The prominence of 3D printing is not a whisper anymore. After long years of being shut behind the industrial applications, the technology has made its place among the consumers in the last few years.

Since then, the loud is roaring through every niche. Most of the businesses have already started using 3D printers and many seek to start at the earliest. However, the question remains, which professional 3D printer would better suit the specific needs of a user?

There are many companies selling 3D printers. Some at cheaper rates and some are highly expensive.

What is the reason for such a huge price difference? Definitely the difference in the features and benefits these 3D printers offer. And, it makes it even more difficult to know which one would be the right choice.

Selecting the right one for your business may seem like a tedious job and it sure is. So, what to look for when you choose between various professional 3D printers offering diverse features.

A professional 3D printer is used for commercial purposes. Hence, it must be bought taking every important feature into consideration.

The professional or commercial 3D printer is not as expensive as an industrial 3D printer, however, it holds the same important for businesses that own it. As the quality of products printed with these 3D printers reflects the company’s brand.

Which company would ever like to compromise with its brand image? Hence, you must give time to research and buy the right 3D printer.

Criteria for Selecting Professional 3D Printer

If you are up for the roller coaster ride of going through specifications of various 3D printers, start with these criteria for the best selection.

However, remember that you do not have to look for the 3D printer offering all the best features, but the ones that is important for you.

For example, if the best quality design is what matters to you, you can compromise with the speed.

So, choose according to your needs and not based on other’s perspectives.

For Which Application Do You Need a Professional 3D Printer?

This is the most important question that you must ask before starting to scrutinize the various options. Your application requirement would lead you to the right technology you must be looking for.

For example, if you want metal parts, buying an FDM printer would be a huge mistake. Think about what do you want to build and how do you want to use the professional 3D printer. Consider checking our article about 3D printer types to help you choose.

If you are looking for a professional 3D printer, you must be wanting production in batches. It is not a necessity though. However, if you are, you must look for the 3D printer that makes batch production possible.

Likewise, you must choose between the various application that can be done through 3D printing. Such as tooling, prototyping, 3D printing patterns for casting, molds, fixtures and end products.

A better understanding of the application would help you determine which process to go with and which 3D printing technology to choose. This will further narrow the list to choose from. Hence, making the selection task easier.

What 3D Printing Quality Are You Looking For?

The next important criterion is the quality of the products you are expecting. Every 3D printer provides prints with different accuracy, resolution and surface finish. If these features are foremost for your printing needs, select the 3D printer accordingly.

Accuracy:

The accuracy of the 3D printer is the precision of the parts printed. If your parts have complex geometrical designs that are difficult to print, you must look for a professional 3D printer then prints with utmost accuracy.

If you are printing adjoining parts that are assembled later, the accuracy will matter the most. So, deciding which 3D printer to choose will greatly depend on the accuracy you seek.

Resolution:

There are certain 3D printing processes which print parts with visible layer difference. The resolution is minimum for these parts. However, you will also find alternatives to these 3D printers which provides great resolution.

The layer difference is notably reduced and you won’t be able to make out that the product is manufactured with additive technology. The layer height determines the resolution a 3D printer provides. The minimum the layer height, the higher is the resolution.

Surface Finish:

Surface finish matters a lot for a few parts. Although one can further smoothen the surface during post-processing methods, it is best to find the 3D printer that already prints smooth surfaces.

There are two major reasons for the same. First of all, the post-processing task will increase production time. And, post-processing may ruin the part all together if not done properly.

Hence, if quality matters a lot, look for the professional 3D printer that gets you all these three features.

Which 3D Printing Material Would You Print With?

Moving on to the next criterion, here is what you should look for. Do you know that the pool of material used for 3D printing is been increasing with time? When the technology surfaced, the photosensitive resin was the only material used for 3D printing.

However, as the technology progressed and different 3D printing processes came into the picture, the material options surged too.

Choosing the right material will also depend on the physical properties you wish to achieve through 3D printing. For example, you may want your parts to be flexible or durable. Or, you may wish to print stiff parts.

Depending on many such parameters, selecting the right material that gets you all these features is a must.

