Do you also believe that choosing the right nozzle is a tedious job? A lot of beginners often struggle to find the right match for the job they wish to accomplish through 3D printing.

Apart from depending on the material in use for printing, the decision also changes with varying nozzle diameter. So, let us check out the ways to choose the right 3D printer nozzle as well as the best 3D printer nozzle you can find in the market currently.

The article will help you find out the specific 3D printer extruder nozzle that would suit your specific 3D printing goal.

Also, it aims at suggesting some of the best makes you can pick from. Depending on your preferences, you can choose the one that makes your job precise and simpler.

What Are The Factors to Consider When Choosing the Best 3D Printer Nozzle?

Before we jump into the recommendations, let us have a brief idea of how to classify our requirements. When it comes to installing a nozzle, you must check two important factors: The output diameter of the nozzle as well as the material it is made of.

Output Diameter of Nozzle

Depending on how precise you wish your layers to be, you can pick the one with a smaller output diameter. The smaller the diameter, the intricate are the details.

However, the smaller nozzle would eat up more time during 3D printing as less amount of material will be extruded at one time.

On the other hand, if you can compromise with the intricate details a little, but wish to accomplish the job faster, you must consider the larger nozzle diameter.

For your input, the nozzle is available in different diameter sizes. Starting from 0.1mm to 1.0mm, there are many variations in between.

Material of Nozzle

The next thing is the material of the nozzle. This again is the base to find out what you need to pick. The nozzles are typically made of 4 different materials.

The first and most common one is the brass. It is great in terms of high thermal conductivity and provides great stability. The maintenance isn’t too high as well. But it cannot work properly with abrasive materials.

The next one is hardened Steel. This is an alternative to the brass nozzle when you need to work continuously with abrasive material.

It provides 10 times better resistance to wear and tear from abrasive materials. The problem is, you cannot use the nozzle when printing models to store food or skin related products. This is because they contain lead.

You can also use Stainless steel nozzle. These are much better in terms of safety as they are FDA approved.

These may not be as resistant as hardened steel for use of abrasive materials but can take that load significantly. Above all, you have the special nozzles with ruby tip.

This one is the best for precision as well as for maintaining a stable temperature. But are very costly and not affordable for all.

How to Select the Best 3D Printer Nozzle?

The need for 3D printing is what creates a difference in the selection of the best 3D printer nozzle. The one that suits you may not be an effective choice for others and vice versa.

Hence, you must assess your 3D printing goals before selecting the 3D printer extruder nozzle.

If you wish to use conventional materials or the standard ones, you can go with an intermediate size diameter nozzle made of brass. A 0.40 mm nozzle will do the job.

For achieving higher precision and intricate details, you can switch to Brass Nozzle with 0.25 mm. In the case of faster prints, you can select the Brass Nozzle 0.8 mm.

In case, you wish to 3D print with abrasive materials that contain fibers, a Hardened Steel Nozzle with a 0.50 mm diameter will be the best selection.

When printing with abrasive materials, avoid using small nozzle diameters. This would prevent the clogging of the nozzle. Do not use the nozzle for printing food containers or products that would be in contact with the skin.

To 3D print FDA approved materials, you can make use of Stainless Steel Nozzle with 0.40 mm. Once again, if your requirement is to print highly precise models, you must choose a smaller nozzle diameter of 0.25 mm. If the requirements are to get the fast print results, you can go with a 0.8 mm Stainless Steel Nozzle.

Does Nozzle Size Affect The Layer Height?

Do you know that difference in layer height of the 3D models can create huge changes in your resulting models? This would help you stay balanced when selecting the resolution of the print and the speed at which the print completes.

By using the thumb rule, you must set the layer height not more than 80 % of the nozzle output diameter. Hence, as we go down the nozzle diameter size, we are able to achieve higher precision. And hence, better surface finish. However, these prints take longer to accomplish.

If you can at all compromise with the intricate details, not much but a little bit, you can go for a larger nozzle.

Recommendation for Best 3D Printer Nozzle

Now that you know what to choose, here are few makes of best 3D printer nozzles that are popular and used widely across the 3D printing professionals’ community.

E3D V6

Who does not know about the all-metal hot end, E3D V6? This is one of the most popular selections among 3D printing professionals.

It very reliable and has proven its capabilities at all times. It can create high-quality prints using a wide range of filaments.

