Ultimaker has been building 3D printers for 10 years now. From the very beginning, the company has been on a mission to speed up the world’s transition to local manufacturing and digital distribution.

After spending all these years, Ultimaker 3D printers are known to its customer for being reliable and delivering high-quality prints.

The company’s history says that in 2010, it started with a Rep Rap project. The objective of this project was accomplished and used in the building of Protobox- the predecessor to Ultimaker 3D printers.

Although having moved its headquarters in New York in the year 2012, the company is still known in the market as a Netherlands based company.

Cura, the software that every Ultimaker printer comes with, is extremely user-friendly software. Even the most non-technical person can learn it with a little bit of effort from his/her side.

After its success in building Ultimaker 2 and its sale in the market of additive manufacturing, Ultimaker has also strived to achieve more and more. Let’s look at the top 4 best Ultimaker 3D printers.

List Of 4 Best Ultimaker 3D Printers

Ultimaker’s 3D printers are known in their market for carrying dual extrusion capability, high print quality, and speed. Although overall, any printer that you buy from this manufacturer is perfectly fine.

Then too, there are some minute details that you will only know after reading in-depth about its design, features, and pros and cons. So, let’s get started with our list.

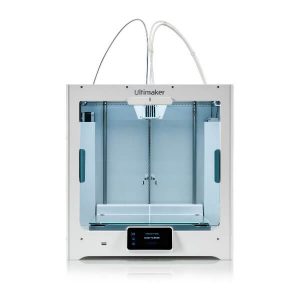

Ultimaker S5

This printer was revealed by Ultimaker in April 2018 at the Hannover Messe manufacturing trade show. Ultimaker 3 which was by then, the most loved 3D printer of Ultimaker in the market was replaced by S5.

This Ultimaker 3D printer is a bigger and better model of the former 3D printers. So, let’s take a dip into the features to know what is inside this techy looking machine.

Features

The most compelling feature of S5 is that it can print parts up to build a volume of 330 mm * 240 mm * 300 mm. For those who don’t know, Ultimaker 3 could only print parts and functional prototypes up to build a volume of 215 mm * 215 mm * 200 mm.

Another upgrade that has been made by this 3D printer is that it comes with dual extrusion capabilities. Its feeder system has improved than the previous one and has a filament flow sensor that automatically pauses prints when filament runs out of stock.

This feature makes Ultimaker S5 join the list of other intuitive printers in the same price range.

By using the swappable print cores that you get with this printer, you can design your prints in a versatile manner. Also, there isn’t much effort that goes into maintaining these print cores and they are easy to use.

The different nozzle size of this printer allows you to achieve ultra-fine detailing in parts and prototypes. And this doesn’t mean you will have to lose speed while printing. You can print at the same speed and yet achieve the quality which you wish to achieve.

The two build plates that this printer utilizes are interchangeable. One is made up of glass, which can be used in general. While the other is made of ultra-fat anodized aluminum which can be used for advanced engineering material such as ABS and PC.

Another important aspect while buying the Ultimaker 3D printer is the design of the 3D printer. So, let’s have a look at that.

Design

If you have seen Ultimaker 3, you’d probably feel that the design of S5, is just similar. The sleek box-like appearance of the machine is kept the same, but this is because of the stability.

Ultimaker S5 is known in the 3D printing market for an eccentric design change that was offered by no printer at that time. In 2018, the majority of 3D printers were focused on providing more advances on Z-axis. Whilst Ultimaker S5 provided more advances on the X-axis.

Like, Ultimaker 3, S5 is also capable of printing objects of height 300 mm. However, the width of the build platform has increased from 200 mm to 330 mm.

This change in the design feature enabled users to put a greater number of parts on a single print area or produce larger-scale models with more width.

The interior of this machine is well lit. Something that allows your eyes and the built-in camera to monitor the print process completely.

The glass bed is removable, keeping in mind the post-processing and cleaning of this Ultimaker 3D printer. The filament feeding system is controlled with a touchscreen interface.

