3D Printers

Filter

Showing 1–30 of 285 results

PROS:

- Affordable;Assembled

- A great choice for those wanting to try 3D printing for fun

- Supports multiple materials

- Allows the use of open source slicing apps

CONS:

- Not very accurate and precise

- Non-heated bed

- Open frame design

- Weak motors

PROS:

- Modularity for a Scalable Factory Solution.

- Uniform, Repeatable Quality

- Metal 3D Printing with Lower Part Costs

- High Productivity

- Seamless Large Parts

CONS:

- Cost may be an issue for most of the people willing to buy this 3D printer.

PROS:

- Fab Pro 1000 can produce parts in hours, which other printers take days to produce.

- The materials that you can print using Fab Pro 1000 are a very wide range.

- From start to finish the print process is very simple.;3D Sprint, the slicing software of this printer is very helpful and user-friendly when in use.

- According to the claims made by its company, Fab Pro 1000 produces parts at a 22% lower cost.

- The post-processing of this printer is very easy.

CONS:

- Overall operating the printer could be a little bit difficult if the setup hasn’t been done properly.

- There are reviews available online in which users complain about how complex is Fab Pro 1000 until the first successful printing.

PROS:

- Easy to operate

- Highly accurate and precise parts

- Affordable

- Compatible with almost 30 different resins

- 4 times faster than its competitors

CONS:

- Small build space

- Closed material system

PROS:

- Easy changing of materials.

- Single source solution.

- Ease of use because of integration.

- Good quality parts and functional prototypes

- Integrated management system.

- Large-scale application of parts and functional prototypes.

CONS:

- The cost of this printer is something not everyone can afford. So, one needs to see a long-term future in the 3D printing industry before buying this printer.

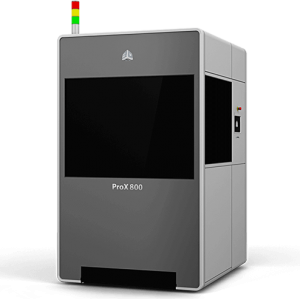

PROS:

- Huge build volume.

- High-quality parts and functional prototypes.

- Great print speed.

CONS:

- The cost of printing per part is greater.

- Resins are expensive.

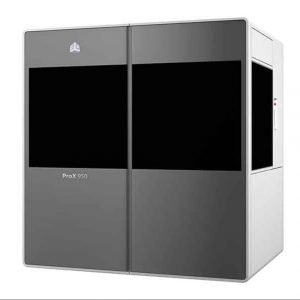

PROS:

- Big build volume

- High accuracy of parts and functional prototypes

- Cleaner and safer printing environments

- Integrated solution for manufacturing parts and functional prototypes

- Builds objects that can be used in various industries

- Conformal Cooling

- Large tool inserts

CONS:

- By mentioning the features of this printer in a little more detail would have done tons of good in explaining the printer, rather than just plainly stating the claims

- The printer is very expensive and is hardly affordable for someone who runs a small business

- The overall printing cost per part on this printer, when compared with other printers in the same price range but built on a different technology is higher

3DCeram C3600 Ultimate

C3600 Ultimate is an industrial-grade 3D printer based on the Stereolithography technique of 3D printing which comes with a free link support technology at a reduced price per part is available on there. PROS:

- Bigger build volume.

- Reduced cleaning time.

- Good speed.

CONS:

- Expensive in cost.

PROS:

- Enclosed print chamber.

- Material flow control system.

- Enclosure.

- Open material base.

- Dual swappable hotends.

- Autocalibration.

- Water-soluble support.

CONS:

- Clogging and oozing are the two main problems reported with the printer.

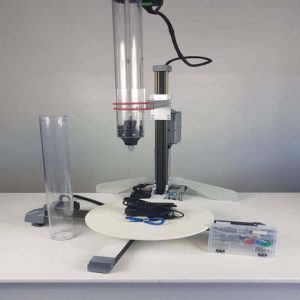

PROS:

- Real clay in use.

- Direct extrusion of raw material.

CONS:

- The cost of the printer might be an issue for some people.

PROS:

- The printer has an open design, so there is a lesser issue while post-processing.

- The company uses real clay in making and also offers factory-made clay for you to use.

CONS:

- The printer is a little on the expensive side.

PROS:

- Cooling a part or prototype that is printed using this printer won't be much of a problem because of its open design.

- Post-processing of parts and functional prototypes will be easier.

CONS:

- Because of open design, temperature generation is a big issue. And it may lead to higher print times.

PROS:

- Open design.

- Post-processing is easy.

CONS:

- Temperature generation is an issue.

PROS:

- Scara V4 has an open design, so there is a lesser issue while post-processing.

- The company uses real clay in making and also offers it to its customers. This is a factory-made clay for you to use so that increases the overall quality of parts and prototypes manufactured by it.

CONS:

- The printer is a little on the expensive side. So, if you are a small business owner you may not find it as affordable as you may other printers.

PROS:

- The cooling of the printer won't be much of a problem.

- Post-processing of parts and functional prototypes will be easier.

CONS:

- Because of open design, temperature generation is a big issue.

- Print time is more than that taken by a printer with an enclosed design.

PROS:

- By displaying complete information about the technology, the company has given the complete idea to its users to compare with other technologies out in the market.

- You can print with powder as well as with wire using Additec uPrinter.

- The company gives you an option to customize your printer to your needs, in terms of an upgrade.

CONS:

- There are not many pictures of parts or functional prototypes that are manufactured using this printer.