The number is huge when it comes to finding those using this particular hot end. And, the reasons are obvious. It actually caters to most of the requirements of a 3D printing professional.

The biggest reason for its reliability is the way its parts are expanding and including whatever it can. You can get the smaller nozzle diameter of 0.15 mm as well as larger ones.

They also come into standard brass nozzles designs as well as nickel-plated. The other variants are tool-steel Nozzle X, WS2-coated, and much more.

The range of different nozzles offered by E3D is huge. It can fall in place to almost every use case. In other words, you can find a nozzle for specific temperature ranges and types of filament being used.

In short, the nozzle is for everyone. You can certainly find the type of nozzle you are looking for with the E3D V6.

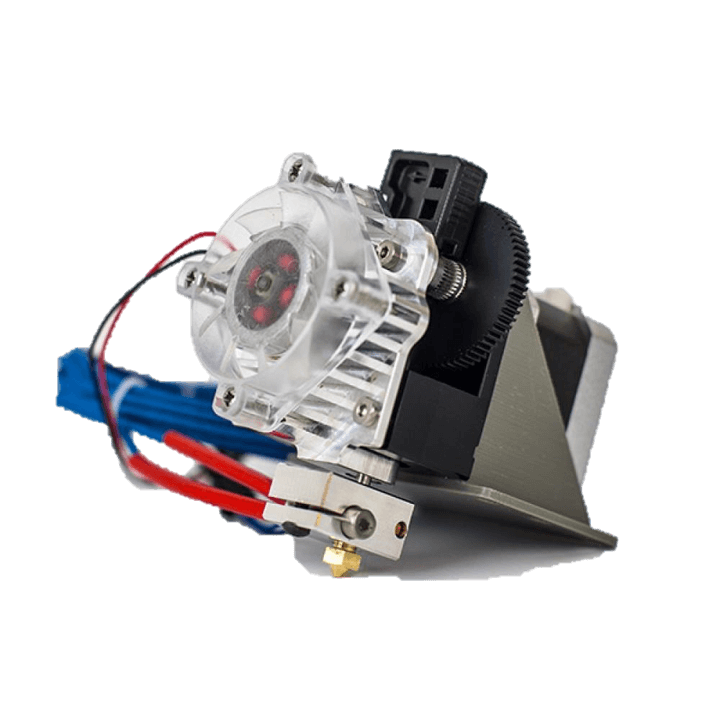

E3D Titan Aero

E3D very well knows how to impress the 3D printing community through its unmatched offerings. Hence, we have another one on the list from the same company.

The only difference is that it is about the Titan Aero and not V6. As the name suggests, the hot end is more like a combination of E3D V6 hot end with Titan extruder. This is a highly compact variation with amazing assembly to compensate for direct-drive 3D printers.

In this design, the company makes use of the Titan extruder set and connects the direct heatsink. Hence, completely taking away the need for maintaining any source of the external heatsink.

The benefit of this assembly is that the design comes down to a very shortened direct-drive assembly. Hence, the filament can go straight into the heater block, apart from traveling through different unnecessary parts.

So, how does this help? When working with high-speed printing, where wooble induction is common due to quick acceleration, this design helps a lot. However, the addition of heatsink directly to the extruder design does add extra weight to the overall mass.

The best part is that the nozzle is completely customizable and can match your goals and budget at the same time, providing you with the ultimate hot end design to print with.

Installation of the nozzle is also kept simpler to provide users the best 3D printing experience as well. This may be considered as the tiniest of all extruder hot end. But does deserve to stay in the list of best 3D printer nozzles.

