Undeniably, working with 3D printers opens doors for unlimited possibilities. You can 3D print almost everything that is functional using these machines.

And, the most popular among these is the FDM 3D Printer. Being highly affordable and easy to manage, the FDM 3D printers have acquired a special place among consumers and makers.

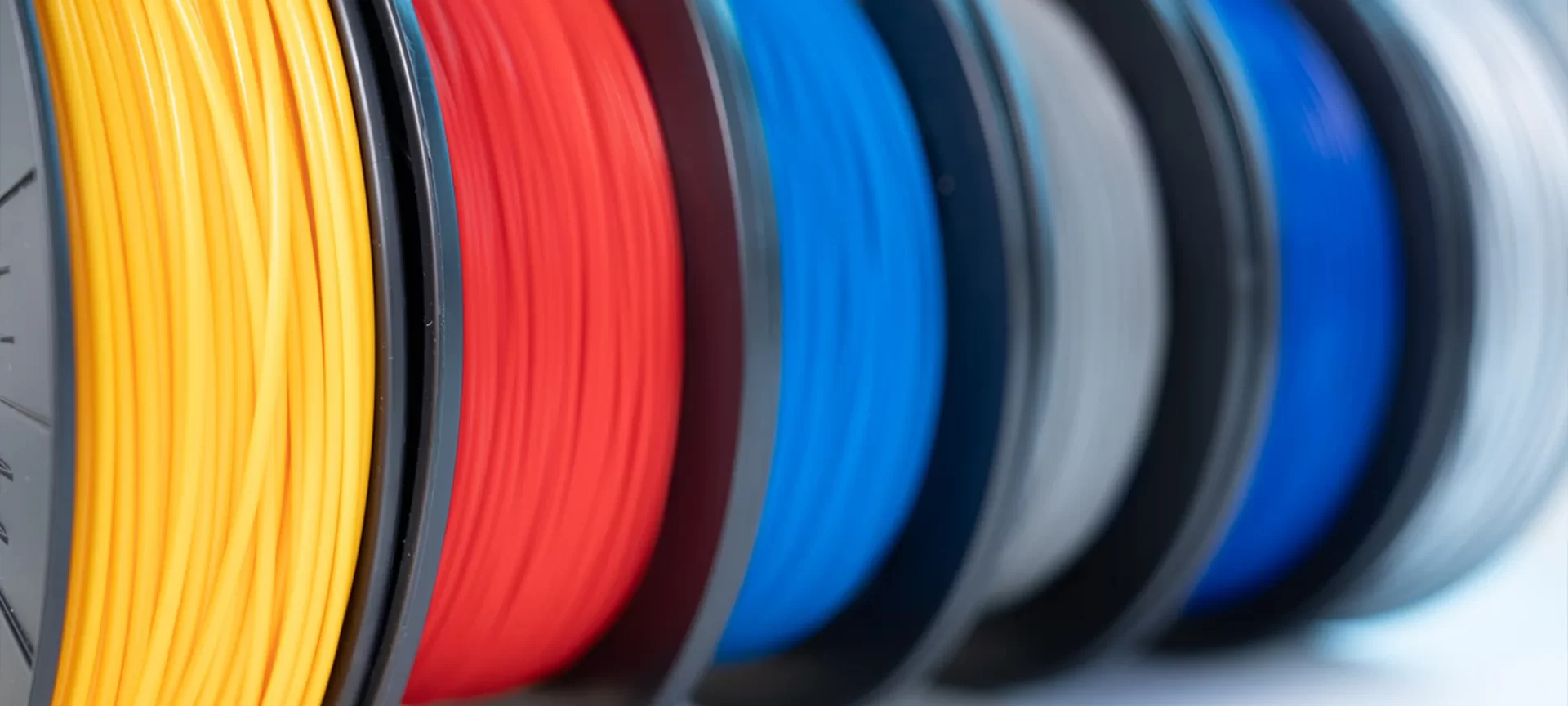

The thing that makes this technology so desirable is the material versatility. 3D printer filaments for FDM machines come in different configurations.

