The automotive industry is by far, one of the biggest admirers of additive manufacturing. From the start, the technology has been able to help the niche in one or the other way.

Most of all, it has provided the automotive sector a fairer chance to outgrow its developments. AM has opened doors to innovations.

Starting from testing of functional parts, companies are now 3D printing automotive parts. It would be soon when most of the car parts will be created using this very technology.

Today, we can create automotive parts that are lighter, stronger, and even safer. Thanks to 3D printing, we have also minimized the lead times along with reduced costs of manufacturing.

How Does 3D Printing Help the Automotive Industry?

Additive manufacturing, although not completely, but have started to impact almost all the different process involved in the automotive industry.

And, why not. 3D printing offers ample flexibility to experiment with new and complex design and at a feasible rate.

The size of the industrial printers and the time it takes for printing large scale parts is still a question. However, the way the technology is progressing, we may soon find the difference fading away.

As of now, 3D printing in the automotive industry enjoys a respectable place by involving itself is an important process.

Designing of New Vehicle Variants

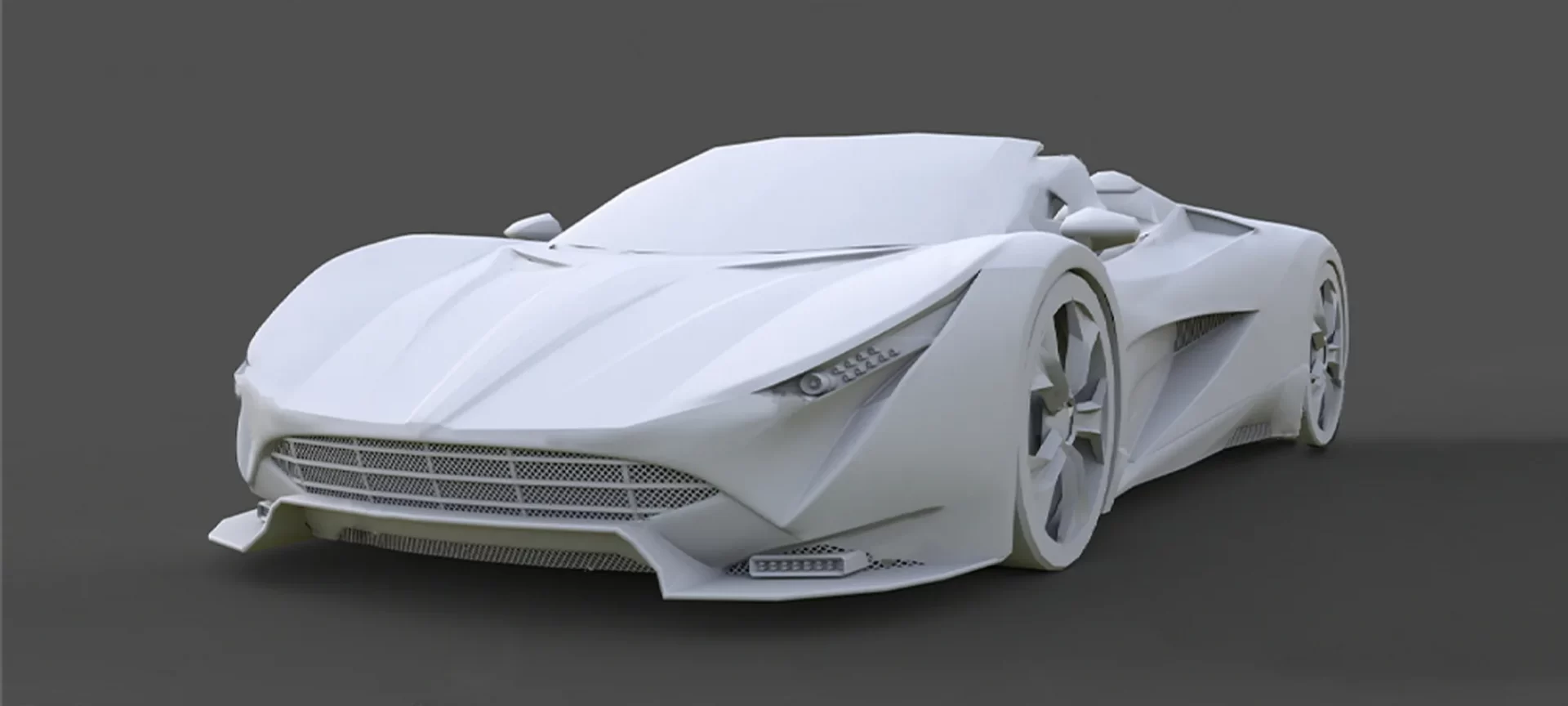

Whenever we come across a new design, we often try to figure out what it would look like in the real world. Hence, the same goes for the automotive industry.

We start with a scale model to experience the look and feel of the proposed design. With 3D printing, the creation of these scale models has become too simple.

These scale models showcase the vehicle form and provide the expert with the start of the discussion. These are great when performing aerodynamic testing.

To create these scale models, companies use SLA or material jetting to produce high detail, and finer surface models.

Accuracy is necessary to ensure that the design goal is properly communicated to others without any doubt.

The scale models are the base of every design concept and must be created with high precision.

Hence, a 3D printer for automotive parts is not the usual one that we work with at small offices or homes. These must be equipped to work in an industrial setup.

