Do you wish to master the art of using 3D Printed resins for your additive manufacturing projects?

While FDM is more of a commercial 3D printer, machines that run on resins are often complex to utilize to their highest potential.

Hence, resin 3D printers are mostly found with businesses that work for specialized niches.

3D Printing may sound like a familiar term nowadays. However, a few years back and very few knew that the technology even existed.

Mostly used for industrial use, the technology was limited to a few applications.

Fast forward today, and it is difficult to believe that additive manufacturing, also known as 3D printing dates back to the 1980s.

The first-ever 3D Printer, based on SLA (Stereolithography) was released in 1986 by Charles Hull. Later, a number of 3D printing processes came into existence.

Among which, FDM remains the most popular technology among home users.

Although after the invention of desktop resin-based 3D printers the accessibility surged, the usage remains limited with a lack of proper expertise to handle such material.

But as you can see, trends are changing. Even the artists and enthusiasts like to leave filaments behind and work their magic with resins.

This is because of the isotropic qualities and various other perks that these materials offer.

So, before we jump into finding out the various kinds of resins and how to choose the one for your job, let’s talk a little more about the technology supporting these materials.

3D Printing Technology Supporting 3D Printed Resins

As mentioned before, the SLA 3D printer was the first-ever machine that was introduced after Charles Hull reserved the patent for the technology.

That is why people call SLA, the mother of all 3D printing processes.

Starting from its early years of release, it still remains one of the most reliable 3D printing technologies for creating models out of plastic.

Unlike other technologies that make use of either powder or filament, SLA works with liquid resin.

Since the beginning, SLA has come along with its own limitations.

For instance, the need for support materials for overhangs and cavities as well as the involvement of a lot of post-processing steps.

Still, it has been recognized as the most fascinating technology of all. This is due to the amazing results it produces.

The 3D models created with liquid resins are highly isotropic. Not just that, the smoothness is quite impressive.

Well! When weighed against the limitations, SLA has never ceased to impress everyone with its astonishing perks.

Therefore, you can find a few variations of the technology being innovated, giving users different shades of experience and results. Such as DLP.

There are other 3D printing technologies apart from SLA and DLP too that use resin as materials. For instance, PolyJet, MJP, DUP, and CLIP.

