Every time someone plans to purchase a 3D printer, the first question that clicks is the cost for 3D printing.

While 3D printing cost differs for different 3D printing processes and the material used for printing, there are certain guidelines that can help reduce the cost significantly.

3D printers are available for as low as $200. However, what about the amount that you would need to invest in using the 3D printer? One must consider every side of the coin before making the final decision.

If you are an expert, you would know what to do to make your designs and prints as cost-effective as possible. However, for beginners, the 3D printing cost may come as a shock, if not properly executed.

There are various do’s and don’ts for those operating 3D printers. Getting to know the right strategies would help in the long run for those looking to build a business over 3D printing. Even those 3D printing for fun can save a lot when 3D printing keeping some specifics in mind.

Many people would question: Is 3D printing expensive? The answer to this lies in the way 3D printing is done. Some can print the same object for less amount and some may invest a lot of money because of a lack of knowledge.

Certainly, 3D printing is easy as compared to other traditional methods of manufacturing, however, using it for the most efficient and cost-effective results could be brainstorming.

Parameters Affecting the 3D Printing Cost

To begin with, let us understand the factors that affect 3D printing costs. There are many parameters which ultimately decide the cost you would be spending on a 3D print.

For example, the material cost, size of the 3D print model, the occupying volume, if the object is solid or hollow, the thickness of the layer, and many others.

So, why not learn about a few of the major parameters affecting cost in detail and how to optimize those.

What Are the Ways to Optimize 3D Printing Cost?

If you are interested in 3D printing, the better way to proceed further is by learning the technology for better optimization of printing costs. If one has the 3D print file, 3D printing using the plug and play 3D printer won’t be a difficult task.

But, would that knowledge be enough to save some extra bucks from your 3D printing?

The answer is ‘NO’. You must learn how to reduce the 3D printing cost or you may end up paying more for the objects you print at home than those available outsides.

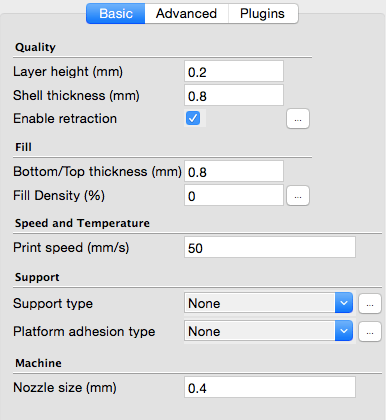

Work on Your 3D Printing Settings a Little More

3D printing can be done in many ways. If you know what are the right settings for your print, you can save yourself from a lot of problems later.

For example, clogged nozzle, failure of the prints and many other challenges that beginners face. You may have to go through some trials and errors, but you would learn as you proceed.

During scaling, there are certain settings related to the design and material. Selecting them wisely will help you succeed in the first go itself. Instead of you spending on filament multiple times to get that one item 3D printed.

You can also access online help available for the print settings. However, your experience matters most. So, learn eventually and start saving on your 3D prints by not investing twice on the same object because of print failure.