This allows for quicker material loading and unloading. Now let’s take a look at the Pros and Cons of this printer.

- Easy to use and setup.

- Delivers excellent print quality.

- It is able to manufacture parts and prototypes of larger build volume.

- Has an intuitive touch screen interface.

- It is expensive to buy if you are only a hobbyist.

- Has relatively slow print time.

- The functioning of the camera is not that smooth.

- Extends difficulties when printing with some materials.

|

Final Call

Being on the expensive side of the 3D printers, Ultimaker S5 makes it for a perfect choice of designers, engineers, and even small businesses who plan to earn with it.

The printer has excellent print quality and speed. Because of this, it can be used in various industries that involve the manufacturing of complex parts in lesser time.

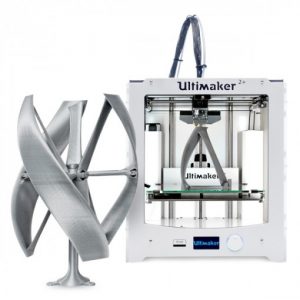

Ultimaker 3

Dual extrusion is very common to have in a printer right now, but it wasn’t the case when this printer was released.

Because of this reason, Ultimaker 3 came as a gift to many designers and engineers who were waiting for this break. Also, this 3D printer gave many options for its users to connect with it.

So, when the announcement was made about this printer, it was then, the most anticipated printer of 2017. In 2020 too, this printer does not upset professionals of 3D printers who wish to print with multiple materials.

Features

Coming to Ultimaker 3’s features there are two anomalies that we would like you to know. Normally in when a printer is updated from its previous version, the build volume is increased in the latter.

That is not the case with Ultimaker 3. This printer has a build volume of 215 mm * 215 mm * 215 mm compared to Ultimaker 2+’s 223 mm * 223 mm * 205 mm.

Also, the filament reel holder, guide, and toggle are similar to its previous version. However, this doesn’t mean that Ultimaker doesn’t have anything new to offer.

The most notable thing which Ultimaker 3 offers is its dual extrusion print head. These print heads are fed by two nozzles in a Bowden style.

If the print is only taken by one extruder, the other one will automatically partially retract into the print core and it out from the active print zone.

This will reduce the contamination between materials to a great extent. For travel inside the printer, the company has not experimented with its already hit mechanical rotating linear guides that move along the X and Y-axis. Whilst the print head moves through the Z-axis on a single lead screw.

Instead of fixed nozzles, Ultimaker 3 uses swappable ones. This is a simple way to mix materials and nozzle sizes without getting your hand dirty.

Design

Size-wise, Ultimaker 3 is a larger machine that has Bowden tubes attached to the printer. The overall weight of the printer is 10.6 kg.

The 3D printers that are manufactured by Ultimaker have a standard design which is like the signature mark of this company. Although the traditional plywood which was laser cut is now, gone from the design so, arguably the design has changed a little bit.

The company has taken special care that while servicing, everything can be dismantled. This can be observed from its construction of linear bars remaining at a distance from 6mm to each other and the main bar at 8mm from them.

The other benefit of this construction is less vibration. While the printing process starts, many printers are known to vibrate and produce a lot of noise. That is simply not the case with this printer.

- The dual extrusion of the printer performs brilliantly.

- The printer has hot-swappable print cores.

- One can connect using Wi-fi.

- The reels of this printer are equipped with NFC which simplifies the printing process.

- The printer has an open front due to which there are complaints about the printer being unsafe.

- Spool holders of these printers are poorly positioned.

|

Final Call

Ultimaker 3 manages to live up to the expectations of its predecessors that were single extrusion 3D printers.

This dual-extruder possessing machine comes at an affordable cost and can produce complex parts and prototypes with excellent print quality. However, this might reduce the speed of overall printing by a little.

Overall the machine is very reliable and does produce higher-quality prints than its competitors. This is what makes Ultimaker 3 and all-rounder printer in the market.

