By far, FDM has been the most popular 3D printing process because of its accessibility and ease of use. FDM 3D Printers work on various filaments, and Polylactic Acid (PLA) being one of them.

It is not only the cheapest known material for 3D printing, but it also is easy to manage. That is why PLA 3D Printing is way more widespread than various other counterparts.

There are many reasons why the material is so common among makers and enthusiasts. As well as, plenty of perks why PLA is also chosen for creating prototypes.

While there are many advantages of printing with this filament, there are certain limitations that restrict the utilization of the material for more specialized jobs.

However, that does not minimize the benefits it is capable of providing. The 3D Printer based on PLA materials is affordable, space-friendly, and comparatively easy to work with. And, if you are also looking to find more details of how it is like to work with a PLA 3D printer, you are at the right place.

The article below describes the many ups and downs of the technology that together has brought PLA 3D printing to such heights.

It is the most used and preferred material among home users. And, many professionals also dig into its perks to find more sustainable solutions that stay affordable too.

What is PLA 3D Printing?

Do not be surprised, this isn’t anything new. It’s the FDM 3D printing that is done using PLA material. We have been witnessing so many changes and developments in the industry. Many processes designed and recreated to offer users a balance of quality and affordability.

In midst of all this, one technology that has not faded among the many new advancements is the PLA 3D printing. And, for obvious reasons. It isn’t some fancy technology costing you an arm.