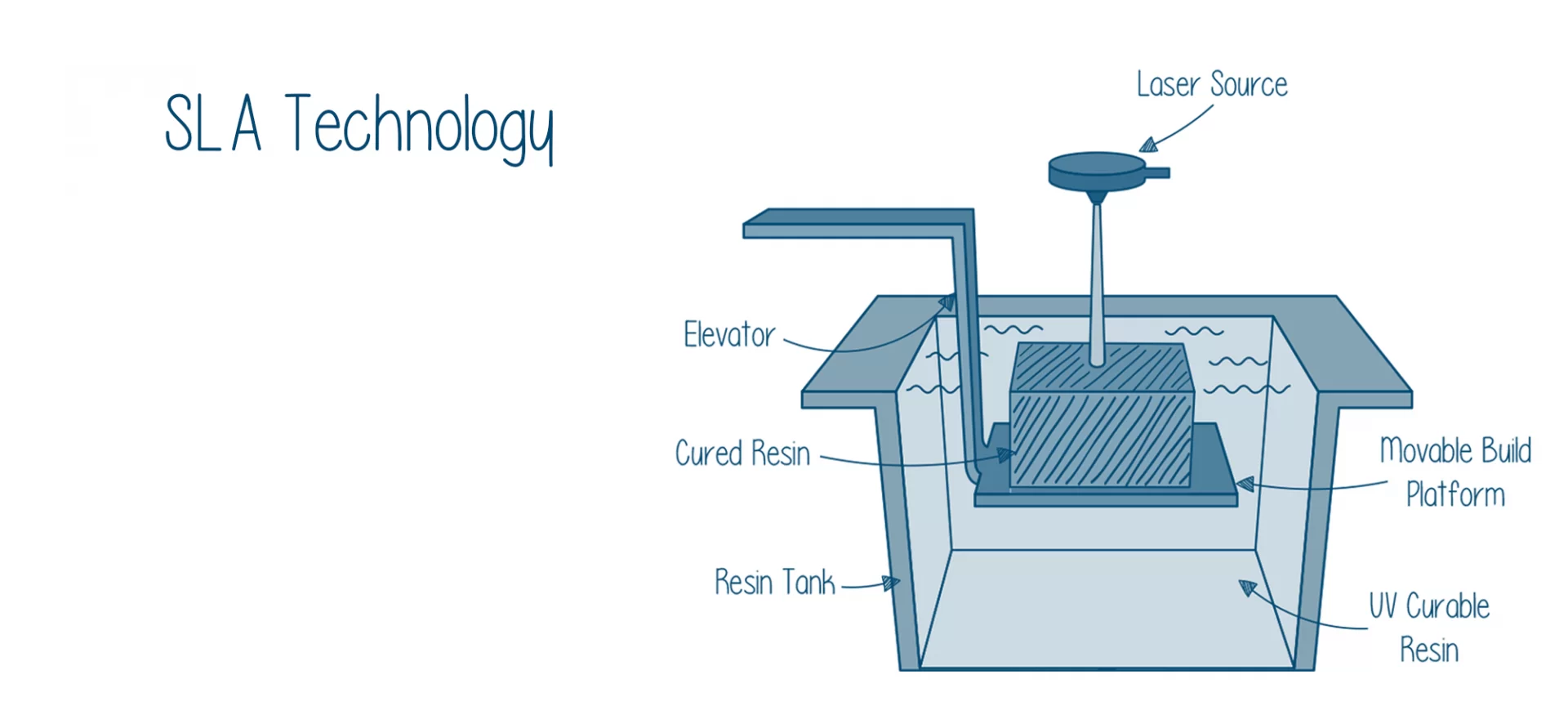

How Does SLA 3D Printer Works

SLA 3D printers are accompanied by a large tank. This is where the liquid resin is stored.

After the 3D printing begins, the liquid resin, UV-sensitive liquid polymer is scattered over a flat platform.

Being sensitive to light, the polymer hardens when subjugated to the light beam.

Hence, applying the same theory, a UV laser is subjected to the selective parts of the resin, based on the 3D model uploaded.

Wherever the laser strikes, the liquid hardens. The left-out material remains in its original form.

After each layer hardens, the platform goes a step-down. Preparing the space for the next level.

The same process continues until the complete 3D model comes out of the machine.

It may sound like an easy affair, but don’t judge the book by its cover. The process is very intuitive and highly elaborative.

Apart from various tricks and skills, picking the right 3D printed resin should be taken into consideration when starting to print with an SLA 3D printer.

So, let’s learn about 3D printed resins and how to make the right choice when preparing your 3D models.