To be precise, no other additive manufacturing technique offers such a huge list of material options. And, the progress is still in action. Apart from the standard PLA, you can find a lot of flexibility as well as the composite filaments for FDM printers.

If you really wish to explore the different 3D printer filaments, you must take a look at what each of these materials provides to the users.

Some are strong and some are softer. Few have the characteristics to withstand high stress and few are just for creating showpieces and figurines.

Hence, it becomes important to find out the strength and weaknesses of each of the filaments and know what would suit your application the best.

In such a manner, you would be able to achieve the desired results. Or else, you can just keep juggling around with different 3D printer filament types and waste your efforts and money.

Different Types of 3D Printer Filament

Let’s get started with different categories to summarize the results. We will discuss the most commonly used 3D printer filament types and know about their properties.

We would also talk about their features and what they offer to the makers. Ultimately finding out what applications they are suitable for.

PLA

This 3D printer filament is the most commonly used option and for many great reasons. First of all, it is the cheapest one. And, it is easier to handle.

It does not require a heated bed and can be printed with an open frame 3D printer. It has a lower melting point when compared to the other filament types.

Plus, it does not produce any awful odor when used for 3D printing. And, what’s most appealing is that it is available in a variety of colors and textures.

Moreover, it is a biodegradable thermoplastic. Hence, it is environmentally friendly and is created with renewable resources. It can be made from corn starch or even sugar cane.

Looking at the dark side, the material is brittle and isn’t very great when providing strong mechanical properties.

Application of PLA

PLA can be used for plenty of applications. But there are few constraints. As we have already found out that PLA is a brittle material when compared to other 3D printer filaments, it must be avoided for items that need to bent or twisted. For example, phone cover, tool handles, and similar objects.

We also discussed that PLA has a lower melting point which means it is not favorable for creating items that must withstand higher temperatures. PLA will deform when exposed to higher temperatures of 60°C or more.

Apart from that, PLA can be used for various applications. And, it is one of the best choices for beginners with less hassle of 3D printing.

ABS

Looking for flexible 3d printer filament? This is one choice that you can count on. Right after PLA, ABS is yet another popular 3D printer filament widely used by makers and exerts.

Although it comes next to PLA when considered the number of users, it is superior and better in terms of material properties. The reason why it stays behind in terms of popularity of usage is that it is pretty difficult to tame.

But that does not hide the amazing properties it entails. Because of this, ABS is used for creating a household as well as consumer goods.

Who can forget the precise LEGO bricks? ABS can get these designs printed in a matter of time. The material is also used for products such as helmets.

ABS adds high durability to the product. Because of its high melting point temperature, the material can print items to withstand high temperatures.

However, because of the same property, the material is susceptible to warping and must be handled with care when 3D printing. To avoid such issues, you must use a heated bed to print with ABS. A closed frame would be even better.

It also emits foul odor fumes which could possibly pose a threat with long term exposure.

Application of ABS

ABS is a great filament for different applications. However, its worth is more pronounced with items that are often exposed to high stress and temperature. Also, those items that are flexible a bit. You can use ABS for creating phone cases, electrical enclosures, and whatnot.

Nylon

Nylon is a well-known name, isn’t it? Its usage is widespread across many industrial applications. And, it rules within the professional setups.

Nylon comes from the family of synthetic polymers. No other 3D printer filament can be as better as Nylon in terms of strength, flexibility, and durability.

There is more to the perks that this material provides. You can actually dye it. And, this process can happen before as well as after 3D printing.

However, it does have a few negative aspects as well. The material is hygroscopic. This means that it is very receptive to moisture. Hence, you must store Nylon in a cool and dry place.

Otherwise, the filament will degrade over time and won’t be able to provide the desired result when used for 3D printing. It does require a heated bed and a high temperature to work with. So, one must take precautionary measures when working with Nylon.

Application of Nylon

As you have already checked all the great properties that the material holds. So, you must have already guessed that the material can serve a lot of purposes when it comes to application in 3D printing.

You can use Nylon for building tools, mechanical parts, and even functional prototypes.