Testing of Automotive Parts

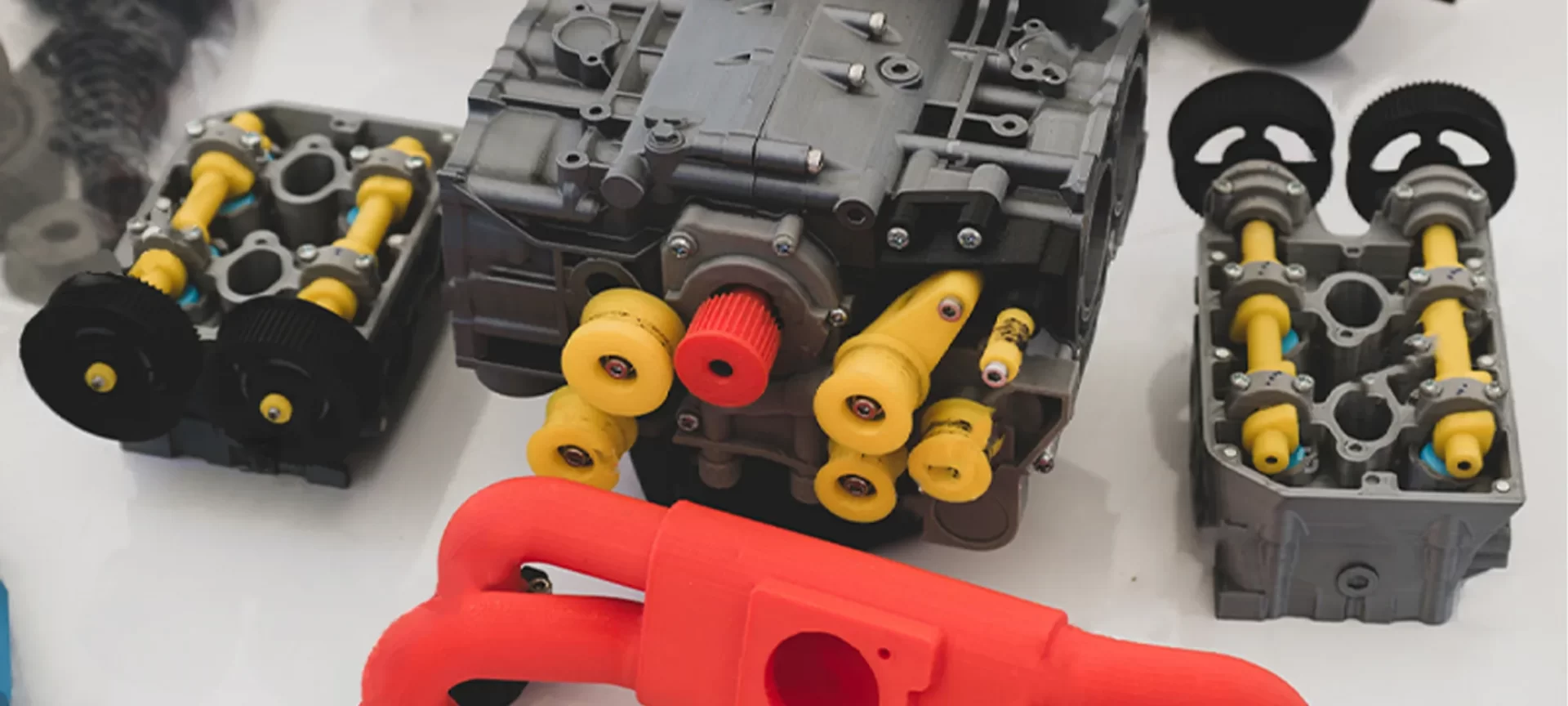

3D printing automotive parts for testing is one most common applications of additive manufacturing within this industry.

One can easily create low-cost FDM parts to test for its functionality with the vehicle. From a wing mirror to the textured dashboard, one can test a variety of parts using 3D printing.

The best part is that the time taken to produce these prototypes is very less as compared to traditional methods.

Plus, 3D printing can provide better accuracy and precision increasing the chances of success with each prototype in the first go itself.

Even if the changes are needed, 3D printing can accomplish it in a matter of time. Just a few changes to the 3D file and the parts are ready for testing again.

Manufacturing of Tooling for Injection Molding

This is where 3D printing makes it clear that there is no better choice than AM. Using the technology, companies can create low-cost rapid tooling required for injection molding.

This pre-production work is very helpful in creating tooling for complex designs for thermoforming and jig and fixtures. This further helps in reducing the overall cost of production.

With low-cost tooling, one can create low to medium runs for actual parts. A lot of great things come handy when you know you are in good hands. 3D printing provides assurance to companies.

Production

3D printing hasn’t been able to impact the long production runs. Usually, the automotive industries go through a huge production scale every year.

And, the size of the 3D printers and the cost associated to buy the industrial 3D printers aren’t always favorable. Plus, the speed of production also comes in the way.

But the 3D printers are well adjusted to the medium-sized production run which is still limited. However, with time, as 3D printing is determined to grow, we will soon find solutions taking over the large-scale productions as well.

Creating Custom Parts

Car and Bike customization is never getting off trend. Either you look 10 years back or foresee the future, a lot of customers find it enthralling to ride a customized car.

