When 3D printing was first introduced, printing with resin had a lot of limitations. SLA was the first resin-based 3D printing process that gave industries a new way of creating prototypes.

However, the properties of these parts weren’t very impressive. With time, various developments took place. Not only better-specialized resins came into the picture, but different parallel processes similar to SLA also developed.

DLP is one such 3D printer types that works on the same principle as SLA, with the only difference being the light source used to cure the resin.

Hence, companies started developing resins that could meet the needs of different applications. Some needed to have flexible parts and others wished to achieve transparent models.

Resins were further worked upon to make sure these demands were well served. There are many companies that provide specialized resins.

Ameralabs is one such company that provides resins for multiple uses such as AMD-3 LED and many others. Either its educational purposes, entertainment, or modeling, one can achieve great details using these resins offered by Ameralabs.

So, let us know more about the different kinds of resins that this company provides. And, with what processes and for which applications these resins are compatible.

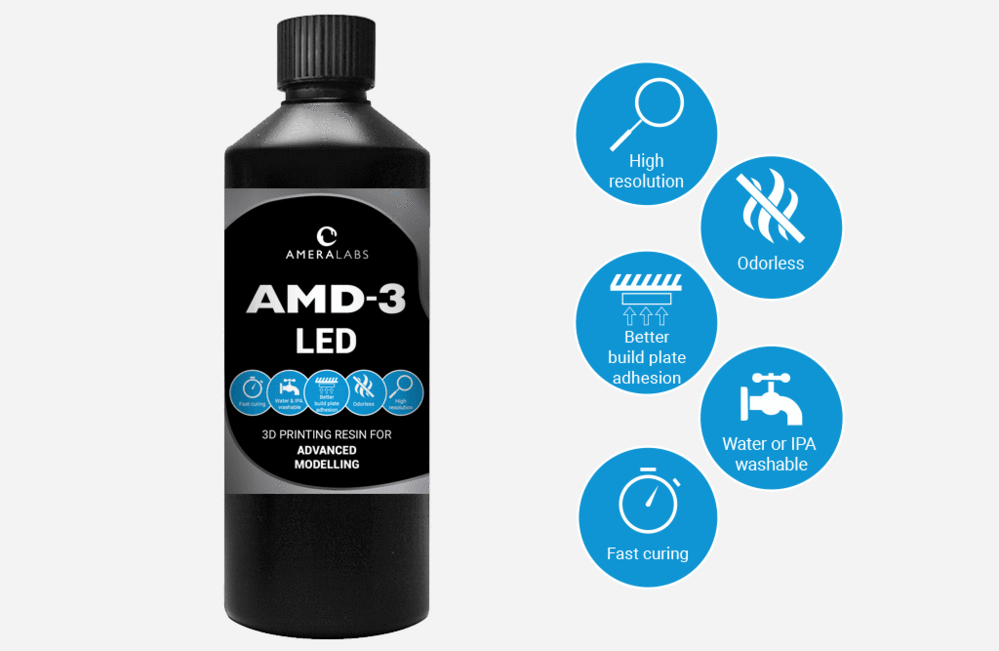

AMD-3 LED Resin

The first one on the list is AMD-3 LED resin. Ameralabs designed this resin for rapid curing while still maintaining the satisfactory details of the parts produced.

This resin could be used for fast printing as well as for achieving high accuracy and resolution. The focus was on creating a resin that could work with low powered 3D printers such as LED or LCD 3D printers.

Hence, the resins are highly reactive and according to the claims made by the company, a 50 µm layer of black UV resin would take 5-6 seconds for curing. This would vary depending on the resin used.

Moreover, the reactive property of this resin makes it incompatible to be used with laser SLA 3D printers. These must not be used with printers that have PDMS coating inside their VAT trays.

The resin could damage the coating inside the tray, hence, it must be avoided. On the other hand, 3D printers using FEP Teflon film inside their VAT trays work fine with this resin.

AMD-3 LED Resin Applications

Based on its properties, AMD-3 LED could be used for modeling, entertainment industries as well as for educational purposes, being affordable and faster.

What to Expect?

Every resin is designed for a purpose. The properties and characteristics differ immensely. There are many good things about this resin with a few limitations that make it a great choice for a variety of applications.

✔️ High-Speed Curing:

As mentioned above, the curing process happens fast. The Resin hardens extremely fast as compared to the other resins, even on low power LED/LCD 3D printers.

Hence, the 3D printing process takes less time without compromising much of the details of the prints. The resin is really wonderful when one needs to print faster without losing the details of the parts.

✔️ Easy Post Curing:

The resin has a low viscosity which means that cleaning parts post 3D printing is easy. The parts tend to maintain features of the original model because of this property, hence, easy to handle.

✔️ Parts are Printed with High Resolution:

The parts printed with this resin has a high resolution, unlike the fast printing resins that tend to lose the details and accuracy. It could create up to 20 um layers if used with resolution 3D printers.