PETG

You must know PET, the most common polymer used for creating water bottles and food containers. PETG is the 3D printing material variant coming from the same family.

The material is glycol-modified, hence the name ending with a ‘G’. Because of this, the 3D printer filament results in properties such as being clearer and less brittle. Above all, it is simple to 3D print.

Hence, this material is somewhere between the two most common 3D printing filaments, PLA, and ABS. PETG is extra flexible as well as durable when compared to PLA. On the other hand, it is easy to print than ABS.

There are certain negative points that one must note when using PETG for 3D printing. It is hygroscopic as Nylon. So, it must be stored in a cool and dry place. Otherwise, it will absorb moisture.

Also, the material is sticky. So, you must not use this material for support structures. And, it is more susceptible to scratches than ABS.

Application of PETG

You can create mechanical parts, protective components, and many other functional items that need to go through sudden stress. Thanks to the strength and flexibility that it offers.

Wood

You must be thinking, WHAT! Yes, you can achieve a wood-like finish with FDM 3D printers. This is among the exotic filaments present for users who need more than just durability.

So, what does it actually mean? Those who want to provide their 3D models with resemblance of wood can use this PLA infused with wood fiber to get that desired look.

Because of the increased demand for such filaments, you can find a lot of variants for the wood-PLA 3D printer filament.

The wood fiber blend differs to provide it a different finish. Starting from standard wood varieties, for instance, Birch, Pine, Ebony, Willow, and Cedar, it also ranges to Bamboo, Coconut, Cherry, and many others.

However, when using these 3D printer filaments, you must compromise with flexibility and strength. In turn, you achieve a better aesthetic appeal.

When looking at other printing properties, you must take extra care when adjusting the temperature for working with this material.

As too much heat could end up in caramelized or even burnt appearance. A little post-processing could get the best results out of your 3D printer filament.

Application of Wood

If you are printing an item that isn’t for functional use but mostly for decorative items or objects needing natural looks, you can consider working with wood. You can print bowls, figurines, and many other display items.