PROS:

- You can produce large components.

- Quickly switch materials.

- You can custom your needs.

- The machine has increased efficiency.

CONS:

- For those who haven’t used DLP printing technology, the cost of this printer may seem very high.

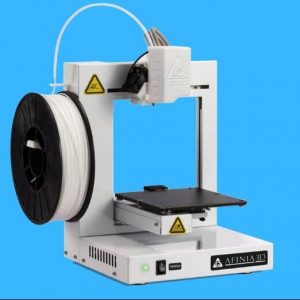

PROS:

- The printer has an open platform.

- Its price is affordable.

- Afinia H480 is a good entry-level DIY printer.

- This printer is portable and relatively lightweight.

CONS:

- Printing with this printer requires patience.

- IT has a smaller build area compared to the price at which it comes.

PROS:

- Matrix touchscreen.

- Air cleaning system.

- Thermal management.

- Build size.

- Multi-material printing.

- Water solubility support compatible.

- Auto-leveling.

CONS:

- Weight of the printer.

- The exclusivity of the software.

PROS:

- Anet A8 makes up for a very affordable 3D printer kit.

- It is a capable 3D printer if compared with other 3D printers in the same price range.

- You can modify Anet A8 in the future.

- There are many enhancements available with Anet A8 in the future.

- The printer can provide you a great learning experience about FDM 3D printing.

CONS:

- The assembly instructions of this printer lack luster.

- The user interface of this printer is not as smooth as others.

- Manual calibration is something that can be a pain.

- The printer is not aesthetically pleasing.

PROS:

- Automatic bed leveling frees you from time-consuming and labor-intensive leveling tasks.

- Power outage recovery lets you resume printing and recover from exactly where it left off. No worries about unexpected power outages.

- Automatic filament assignment permits you to automatically load and unload the filament with just a click.

- An all-metal frame is built to last with high strength aluminum frame. Enclosed metal unibody design enables a more stable and rigid structure with compact size.

CONS:

- The print quality of Anet ET4 is not reported up to the mark and can be a lot better considering the price range at which it is offered in the market.

- The printer’s open body is a little bit of an issue when it comes to 3D printing with filaments that require it to withstand higher temperatures.

PROS:

- Overall, the cabling and general appearance of this printer are neat and tidy. There is a drag chain housing that consists of a thermistor, temperature probe, both fans and leveling probe cables, all these things are organized and the only projection from the hot end being the PTFE filament guide tube

- The Anycubic Chiron brings particular delight with its large build area of 400 x 400 x 450mm

CONS:

- Notable is the fact that while unwinding this printer there are reports of screw falling out will the tapes that you try to remove to unwrap the printer

- This printer does not give you the best start, considering the included quality control card has a huge “Pass” stamp

PROS:

- The print quality is amazing

- Works great with PLA

- Affordable

- Great customer support

- Various upgrades available

CONS:

- It's difficult to level the bed

- No automatic leveling

- No wifi support

PROS:

- Highly affordable

- Easy to work with and setup

- The reliable 3D printer at a cheaper cost

- High-quality prints

- Easy to level the 3D printer

- Compatible with third-party filament

CONS:

- The firmware is a little confusing

- Non-heated bed

PROS:

- Fast heating bed speeds up the entire printing process.

- Large leveling knobs for a better user experience.

- Large build volume.

- Metal frame for stability.

- Resume from the power outage.

- Double Gear Extrusion.

- Quick Assembly.

- Magnetic printing bed.

CONS:

- Open body meaning temperature maintenance would be a problem.

- Safety issues while printing from home.

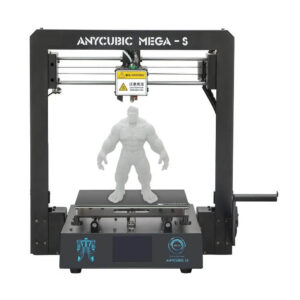

PROS:

- Delivers good print results.

- Quick to assemble, no previous experience needed.

- Continued 3D printing even after power interruption.

- The print bed heats up quickly.

- Low error rate.

- Relatively fast print speeds.

CONS:

- The filament holder’s position is unfavorable.

- The printer is relatively loud during printing.

- Printing with metal PLA is not possible with Mega S.

- High power consumption.

PROS:

- Has amazing print quality for the price

- It is easy to use and set up

CONS:

- Manual bed leveling can be a hassle

- The printer has flimsy housing

- You cannot connect with this printer using any kind of network/internet connectivity

PROS:

- Available at a very affordable cost.

- Comes with a single screw leveling that decreases human effort like no other.

- Low resolution of the printer is covered to a considerable extent with the printer’s Anti-aliasing technology.

- Low power consumption.

- Quick FEP replacement.

- Equipped with important tools that are highly useful in the due course of 3D printing.

- New slicing software makes possible quick slicing of parts and functional prototypes.

CONS:

- Despite the anti-aliasing technology, the printer is only able to provide a resolution of 480 pixels.

- Lesser printing materials.

- Works only with Windows and mac operating systems.

- Leveling of bed becomes a headache as you need to do it every time.

- The Z axis lead screw and linear rail setup doesn’t give the printer same level of stability as the former versions.

PROS:

- Has a neat design.

- Is capable of heating extremely fast.

- When in operation it does not make much noise.

CONS:

- The filament holder of this printer is very frustrating to deal with.

- You will have to take care of the delicacy of this printer’s wiring.

- Sometimes there is even uneven heat dissipation which leads to print failure.