There are many manufacturing processes used around the world. Among all, laser cutting and 3D printing are two of the most used manufacturing methods businesses rely on.

3D laser printer and 3D printer might sound similar, but there is a huge difference between both.

Based on different technologies, these devices perform the same task in a unique fashion to produce different quality parts.

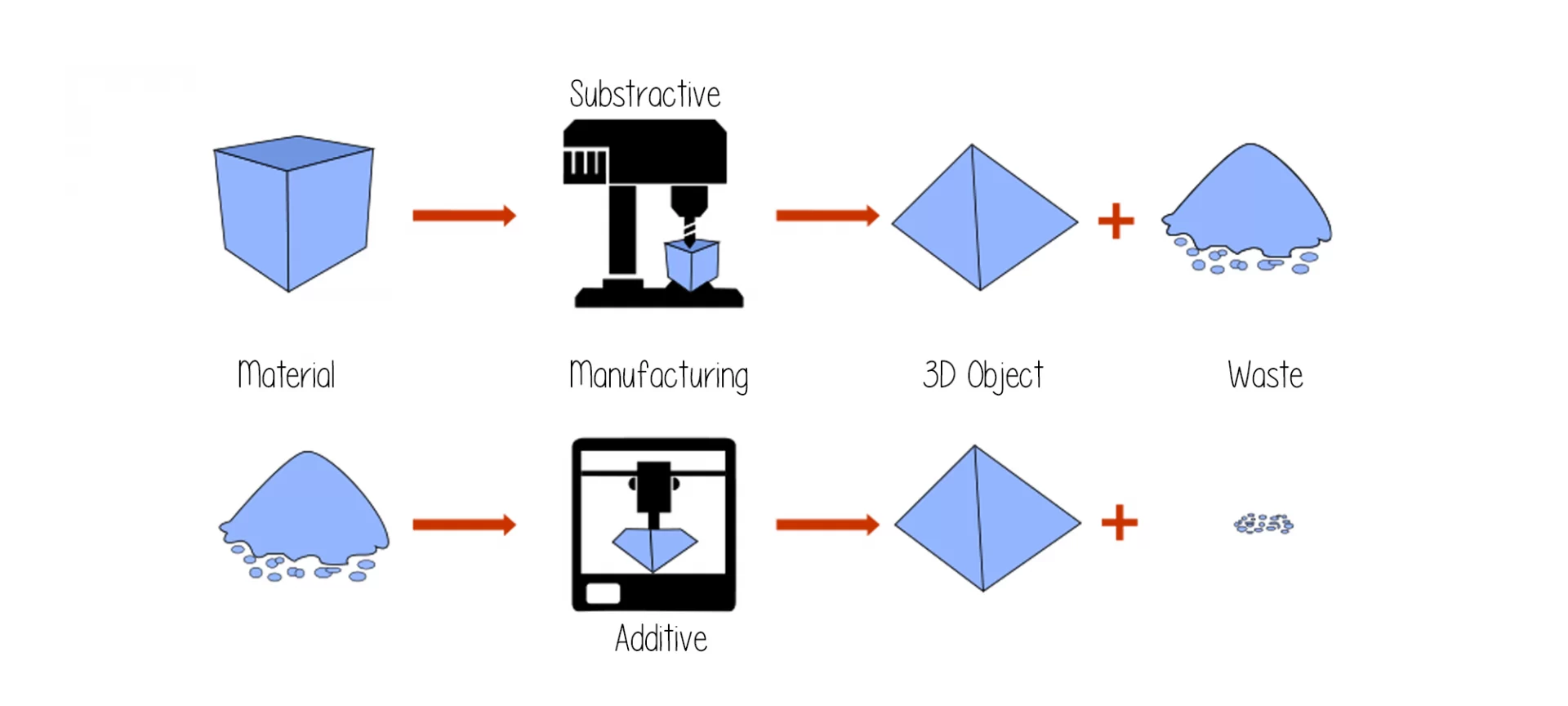

The major difference lies in the terms itself. While laser cutting is based on subtractive manufacturing, 3D printings are based on additive manufacturing.

