3D printing has given wings to entrepreneurs and industries looking to reveal the real potential of the fastest growing technology.

The reason that it offers speed and accuracy is one of the most cost-effective choices, leave no room for confusion.

The same goes for jewelry making companies. There is no doubt that technology has reached millions of businesses worldwide and is penetrating even deeper as the economies are becoming synced and demanding.

There are a variety of spaces where 3D printing has instilled its importance becoming the major reason for the profit curve going upward.

From casual visual prototype printing to serious prosthetic manufacturing, 3D printing has been the key to many new developments happening across the globe.

Understanding the same, businesses offering new designs and capabilities through their 3D printing machines have also surged.

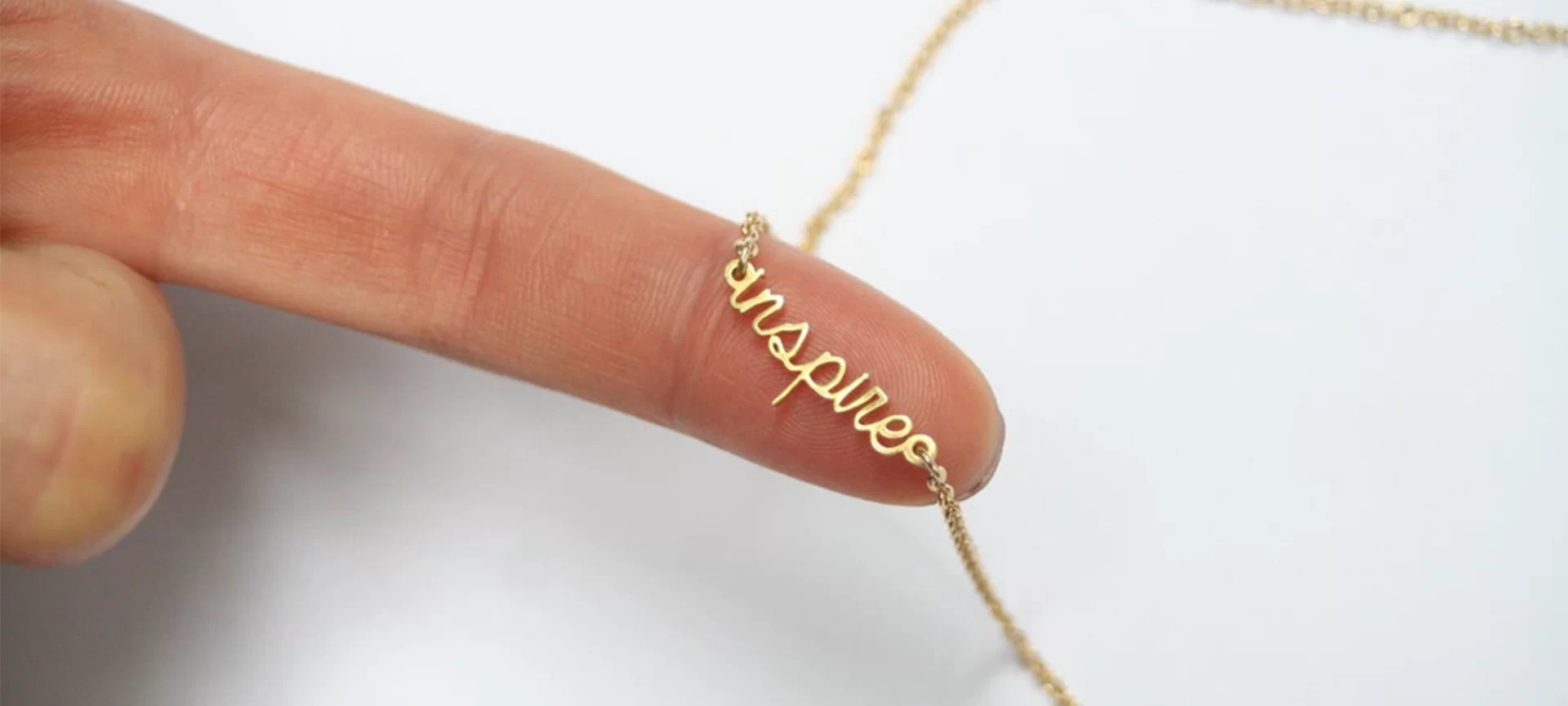

While a few years back 3D printers were sufficed to the hardcore industrial environment, today it has reached even small outlets offering customized pieces of jewelry.

Isn’t that a big leap? The obviousness is because of the benefits the technology shares.

Starting a Jewelry 3D printing business would have sounded like a dream a few years back, but now, people are already using the technology to make maximum profit.

Because the difference between handcrafted jewelry and those printed from a 3D printer is hard to point, the day is not far when 3D printers for jewelry making would become mainstream.

However, there are certain things that you must equip yourself with before joining the league of 3D printing entrepreneurs.

One should never forget that whatever if your skill level, you must face a certain set of complications when thinking of jewelry business.

3D printing has definitely made things easier and faster, the lurk isn’t over until you have learned to consider all the pitfalls before facing it.

Introduction to 3D Printing Jewelry

At its initial stage, 3D printing aimed at creating prototypes. As the demand and creativity surged, the versatility of the technology has widened the scope of its application. And, jewelry 3D printing is among those many possibilities that are accessible through 3D printing.

Many start-ups may feel a nudge to dive into the evergreen and in-demand niche of jewelry making.

Or those already in the business for a few years may feel a need to scale the business involving the latest technology and tools. 3D printing is the answer to both of these categories.

Steps Involved in Jewelry 3D Printing

Like any other 3D printing processes, jewelry 3D Printing works in similar basic steps.

For designing jewelry, specific CAD software are available. The CAD software is used to design various different jewelry and specifications.

If you are not familiar with the software, you must feel a need to complete a crash course before planning to start a business. The software isn’t difficult to learn and uses simple pick and drop features to create designs.

-

- After the CAD file is designed and one knows how the jewelry would look like, the file is exported to STL format. This is done using scaling software.

- Later the 3D printing starts using 3D printers for jewelry printing. Layer by layer, the printing completes.

- The last step involves removing support material which usually is made of wax. There are various steps involved in the post-processing step depending on the jewelry finish and design such as setting stones or polishing jewelry pieces.

You’re welcome to check our article: Best Sites for Free 3D Printer STL Files in 2019

Why 3D Printing for Jewelry Making?

Jewelry making and designing is usually a hectic process when carried out using traditional methods. From carving to finishing, the steps involved may make jewelry makers less interested in the overall process. But, not with 3D printing. It is not only creative but cost-effective as well.

-

- Create Complex Designs: Certain designs are complex and some are even impossible to carve with the help of traditional methods.