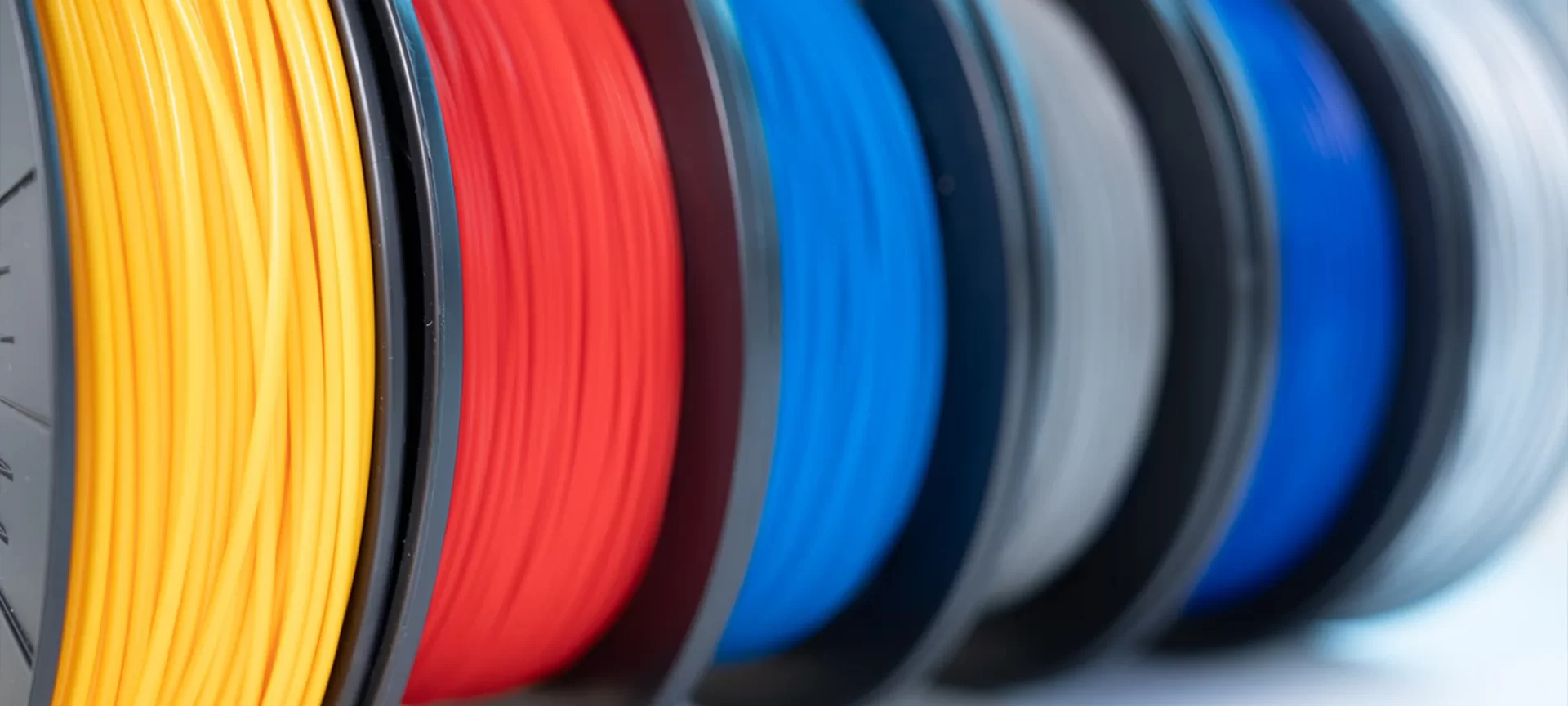

On the contrary, it is reasonable in pricing and easy to 3D print. And, not to forget, the material is available in plenty of colors and combinations with other materials.

Hence, providing its users with huge options. You are not limited to printing with white, black, and clear material as it is the case with resin 3D printing.

However, you can choose plenty of colors and textures. How about some color-changing PLA material? We do have that option too (discussed later in the article).

Among all this, the PLA 3D printers are also readily available. You can even print in two different colors when working with PLA with the help of dual extruder FDM 3D printers.

If we start pointing the good things about PLA, the list will go on. So, let’s keep our discussion brief and explore as much as you can.

How do I Print PLA?

As much as, the material is concerned, PLA has found its own set of reasons for being the most used filament today. If you have a well-calibrated FDM 3D Printer, other settings could go a little bit here and there.

Unlike ABS, Nylon, and other materials that need precise settings for successful printing, PLA can work with minimal efforts. It is very flexible to print with PLA being not very concerned about the temperature and other values.

Some 3D Printers even come with PLA print profiles. That means the settings would already be there. If not, you can verify the same and make the changes needed. Here is what the usual settings would look like.

The Required Print Head Temperature – 190 degrees Celsius to 220 degrees Celsius

Print Bed Temperature – You can print PLA without a heated bed. However, if you do have a heated print plate, you can use a setting between 50 degrees Celsius to 70 degrees Celsius.

If your 3D printer has been set within these flexible settings, the rate of success when printing with PLA is highest.

Post Processing Requirements

Now that you have created a model using the PLA 3D printing process, it is time to find out the post-processing requirements.

Post-processing includes two steps. One is for removing support. And, another is for adding colors or providing the desired finish to your parts.

Support Removal

There are a number of methods for removing support. You can take away supports with the help of drilling and sanding paper. You can even make use of filing and tapping.

However, ensure that you do not cross the temperature requirement. Or else, you will end up softening the PLA material, leading to the crashing of your 3D model. The parts will easily deform.

Hence, there is certain caution that you must follow when carrying post-processing steps. To start with, you can keep a watch on the tools if getting heated when in consistent contact with the surface of the model.

While filing, drilling, sanding, or tapping, take breaks in between to let the tools cool down. Instead of using dry sanding tricks, use wet sanding. This can be done by wetting the sandpaper. This will prevent the tool from getting overheated.

Sanding can also be used for surface smoothening. In case, you wish to add layers of coating, you must go with sanding as the initial step of the process. There are options available for chemical smoothening. However, this will require an experienced hand.

Finishing of the Parts

This is the easiest part. Either you need to glue different parts together or want to paint it, you won’t require to invest much effort.

The best part is that the spray paints and acrylic colors work best with almost every print. In addition, additives such as super glue will do the trick.

When to Use PLA 3D Printing?

When lurking at the benefits of PLA, we find the material to be highly incredible in terms of printability. And, the versatile character of the filament adds to its desirability.

So, if you are thinking of choosing PLA 3D printing, here are the reasons you must go for it.

Easiest Filament to Tame

You can read it almost every article concerning PLA that the material is the most chosen option for beginners. There has to be a reason for it. And, there is. Not one but many. PLA is simple to tame.

Those who are not very experienced in handling the varying temperature requirements must choose PLA. The material is a bit flexible in terms of working along with differing values from what is called the perfect print settings.