Today, there are a plethora of options to choose from. Even there is a huge difference between the quality of the same material offered by different providers. All these have made it challenging to select the 3D printer without visualizing the need for material compatibility.

If you are looking to print with PLA filament, your 3D printer must allow that. Also, if you are looking to print with different materials such as PLA, ABS, etc, look for the one that supports material multiple materials.

These will save you from problems later. There are companies that start printing with PLA, however, they decide to bring ABS into the printing process.

If the 3D printer does not support ABS, the companies either outsource the requirement or get another 3D printer spending more money. If you do not want to get into a similar mess, you must be prepared for the upcoming needs that may arise later.

How Much 3D Printing Build Speed and What Build Size Matters?

The speed of 3D prints is measured in inches per hour. The speed-time depends a lot on the complexity and size of your design. Sometimes, it may differ depending on the choice of your material. Taking all these into account, choosing the 3D printer with the best speed would be rather easy than searching cluelessly.

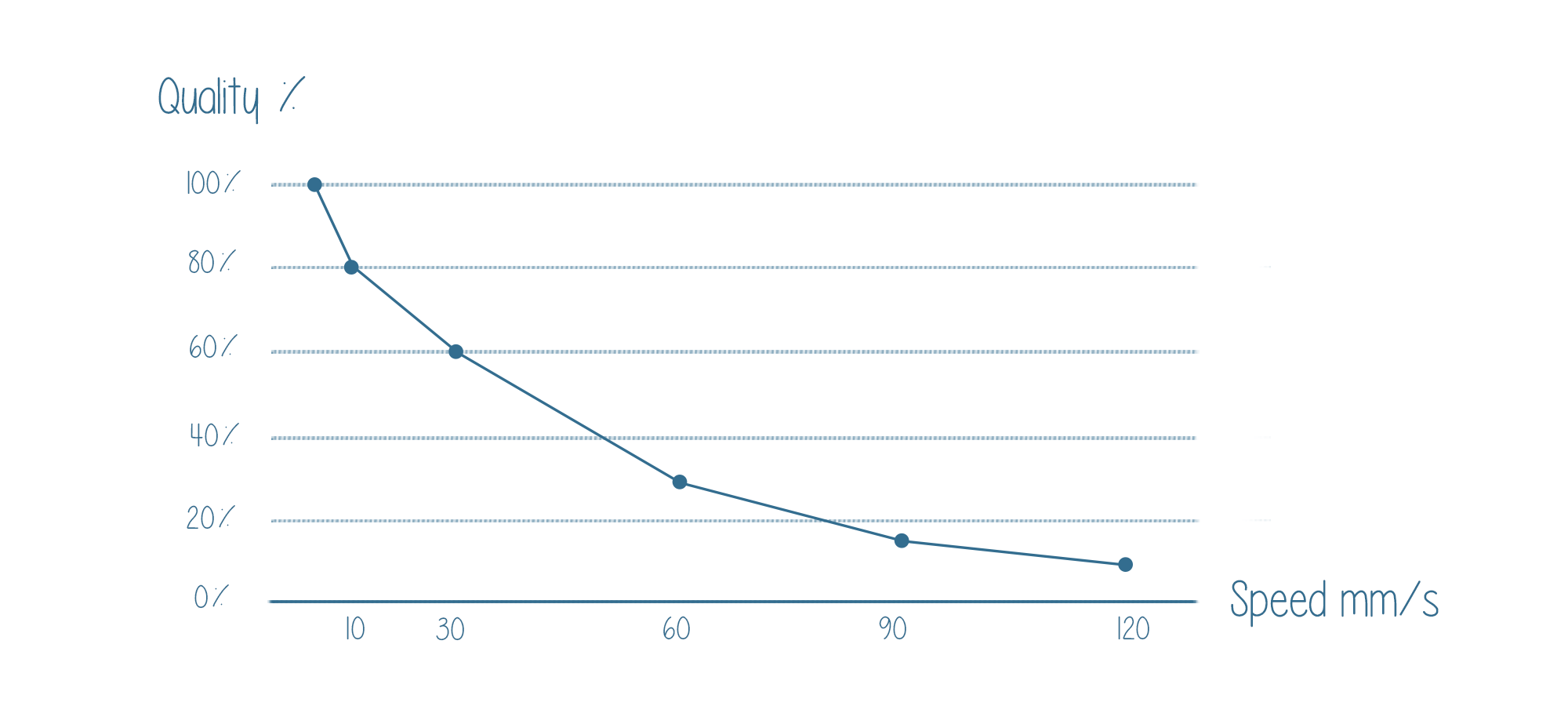

For some businesses, print speed matters a lot. However, for others, it does not matter much. You may think why not go for a higher speed even when not in need. The problem with high speed is that it cannot provide high accuracy.