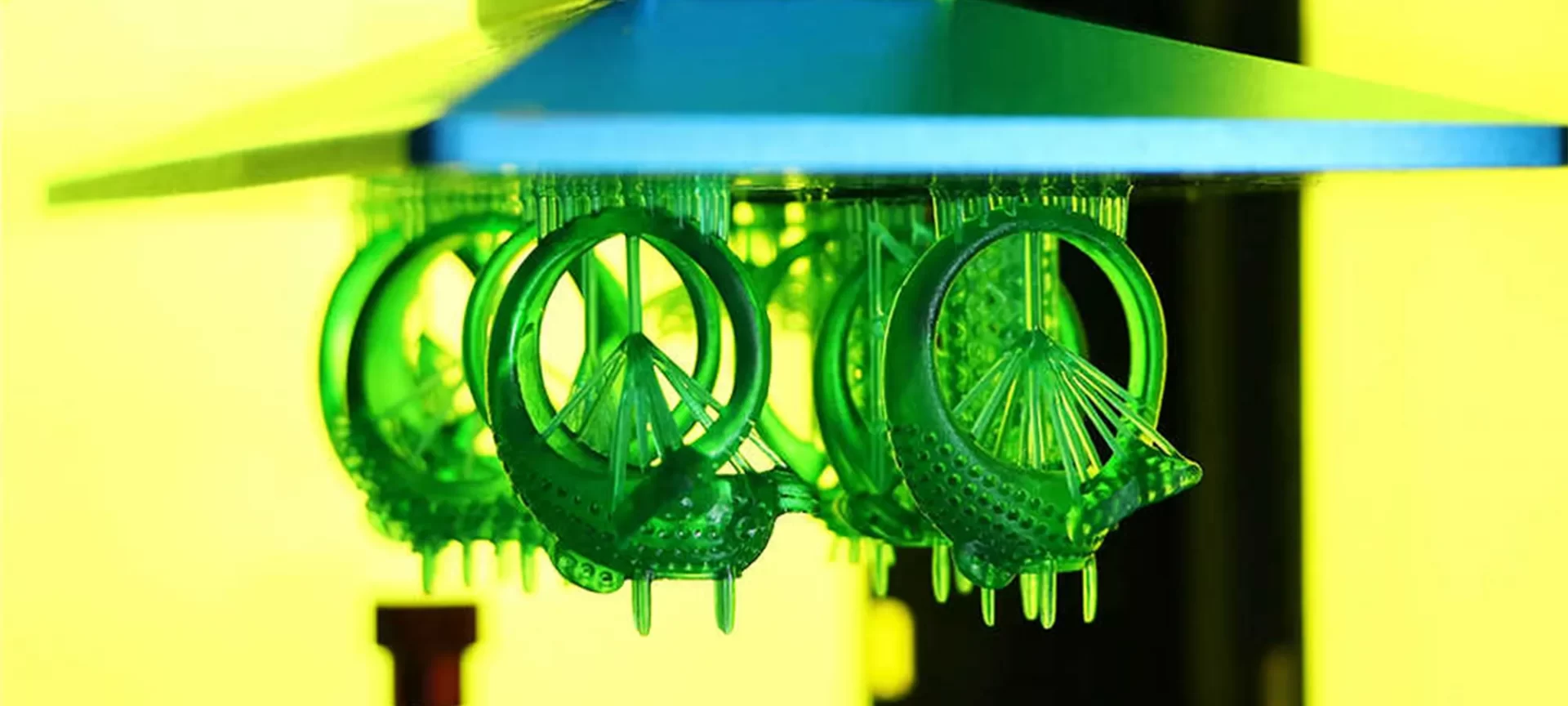

However, 3D printing can make every complex design possible without much of a hassle. The limitations of CNC machines that made traditional jewelry making a challenge isn’t going to hamper the processes involved in 3D printing. - Print Multiple Design: One can easily print multiple designs simultaneously using 3D printers. No longer wait time and the results are astonishing.

- Cost Saving: Because one can easily print different patterns at a time, the cost is highly reduced. The process is cost-effective and saves a huge sum of the amount involved in jewelry making using old methods.

- Create Complex Designs: Certain designs are complex and some are even impossible to carve with the help of traditional methods.

Techniques Involved in Jewelry 3D Printing

3D printing is a well-known technology around the world now. No more confusions remain when it comes to choosing between the old techniques and 3D printing.

In common, there are two techniques famous for designing jewelry: One is investment casting and the other is direct printing.

Investment Casting

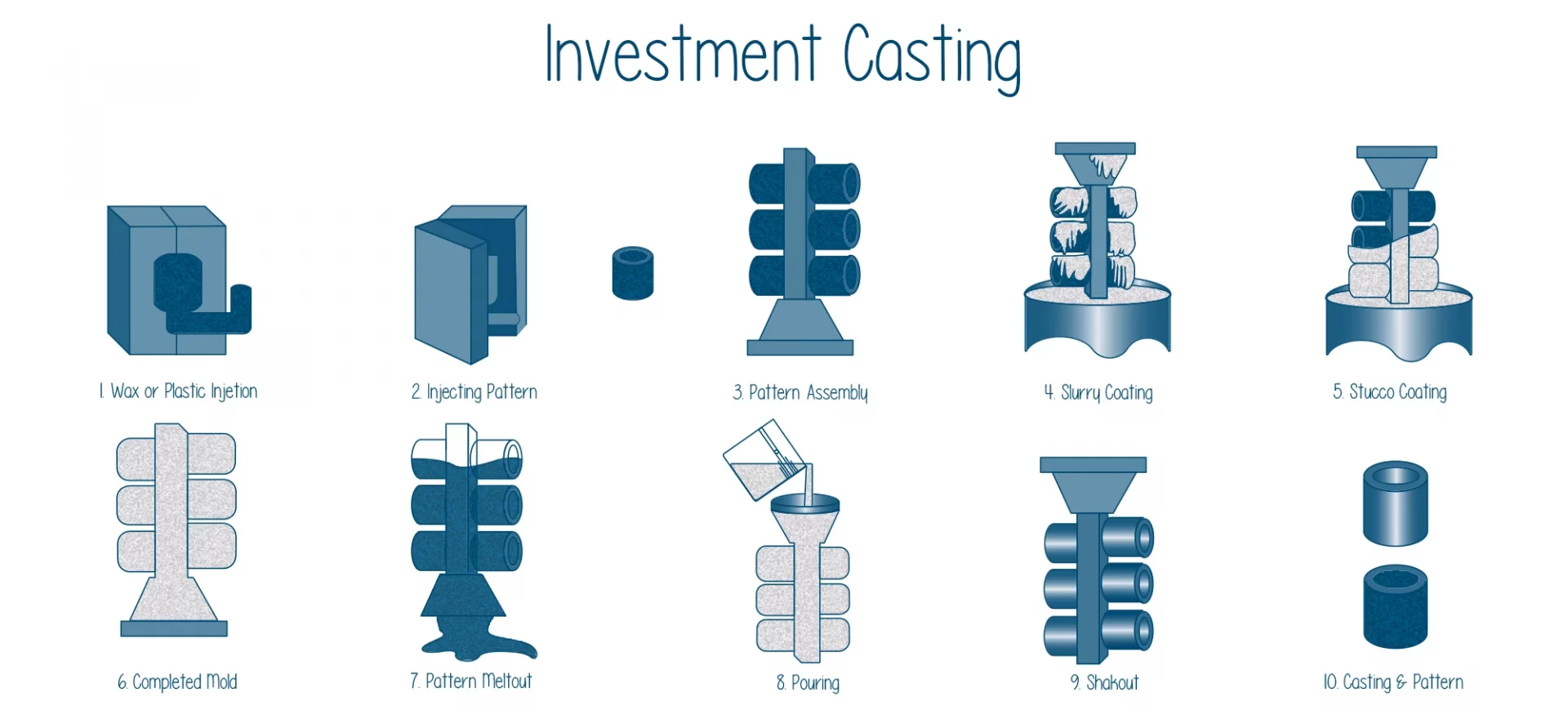

This is the widely used technique for jewelry making. This is completed in 8 steps.

Step #1: Formation of Different Patterns

Before 3D printing was brought to practice, the patterns were made by pouringwax used especially for casting inside a metal mold.

However, with 3D printing, the mold is prepared directly using resin or wax.

Step #2: Assembling Mold

The next step is to prepare the casting tree. The aim of preparing this tree is to be able to cast multiple parts simultaneously.

Step #3: Building of Shell

The tree is then emerged in a slurry multiple times and is left to dry. This solidifies after a while leaving the outer ceramic coating over the pattern.

Step #4: Meltdown

This pattern is placed inside a furnace which results in the melting of wax, leaving the hollow design behind.

Step #5: Pouring

After the wax or resin used to form the pattern has been taken away from the hollow ceramic mold, the casting material is poured inside the mold.

This is left to solidify after cooling. These are usually done with the help of brass and finally coated with metals of choice during the finishing stages.

Step #6: Removal of Ceramic Mold

The ceramic mold is then removed or knocked off by force. It is either achieved by vibrations or literally knocking off the ceramic wall.

Step #7: Cutting Parts

The final parts are cut out from the casting tree to take off the different parts attached to it.

Step #8: Final Touch

These casts are further treated with traditional finishing methods to get the final jewelry ready for selling.

These can further be coated with precious metals or can be joined if in the beads form to make bracelets.

Direct Printing

Being expensive, direct printing is less popular among jewelers. In these methods, the jewelry is directly printed using precious powder.

3D Printing Processes for Jewelry Designing

Among all the major 3D printing processes, three are commonly used for jewelry designing.

-

- Stereolithography (SLA): This 3D printing technology is based on curing liquid resin with the help of light.

- Digital Light Processing (DLP): DLP is similar to SLA, however, it uses a projector instead of a laser beam.

- Material Jetting (MJ): Material jetting with two print jets is used where one print jet deposits the wax-like material and the other one is used to print the support (made with dissolvable material).

- Selective Laser Melting (SLM): This belongs to the powder bed fusion family and is used for printing metal parts. This is usually opted by those looking for direct printing techniques.