With demand, the parts can be customized with a variety of designs. Not just that, industries can also take advantage of the same.

By tailoring the parts to achieve desired changes such as lightweight suspension arm and many other automotive parts can perfect the results of the vehicle far beyond.

What Are The Advantages of 3D Printing Automotive Parts?

Everyone is waiting to drive the fully 3D printed vehicle. The dream isn’t too far though. A lot of companies are already testing their models in the same direction.

In the midst of all this, technology is already making a lot of noise within different processes of the automotive industry. We have already discussed it above and it is time to check why?

With time, the need for 3D printing and its applications are surging. While companies were mainly dependant on prototypes a few years ago, they are now attempting to create a complete 3D printed car.

A lot of progress has spurred in a short period of time. Not just that, consumers are also waiting to see the 3D printed car running on the streets.

All this is because of the various perks that the technology adds to the kitty. The automotive industry is able to enjoy quite a handful of promising benefits.

Accelerated Production Process

This is possible with the use of 3D printers for rapid prototyping. The success of companies depends a lot on the lead time for creating prototypes. The shorter the lead time, the higher the profit.

The production process is wrapped in less time. 3D printing is not only used for prototyping in the automobile but in various niche. It does help to accelerate the entire production process.

Using traditional methods, companies have to wait for weeks or even months to get the prototype for testing. However, with 3D printing, the work can be completed in days or hours.

Not just that, the changes in the prototypes can also be concluded in days’ time. One just needs to tickle the 3D file, and the changes come to life.

In House Prototype Production

Prototypes can be 3D printed using FDM printers. These are easy to handle and are affordable comparatively.