Also, PLA is less susceptible to warping. Those who do not know, warping is one of the most frustrating 3D Printing challenges user faces when 3D printing.

However, with PLA, you do not have to worry much about a closed frame of a consistent temperature availability for processing the prints.

Most of all, there are no foul odors when using PLA for printing models. You can easily work around the machine with minimum ventilation requirements. That is also one of the reasons why PLA 3D printing is popular among home users.

For Models Where Aesthetic Matters

As mentioned above, PLA is available in different colors and blends providing users with plenty of options. In addition to that, the material produces great print quality.

You can use the material for various models and print jobs. Being able to add a more vibrant feel to the resulted prints.

For Lighter Prototypes

Many uprights would tell you that PLA is not for practical applications. However, this isn’t completely true. While there are certain limitations that make PLA unfit for many functional prototypes, there are quite a few jobs that PLA can serve well.

To start with, PLA offers sufficient strength to satisfy the requirements for light prototypes as well as 3D models.

To further work on achieving its improved performance, users can also make use of various blends that add to the durability of the material.

These blends could even provide stronger and more durable results that ABS, a popular filament for functional prototypes.

Hence, until and unless you are creating a prototype that needs to sustain high stress and load, you are good to go with PLA.

Wish to Carry Environmentally Friendly 3D Printing

The good news is that you can contribute to the green planet by making use of PLA for 3D printing. This is because the material is made out of plant matter.

Hence, it is biodegradable. But do not worry, the biodegradability isn’t too strong. The 3D printed parts are safe inside the usual room conditions.

Looking for a Variety of Options?

The most important factor making PLA the most desirable filament is its affordability coupled with a variety of options.

Not just that, the material price is also highly varying, giving users cheaper options to look for. For instance, you can order a spool is $20.

For blends and other variants, there are spools available for $50 or more. You can choose to print with the metal blend, wood blend, and a lot of other options.

In other words, you can find a choice with PLA 3D Printing for every application.

Limitation of PLA

We have already talked about many perks that the filament provides. However, none of the material available in perfect.

With all the many benefits, there are few drawbacks that tag along with these materials. Although PLA is the most used material, it is not different from others in terms of carrying a few limitations.

Hence, here is a list of a few of the challenges that user face when trying to print with PLA.

Poor Temperature Resistance

We do have many blends for PLA. But almost all of these would start softening when the temperature goes beyond 50 or 60 degrees Celsius.

This makes the filament for the best choice for prints that are meant for outdoor use. For instance, the garden equipment won’t be able to withstand the heat and would degrade over time.

On the other hand, inside applications also need to be chosen with care when using PLA 3D printing. You cannot expect a PLA printed jar to withstand hot and boiling water. Likewise, you must select the applications wisely.

Degrade Over Time

As mentioned before, PLA is a biodegradable material. This means that the filament would degrade with passing time when exposed to an extreme environment.

You won’t be able to notice the change when using the PLA printed parts inside of your home. However, if you are planning for a model to keep outside of your house, the degradation will be pretty soon. For such applications, ABS, or PETG is a better choice.

Not for Food Storage

While there are few variants that are considered food safe, most of the PLA materials aren’t designed for carrying foodstuffs. The material, in its purest form, is safe. But with added pigmentation, the properties soon change.

And, even those blends that are considered food safe are susceptible to bacteria build-up. So, you must think twice when 3D printing a kitchen bowl with PLA.

The Conclusion

Learning to work with PLA could help you achieve a variety of results. This is why, even being sensitive to heat, the material has found its sweet spot among the makers and enthusiasts.

You can depend on this filament for various tasks. And, if printed with care, you will be astonished by what comes forward.

3D printing has been proving its worth at every step. Gradually, the technology’s popularity is shifting from industries to households.

This is a huge leap and the progress still keeps on surging. Among all the major 3D printing technologies, PLA 3D printing has made remarkable advancements in winning the hearts of end-users.

Not only small industries and companies, but even the home users are also welcoming the 3D printing technology for various smaller and bigger projects. And, it seems to be getting even stronger with time.

If you feel worried about the various challenges 3D printing would pose on you as a beginner, it is safer to go with PLA 3D printers. If that rings some bells, check the information above, and decide what fits your need.