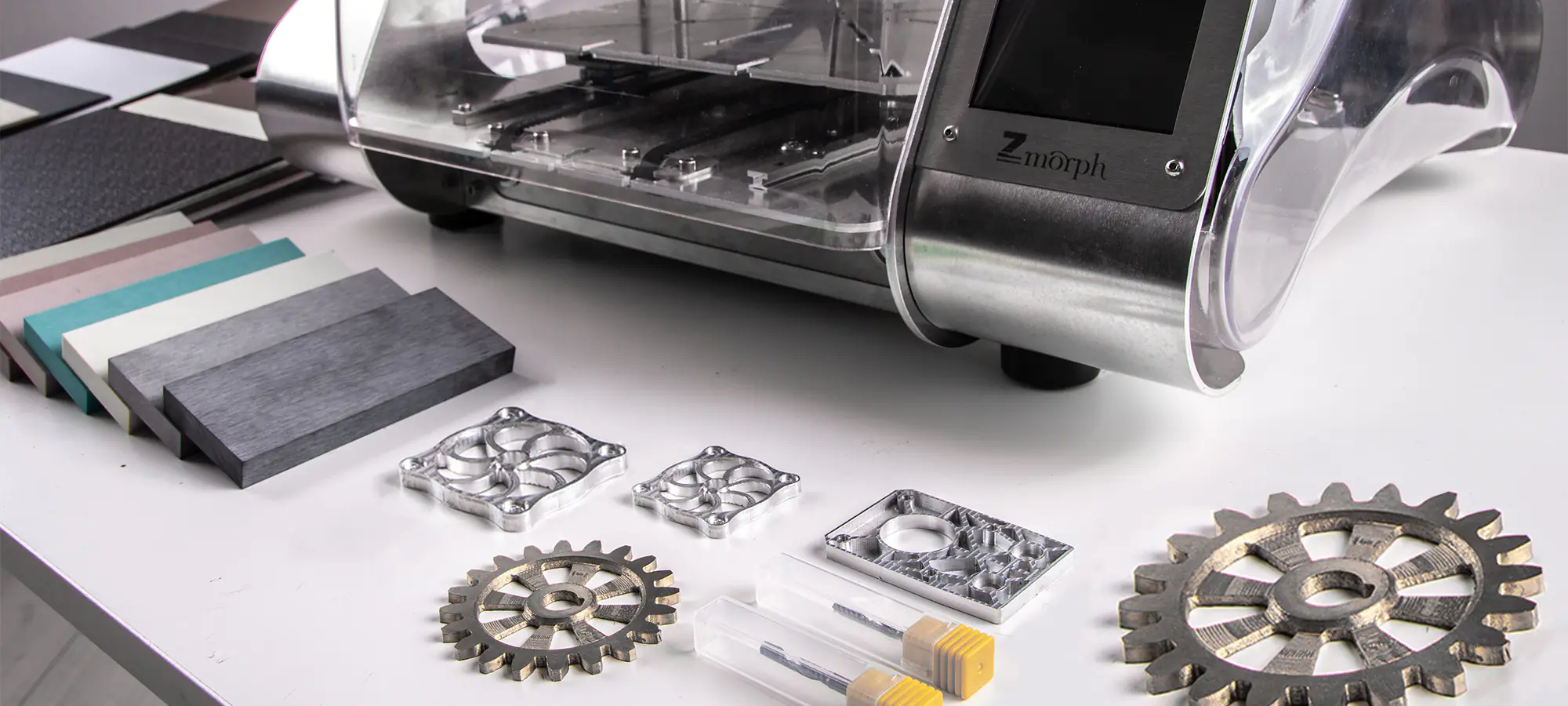

Metal

You would be impressed to find out what all is in store. Yes, you can achieve metal like aesthetics and shine. You must have known by now.

Like wood infused filament, this 3d printer metal filament is again a part of metal and part of either PLA or ABS. However, that does not mean it would not look like metal.

It does have mixed ingredients, but the look and feel are yet attractive. Not just that, the weight also feels like metal. And, the blend produces denser results when compared to standard PLA or ABS.

So, what all metals can you add? You can get a blend of brass, bronze, aluminum, stainless steel, copper, and a few of the choices.

Also, you can carry the post-processing steps to achieve the desired finish. You can polish and tarnish after the 3D model is ready out of the printer.

There are a few problems you may have to face when printing with metal. As the grains are somewhat abrasive, it can harm your nozzle when used more often. And, the nozzle replacement will become a regular deal.

Application of Metal

This exotic material is not just for appearance but for functionality as well. You can create toys, tools, figurines, finishing components, and many others.

Carbon Fibre

Once again, a composite, however, created mostly for professional use. To prepare this filament, the carbon fiber is infused with different standard 3D printer filaments such as PLA, ABS, PETG, and even nylon.

The results are very impressive. You get stiffer and rigid material which has relatively lesser weight. Hence, these can make a great option for structural applications.

As you know, the other side of the coin does exist. And, this is no exception. When 3D printing with carbon fiber, one will experience increased wear and tear of the printer’s nozzle.

This is most common when the nozzle is made of brass. Even the little use of the material is capable of increasing the diameter of the nozzle.

Application of Carbon Fibre

You can try creating mechanical components using this material. It is the best alternative for printing automotive parts and various other items that require to withstand stress.

PVA

PVA, the abbreviation for Polyvinyl alcohol, is a really impressive material. The most pronounced properties of PVA is that it is soluble in water.

The material is used for its unique properties for many applications. From the creation of packaging for detergent pods to bags for fishing bait, it shines at a lot of utilities.