Both are completely different in terms of their working and so are the end parts. To decide which manufacturing technology will better serve your business process, let us gather some brief idea about both the options available.

What is the Difference Between a 3D Printer and a 3D Laser Printer?

A 3D laser printer is based on laser cutting, a technology also known as a subtractive process.

In this process, the material is cut with the help of 3D or tube laser to shape the object as per the 2D design.

Because of the extreme accuracy of these lasers, one can manufacture intricate and precise designs with its use. Moreover, the material available for the laser cutting process is also huge.

One can use fabrics, composite materials, wood and even metal with laser cutting technology.

With all the benefits it has, it does require post-processing steps such as welding to finish the parts.

Either its prototypes or any other finished product, one must include the hectic post-processing methods to get the desired object.

On the contrary, 3D printing involves adding layers of materials one over another and joining them with different processes to get the finished part.

It is more of an additive process which makes it completely dissimilar to the laser cutting process.

To build a 3D part, one needs the printable 2D model of the object. Once fed to the 3D printer, the machine progresses to build the final object.

Unlike 3D laser printers that cut the material, 3D printers join layers together.

What is Laser Cutting?

Did you know that you have two different choices here? Laser cutting and laser engraving. Both are used for different purposes.

Laser cutting cuts the material and laser engraving is used to engrave materials. Using both the processes you can turn your designs into real objects.

This manufacturing technology is widely used for prototyping as well as within industries for manufacturing different parts.

One can use materials ranging from acrylic to metals. You can choose among cardboard, plywood, MDF and many other materials when working with a 3D laser printer.

One of the most important things that differentiate laser cutting from 3D printing is that laser cutting only works on large and flat surfaces.

Moreover, you will have to assemble different laser cut parts to build the final object. The process is cheaper when it comes to printing larger parts when compared to 3D Printing.

Laser engraving is mostly used for printing custom visit cards, custom jewelry items, and others.

What are the Benefits of Using 3D Laser Printer?

Huge Choice of Material: Because of the variety of materials available with laser cutting, laser 3D printer can build many items.

From the visitor’s card to the circuit board, everything is so easy to print using a 3D laser printer. The choice of material offers the printing of jewelry as well.

You can even print easily using wood. To put it in a better way, if you are working with woods, you must choose laser cutting over 3D printing.

Acrylic is also one of the most popular materials used with a 3D laser printer. Acrylic available in colors and its transparent properties, make it favorable for different applications.

- Cheaper for Large Parts: Laser cutting can print larger parts in less amount. You can build cheaper parts even when the material used is more than usual.

- Parts with Precision and Clarity: One can produce parts with high precision and clarity using 3D laser printers.

What is 3D Printing?

3D printing is much deeper and has a steep learning curve than you would have known so far.

This is the fastest-growing technology and is being used for various applications. Within 3D printing, there are many processes involved.

Materials are also used in different forms to be used with different process-based 3D printing machines.

Depending on the characteristic of your project, the budget, quality of the object and what you want to print decide which additive manufacturing process would be better than the others.

Your specific need is the best parameter to judge which 3D printing process would be your mate.

You can 3D print with Plastics using technologies such as Fused Deposition Modelling, Selective Laser Sintering or Multi Jet Fusion.

To 3D print with resins, you can go with SLA, CLIP technology or Polyjet. Metals printing is also possible with Selective Laser Melting, Direct Metal Laser Sintering, and Binder Jetting.

There are other materials also which could be printed using these technologies such as alloys, ceramics, and a lot of others.

3D Printing is highly recommended for diverse projects when one needs precision and quality together.