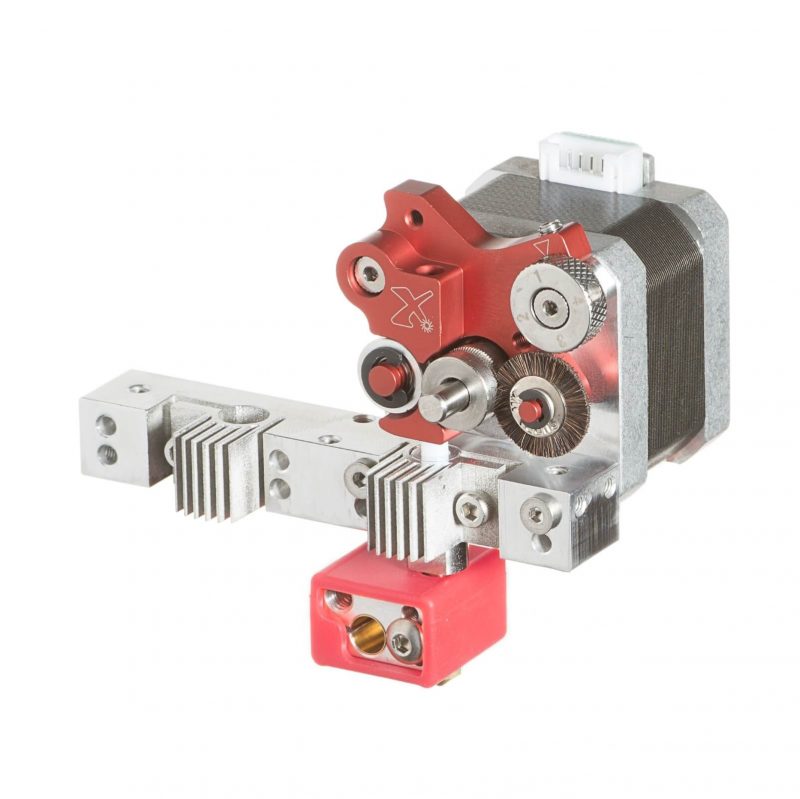

Slice Engineering Mosquito

You can expect this new addition the family of hot end offers to be the most versatile ones in the selection of the design for its nozzle.

It has come up with a successful design that instead of using a heat sink latched to a heater block, takes everything too seriously and makes use of a sturdy metal frame to accomplish the job with an edge.

You can just count on the number of advantages the change of design provides. It enhances the thermal performance of the machine.

Plus, one can easily switch to a copper heatsink that is more effective instead of continuing with the large aluminum heatsink. Hence, there is no need for carrying the mechanical load. Hence, one can get rid of heat creep in a more efficient way than ever.

Not just that, the mounting isn’t difficult too. The heater block can be connected to the frame directly. This is the reason why the process of mounting seems so easy and hassle-free.

How about changing your nozzle with one hand? Not used to it, don’t worry. This choice would help you do that too.

Moreover, this one here is compatible with the entire range of products offered by E3D. And, you also get to check their Vanadium nozzles which again are very competitive.

You can actually get a plug and play nozzle, easy to install without compromising on the quality. It helps you print great quality models as well as make it easier for you to handle the entire extruder assembly. Isn’t that too much to offer?

Diabase Flexion Extruder

If you constantly work with flexible filaments, you must have found it difficult to tame through most of the popular nozzles.

These actually are very stubborn to perform as desired. But no worries. You can use the Flexion Extruder to print flexibles as awesome as you print with standard filaments.

The nozzle is from the same company that got us Ninjaflex filament. They have figured it out in the best way possible to tackle the flexible filaments with ease. And, at the same time, printing with these materials at a considerate print speed.

To make this possible, Flexion has made use of a restricted filament path. This further helps in avoiding giving any excess room to the flexibles. Hence, they do not squeeze while continuing through the path that offers the very least resistance.

In addition, the company has used micro-teeth in the feeder for getting a better grip of the flexibles. It also contains a replaceable wire brush. This helps in clearing out the teeth of the constantly to make sure that the grip isn’t lost at any instant.

You can expect to experience 70-mm/sprint speed when using the nozzle diameter of 0.4 mm with 0.2 mm layer height settings. The speed is good enough for working with flexible materials, isn’t it?

The Conclusion

No need to rush. If you want to choose the nozzle that does the task efficiently, you must go through the factors and recommendations listed in the article above.

Nozzle selection plays a crucial role in getting your 3D prints better in terms of speed and quality. You cannot just fix and mount any nozzle that comes your way. Look for the right parameters and they would direct you towards the right nozzle.

Most of the options available in the market may promise you the entire world. But not each of these hot ends would work as expected.

You must always look for the make that is reliable. Apart from the type of nozzle you wish to buy, you should also concentrate on getting it from the best company. Or else, you may end up with a damaged nozzle only after few 3D prints.

Hence, select the best 3D printer nozzle that sets your prints apart from others. And, never forget to keep learning as you advance to the next expertise level. Find out what works out best for you and stick to that.