Not many people know that the technology that surfaced as the most revolutionary invention just a few years back was founded in the late 20th century.

The first patent was made by Charles Hull for inventing Stereolithography in 1984. However, the knowledge and popularity of 3D printing could not reach too many because of the walls of patents and lack of accessibility build around the technology.

As soon as the patent expired, 3D printing, also known as additive manufacturing became available to everyone.

This is when the consumer 3D printers came into existence which further surged its penetration into more applications. Later, the internet did its mercy to spread to word all across the globe making even the home users aware of its various capabilities.

When considering 3D printing as a whole, many things are still inaccessible to the consumers and most are used within manufacturing industries.

However, a lot of it has reached the consumers. A few years back, SLA wasn’t very affordable and remained restricted to the manufacturing hubs.

However, with Formlabs coming up with a desktop version of SLA 3D printers, the reachability has been given new form. More users are connecting with the technology which is further impacting its growth and development.

A Peep into 3D Printing Surging Accessibility

After 3D printing landed up into the hands of a greater number of people breaking the chain of patents, the technology paved the way for higher developments.

More people started getting attached to the technology, hence, creating a significantly higher impact as a whole. How can we forget about the RepRap movement? The idea of just one person made history in the field of 3D printing.

After he gained access to 3D printing, he made efforts to create a re-printable printer. This had a huge impact on the other users from the community and it spread like a wildfire in the forest. And, thousands of people gained access to this most pampered technology kept away from the sights of others.

Today, anyone who has the budget to buy a smart TV can make room for a 3D printer too. The machines are available on Amazon and for very affordable rates.

You can not only think or dream, but can buy a 3D printer to experiment on your own. Now, anyone can buy a 3D printer from Amazon, a remarkable shift for the industry, as a whole.

Doesn’t that sound similar to something? If you can recall, there was a time when the internet was thought of like an experiment for a few highly skilled nerds and that it would not reach the consumer or masses ever.

It is 2025, and we have already witnessed the way the internet has brought a huge change to humanity. By making information available to everyone, it made learning and doing things, simpler.

While there was a time when owning a television was a big question, now, anyone can upload a self-directed film on YouTube.

There are certain limitations though. The information is accessible but not everyone can become a dancer and start an academy for others.

Similarly, 3D printing, which may seem like a far-fetched dream to be available in every one of the three homes now, the future will talk about itself sooner.

Progress is the Key to Future Development

As mentioned, 3D printing is evolving. When the technology was first invented, it was only used for rapid prototyping. This was because of the limitation of its speed and the restricted output is created.

However, currently, 3D printing is being used for full-fledged production in many industries. That surely is a huge leap. And, the developments have taken place right after the accessibility was broadened.

Enhancement of Print Speed

We all know that the major reason behind the slow acceptance of the technology lies in its speed. For many years, 3D printing has suffered low print speed.

It may have defeated every other alternative in terms of accuracy or precision, the speed had always been a constraint.

However, things are changing. 3D Printers are improving in terms of speed and the results are very much obvious.

SLA has been regarded as one of the slowest 3D printing technologies. After the invention of similar 3D printing processes such as CLIP from Carbon 3D, the changes in the speed have been remarkable.

The 3D printers are now capable of printing photocurable resins at a very high speed. Speeding more than 50 times from the speed of usual SLA printers.

Counting on the continuous development, we can deem that the print speed would be further impacted by the growth and necessity revolving around the technology.

Without a doubt, 3D printers have already started playing major roles from designing to manufacturing and would continue to grow in the future as well.

Now, you can expect to print parts in as less as 15 minutes, depending on the size and complexity of the design.

Growth of Existing Processes

As the competition is rolling among manufacturers of 3D Printers, aside from the gain in demand from the consumer end, companies are fighting to improve on the existing processes to stay popular.

Direct-Metal 3D Printing

Let us start with Direct Metal 3D printing. It used to be slow, however, it has now gained speed. With time, the process is becoming even more capable of accomplishing things that it was able to do before.

Direct metal has been a great option for those printing with metals. Hence, technology has always been looked up to. Any development is counted as a lead towards enhanced future acceptability.

Moreover, the metal alloys used as the material for printing with these 3D printers have also increased. Moreover, these materials are capable of showcasing exceptional characteristics.