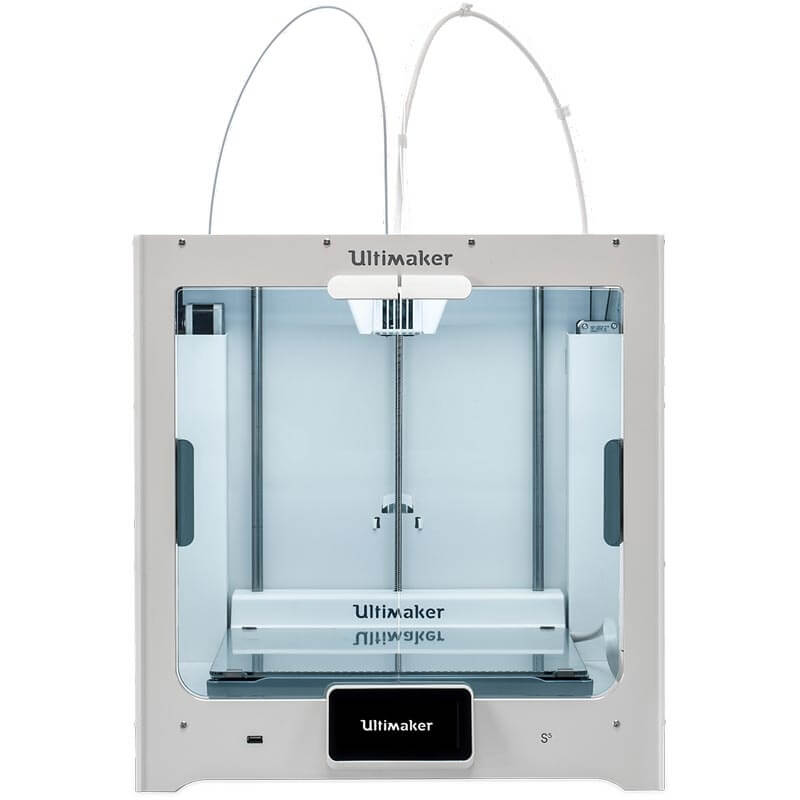

Ultimaker 2 Plus

A surprise announcement at CES 2016 was made by the manufacturer about the introduction of Ultimaker 2+.

There was a lot of curiosity in the minds of people that how much exactly would this “+” sign signify? To get an answer about this let’s first start with a difference between Ultimaker 2 and Ultimaker 2+.

Features

This machine is an incremental upgrade of the venerable workhouse Ultimaker 2. Meaning that 2+ has the exact same user base at Ultimaker 2. It can be used by professionals such as home-users, academic institutions, designers, and small businesses that need a 3D printer for prototyping and part production.

The machine is able to produce parts and functional prototypes with a build volume of 8.8 * 8.8 * 8.1 inches and a layer resolution range of 20 to 600 microns.

The print bed of Ultimaker 2+ is made up of glass. Both, the print bed and extruder of this printer are moveable. The print bed moves along the Z-axis, while the extruder moves along the X and Y-axis.

Ultimaker 2+ has a semi-open frame, which means that it is partially covered from all four sides but has no door or top cover.

If its predecessor and the machine are kept side to side, it is hard to tell the difference at first glance. But looking from the design and feature point of view, only on hard observation one can tell the differences.

So, here’s presenting you the differences in design which can take you some months of operation to point out.

Design

The extruder assembly of this printer has a cooling fan that is different from Ultimaker 2. This one’s a lot flat than the previous one.

An observation like this has come when fans are kept at an angle to each other. When the fans are attached adjacent to each other instead of the extruder, you can also get to see this.

When we have the cooling air directed towards the print head, as opposed to fans that directly blow it, greater consistency and control is achieved.

When you stop noticing the front and start to notice the back of this printer, you find an improved material feeder. This new part is meant to service the filament.

It is this improvement that has been designed in Ultimaker 2+ after learning from Ultimaker 2. The former always had a complaint about the failure of print jobs due to the stripping of filament.

With this improved material feeder, the makers of the printer have bid adieu to that problem.

