Yes, this is no more just a thought, but people are already 3D printing food in their kitchen. While you sit there fantasizing what it would be like to have a 3D printed food, there are others who are already working to bring the technology to their kitchen counter.

Hence, without much wait, let’s find out how can you too print food from these astonishing machines. If you are already a maker and have been working with 3D printers, you may have most of the things available to start 3D printing food.

How to Prepare 3D Printed Food?

Like always, 3D printing has huge potential, however, it does have few limitations too. In terms of speed, you may like the idea a bit restrictive.

So, if you wish to use 3D printers for mass production, you may have to deal with the challenges of speed. However, if it’s not about serving the orders right away, a 3D printer could be a huge deal.

So, let’s find out what all things you would need to prepare 3D printed food. Above all, how to start with the entire process.

Think of a Recipe You Want to 3D Print

As you must have expected, you would need to think of a recipe you would like to create using 3D printers. Let me explain this clearly, not every extruder will be able to print different kinds of food.

And, the food 3D printers that are available out there are engineered to perfect one or a few items. So, deciding what to print using a 3D printer must be your first goal.

A lot of people do think of chocolates, because, they are everyone’s favorite. And, you can actually sell them when printed in attractive shapes and flavors.

However, these are the messiest when it comes to printing. This is because of the precise temperature requirement and a lot of other constraints.

Although if you are someone who likes challenges, you can go for it, do not forget there are other options too. As a starter, you can go with easy choices that offer consistency of the material you use. For instance, puree, doughs, and even mashed potatoes.

Get a 3D Printer for Creating 3D Printed Food

Choosing a 3D printer is a huge task. We have mentioned a few recommendations below. You can pick from those. Or else, if you have an open-source 3D printer, you can make enhancements to the same.

And, if you at all decide to go for upgrading an existing 3D printer, you must look for the right extruder.

The usual 3D printer would allow you to achieve a three-dimensional motion, however, you still need to work on the right extruder. Here is when the choice of recipe would help decide which extruder mechanism you must choose.

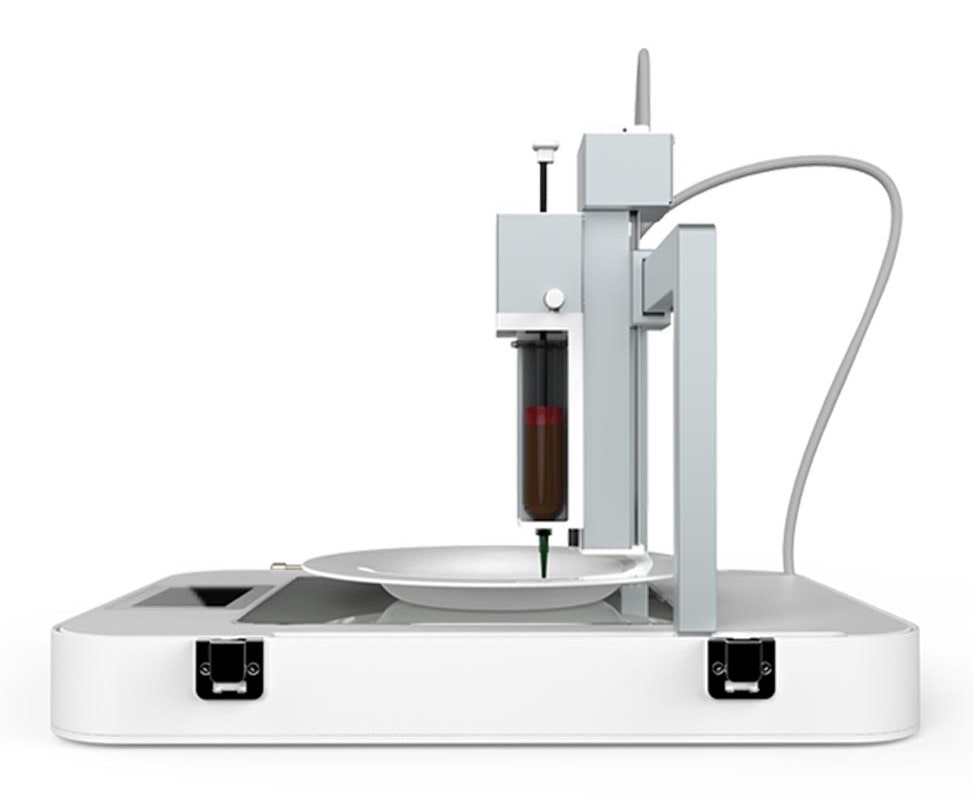

Here as well, you can create your own extruder. The syringe mechanism extruder is the most popular one.

This is because of its simple workflow and use. There are other designs though from the open-source community.

The thickness of the material would help you choose the right fit. For instance, if your material solution has a thinner consistency, you can use a small syringe extruder. However, in the case of thicker solutions, you must go for powerful extruders such as beefier.

Also, there is a certain pre-existing extruder that could go well with your 3D printer, requiring a few modifications. You have got a lot of choices to buy.

For instance, Discov3ry, 3D drag extruder, and others. In case, the mixture is as touch as cookie dough, you can look for air compressed extruders. You can control these manually in between the prints to adjust against the material consistency.

After you have chosen the extruder, install it on the machine.

Prepare the 3D Design File

The food 3D printer also works similarly to its standard mechanism. Hence, you will require a 3D file. If you are not good enough with the 3D art, you may have to face challenges looking for the designs online.

Also, if you design and good at it, there are problems such as compatibility issues. For instance, you may find a design app, however, it may not be compatible with the printer you are using. Hence, it is better to go with the application that you are already using with your 3D printer.