Challenges with Jewelry 3D Printing

Either you choose any of the techniques discussed above, there are certain challenges that you might face and must be ready to overcome with the right design strategy.

❌ Problems During Meltdown:

When carrying the meltdown during the investment casting, one should make sure that the meltdown does not happen too quick.

This is made sure to ensure that the resin does not expand from its expected size.

This can severely damage the investment surface and thus the final casting.

Moreover, if the process isn’t taken under the required temperature, it can leave ashes inside the final casting. Hence, the process is the most critical among the investment casting stages.

❌ Removal of Support:

Few 3D printing processes allow dissolvable support while others need to be taken off manually.

If the support is in contact with the surface of the cast, one must have to include further post-processing methods to smoothen the surface in contact.

Jewelry by: 3D Printing vs Traditional Methods

Traditional methods for jewelry making still make up for most of the percentage of business around the world. However, there has been a huge demand for 3D printers and its adoption is surging with time.

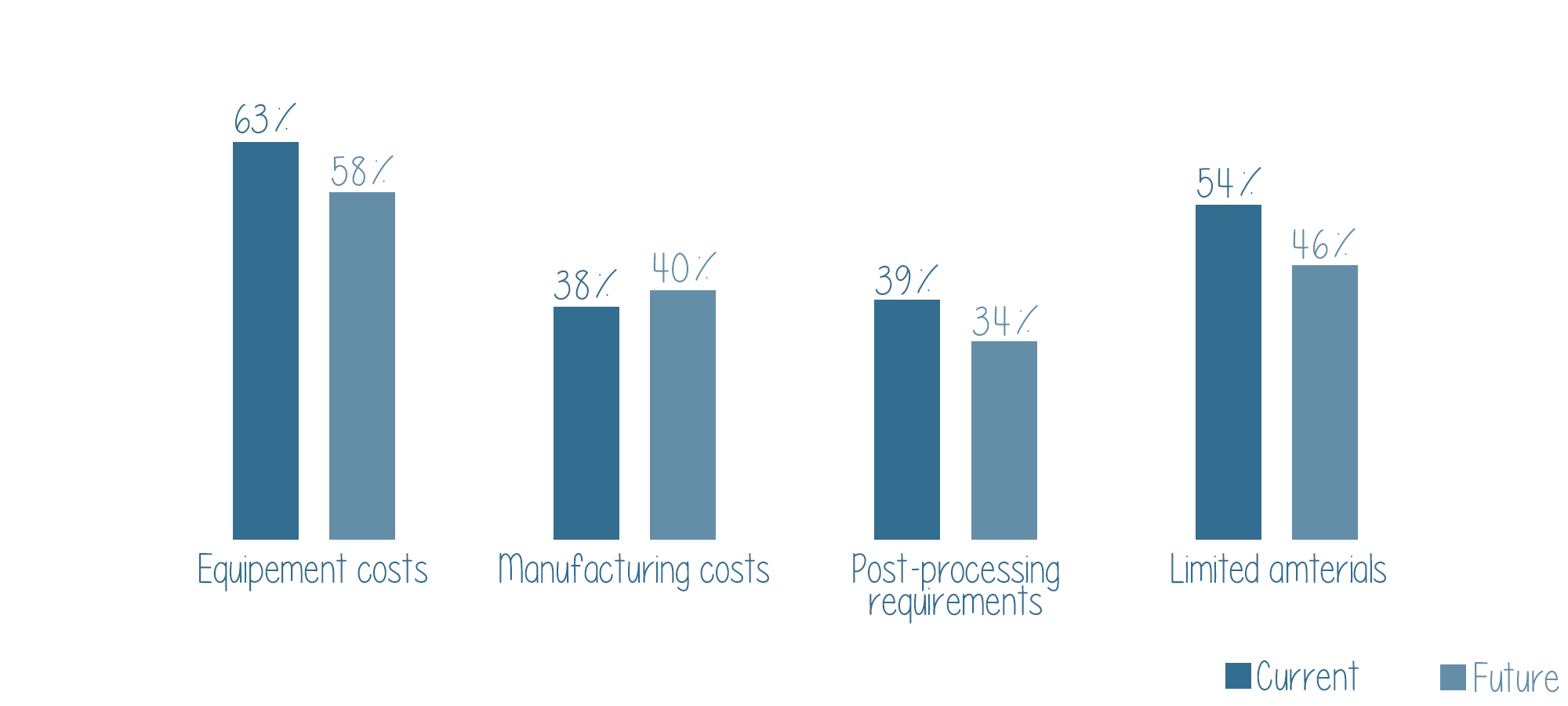

Reasons Restricting the Adoption of Jewelry 3D Printing

As we have discussed how amazing 3D printing technology is, it is imperative to question: why the adoption is still limited to a few jewelers.

#1 Losing the Handmade Touch:

Many jewelers feel that 3D printing will eliminate the feeling of handmade touch that is highly valued across the continents.

Jewelry making has been with us from the last many eras and has been worshiped as one of the holy professions.

Those carving metals to make jewelry are attached to their skills deeply. The introduction of 3D printers would take away the privilege of using their hands to cast the metals.

The emotional quotient attached to the industry resists most of the jewelers from adopting the new technology.

#2 Technical Know-How Challenges:

3D printing comes with its own know-how techniques and learning how to operate the 3D printer is a must before indulging into 3D printing.

To realize the maximum benefit of the technology, one must understand its limitations and how to work around it to compensate for the challenges.

A need for such skills makes many jewelry designers neglect the idea of adopting 3D printers.

#3 The Initial Set Up Cost:

3D printers come with a cost. Fear if the new setup would work or not, compel jewelers to stick to the old style of jewelry designing.

How to Fight the Challenges Restricting Adoption of 3D Printing

As discussed above, there are quite a few challenges that restrict jewelry designers from choosing the new technology quoted as 3D printing over their traditional methods.

However, the good news is that there is a solution to every confusion one has regarding 3D printing.

First of all, there are humans who are involved in designing the 3D models of jewelry that is finally printed.

This means that the inspiration is always passed by a human and not the machine. The printing machine is only a way to make the work faster rather than stealing the human touch.

Moreover, the steps involved during printing as well as post-processing required manual intervention.

There is no step that goes without human supervision

Not just that, the new software and tools are enabling the jewelry design skill to reach to masses.

Because of the ease of design using CAD tools and other software, a greater number of people are involving in jewelry designing, passing the skill from one to another.

Also, those who fear the change or worry about learning to operate 3D printers can find many useful courses for beginners as well as experts available online.

It is easy to learn and practice at the same time while going through these online courses. Once that fear of the unknown is eliminated from the equation, it would become easy to move on with the new and latest technology.

Finally, the set-up cost can be also minimized using different strategies. One can either choose to opt for a crowdfunding website or can outsource the printing requirement for the first few orders. If the returns are noticeable, funding can be taken seriously.

Above all, if setting a jewelry business is your aim, you must find the best way to suffice your goals as well as those of your customers.