The teeth in Ultimaker 2 which couldn’t get a grip on the filament can now manage to get a hold of the filament because of the change in the arrangement in 2+.

The overall design of the printer is so, complete that its setup is a lot easier than other printers. All you need to do is unpack it, remove bits of foam, cardboard, and plastic ties that were inserted between the components to not let them have a touch of each other are to be removed and that’s it. Your printer is good to go.

After having read about the features and design of Ultimaker 2+, let’s read about its pros and cons.

- The machine is incredibly easy to setup.

- It has a very reduced level of noise pollution.

- The design improvements to the material feeder and extruder fans make it easier to operate.

- With this printer, you can print with any category of filaments.

- The printer supports all operating systems.

- There is no auto-calibration facility available in the printer.

- It has an open-frame design, hence prints are sensitive to the atmosphere.

- While printing with ABS, there is a complaint about foul odors.

|

Final Call

In a nutshell, Ultimaker 2+ was an evolution of that time when FDM technology was still new in the market. And companies were trying to make sure they had at least one printer that was based on this 3D printing technology.

There are critical improvements that a user can get over Ultimaker 2 in 2+. So, if you are someone who is looking to buy a new 3D printer for the first time, this one’s highly recommended because of the price at which it is available in the market.

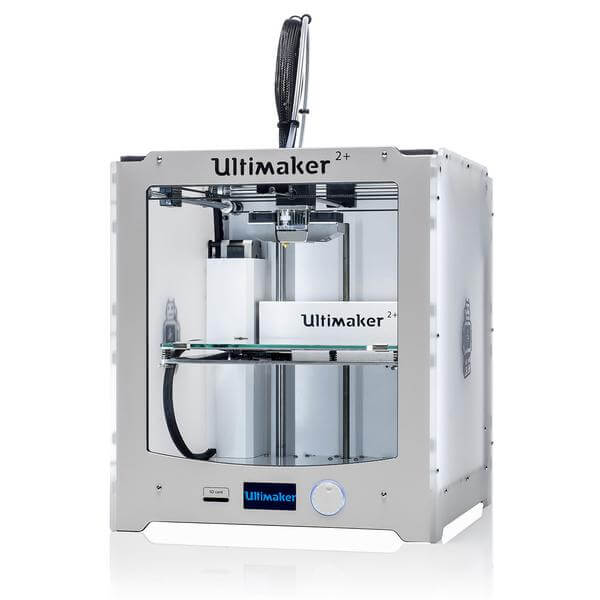

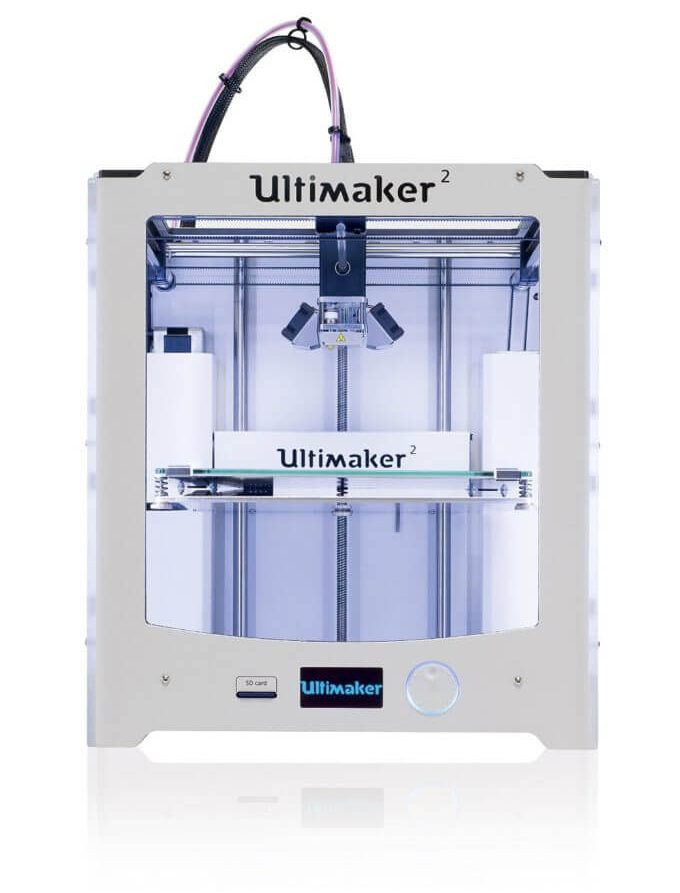

Ultimaker 2

This version by Ultimaker was known in the market of that time because it allowed users of that time to process a variety of filaments.

Compared to its competitors in the market, there were very few which offered such a service. The prints of parts and prototypes produced by this printer are of high quality and that’s why it is still preferred by professionals in 3D printing.

Features

Ultimaker 2 is based on FFF 3D printing technology and has a build volume of 23 * 22.5 * 20.5 cm. It can offer a layer resolution range of 20 to 200 microns.

The X and Y resolution of these printers are 12.5 microns each and the Z-axis resolution is 5 microns. The print and travel speed of this printer is 30mm per second and its nozzle diameter is 0.4mm.

This 3D printer is more suited for those who are enthusiastic and professionals in 3D printing. Users of this printer can print using a 3mm PLA or ABS filament that is held on a 1kg spool which is present on the back of the printer.

The makers of this printer have kept it open to every filament, instead of specializing. Unlike the ones that are previously mentioned on this list, this one has a single extruder.

The only extruder of this printer is located on the top of it and is driven by two belts. While it is a known fact in the market that if it is an FDM printer, it moves the extruder up to build a successive layers, Ultimaker 2 does the opposite.