✔️ Negligible odor:

The resin is almost odorless and does not irritate the skin. Hence, those printing at home can relax and continue printing with AMD-3 LED without much hassle. A pair of gloves and nice ventilation would help make the printing simple and easy.

✔️ Easy Post Processing:

The resin is water-soluble. Hence, you can simply submerge the printed parts inside the tap water for cleaning.

The models will be cleaned in a few minutes. Hence, no more dangerous IPAs to continue with the post-processing steps.

✔️ No Shrinkage:

Worried about cracks or shrinkage. This resin is one step ahead of others and performs its job well. There is a minimum or no shrinkage as well as a crack-free finish.

✔️ Tough parts:

Unlike standard resins that produce brittle parts, AMD-3 LED gets you tougher models. You can use this material for many purposes that require hardness.

AMD-6 DLP Resin

As the name suggests, the resin is designed for DLP printers. For those who do not know, DLP printers are faster than SLA, however, cannot produce detailed prints with most of the resins.

However, this is not the case when the DLP printer is combined to use AMD-6 DLP resin. The resin is designed to keep the needs of artists in mind.

Those who create models are very specific about the details of the parts. And, this resin is capable of providing magnificent results to these artists.

One can easily print details such as wrinkles and hair of the models using AMD-6 DLP resin.

AMD-6 DLP Resin Application

Although the resin is designed for modeling artists, it could also be used for other purposes. As it is faster and produces high-resolution parts when printed with DLP printers, it can be used for educational purposes and by enthusiasts.

What to Expect?

The properties of AMD-6 DLP favors those who are looking to achieve high-resolution parts with DLP 3D printers.

✔️ Parts have High Resolution:

If you own a 3D printer capable of producing high-resolution parts, this resin would be a great accomplice. It can print up to 20 um layers. The resolution would highly depend on the printer you own.

✔️ The Parts are Smooth:

As the parts produced using this resin is scratch-resistant, the surface is smoother. It also helps in handling parts during post-processing without a fear to lose the impressive finish.

✔️ Easy Cleaning of Parts:

Because of its low viscosity, it is easier to clean the parts during post-processing.

✔️ Odorless:

Like AMD-3 LED, this resin is also odorless and safe for skin. It does not irritate skin and can be used wearing usual gloves. You may require some ventilation to ensure the slightest of odor, if there is any, can leave the room without disturbing you.

✔️ Not Prone to Shrinking:

The parts do not shrink and maintain their dimensions.

IPR-12 DLP Resin

Now, here is another resin by Ameralabs named IPR-12 DLP. Similar to AMD-6 DLP, this resin is also suited best with DLP 3D printers.

So, what is the difference between AMD-6 DLP and IPR-12 DLP? IPR-12 DLP is sure catered to toughness, it also combines a bit of flexibility for printed parts that are not possible with AMD-6 DLP.

In other words, one can print fracture-resistant parts and the resin is extensively used for creating functional prototypes.

It is used for creating parts for the aviation industry, however, it is very affordable and helps many artists and enthusiasts realize their designs using DLP 3D printers. One can design for more than 12 hours without worrying about pigment settlement.

IPR-12 DLP Resin Application

Depending on its amazing features, the resin can be used for a variety of applications. For example, aerospace, automobile, prototyping, consumer goods, manufacturing, modeling, and many others.

What to Expect?

The parts produced by IPR-12 DLP have various favorable properties that make the resin helpful for printing various parts for different applications.

✔️ Faster Prints:

The resins harden faster as compared to other alternatives, hence take less time for printing parts and models as expected.

✔️ Parts are tough:

The tensile strength of 62 MPa with 13% elongation produces parts that are capable of handling huge tension. Hence, the parts are tough as well as flexible.

✔️ Odorless:

One can print without worrying about odor and smell. With minimum ventilation, one can print safely inside the house as well.

✔️ No Shrinkage of Parts:

Parts printed with this resin sustain their dimension and hence, accuracy is maintained.

Limitations of Resins by Ameralabs

We have talked about these resins and their benefits. However, they do possess a few limitations. As AMD-3 LED is highly reactive, it cannot be used with laser SLA 3D printers. Moreover, the printers that have PDMS based resin trays are not compatible with this resin.

For best results, the AMD-6 DLP and IPR-12 DLP must be used specifically with DLP 3D Printers that feature projectors emitting 400-420nm UV light.

The resin is not compatible with PDMS based resin trays. The fact that it is too reactive and can damage the PDMS silicon layer, it must be avoided with 3D printers using PDMS trays.

The Conclusion

3D printing with resins could be highly tiresome. The liquid material is not only difficult to handle but if incorrectly selected, could ruin the entire 3D printing process.

The resins offered by Ameralabs are very well designed and are fit for various crucial applications. Moreover, these are affordable and safe for users to work with.

Either its AMD-3 LED, AMD-6 DLP, or IPR-12 DLP, all these resins are calibrated to ensure that the models are printed fast and could retain most of the detailed accuracy.

All these resins are great choices for those looking to build unique parts with some fantastic features and properties.