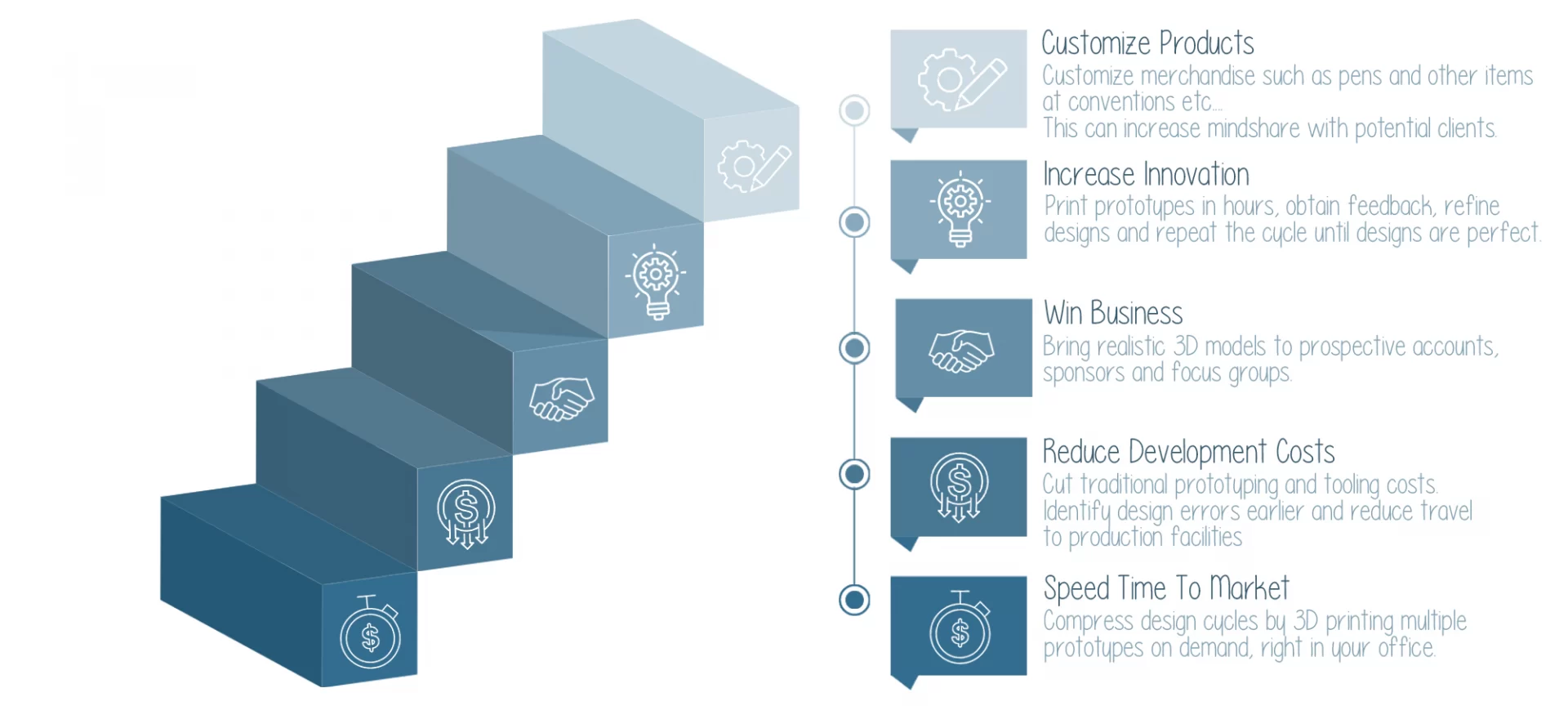

Benefits of Using 3D Printer to Make Jewelry

Jewelry making has always been a huge market and the niche is evolving rapidly making room for newer technologies to take over the older ones.

The need for better designs and fast service has left the industry with no choice but to adapt as per the changing demand.

With time, a greater number of designers are joining the league of 3D printing. And, there are various reasons why 3D printing is being worshiped so much:

✔️ Production Worries are Over:

The best part about 3D printing is that it has made production easier. Once the STL file is generated, there is no longer a need to follow up with the workers and designers for the final part.

There is no difference between the jewelry designed with the same STL file. However, when handcrafted, there is always some or the other difference between each design.

Production aftermaths are reduced greatly when designed with the help of 3D printers. The manual error can also be completely eliminated when using 3D printers.

✔️ Easily Customizable:

Once the CAD file is designed, one does not need to create new files for slight changes.

One can easily customize the already existing file to make changes and create designs with few changes. And, printing is equally easy.

3D printing has given options for designers to print designs that were completely impossible with traditional methods.

Why start from scratch when you need a few changes to the original design to come up with a new model?

✔️ Time-Saving:

Many won’t realize how fast the industry is growing. Customers do not like to wait for weeks to buy the chosen designs.

Also, the hard work involved in traditional methods won’t count when it comes to customer satisfaction. The faster the better.

With this, the time has always been the game changer for those who have been able to serve their customers at the earliest.

So, 3D printing is very much an edge for those looking to build a customer base and win over competitors.

✔️ Easy Prototyping:

Without wasting time and material, one can create prototypes easily with 3D printing.

Think of the changes that you may require after the first prototype is ready. With traditional methods, you are required to go through each step from the start.

However, with 3D printing, you only need to make changes to the CAD file and get the plastic prototype ready right away.

It is cheap and economical as well. Moreover, you do not need to spend extra working hours on another prototype that may again need changes.

What Type of Jewelry Can I 3D Print?

One should better ask what type one cannot print with 3D printing. It is very easy to understand how the definition of jewelry designing is shaping after the introduction of 3D printers.

Just google and you will know to find a huge list of jewelers already offering 3D printed jewelry. The possibilities cannot be summoned as the creativity keeps making it wider.

One can do everything that was not even possible before. The complex designs or geometrically impossible dimensions are just a click away.

Apart from the exaggeration, to make it sound so simple, the technology has definitely made it possible, definitely requiring a part of input from our end.

Which Metals Can We Use?

There is a huge choice for those looking to use 3D printing for designing jewelry. The vast material range also is one of the reasons why the acceptance of this new technology has been easier for jewelry designers.

Here are the most common metals used for jewelry designing:

Brass is an alloy consisting of copper and zinc. Because the metal is highly versatile in terms of color availability and plating options, it is highly popular among jewelry makers.

It is possible to achieve similar visual qualities as expected with other precious materials, however, at a very low cost.

Brass can be used in a number of ways. One can print miniatures with complex details, create sculptures, or print demo models before printing the jewelry with a costly material.

With the use of wax casting, one can design amazing jewelry with brass. Stereolithography is the most common 3D printing process used to design brass jewelry.

One can also use PU coating for smoothness and protection against erosion.

Popular among women of all ages and ethnicity, silver is one of the precious metals around the globe. A lot of jewelry is carved in silver.

The metal itself is soft and isn’t very durable. To add to its strength, it is mixed with alloy for sustaining its usability.

Silver shines even brighter after polishing and is available in various finishes. You can choose between satin, high gloss, antique or rustic look, etc.

Silver is used for designing bracelets, pendants, cufflinks, rings, earrings and other pieces of jewelry in style.

Another precious metal for jewelry designing is gold. Highly popular in every part of the world, gold has its own charisma. Jewelry designed in gold has higher pricing that one designed with silver or various other metals.

Similar to silver, gold has weak strength and is soft. For this reason, gold is mixed with alloys to cast into jewelry that hardens it and stays unharmed for long.

There are different karats of jewelry is cast with the help of 3D printing. You can also design jewelry of gold in mostly three colors: yellow, white and red.

Bronze is also an alloy like brass and consists mainly of copper. It is a stronger option of metal as compared to silver or gold. Moreover, it is affordable too.

The copper is usually designed either with antique looks or with a reddish tint. The most suitable and cost-effective way to print copper pieces of jewelry is by using Stereolithography 3D printing.

One can cast miniatures, jewelry, sculptures and much more with the use of this cheap and affordable metal. Bronze can also be coated with PU coating for a smooth finish and long-lasting use.

Apart from all the above metals, jewelers also use polyamide (nylon plastic), alumide (a mix of polyamide with aluminum powder), flexible plastic, ceramics and much other material for 3D printing jewelry.

Jewelry Printed with 3D Printing

While we are discussing the plethora of options that are possible with 3D printing, many businesses have already made huge profits using 3D printing for jewelry designing.

Here are just a few examples of the companies that are already using the technology to realize the maximum profit.