Hence, companies can even own such machines and carry the creation of prototypes inhouse. Hence, further reducing the lead times by eliminating the wait time for delivery of prototypes.

Sometimes, the prototypes are created cross borders. And, even if they could be printed in a few hours of a day, shipping consumes a lot of time.

Plus, the shipping cost adds to the production cost. Using an in-house 3D printer, companies can create their own prototypes and reduce the production cost even further.

Creating Lighter Parts

Car manufacturers keep looking for ways to further go short on their product’s weight. This is because the lighter vehicle eats up less fuel. Plus, it is also environmental-friendly.

By offering better mileage, companies can gain popularity and fame. It is also great to leave the competition behind.

We certainly cannot take away car parts to reduce the weight. Because the car won’t drive and would be useless. But we can always think of optimizing the design of different car parts.

There are companies that are already making use of such an opportunity. Volkswagen already has proved it by redesigned a reinforced A-pillar window support using a 3D printer. This part weighs 74% less as compared to their standard part.

Variety of Material Option

3D printing provides you a plethora of choices for material selection. For the automobile industry as well, the same stays true. Plus, there are better and newer materials being invented every now and then.

These provide great mechanical properties. You have the option to choose from plastics to metal. Depending on your need, you can even go for the materials that provide better resistance to wear and tear or corrosion.

Not just that. There is more to it. As we all know that AM works by creating parts one layer at a time. Hence, the amount of material needed is much less than the subtractive method.

In the subtractive method, the material is cut short to provide it the desired shape and structure. Hence, these lead to wastage of material.

This is not the case with additive manufacturing though. This is not only economically friendly but also safe for keeping nature free from excess waste.

Possibility of Complex Designs

How about creating designs as you please? With traditional methods, you cannot create every design. But with 3D printing, you can.

3D printing automotive parts provide you with the flexibility of playing with the design as you please. You can create complex and difficult geometries without any hassle.

However, you must ensure that the design is functional and following the gravity rule.

Part Consolidation

One most important advantage of 3D printing over conventional methods is its capability to consolidate different parts into one complex component.

This can help reduce the total number of items in an assembly. Hence, the material used would be less as well as the weight will also reduce.

Looking at other aspects, part consolidation would minimize the inventory. Moving on, consolidation of parts would also help counter the problem of maintenance and assembly of different items. Overall, it could be a huge perk for industries if channeled well.

All you need is to think of a 3D design that can assemble the different parts together to form one complex part.

How to 3D Print Car Parts?

As it goes with 3D printing, the parts must be designed before printing. Hence, 3D modeling is the first step towards your goal.

Specifically, there are no applications developed especially for automobile parts. Do not be disappointed. There are many great programs that could help accomplish the job though.

You can try the software that is designed for mechanical and engineering uses. These could help create industrial as well as technical equipment.

These are the apps that industries utilize for 3D printing automotive parts. These are perfect for accelerating your project’s iterations. Moreover, you can even check the simulation and visualization features and find out what the part will look like when printed in real.

Once you design the 3D file, you can feed that to the 3D printer. In case, the 3D printer does not have an inbuilt slicer, you will also have to slice the file with third-party software. This will convert the STL file into G-code. This is when the design becomes ready for printing.

You can use the G-code to print the model. The rest is taken care of by the 3D printer itself. Depending on the need and support structure, you may have to go through a few post-processing steps.

The Conclusion

The automotive industry has a long reputation to serve. From affordable to luxury cars, consumers expect a lot of things from their vendors.

Either it’s the interior comfort, car performance, or the looks of it, one wants to buy a variant that is bang on at every front. And, companies are working harder to stay tuned with the demands of the consumers.

In such a scenario, increased competition is very usual. And, manufacturers can benefit by implementing the revolutionary technology to take care of the task at its best.

3D printing automotive parts could bring a huge difference to the offerings. Automobile manufacturers could make a great profit by reducing the production cost as well as meeting the demand on time.

From customized parts to various other requests, everything could be included with a snap of the finger. And, it is all possible with the help of 3D printing.