While designing, you must not forget to adjust settings depending on the material you are printing with. Some solutions would allow you to hold higher builds.

However, others may fall off in between. Also, there are chances for deformation. The best way to sort these problems is to experiment with your settings and find what sails you through.

Try to learn about the limitations that each material brings with itself. Food 3D printing is still growing and we may not have the obvious answer for everything.

But sooner or later, with experiments and conclusions, we will reach a satisfactory stage. Until then, you keep trying to make wonderful dishes from your 3D printers.

Last Step to Printing – Adjusting Slicer Settings

Once again, the steps remain the same as it is with the usual 3D printing process. You must adjust the slicer settings to accommodate to the needs of the material chosen to print.

To be on a safer side, you must not choose a very high speed. On the contrary, go with slow printing speeds.

Allow for multiplier settings to give way to the right flow of the mixture. Also, do not forget to use the retraction settings for avoiding dripping of material in between.

The settings will mostly depend on the food you want to create. And, the material you choose to print with. Hence, you must go through the settings a few times to understand what slicer settings fit the best results.

The mantra here is to not give up. Trust this, when finally, you would start printing, there will be a huge amount of frustration handling different consistency of solutions. But you need to play around with the settings to ensure you have tried all the possible ways.

Because if you do that, there is certainly a chance that you would find the right settings for your desired material.

Tips for 3D Printed Food

Now that you know how the 3D printed food is prepared, it is time to learn about some dos and don’ts. Although it is a fun experiment to 3D print food, you must not forget that you are going to eat it. So, it is important to take some safety measures.

To start with, you must keep things clean. Any direct contact surface with the material must be washed perfectly. This would help you keep your food items edible.

What are the Best Food 3D Printers?

You must have geared for counting on the popular Food 3D printers available in the market. So, here is a list of a few of the most adored options out there for consumers.

PancakeBot

Did you know that the PancakeBot first surfaced after being made out of LEGO? Yes, it did. However, it did hint the inventor of its huge potential.

With flaunting a huge success with the Kickstarter campaign, the 3D printer became available for purchase.

There are various new features included with the PancakeBot 2.0. It features better and faster speed control coupled with a user-friendly interface. It would cost around $299.

Byflow Focus

This again is a nice option for those with serious love with 3D printing. It costs around $3700 and is one of the most unique offerings by far. The fact that the machine can be folded into a suitcase weighing just 7 kgs, make it a perfect fit for those who love traveling.

You can carry your 3D printer with you, wherever you go. And, have food prepared on your own. Sounds interesting? You must try it to find what’s more astonishing about the choice.

Setting up the 3D printer takes no more than a few seconds. And, it can start printing right after 2 minutes of setup. It comes with interchangeable print heads.

The best part is that the print heads can be shuffled with the choice of your material, either provided by the company or made yourself.

Bocusini

Bocusini is one of the most popular selections with offering various latest features common among the machines available today.

The 3D printer is a hard work of Print2Taste, a Munich-based company that launched the idea back in 2015.

With huge progress and advancements, the company has already released its 3.0 Pro version in a short span of time. Apart from the food 3D printers, the company also engages in offering customers with a variety of 3D printed food materials.

What makes this company unique is its disposable cartridge system. Using which, the food material never comes in contact with any part of the 3D Printer, keeping it safe.

Pros and Cons of 3D Printed Food

The technology has not been acclaimed commercially, and there is a reason for it. Hence, let us find out the various pros and cons of 3D printed food and know where we have reached and what entails beyond.

Pros

One can create huge differences in the way we expect our food to be. It can provide varieties for the textures, artistic designs, food shape, and many features of the existing food. It can immensely help in bringing impossible varieties to the table.

The food can now be easily transportable using 3D printing solutions. Even in space, the availability of meat and other variants can become accessible. It could add sustainability.

3D Printers, with the right settings, could even surpass the traditional method of cooking in terms of the consistent temperature availability and various other parameters.

Cons

As you know that the technology is still growing and there is a lot to learn while we progress to the future, the need for a reliable solution is still far-fetched.

For instance, you may be able to achieve the perfect texture every time you 3D print, however, there are still limitations when printing fragile structures.

Again, speed is also a huge issue. The food 3D printers take a lot of time. And, in a commercial setup where orders need to be processed in the minimum time possible, depending on a slow device would ruin the entire restaurant’s workflow.

Mass production becomes a huge problem too. Serving a huge bunch of people may get you into trouble if you plan to use the 3D printer inside a restaurant’s kitchen.

There are ways to reduce the overwhelming costs of specialized food 3D printers. You can set up a food extruder on your regular 3D printer.

However, the results won’t be satisfactory. While this could work for home use, it won’t help commercially. So, you must expect a huge investment when considering to buy a professional food 3D printer.

Last but not the least, the safety of food must be the priority for every maker. And, it becomes an extra load with working with food 3D printers.

The Conclusion

There has been huge progress in the 3D printing arena since the time it first surfaced in the 1980s. We have traveled a long way.

Undeniably, we do have surpassed our expectations. However, there are few niches, where the application of 3D printing is still new. And, the food industry is one of them.

The 3D printers which have been designed so far, do offer huge potential. But currently, they lack the edge to suit the commercial setup.

You can definitely buy your own 3D printer and experience the perks of the technology. But there are almost slim chances that you would find a restaurant nearby serving you 3D printed food.

That brings us down to the same question: Is this technology sustainable enough? We are hopeful that in the near future there would be considerable changes.

The developments are already in action. And, anytime, we may hear the announcements that would amaze us, as the release of first desktop 3D printers did.