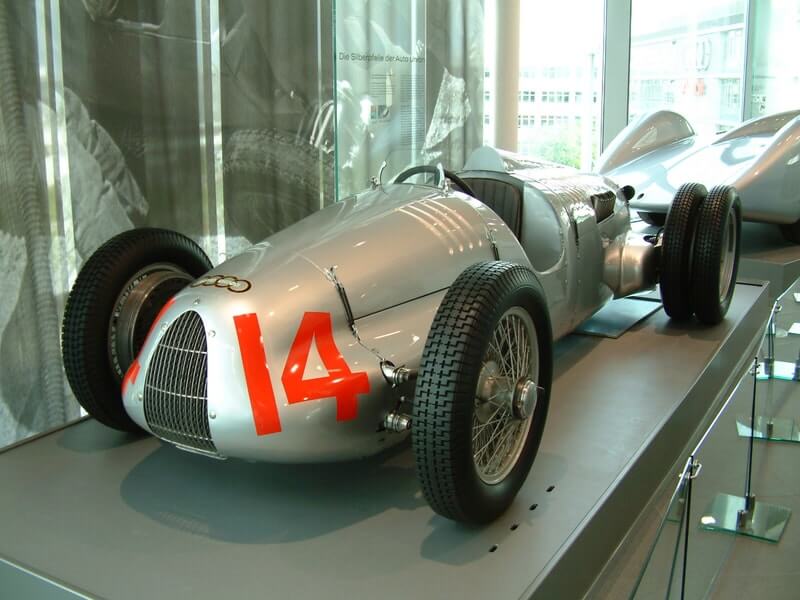

Audi 1938 Grand Prix

Credit: wikimedia.org

Credit: wikimedia.org

Audi is also not okay with falling behind on implementing the 3D printing technology. Their first attempt was the creation of a half-scale 1938 Grand Prix sports car by the use of Selective Laser Sintering technology.

Since this attempt was a success, maybe someday upcoming Audi’s will have 3D printed metal bodies.

Best ABS 3D Printers

Best Metal 3D Printers

Best 3D Printers for Mechanical Parts

The Conclusion

As you’ve seen, the time of the mass-created completely 3D printed vehicles is almost a reality. However, the most developed ventures are either just 3D printed vehicle parts or models.

Yet, research in this field is going very quickly since there’s a ton of interest in the worth-added substance assembling can bring to the auto business.

Significant trouble is the expense of 3D printing. In fact, added substance fabricating isn’t generally the least expensive creation strategy for a huge arrangement of huge parts.

That issue is particularly risky for metal 3D printed parts, comprehensively utilized in the car field. Yet, the progressing decline of 3D printing costs for all advances is changing the current elements.

Accordingly, we may need to sit tight for years and years for this innovation to turn into a customary method to deliver total vehicles and to see the world’s first commercial 3D printed car.

However, to make spare parts, 3D printing is now an amazing partner, making brilliant prospects. So yes, we can conclude that it is completely possible to 3D print a car. Sooner, we will find more examples.