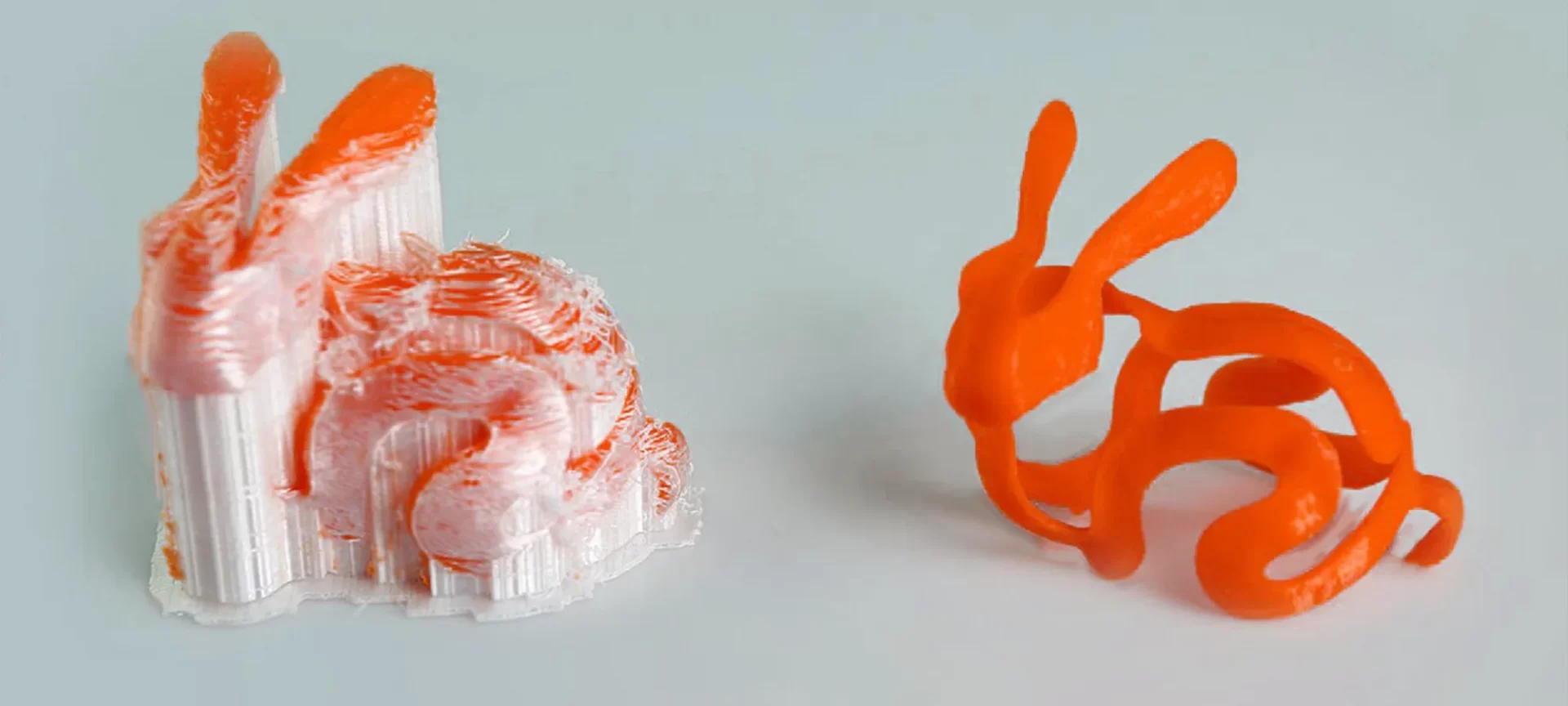

Another important use of PVA comes out when it is used with another 3D printer filament with a dual extrusion printer.

PVA can be used for creating support structures. Hence, when the final item is dissolved in liquid, the PVA melts in and what remains is the 3D model.

However, the material is a little difficult to handle from the rest of its counterparts. Also, it is susceptible to moisture absorption.

Hence, one must take extra care when storing the material. If kept properly, you can make use of the filament for long. Or else, it can deteriorate in a matter of minutes.

Application of PVA

In 3D printing, the material is famous as the filament for support structures. Because it dissolves easily, the post-processing becomes a breeze. Plus, it results in a smoother surface finish.

The Conclusion

These are the most common 3D printer filament used widely across the additive manufacturing niche. However, the list is not limited to the above inclusion.

You can find many other filaments as well. However, most of the tasks and applications can be concluded using these variants. You just have to know what are these best suited for.