Formlabs Fuse 1 3D Printer

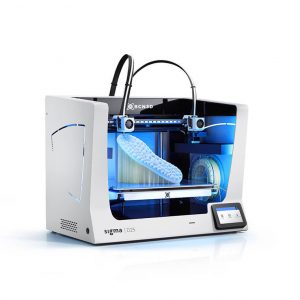

Formlabs is a Massachusetts based company started in the year 2011. In the year 2017, the company introduced its first selective laser sintering 3D printer to public FormLabs Fuse 1. It gave new possibilities to the engineers and the designers to manufacture high-quality prototyping with access to SLS technology. It has brought the industrial power of SLS 3D printing to the benchtop, with its intuitiveness and reliability. FormLab 2 is one such release from the company that surpasses all the barriers present in the previous releases and presents itself as a completely unique solution.

It is also very cost-effective compared to the other machines and enables the production of large geometrically complex figures. The printer uses the fuse nylon powdered layer after layer, as the nylon is good for structural or mechanical parts. Nylon is also considered suitable for high-temperature applications for the parts that need to tolerate heat. Nylon is also used to make end-use parts and durable prototypes.

The printer with the help of the SLS technology is able to give high accuracy and is also very cost-effective as it can reuse the material once used. The printer build volume is 165 ×165×320mm.

If you wish to get hands-on with a pretty amazing deal, this is your way to go. Check out the complete feature of Formlabs Fuse 1 to understand what it can uncover for your production needs.

Specification: Formlabs Fuse 1 3D Printer

|

- Bigger built volume.

- Removable chamber.

- The printer produces amazing prints in parts and prototypes that are manufactured using it.

- It has a layer thickness which is probably the most minimal.

- Available at an affordable price.

- Not very fast print speed.