Even with heavy materials, you can create a solution that can provide you lightweight printed parts inhibiting complex geometries.

Applications in niches like aerospace and automotive are no more just a goal. It has already been in play because of the extremely complex designs possible through 3D printing.

Not to ignore, you can also experience the completely automated and multi-stationed direct-metal 3D printers. These can be undoubtedly regarded as a whole manufacturing unit.

Selective Laser Sintering (SLS)

Like many other 3D printing processes, Selective laser sintering has also gained immense popularity in terms of application in the last few years.

It creates models from nylon materials. With its enhanced capabilities, the SLS 3D Printers are being utilized for some of the advanced applications within many niches.

For example, SLS printers are used for printing air ducts and various other components for F-18 fighter jets in service today. And, it has been carried out for a decade now.

Gazing the prospect of this particular 3D printing process, many companies, including HP, are trying to bring the technology to the mainstream. Instead of being confined to some of the specific applications, SLS is going to rule the consumer industry as well.

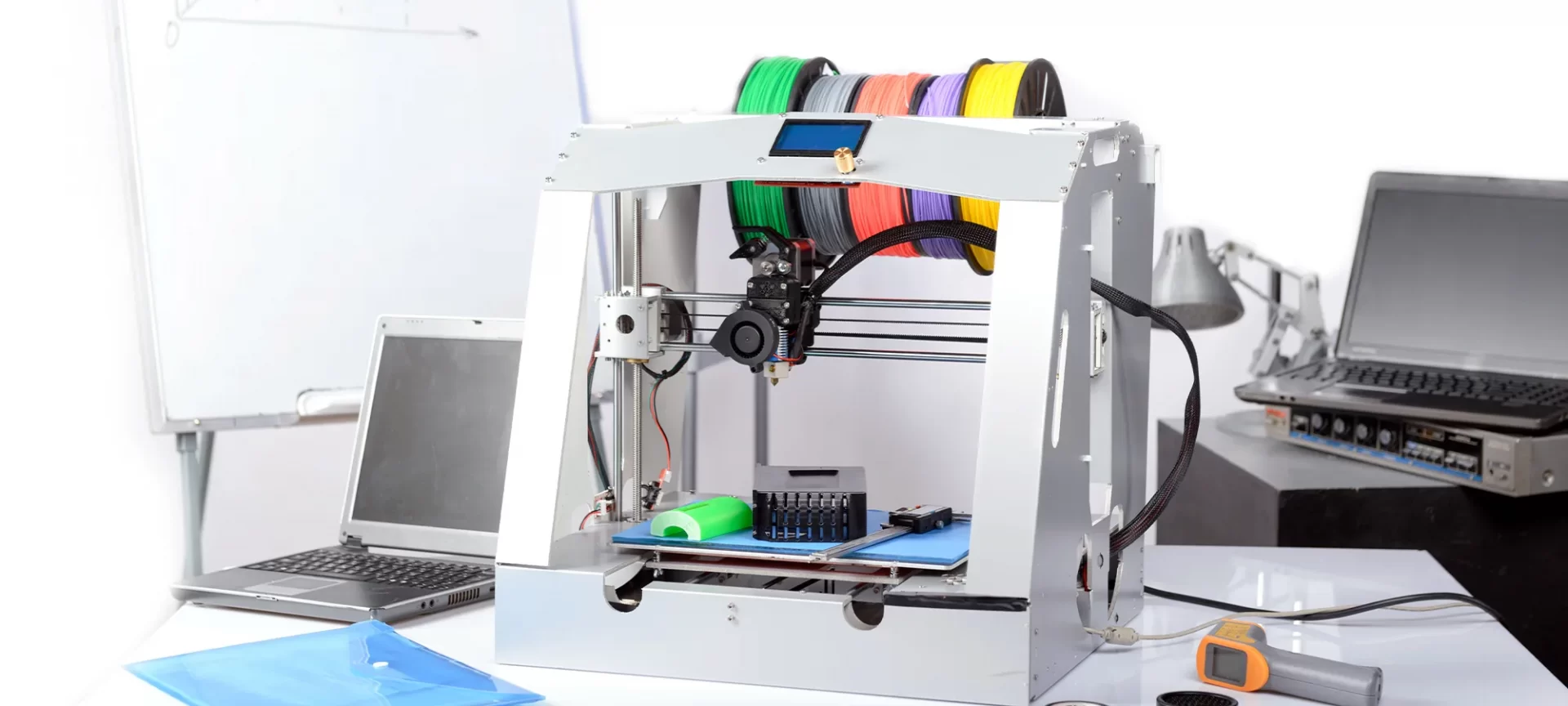

Fused Deposition Modeling (FDM)

FDM 3D printers are the most common ones that are being used by consumers around the world. The printers are also used by home users, although the number is highly limited.