Here are a Few Examples of 3D Printing Processes

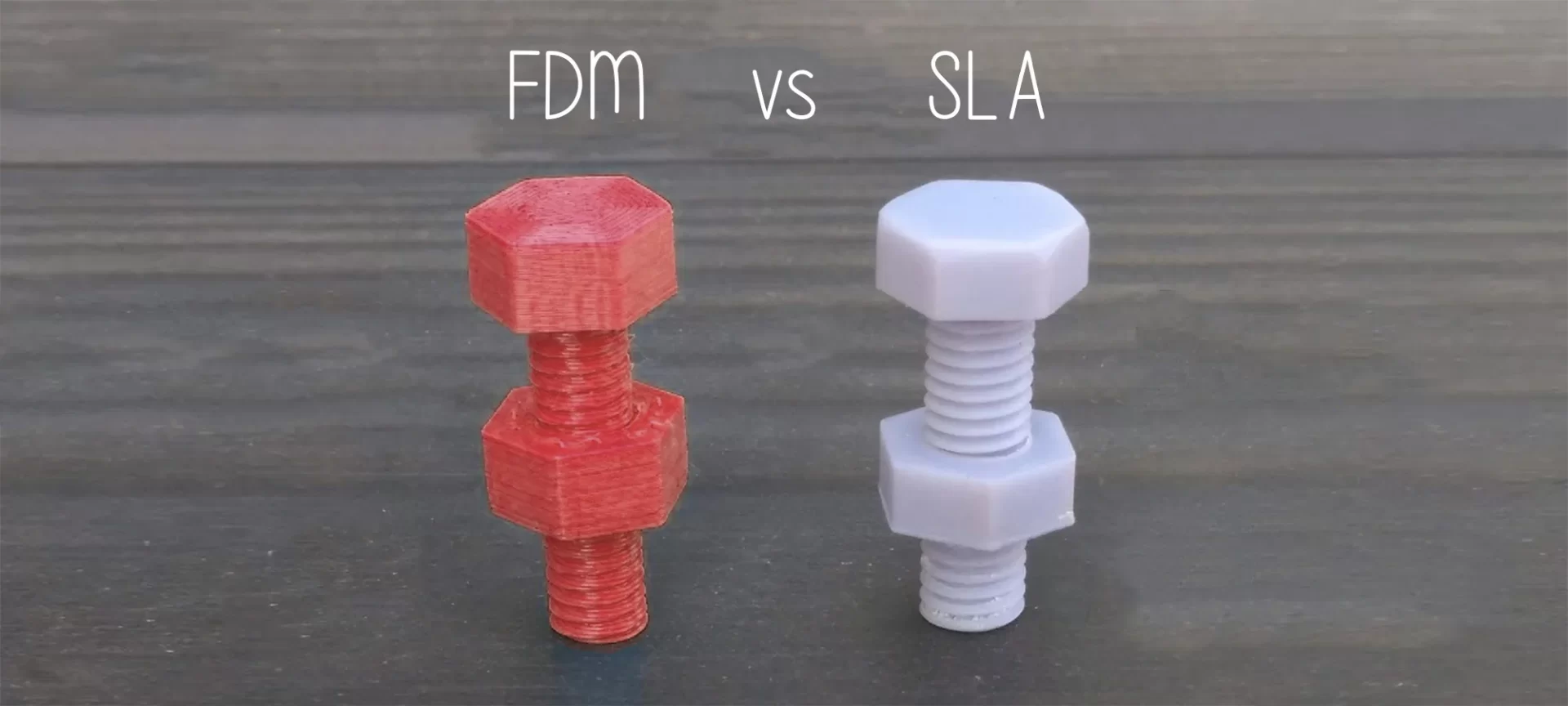

#1 FDM:

Fused deposition modeling uses a heated nozzle to melt the filament material and deposit it layer by layer on the build platform. Each time the layer is deposited, it solidifies while the other layer is prepared to be deposited over the prior one. This way, the entire part is printed.