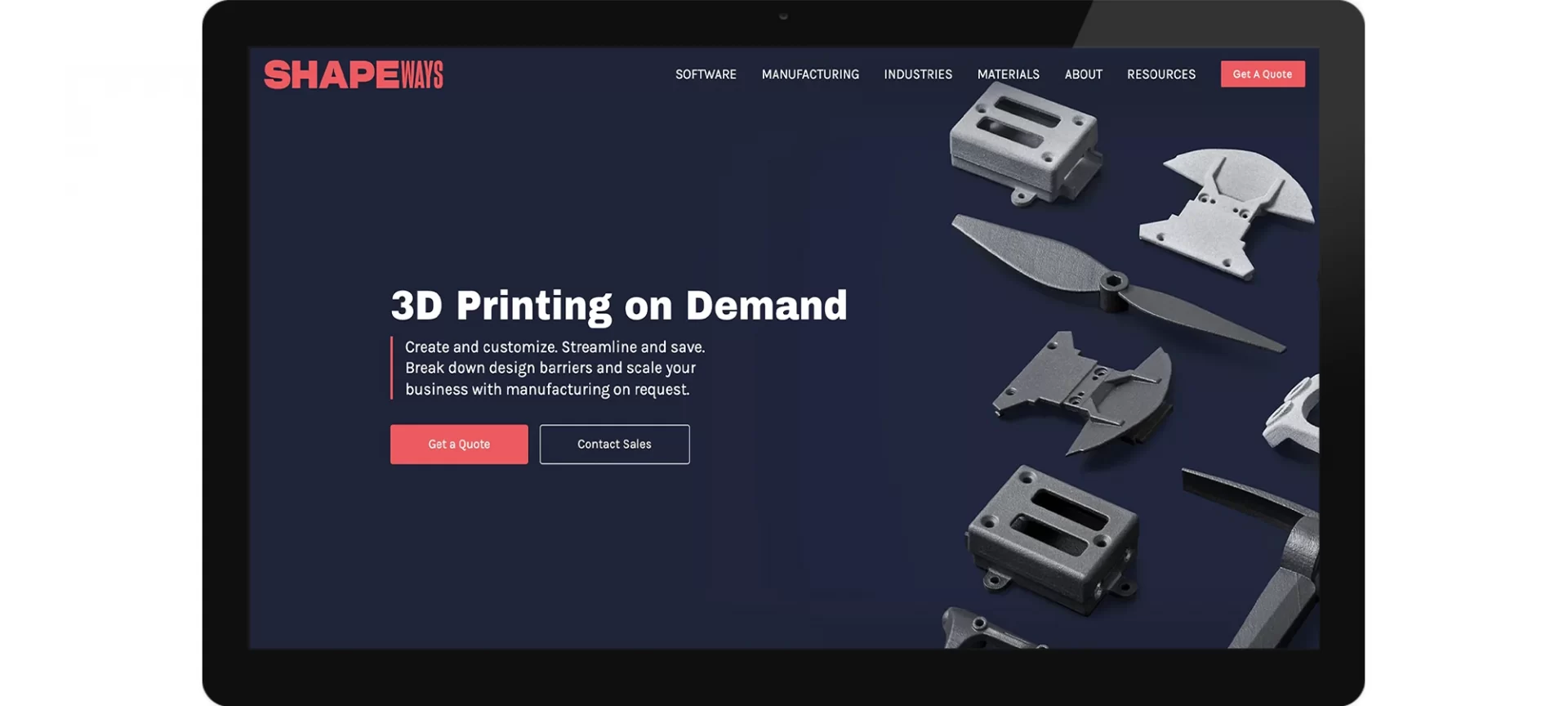

The company was founded in 2007 and is headquartered in New York while collaborating with a chain of partners around the world and serving to almost every country.

The company prints in 50 materials and finishes. Their innovative designs printed with 3D printers can awe every eye. They have created masterpieces in the world of 3d printing fashion accessories.

The company provides you the option to outsource your 3D designs and they ship it right to you with your printed jewelry with all post-processing included.

You can get 3d printed engagement rings, bracelets, necklaces and anything that you like through the innovative offering by Shapeways. From plastic to platinum, you can choose to print your jewelry from the various options the company provides.

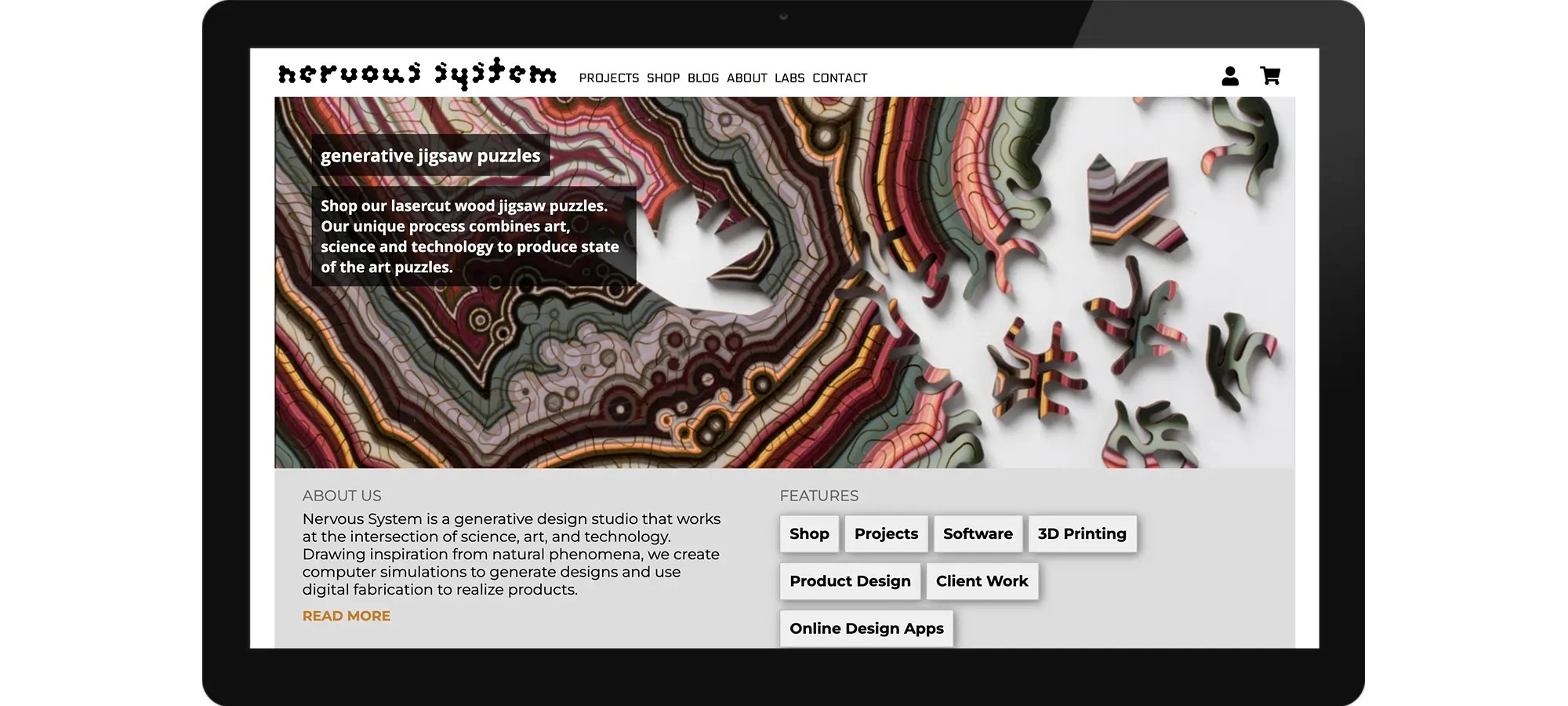

This again is a very unique idea which was started in 2007 and has grown massively in the past years. Located in Catskills in Palenville, NY, the company is serving customers from around the globe with its creative designs and jewelry making technology.

The company calls itself the intersection of science, art, and technology. Using 3D printing, the company is engaged in manufacturing houseware, lamps, jewelry and much more.