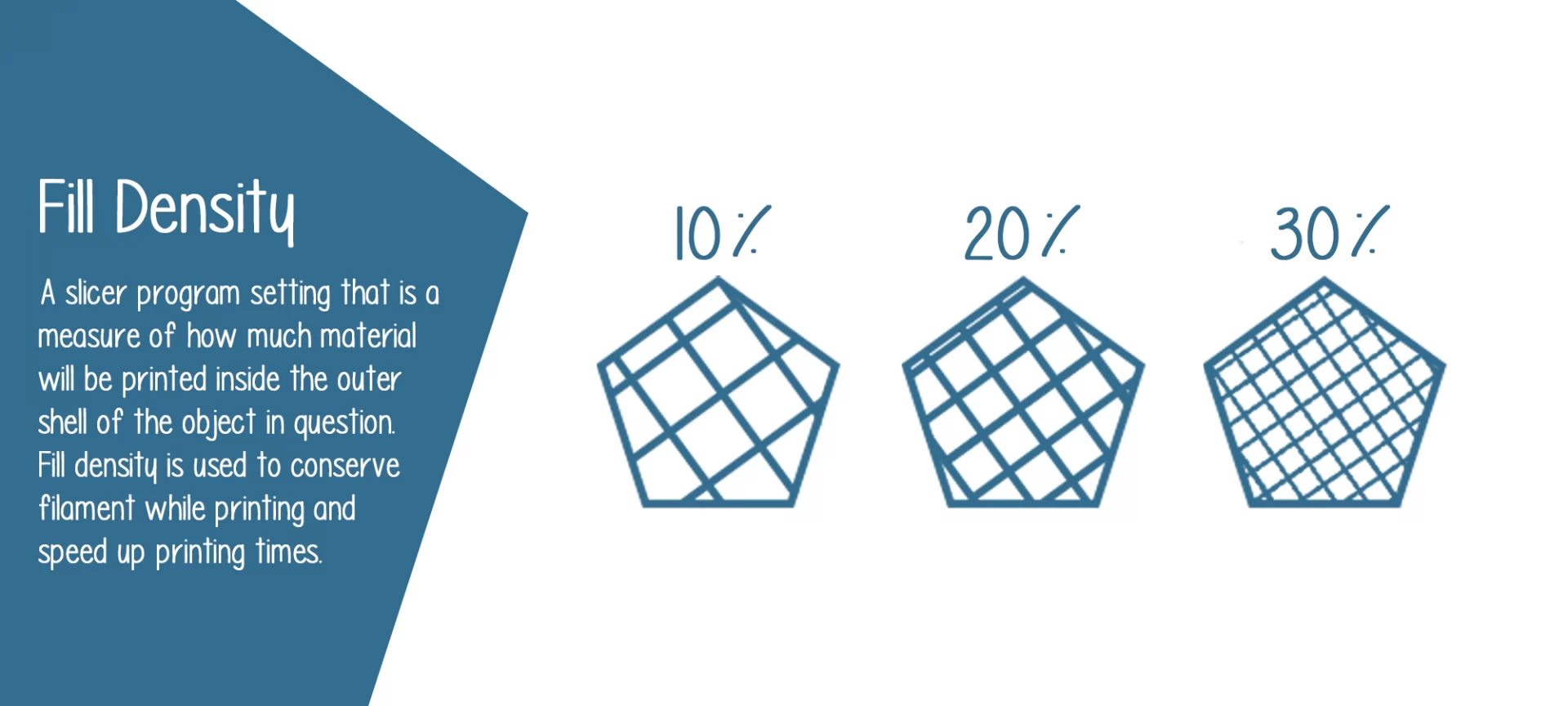

Did You Know Reducing Infill Percentage Help?

You are the master of your products. No one knows your product better than you. So, why not decide when to use the higher infill percentage and when not to.

There would be a certain design that would require you to use a higher infill percentage to meet some mechanical and structural needs. However, why use the same infill percentage for those items that don’t have such requirements?

You not only save a lot of material by reducing the infill percentage but your print is accomplished faster. If your items can be printed without a higher infill percentage, go for it.

Save a little more on these items. It is you who can decide what infill percentage will serve better for which design.

If you think you can go further below, reduce the infill percentage a bit more. If you want to test what infill percentage would suit your design, do that. Few errors can save you from unnecessary long-term expenditure.

Why Not Hollow Your Design?

There are designs that do not require infill at all and work as well as when hollow. Determine which design does not need fillings. However, you must make sure the wall thickness is appropriate as the whole structure will depend on the wall thickness if it’s hollow from the inside.

Every material has its own requirements. For example, if you are 3D printing using plastic, you must maintain wall thickness between 3mm to 1mm.

In case you are using SLS technology for 3D printing, you must add holes for an un-sintered powder to pass through. This way, you may save a lot of 3D printing costs by saving more than 50% of your material cost.