Hence, if your 3D printing is based on the accuracy of the parts, high-speed 3D printers may take that away from you.

Think about your preferences before you go ahead and buy a professional 3D printer at a higher speed. It may not be able to cater to your 3D printing needs. Give it a thought before you spend your money.

Getting to the build size, you must know that the 3D printers come in different sizes. Some are too small and some are large scale 3d printers enough to occupy the entire room. However, a high end professional 3D printer wouldn’t be that huge.

Every 3D printer specifies the build size to help users choose the right option. You must not ignore the build size of the printer. If your parts have greater size, a 3D printer with a smaller build size would be useless.

Or else, you may have to divide the object into different parts and assemble that later. However, this will affect the quality of the end product. So, choose wisely.

Do You Wish to 3D Print in Multiple Colors?

This again is a very specific criterion when looking for a 3D printer for your business. Most of the printers available in the market support only one color at a time.

In case, you are printing parts with different colors, you may have to switch the material from time to time while printing a single part.

However, there are 3D printers available that lets you print in different colors at the same time. These come with full-color capabilities and are easy to use. Instead of changing the material often, you can set aside and check the 3D printer printing your design.

There are cases when a company starts printing with one color and then decides to introduce colorful patterns of the products.

If you think that the need will grow later and you may seek to print colorful parts, why not go for the option at the beginning itself. However, this is completely a personal decision.

The company may never decide to do that. And, may end up paying extra for a 3D printer with full-color capabilities.

How Much Does 3D Printing Cost Initially and What are the Recurring Cost?

Everything depends largely on the initial investment. Whatever you wish to do with your 3D printer, if you do not have an excess of initial investment, you may have to compromise with a few of the requirements. Hence, it is always good to prioritize things before you start looking for a 3D printer.

A 3D printer is available for as low as $200. However, you must know that these 3D printers are mostly for beginners and won’t serve the purpose of small setups with a requirement of batch production.

You must be willing to spend a few thousand dollars for a professional 3D printer. There is a range difference within these printers too. Hence, underlining the most specific features is most crucial for your business is a very important task you must complete beforehand.

Similarly, there are various recurring costs related to the operation and maintenance of a 3D printer. Some may require less maintenance and others may need it often. Not only these maintenance services are costly, but they also disturb the production time.

Some companies offer free services for a couple of months or a year. Others charge for maintenance from the beginning.

Moreover, the material cost, post-processing cost, and other parameters define the recurring cost one would be paying at every regular interval.

Adding up these costs may put you into serious expenditure if not planned properly.

Therefore, you must take all these costs into consideration before you start a 3D printing company or a small business of your own. Or else, you may later find yourself paying fees and not able to 3D print on time.

The Conclusion

3D printing is not an easy task. And, finding the right 3D printer for your specific needs is even more difficult.

The reason that these printers come at an expensive price, makes it very important to make the right decision in the first go itself.

Businesses have a limited budget and spending more than once on a 3D printer that won’t work later is never feasible.

Hence, going through each and every specific is crucial before purchasing a 3D printer. Unlike 3D printers for beginners, professional 3D printers are expensive and are designed to serve certain specific purposes.

Finding the one for your needs could be easy if you concentrate on the details. Map your requirements with the features a 3D printer provides. You would soon find most of the options being erased right away.

With fewer alternatives and narrowed down a list of choices, you would be able to find the professional 3D printer for your needs. So, dig deeper into your business expectations and decide accordingly.

A 3D printer with every best feature is not what you need. You need a 3D printer that has those features without which you cannot 3D print the parts. Look for those features and you will find the one you must own.