But, this isn’t only because of some style or just doing completely different than what the market is doing. In fact, it is for keeping the prints steady and moving the extruder which helps when the print size is tall and thin.

Design

Ultimaker 2 comes in a white case which makes it look like an Apple product. Speaking about Apple products, the quality of Ultimaker 2 is pretty similar.

Inside this white case, there is this printing area which is built around a heated glass print bed. Above this print head, there is a single extruder that comes with two fans that cool down the temperature of the printed material.

The print head of Ultimaker 2 contains space for a second extruder that would allow the prints to be made with two colors or two different materials.

As expected, the company did then offer this second extruder in the form of a kit for this 3D printer. With Ultimaker 2, you can print using PLA as well as ABS filament. Also, Ultimaker 2 is very easy to set up and it will only take a few seconds after you unpack it to start printing with it.

- Ultimaker 2 is easy to set up and use.

- It has a lower noise level than its competitors during the printing process.

- One can select from a larger group of filaments to print from.

- This printer offers a higher resolution in the parts and prototypes that are printed.

- There is no auto-calibration available for this printer.

- It is expensive enough that if you are a hobbyist you would want to prefer a printer of a lower range.

Final Call

Beginners and professionals, both would enjoy this model by Ultimaker. This printer is considered a workhorse for 3D printing because of its excellent printing speed.

Everything that you need is already in the box of the printer so, it is very easy to set it up. The company is known for its online and offline support.

Even the software with which it comes is very easy to operate and user-friendly. On a whole, this is a very nice 3D printer and if you wish to build a volume of a larger size, you’d hardly get any option other than this one in the same price range.

The Conclusion

With each of those four 3D printers, there is something or the other that you can get different from the 3D printers in the same price range.

The point also that should be noted is that Ultimaker has kept all these printers open-sourced. Filaments that can be used for printing parts and functional prototypes are also open.

Cura, the company’s software allows you to operate itself from any operating system. Most of the printers have an option to connect themselves via Wi-fi, USB, LAN connection.

Ultimaker 3D printers are always targeted more towards small businesses and beginners in the market of 3D printing. So, if you are an enthusiast of additive manufacturing, Ultimaker is your ultimate go-to company as far as 3D printers are concerned.

Lower in cost, produces high-quality print, has a user-friendly software, can print with various filaments and materials, what more can you ask for?