Different Types of 3D Printed Resins

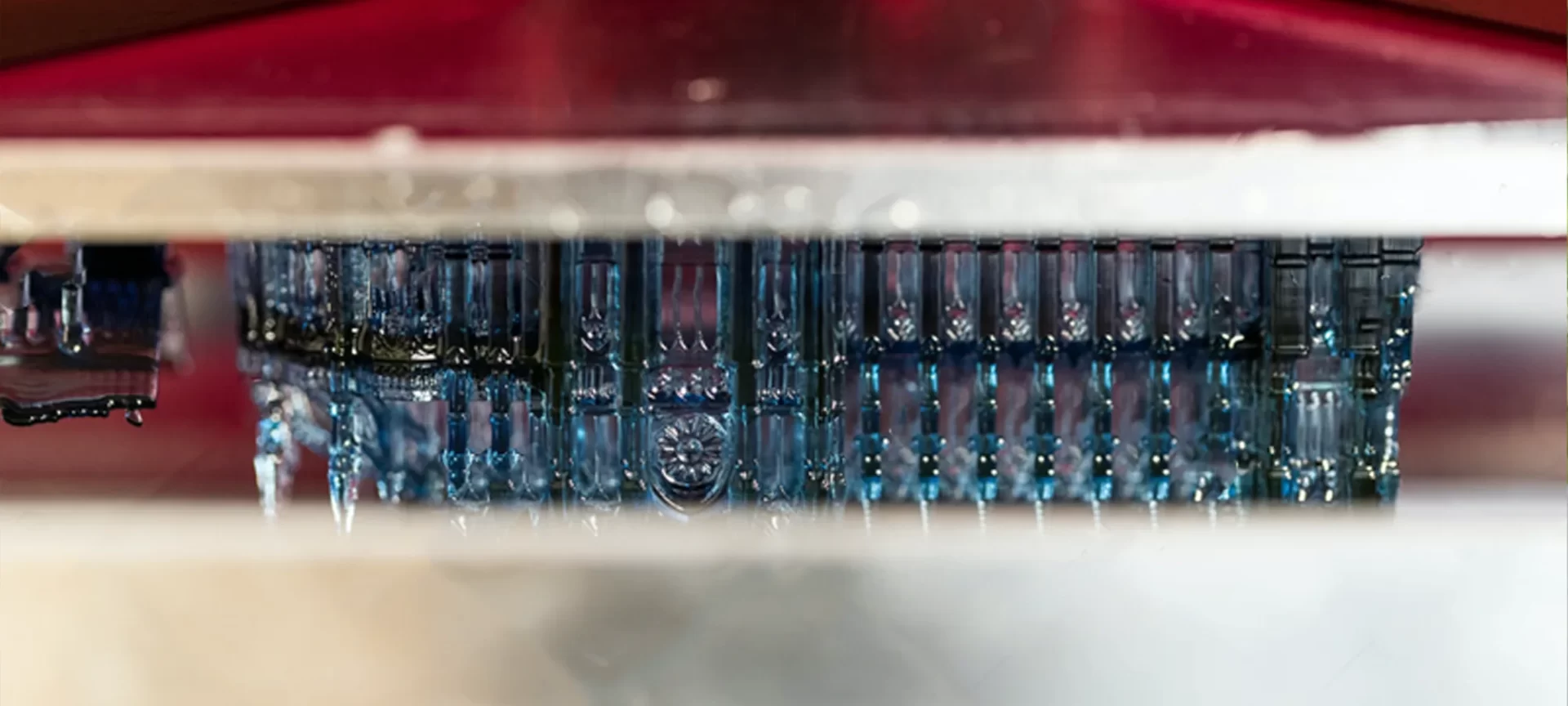

Resins could offer great detailing of models with a lustrous surface. The printed models are of high quality and provide users with amazing results.

Basically, there are various different types of 3D resins (Find a large game here 3dresyns) based on their results and compatibility with different resin-based 3D printers.

Standard 3D Printed Resin

Let’s start our list with the standard resin. If you are looking for an affordable material that offers great quality results, you must take a look at this choice.

Although included in the budget material, this resin could do wonders if used with the right settings. The material comes with both support and without support.

The material is for those who are looking to create colorful models as it is easy to paint over this material after it hardened.

Removing support is also easy. You can use sandpaper or other tools to remove the support manually.

The models are translucent and offer a great depth of detail. Easy to post-process and very common among users with a limited budget.

High Detailed Resin

The 3D printing resin is not for those using the SLA 3D printers. Instead, it is exclusively for Poly jet 3D printers.

For those who do not know, Poly Jet is another 3D printing process that uses resin to create models.

It’s similar to inkjet printing, however, it jets liquid resin on the build plate instead of ink on paper.

Further, these drops harden after coming in contact with the UV rays. The entire process happens layer by layer.

What makes these resins so popular is the detailed results they are able to achieve. Plus, these can be printed with no need for support.

Durable Resin

As the name suggests, the resin is highly durable and can be used for applications that require high mechanical stress including wear and tear.

To make the models durable, these resins are often flexible at the cured parts.

And, it is suitable for those who are looking to create models that might have to go through some mechanical stress. You can count it a lot similar to Polypropylene.

