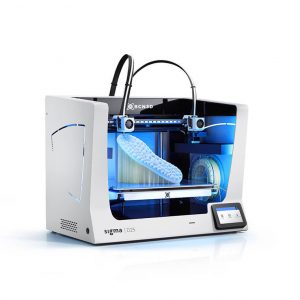

Markforged X7 3D Printer

A continuous Carbon Fiber reinforced part can be made available in hours using X7 and they are capable of replacing machined Aluminum. These parts can have characteristics such as flame resistant, chemical resistant, energy absorbent, high resolution, draft parts, etc. The printer has an industrial material mode capable of fabricating a part for you.

Markforged X7 offers micron-level laser scanning for closed-loop calibration that reliably yields parts with 50 micrometers repeatability and industry-leading surface finishes. You can print with eight different materials to produce parts having different quality. The printer features a reinforced, precision machined gantry and a precision ground print bed that, at times can be removed and replaced with 10 micrometers of repeatability.

There are out of material sensors placed inside the printer that notifies you about the amount of material. Scanning lasers on the print head enables the printer to vibrantly adjust the very first layers of your print for achieving perfect bed adhesion and inspect parts for accurate printing. The printer features a 3rd generation fiber reinforcement system that enables you to lay down continuous fiber into objects. This is something only Markforged printers are capable of doing and no other company printers. The printer is home to advanced hardware, electronics, and software designed to give you a seamless user experience.

Specification: Markforged X7 3D Printer

|

- It lets you continuously print carbon fiber.

- Printing with a varied range of materials is possible.

- Huge build volume.

- Advanced hardware and software to give you a seamless user experience.

- Post-processing of the parts and functional prototypes printed with the printer is difficult because of the closed print chamber.