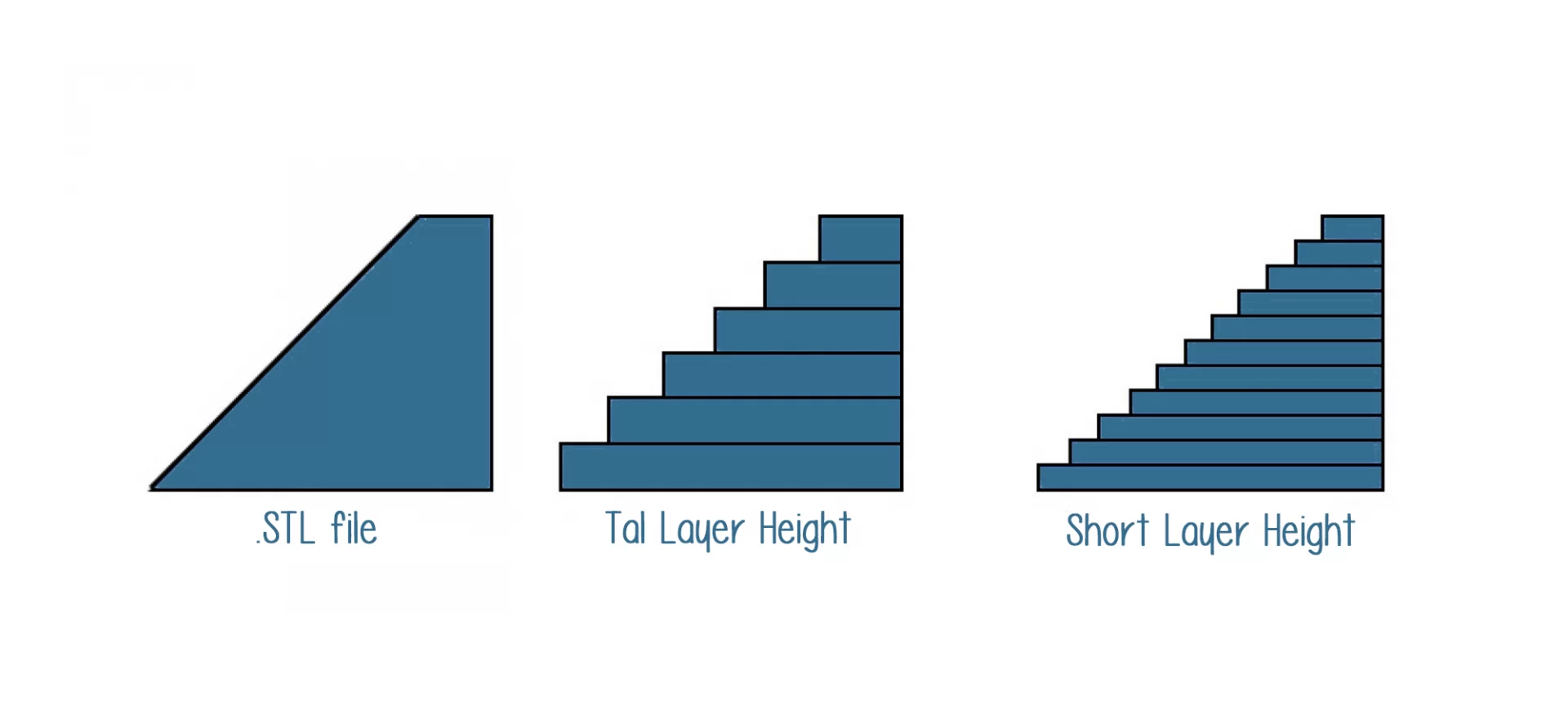

Learn About Layer Height and Resolution

Layer height plays a major role in deciding the resolution and quality of your print. If your layer height is low, your resolution would be high.

Both both parameters are inversely related. If the print quality is secondary, you may not need a lower layer height.

By increasing the height of your layers, you may be effectively able to reduce the 3D printing cost. Also, the objects would be printed faster.

However, the decision must be taken for each item separately. If the design requirement makes print quality a priority, you must stick with the low layer height. When not needed, play around with the layer height for reducing the cost of 3D printing.