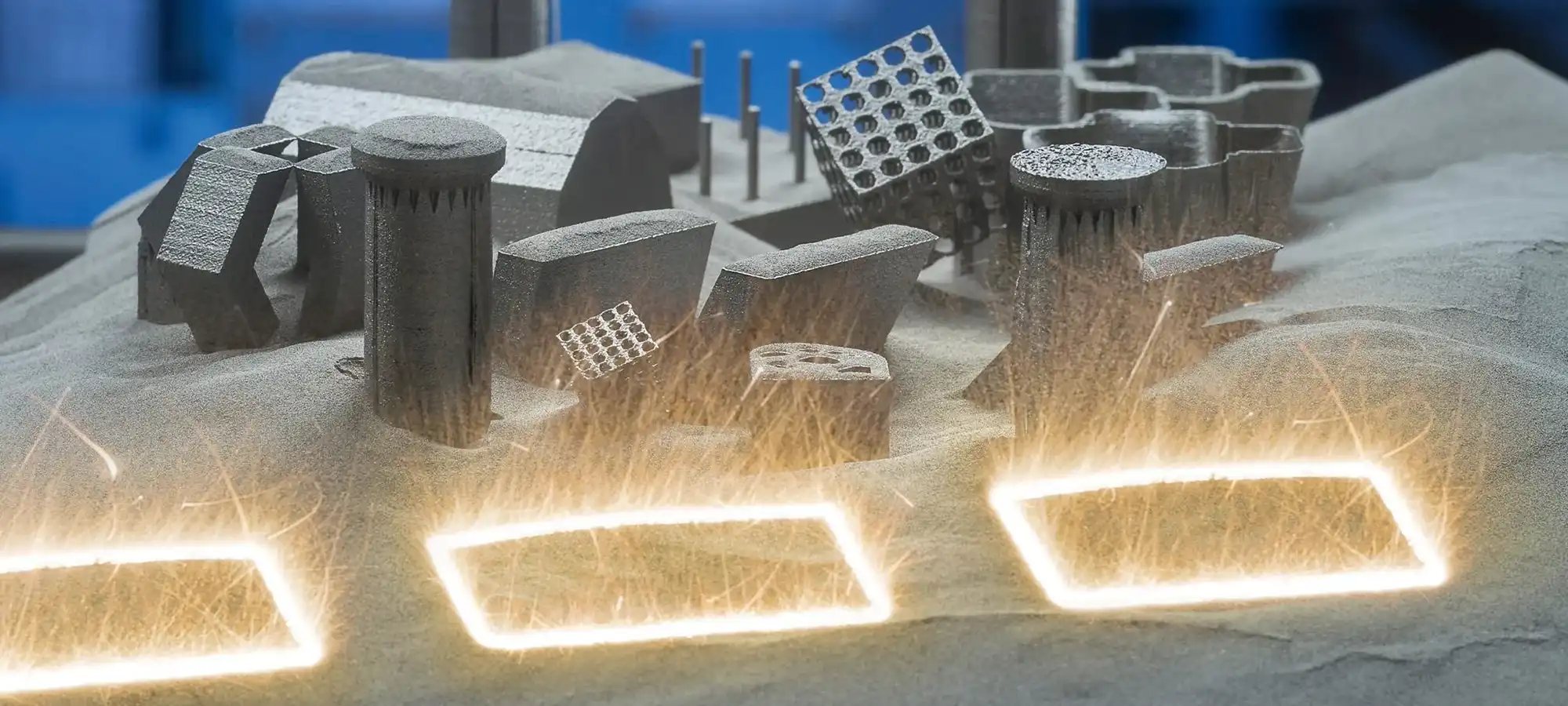

#2 SLS:

Selective laser sintering is the process of fusing powdered material to form solid parts. The laser beam is used to melt and fuse the material together.

The powder is deposited one layer at a time. After each layer solidifies, another layer is deposited. Finally, the part is 3D printed.

Later, during post-processing, the unused powder is removed using a brush or compressed air.

#3 SLA:

Stereolithography, abbreviated as SLA uses resin as the material. The photosensitive resin is cured by photopolymerization one layer at a time.

Once the layer solidifies, another layer is formed. This happens until the entire part is printed.

There are many other processes in 3D printing. Based on one’s need, one can choose the 3D printing process.

3D printing is widely used among various niches. For example, the fashion industry, aerospace, food industry, medical industry, etc.

What are the Benefits of 3D Printing?

✔️ Build Prototypes and End Products:

The application of 3D printing is huge. You not only can create prototypes, but end products are also possible through additive manufacturing.

There are certain parts that are not possible by any other methods other than additive manufacturing.

Using different 3D printing processes, you can create parts with different levels of quality and mechanical properties.

The limits are none and the possibilities are widening with every passing second.

✔️ Can Create Complex Designs:

Complex designs are possible with 3D printing. One can build parts with finer details and well-underlined structures.