Tough Resin

If you have dealt with ABS with FDM 3D printing, you must understand its worth. With high stiffness, the material offers great durability as well as suitable results for a variety of applications.

With resin 3D printing, you can consider a tough resin offering similar outcomes.

It allows printing parts that are stiff and can go through rough mechanical stress without changing their form.

If you feel that your models need to be ready for a tough job, you can very well look for this option.

Just make sure you have mastered the settings for the 3D printed resin to achieve the desired results.

Flexible Resin

Elasticity is a highly desired property for many applications. Hence, prototypes that are able to retain their shape after stretch and squeezes, could help many businesses better their products.

And, a material that could solidify to provide rubber-like results can do the same for different niches.

Flexible resins are very popular and could offer a great amount of elasticity. These could come back to their original form after tough deformities.

Casting Resin

Have you heard of the castable resins? If you are interested in making mold or jewelry, you can check for this 3D printed resin. These are often used for creating the mold for investment casting.

There are many benefits of using these resins along with the 3D printing technologies over traditional methods. Such as clear burnouts, highly accurate designs, and much more.

Dental Resin

Now, this is where we start believing that resins are super cool. Medical applications are the most talked-about field within 3D printing technology.

Experts have been working rigorously to come up with more sustainable and permanent solutions, only attainable through 3D printing.

And, dental is one such space where the potential for great achievements is high. One example is dental resin.

This has certainly revolutionized the dental industry by filling various loopholes such as larger turnaround time, too many revisions of the retainers and other dental aids, and whatnot.

The resin has been able to solve a lot of such issues by offering solutions that could help in creating end-use products.

Devices like retainers and aligners are now possible to prepare in a matter of time. And, these are printed perfectly without a need for multiple revisions.

Clear Resin

This is considered a special grade 3D printed resin. This is because of the fact that the models built using clear resin offer optic transparency.

Definitely, after a few steps of polishing. Although it requires a bit of extra hard work, it is impossible to achieve a similar glass-like finish with any other type of resin.

Often used for printing sculptures and art-related models. However, there is no limitation to its use. And, you can use it for your models too.

What Are the Applications of Resin Printing?

Just by gazing at the number of possible results by resins, one can easily understand the various purposes that the material could serve.

Here are a few applications where resin 3D printing happens to be the first choice for users.

Devices and Products Related to Dentistry

As already mentioned, dental resins have become life savior for this specific industry.

Most of all, these resins aren’t only for creating prototypes or training models.

However, you can even print end products such as bridges, night guards, impressions, crowns, and many others.

These resins are biocompatible and are easier to maintain. Usually, creating these end products using traditional methods would take weeks and multiple steps.

This won’t even guarantee the perfect fit for the patients. However, when using dental resins and creating devices with 3D printers, these problems disappear.

One can create products quickly and with minimal to no error. The precision is high and accuracy is beyond the results achievable through conventional methods.