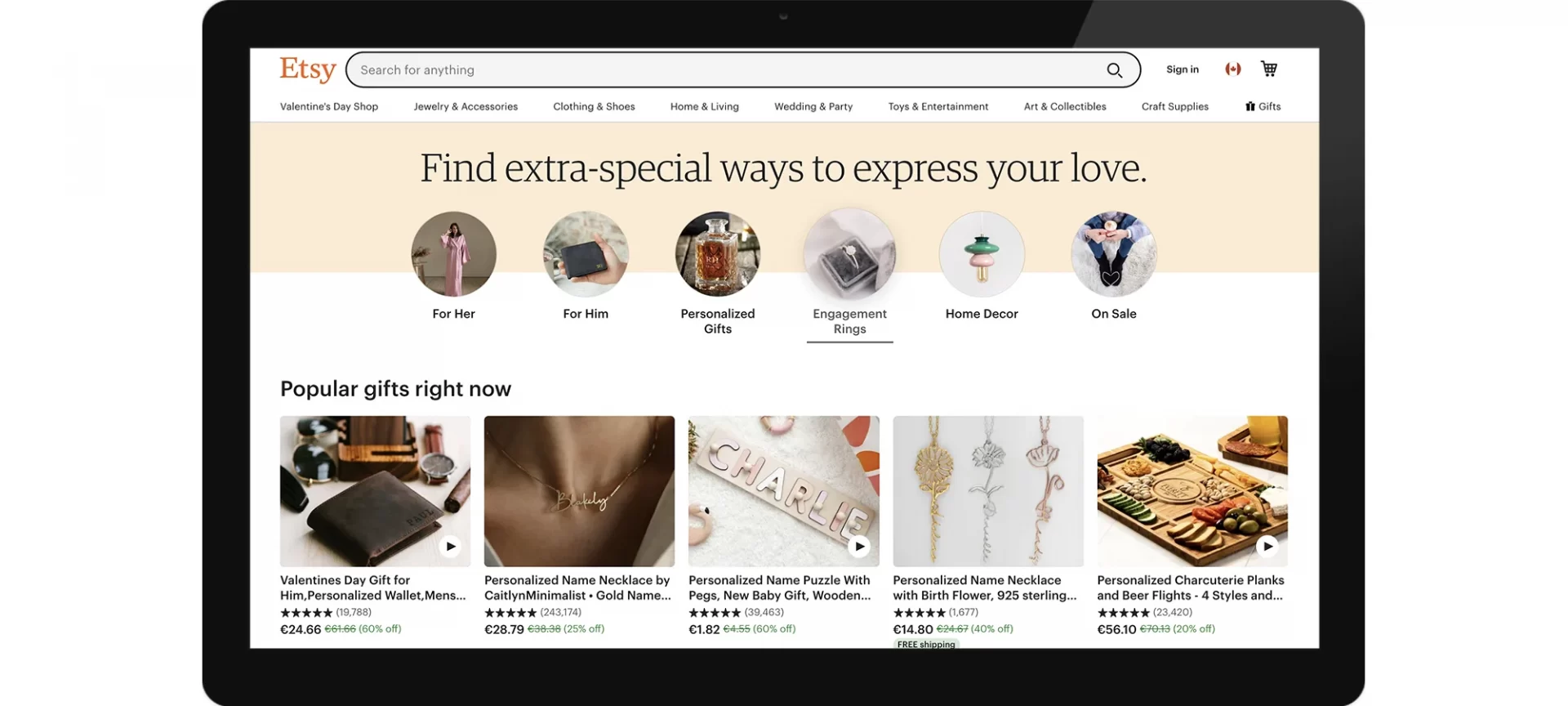

There are many sellers on Etsy selling 3D printed sculptures and jewelry. This is an indication that the technology has reached smaller businesses as well alongside the big manufacturers.

The 3D printed skull, Hummingbird skull ring, frog bracelets are all examples of unique designs that are possible with 3D printing. You can be as innovative as you like when the sky is the limit.

Like many others, you can also choose to feature your 3D printed jewelry on third party websites.

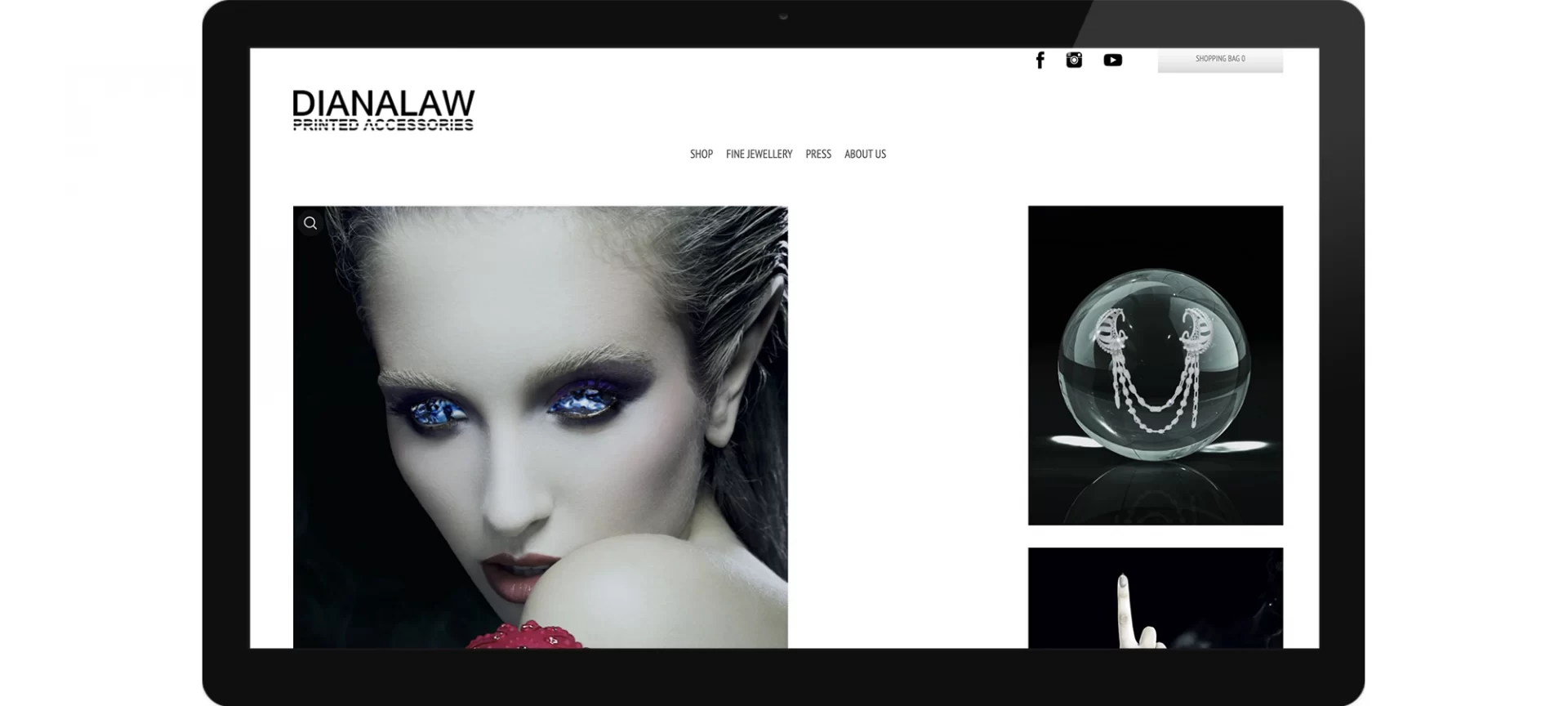

Diana who herself is experienced in the field of jewelry designing started her own brand in 2014 under the name of Diana Law.

She started the company aiming the jewelry designing with 3D printing.

The company creates pendants, handpieces, necklaces, earrings, rings, and much more offering women lovely designs. The company uses SLS 3D printing to manufacture the styles from plastic and steel.

The company is based in Berlin and its designs are influenced by graphics and architectures.