From jewelry designs too difficult mechanical designs, everything is possible with 3D printing. All you need to know is the right 3D printing process for a specific job.

✔️ Do Not Need to Assemble Parts:

Even the intricate designs can be created without the need for printing different parts and assembling them together.

At once, one can come up with the complete object through 3D printing. You have the right material and process available for you. Just make use of these and create an object without much hassle.

✔️ Choose Material as per the Parts you Need:

Depending on the mechanical properties of the object you can choose the material from a long list of options.

For example, you can choose the material based on stiffness, flexibility, transparency and lots of other parameters.

You also have the availability of biochemical materials when working with 3D printing for medical use.

Glowforge Review: The 3D Laser Printer

Glowforge is known for manufacturing laser cutting printers, especially coined as a 3D laser printer. The Glowforge pro laser cutter is one of the most popular devices among all its companions.

So, let us check the various features of the machine that makes it so unique and famous.

Features

This device is a cutter as well as an engraver. The device is desktop-based and can be easily used for home purposes.

Being able to cut a wide range of materials including wood, leather, glass, fabric, acrylic, cardboard and able to engrave aluminum and titanium, this 3D laser printer is a huge hit.

The device comes for $5995 which is way more than its predecessor. However, providing the best results and way more benefits than the older versions.

✔️ High Safety Measures:

The printer has a built-in closed-loop water cooling system. This has been able to remove the requirement of an additional water pump.

The 3D laser printer does have an air compressor. This is included to remove the fumes generated because of the laser beam.

This safety measure taken by Glowforge has helped in preventing ignition as well as damage to the lens.

Moreover, the printer comes fully enclosed so as to ensure that no damage is done to the operator because of harmful fumes and smoke.

With linger lifetime and enhanced safety features, the Glowforge printer has already left many of its competitors behind.

✔️ Laser Tube:

The device has a highly effective and efficient CO2 laser tube of 45W. This provides high power for cutting and engraving.

The precision is up to 1/1000 of an inch. This printer uses a laser tube that utilizes a unique Mode 0′ design.

Because of which the parts are able to achieve higher power density.

Not just that, this 3D laser printer can cut through 1/2 inch of hardwood, all thanks to the powerful laser tube.

Although the build area is limited to 11.5 x 20 inches, it can engrave into any length of material. This is due to the pass-through feature that the device carries.

✔️ Auto Adjusted optical equipment:

This has helped in eliminating the need for lens adjustment that was done manually beforehand.

It also has a honeycombed baseplate which is helpful in allowing optimal heat transfer between the material and the air.

✔️ Cloud-Based Software:

The company provides cloud-based software. The entire software is user-friendly and easy to use.

The software interface is easy to learn and comes packed with various amazing features.

However, the only problem with the cloud-based system is that one has to completely depend on the internet connection for the access.

On the plus side, automotive software updates are available. And, one can use the software with iOS, Android, Windows and Linux devices.

✔️ Proofgrade Material Recommended:

The machine can be used with a number of materials, from various other manufacturers.

However, Glowforge recommends using its own Proofgrade materials. This will help the 3D laser printer in automatically determining the settings, hence, ensuring high-quality cutting and engraving.

The downside of Glowforge Pro

Although there are many benefits to the Glowforge Pro 3D laser printer, the machine is incapable of cutting through metals.

You can still engrave on aluminum and titanium though. For this purpose, 3D printing is the best option.

Read our full review here:

Which One to Choose?

This question is being regularly visited by those trying to set up their manufacturing business. And, the answer isn’t that simple.

Once you know the application of the parts you are building, you must know what characteristics those parts should possess.

This will help you in determining which method or technology would be closest to your needs. There are certain objects that cannot be created without 3D printing. For those applications, the answer is very straight forward.

So, rethink what you need and decide for the best.

The Conclusion

3D printing and 3D laser printing are very different from one another.

While 3D printing is an additive process, laser cutting or 3D laser printing is a subtractive process.

These two are completely opposite and hence are the properties of parts created by them.

While a 3D laser printer is a great option for printing larger parts at cheaper rates, these may require more hard work and extra effort of assembling and combining the parts.

Also, these cannot be used for many applications that are possible with 3D printing.