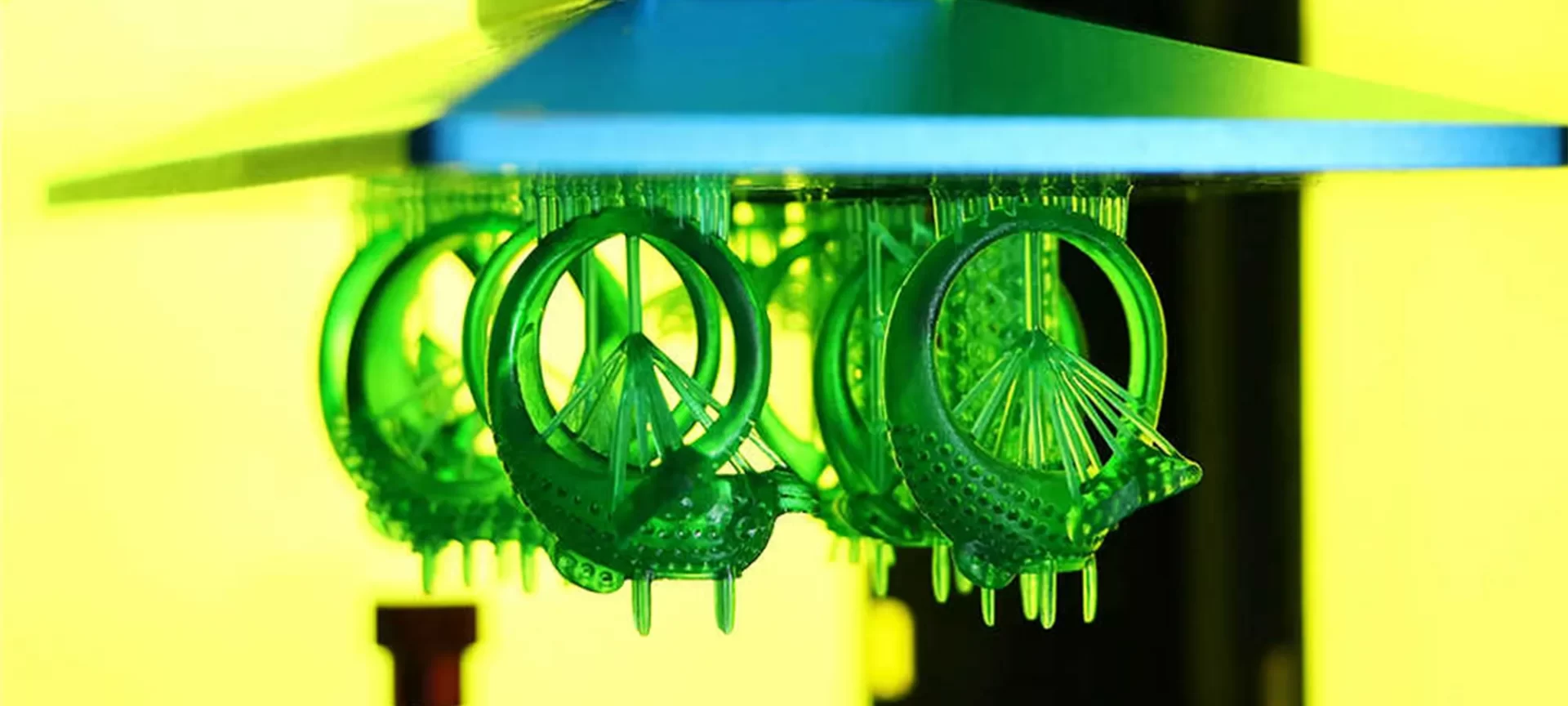

Printing Jewelry

Castable materials are very popular among jewelers. It is easy to produce casts and mold using these materials.

Once done, this mold can be sent for casting directly to get the desired design done straightaway, without much hassle. One can cast a variety of metals using these castable resins.

With the increase in the trend of lighter and cheaper jewelry pieces, manufacturers also like printing final jewelry structure using different types of resins too.

The usages are many. That is why resin 3D printing is so popular for jewelry making applications.

And, if you own a similar shop, trying out this option would certainly help you scale your business.