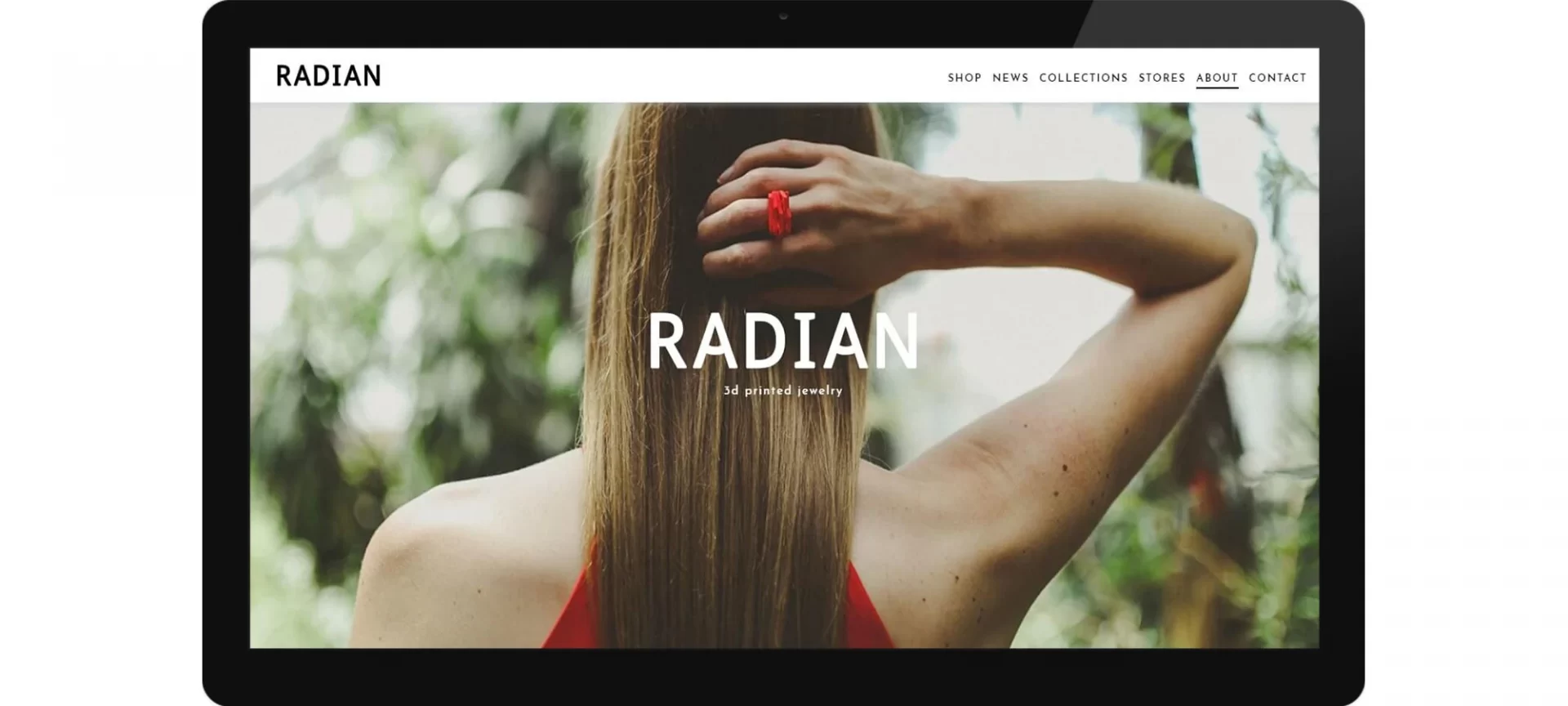

Hence, you would find their jewelry in abstract or geometric shapes. Radian excells at 3D printing jewelry in silver, gold, steel, and nylon.

Radian is very popular among women. The beautiful and excellent styles are printed accurately with 3D printing and sold to their customers.

Can I make a business from 3D Printing Jewelry?

Definitely, one can make a successful business from 3D printing jewelry.

However, as it goes with every other career option, one requires the right skill and intention to succeed.

3D printing may sound like an easy choice, but those whose examples are quoted today have been putting their hard work and experience from years to reach here.

3D printing jewelry is a rewarding business. But it also takes knowledge and experience for those wishing to make it their forte.

If you are ready to fill those pre-requisites, there is no way you cannot create a buzz about your brand alongside many others.

The best part is that there is a huge customer base. Even if you find many competitors, the scope for reaching out and making your own fan following won’t be that difficult when using the right strategies.

Pre-requisites for Starting Jewelry 3D Printing

#1 Find your Inspiration:

Before making any big decision, look for signs. This means you must think of a unique idea that would turn your dream into reality.

When we talk about business, the motive is always to sell and earn a profit. 3D printing jewelry should also end up with sales and more customers on board.

This will only be possible if you have a unique idea to advertise your brand.

As you know that recent developments that made jewelry designing more accessible. So, you must think of a pattern that is unique in itself. For example, abstract designs by Radian.

#2 Take up a Course:

If you are already a jewelry designer, you can skip that course and go ahead with courses on 3D printing jewelry.

However, if you are from a different niche, learning about jewelry and its design using CAD and the latest software would be a plus.

The other skills will follow back. The operating 3D printer is mostly based on trial and error. Once you have mastered the art of CAD jewelry designing, you just need to learn to operate 3D printers.

#3 Research and Choose 3D Printer:

Choosing a 3D printer depends on many constraints (discussed later). So, choose the one that suits your business model and learn about its pros and cons.

Knowing the limitations and benefits of the 3D printer would help you print the best designs with no flaws and less trial and error fight.

#4 Choose the Software:

Not every software offers the same benefit. You can try a few free versions to check how they work.

CAD and scaling software are very important to print designs as desired. So, instead of paying for the subscription of software that you haven’t used before would be a bad idea.

There are companies that offer free trials as well. Utilize everything that you can before paying for it.

#5 Register your business:

This is a mandatory step and every business regardless of what niche it is must register to their territory of work.

Learn about the registration process in your country governing your niche. Make sure you are registered and all paper works are completed in advance to avoid any problems later.

#6 Final Step:

Advertise your brand. This is a very important stage. Printing jewelry and not knowing the ways to sell them would lead you to nowhere.

So, have a plan beforehand and kick start as soon as you have thought of your business line. Do not wait for the prints to come or for the completion of your course. If you are confident about what you aim, keep talking about it.

How to Brand Your Jewelry 3D Printing Business?

It is very important to be visible to your customers. Selling online is the best way to be omnipresent. And, it is also the best way to sell across borders.

Get a Logo:

Why am I stressing on the logo is because this is the first thing that customers will be able to recognize you from?

Jewelry designs from popular sellers do not need an introduction. Your logo should have the same effect.

It should not be too lengthy and able to convey the meaning of your inspiration.

Build a Website:

Many decide to use various third-party e-commerce websites to feature their products as they already have their customer following.

This isn’t a bad idea. However, owning a website does not aim only at selling. A website increases the trust of your customers.

Also, you may have to compete with many other companies when selling on other websites. If you work to get your ranking better on Google, you can build your own customer base.

Participate in Blogs and Forums:

Brands always find it hard to make their presence feel right after inception. This is the time when patience is equally important alongside with the right strategies.

Participate as much as you can on the hot topics related to your niche. Make your presence felt. Write blogs and share valuable information that is difficult to suffice within your website.

Social Media Presence:

Making accounts on social media isn’t the only answer. If your business wants to attract customers, you must give them reasons to connect.

Share your new designs, your ideas, and values that you are trying to add to your customer’s life with your innovative style.

You can certainly use various digital marketing strategies to boost the ranking of your website on Google and other search engines. But, always remember, these may accelerate your advertisement process exponentially, but only your quality and commitment to uniqueness would help you stay on the top forever.

3D Printers for Jewelry Making – How They Work & Which to Choose

There are different 3D printing technologies used for different techniques of printing (Investment casting and direct printing).

How 3D Printers Work?

For Investment Casting, there are three technologies that come into play: SLA, DLP, and MJ.

SLA and DLP work in a similar fashion with few differences. Both both technologies use UV rays to cure the resin, one layer at a time. The major difference in the choice of light source involved in these two technologies.

While SLA uses a laser beam, DLP works with a projector. DLP is a faster technology as compared to SLA. However, SLA is more precise with getting finer details straight.

SLA is the most popular 3D printing technology used among jewelers because of its affordability and quality of prints.

Both SLA and DLP will require support for printing, mostly when the parts are printed with overhangs.

The post-processing is required when working with these two technologies to remove support or smoothening the surface of the support in contact with the part.

On the other hand, material jetting (MJ) comes with two print jets of which one is used to depositing part material and other deposits support material which is dissolvable.

Those looking for direct printing must choose SLM (selective laser melting) 3D printer. This 3D Printing technology is used for casting metals directly and is expensive.

Those working with SLM do not need to worry about printing wax or other processes involved in investment casting.

However, it does restrict the finishing step to certain constraints and is very expensive. Hence, less popular among jewelers.

To learn more about 3D Printing processes go to this post.

Factors Influencing Printer’s Choice

Where can I find the best 3D printer for jewelry? Getting a 3D printer for designing jewelry isn’t an easy decision.

Some take months to learn about the advantages and disadvantages of different options available and still aren’t able to take the final call.

There are many versions of 3D printers available. The most popular ones are those based on SLA 3D printing technology unless you want to direct print the jewelry.

If you are starting it new, you must go with the investment casting technique and select the right SLA 3D printer based on the following factors.

How much you can afford:

When starting a business, you know you have a limited budget for everything you need to kick start your production.

This starts with your inventories to paying salaries and everything in between. You also must stack some cash to ensure you do not fall short with your finances if the plan doesn’t work according to your set milestone.

Hence, buying a printer with all the best qualities and paying everything you have won’t be a wise option.

Jewelry business is an expensive choice. And, making every decision with prior planning would save you from a lot of headaches later.

How fast it prints:

You need a 3D printer to run a business. And, to do so, you would need an option that can get your job done faster.

You must find a decent option that is affordable and prints with good speed. Or else, making it fit in your budget, you may end up buying something that delays all your production time.

How accurate it prints:

Jewelry designing is all about precision and accuracy. Can you ever choose a design that looks vague and has uneven design?

Your customers will also not like the same. Even if you have the best designers to make the most astonishing jewelry, a 3D printer without accuracy will put all the hard work inside the bin.