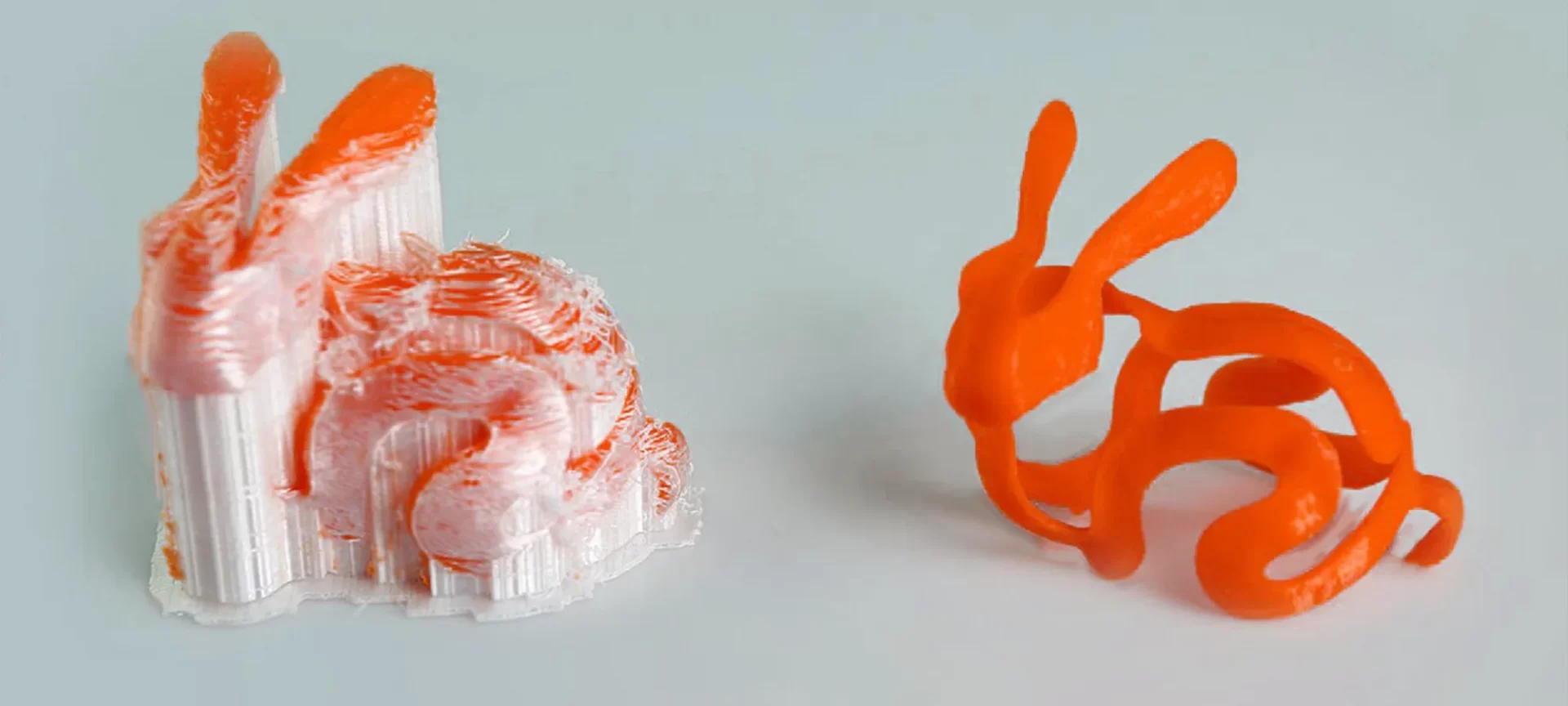

Optimize the Design for Less or No Support Structure

Do you know that most of the designs can be printed without a support structure? A lot of beginners are not aware of this fact and invest unnecessary material and time while printing items with the support that do not require it at all.

Support not only increases the cost and time for printing, but it also leads to plastic waste and post-processing requirements.