But the future growth signals towards something huge. The printers are getting down on the price end while offering better features.

From single to double to a triple extruder, we have seen everything in this decade itself. And, there is a lot that we would be witnessing sooner.

With plummeting costs and rising demand, the industry is ready to make a steep move towards the future with better capabilities and options for its users.

Summing Up the Future Innovation of 3D Printing

A lot has been already outlined, and more benefits are still to be uncovered by us. 3D printing isn’t just a part of the rapid prototyping anymore but has evolved to sit in the front chair alongside the already existing technologies to tame the manufacturing and various other processes.

Have you ever thought of coupling 3D printing with the power of the cloud or big data? How about mixing the strength of 3D printing with next-generation robotics?

You would find a completely different level of results at hand, while 3D printing being the driving force for the changes. We can discover cognitive as well as an adaptive industry being capable of self-optimizing itself in case of environmental change.

A path towards 4D printing. The objects or parts that would be designed using 4D printing would have the ability to adapt to the change or specific triggers in their environment. The MIT guys are already on it.

Apart from that, the already existing processes are going to make a huge shift in terms of performance. Companies are already trying to come up with better photopolymer systems.

It is expected that the growth in photopolymer 3D printers would increase to more than 75 percent in the coming years.

The applications have already boomed. Either its medical field or aerospace, 3D printers are being used for many things.

From hearing aids to hip replacements to, dental fixtures and many other applications, 3D printing has made a huge impact on the medical industry. The same goes for aerospace, automobile, and other specific niches.

If you wish to look more into the depth of importance that the technology has created, look inside the educational setups. Many schools and colleges have started providing students with classes on 3D printing. The children are taught to be able to use it.

Is 3D Printing Going to Replace Traditional Manufacturing?

This is one concern that haunts many businesses that offer traditional manufacturing. However, 3D printing isn’t here to replace any existing technology, however, in building newer things.

There are many forms of conventional manufacturing that would not disappear with the snap of the finger. Think about injection molding. The method is by far unrivaled form of manufacturing for large and uniform batches of objects.

Let’s take another example. We have been listening to the radio for decades. With the invention of the podcast, users started thinking that the radio will take the back seat.

However, that never happened. Radio is still liked and used by as many people as before while Podcasts being a completely different concept of information sharing.

Newer technologies that emerge are not always aimed at replacing the existing ones. The same goes for 3D printing. 3D printing will not be eradicating conventional manufacturing.

On the other hand, 3D printing would offer new horizons for development. It will prospect into newer opportunities for innovation.

Users will have more options in terms of materials, speed, and functionalities with time. The progress is already underway and it seems to stay this way forever.

The technology would certainly make changes at few fronts, but would not eliminate traditional methods completely any sooner.

The Conclusion

3D printing has there been among us for a long time. It started to flourish in 1984 and was thought about much before that. With continuous growth and development, it has reached consumers.

However, it was unbelievable a few years back. The technology was restricted to rapid prototyping and was difficult to handle outside an industrial setup.

People would have called it a huge bluff if someone would have proposed a system that was capable of surviving outside a professional setting. We have already come a long way from there.

Today, we are using 3D printers for home and are printing end products. From home furnishing to tools to an entire house, it has become possible to think and explore and believe in the technology.

It is believed that the technology would soon start impacting the roots of various workflows and processes consisting of the backbone of the manufacturing industry and more.

The technology, that was shut behind the walls of industries is now ready to show up, with extra preparation. 3D printing is evolving and including greater opportunities and options for users.

It won’t be wrong to call it the most revolutionary technology which is capable of changing the face of humanity for good.