Accuracy is a very basic factor that can change the face of your brand. If it’s not satisfactory, your business may never be able to kick off.

Which Material You Want to Print:

Not every 3D printer supports every material. If you wish to print jewelry directly, you must go for the right printer that supports metal printing.

You may have to try various materials as well to understand which one would justify your designs the best.

Hence, 3D printers with multiple material support and affordable pricing for materials would be the right choice.

Mass Manufacturing:

If you are a business owner, you need bulk printing. A 3D printer that prints in mass would be the right choice.

Even if you are starting alone and would like to print a few in the beginning, you must choose the one with mass manufacturing.

With time the demand will increase and you must be prepared to complete them on time.

The Best 3D Printers for Jewelry Making

The 3D printer is the backbone of your business if you are planning to base your casting on 3D printing technology.

One wrong selection and it would lead to a number of problems. Because these 3D printers aren’t cheap, it is safe to research and find out the best available option that fits your design requirement as well as your budget.

Here are a few popular and amazing 3D printers for jewelry designing:

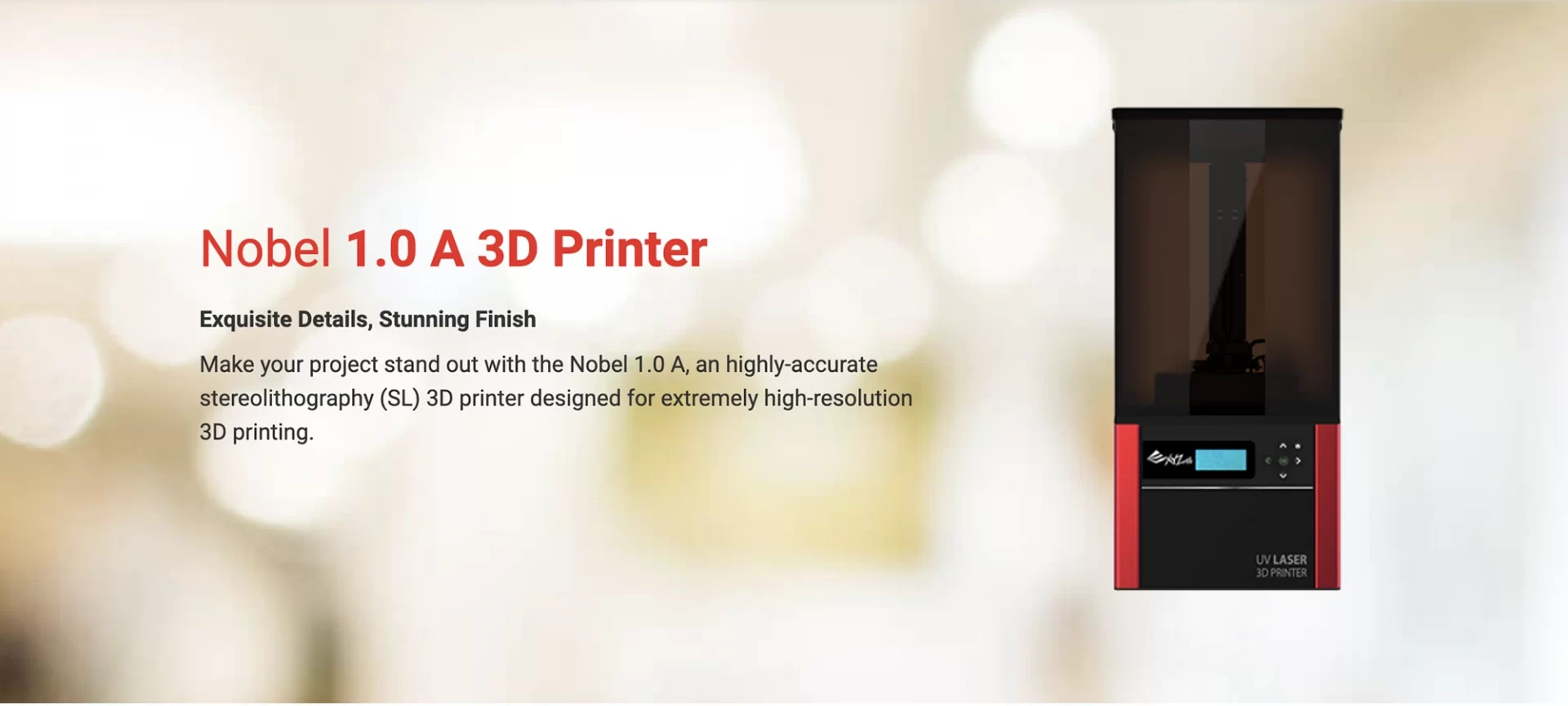

Nobel 1.0 by XYZprinting

This 3D printer, popularly known as Nobel 1.0 is based on stereolithography. Being a prosumer grade desktop 3D printer and providing amazing laser precision, it offers high output printing quality.

This is an affordable resin 3D printer able to print minute details with ease. The best part is that it can be set up in about 1 minute and you can start printing right away.

This plug and play design comes handy and great for someone looking to start the jewelry 3d printing business.

With a simple design, it offers great printing capabilities. The plastic hood lets you peep inside the printer while checking each step of printing closely while blocking the UV rays.

The SLA printer has brought the price point competitive with the FDM 3D printer. However, it is slower than expensive models and a little bit struggles with finer details in smaller parts.

But, if you are struggling to find an SLA 3D printer to design jewelry with a limited budget, you may like to look into this option as it offers some great features for professionals.

S300 Series by Solidscape

Solidspace has come up with three versions of S300 series: S360, S370, and S390. All these three designs are designed for those seeking amazing jewelry designs with fine prints.

These printers produce dissolvable support and can easily be separated from the wax mold without leaving any roughness on the surfaces in contact.

Moreover, printers do not use any toxic material. So, you can work around the printer without gloves without worrying about safety.

When choosing the versions S350 and S370, you won’t even have to worry about post-processing. Only those parts that are made with support would require the application of dissolvent which is nothing more than just a piece of cake.

S390 is, on the other hand, comes for a high cost that not everyone can afford. It clearly suggests that this version is for businesses with clear motives and set targets.

With great post-processing alternatives, S390 saves time and energy and creates best finishes for jewelry casted with this 3D printer.

Form 2 by FormLabs

FormLabs is one of the best companies creating SLA printers. After the breakthrough of their Form series which are specifically the desktop series, made FormLabs even more famous.

Only after the release of their form series, it took no time for jewelers to include the machine to their jewelry designing regime.

Form 2 is easy to work with. The simple and mature software taking care of your design and great resin support to print fabulous parts, make Form 2 one of the most demanded SLA high-resolution 3d printers for jewelry designing.

Form 2 by FormLabs is an SLA 3D printer with an affordable budget. This is not a 3D printer for someone to choose as a hobby.

It is for those who are professionals. One must have a clear vision and budget targets when thinking of Form 2.

This 3d printer specially designed for jewelry making comes with an integrated resin system. This is included to make the management of material easy and simple.

To switch between the materials, all you need to do is replace the cartridge. You get clean and clear operation and it can be operated for larger prints as well.

Form 2 is designed for providing the highest precision and quality. It is a reliable 3D printer and works hard to put your design into play.

SLA 3D Printer by Peopoly Moai

This is one of the cheapest SLA 3D printers for jewelry printing. Being cheap does not always mean bad. And, this is the perfect example of that saying.

This printer is very much capable of delivering affordable as well as professional results. All you need is the right resin and skills to print it right.

If you are starting your business and looking for a choice that can go hand in hand for years until you can afford an expensive one, this choice won’t disappoint you.

Allowing you to produce layers at a height of 5 microns, Peopoly Moai provides high accuracy and great detailed designs.

The 3D printer comes with a simple assembly unit and owns a sturdy body to take you for years in the long run.

The company also provides a build guide with some support material. You can simply call it the beginner’s friendly 3D printer with all the features loaded to support professional print.

Vida cDLM by EnvisionTEC

This printer was launched in 2017 by EnvisionTEC and has since gained popularity over the years with its few amazing 3D printing features.

This is based on DLP technology and print faster by continuously moving the build plate while the printing is happening.

It requires a few hours to create prototypes using this printer. You can create castable models using Vida cDLM especially designed for jewelry designing.

The printer casts amazing models and makes sure that the work is completed in no time.

You can feel at ease while working with the set up as it is easy to operate and does not need consistent supervision when the models are printed.