Hence, optimize the design for reducing the support requirement. By using the slicing software, one can orient the design or find ways to shorten the need for support.

Some designs may require support for printing. But, those that do not, always go with the most optimized design for less requirement of a support structure.

You can save a lot of money by saving material and time. This tip would be highly beneficial in making your 3D printing projects highly successful.

Moreover, no support means smoother designs. The surface finish with no support is better and cleaner than the ones with support.

Modify an Existing Design

If you are not an expert with CAD files and 3D designs, do not worry. Instead of paying someone else to design the file, why not use the existing ones. There are thousands of amazing designs available for 3D printing.

Either you can print the same one or modify it to get your own design. If you know the basics of CAD software which is easy to use, you can modify the designs by a few changes and can get your own design in no time.

There are plenty of things you can do if you learn CAD software. Instead of paying a designer to bring your imagination on 3D prints, why not learn once and use it forever.

You can reduce a lot of 3D printing costs if you know how to work with 3D printing design software and application.

Use the Free Design Software

There are many free designing applications available online. There are paid versions too available. If your work can be completed using these free applications, why to pay the subscription for the paid ones.

The free applications are also great to start with. You can try more than one software and decide which one gets you the best result. Or which one is easy for you to use. All these things can be easily assessed using free applications.

Using these free applications, you can save on a monthly or yearly subscription and optimize your 3D printing cost, a little if not much.

There are free programs such as TinkerCAD that can help you become a master of 3D designing. So, use these free applications and services to make your designs all by yourself, instead of using a copied one.

Why 3D Print the Entire Object?

Sometimes, by printing some part of the object and using an existing part, one can build the entire object. If that is a possibility, why not go with that option. You can definitely be able to save money and time on such projects.

Know Which Material Will Save you Money?

You must be aware of which material will be the best for your designs. There is a variety of printing materials available in the market.

If you are not sure which one to use, you may end up paying for the expensive material and won’t even get the results you are looking for.

Even the same material price can differ with different providers. Within plastic materials, the price range for PLA and ABS differs quite notably. Choosing the cheaper material would certainly put some relief on your 3D printing cost. However, you must know which material would suffice your design as well.

Keeping both things in mind, you can choose the one meeting your needs. The rule does not only apply to desktop printers but also to those using industrial printers too.

Although the cost of materials such as metals is higher, knowing which one would be economical will help save a few bucks.

Taking Care of Filament Storage

By securely packaging your filament, you will ensure that not even an inch of your filament is wasted. This will help save money on the excess of material needed for your 3D printing jobs.

Especially with desktop printers, filament storage is a huge concern. There are systems available in the market for keeping your spool safe, however, they are pretty expensive. Instead, why not use vacuum bags to store your filaments.

Using these bags, you can easily get rid of the air inside the bag and help your filament stay perfect for long. Otherwise, you may find bubbles on your filament or filament becoming brittle when contacted with air.

Hence, you will spend less money on the filament. Although a lot of 3D printing beginners do not understand the worth of saving filaments until they have incurred huge losses, you can start securing your filament right from start.

Even the cheapest PLA has some cost attached to it. If not taken care of, it could lead to unnecessary spending. So, why not control it instead of wasting money uselessly.

The Conclusion

There has been huge success achieved after the introduction of 3D printing within various industries. Experts stress learning about the technology deeply to ensure you do not lose money unnecessarily.

3D printing is one thing and using it economically is another. If you are not able to utilize your learning to 3D print economically, you would ultimately be wasting money.

Don’t you have the same take on this? If you are the one losing money because of mismanagement of your 3D printing techniques, you would know the worth. Instead of asking questions like ‘is 3D printing expensive’, why not stress on learning the right strategies and techniques of 3D printing.

The technology has a lot in store. By only optimizing the 3D printing cost, you can make a huge difference to the entire routine. If your business isn’t able to turn the benefit of the technology into profit, you must be doing something wrong.

And, if cost optimization is the problem, start over with these strategies. The changes would be noticeable sooner.