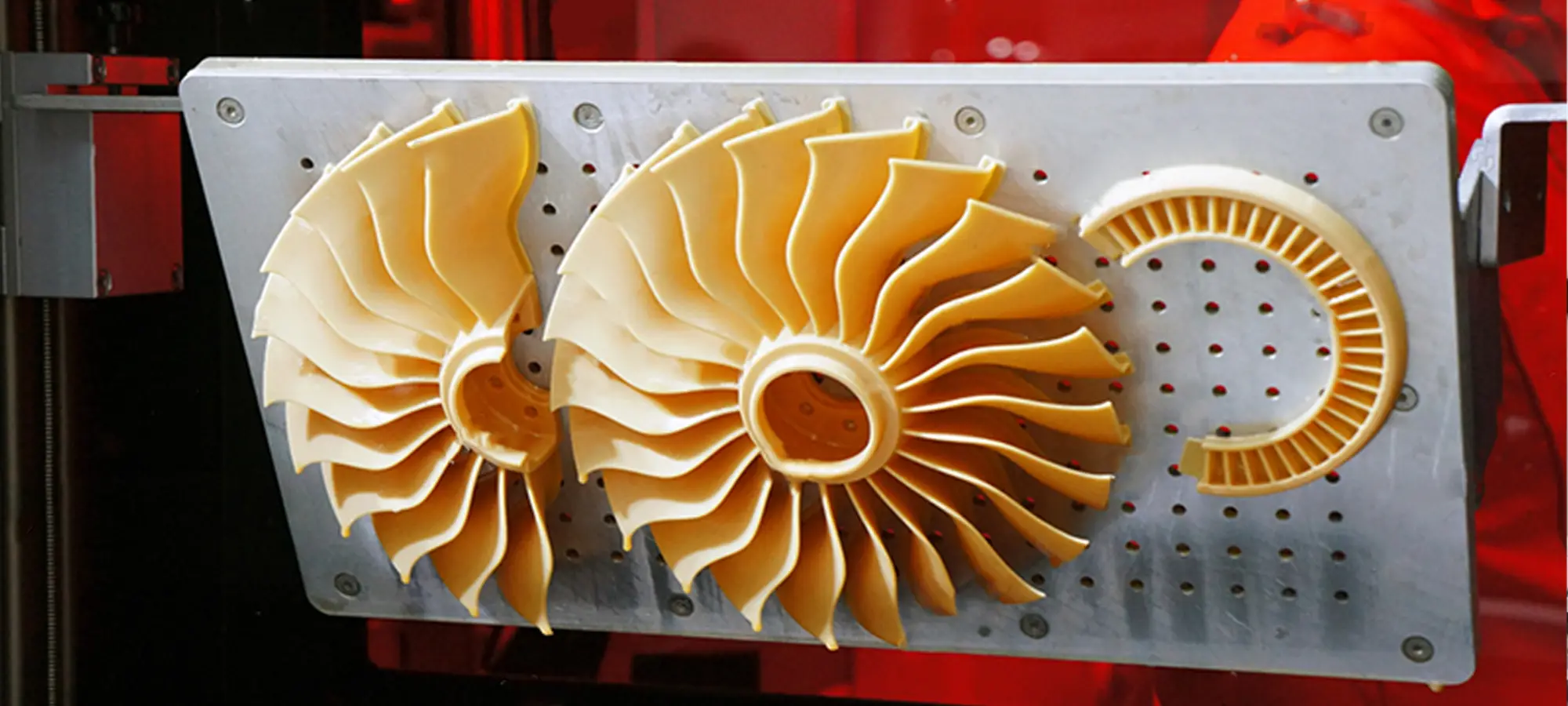

Prototypes

When wanting prototypes for large-sized products that have simple geometry, the resin could help ease the complete production process.

It allows for cheaper prototypes as compared to various other industrial-grade materials.

Moreover, it creates a highly precise and smoother print. So, one can easily depend on 3D printed resins for prototypes as well.

However, if your products have complex geometry, you may want to try other options.

This is because the excess need for support structure could ruin the looks of your prototype, making it difficult for trials.

Miniatures

This is where resin 3D printing is highly notable. Tabletop miniature designers often like to print with 3D printed resins.

We have already talked about the various properties and perks of these materials. And, it is unlikely that we cannot understand the math between the artist priorities.

Overall, resins offer a great depth of minute detailing and lets enthusiasts and makers achieve the highest quality miniatures, difficult to obtain using FDM 3D printing.

The Conclusion

Every 3D printing process has its own perks and limitations. Similarly, the different materials used for different processes also have their own strength and weaknesses.

And, resins do follow the same rule. These materials are very impressive, with a few restrictions.

And, if you know how to choose the right 3D printed resin for your specific need and skill, you can improvise your models with leaps and bounds.

So, anytime you feel a need to switch to resins, do not forget to take a closer look at the variety of options. And, choose the one that suits your application best.