With more people engaging in 3D printing, the competition between entrepreneurs is taking a sharp rise.

The awareness about the benefits of 3D printing and its application is also making its way through different niches.

However, not every 3D printing business is a success. Like every other technology, 3D printing has its own limitations.

Those who are able to overcome those challenges are making huge profits through this technology. And, others are still confused about what went wrong.

If you are seeking help to understand what works and what doesn’t with 3D printing, you must figure out the key elements for a successful 3D printing business plan.

You must plan right from inception to customer acquisition to customer support if you want to provide an edge to your business.

3D printing technology may have surfaced long back, but its potential keeps evolving.

The last time we knew 3D printing was used for prototype creation and the next time the medical industry started creating prosthetics.

Today, the applications are limitless, from space to food items, 3D printers are making their way to every corner of life. The day isn’t far when 3D printers would make to the houses too.

What Are The Key Elements for Starting a 3D Printing Company?

3D printing is fueled through creativity. As time is passing, we are able to understand the unusual things that this technology is capable of accomplishing.

And, it is not stopping here. There are many types of research going around 3D printing technology.

Governments of different countries are trying to make 3D printing available for many causes. From natural calamities to medicine printing, 3D printing usage is surging.

Tapping into the fastest growing industry wouldn’t be a bad decision. Those who are planning to start a 3D printing business at home, however, must know what are the 3 basic key elements that must be followed in order to make this a success.

Selection of Niche For 3D Printing Business

Though the infancy of usage of 3D printing seeded in the 1990s, the technology was mostly limited to industrial use for many years, especially involved in printing prototypes.

However, since the last couple of years, its application has risen. There are many ways one can utilize this technology while thinking of starting a business around this technology.

But the decision isn’t that simple. The good news is: it is not impossible. According to experts, starting a 3D printing business requires one to learn the technology alongside the responsibility of running the business.

This makes it even more important to know where your skill lies. This will help you a lot in choosing among different niches involved with 3D printing.

Usually, the 3D printing uses in business fall in majorly five categories. Once you have a lucid vision of what option suits your skillset best, you can start building your business around it.

Creation of Files

As the name suggests, this category is mostly about working with the software instead of 3D printing.

If you are great at CAD software and have a design background, you can help your clients by turning their imagination into 3D printable files.

If you are interested in learning CAD, you can do that too. Businesses involved in creating 3D printable files are easy to start and require fewer funds.

Even if you do not have a printer to print those files, you still can sell the files to your clients making a huge profit.

Service center

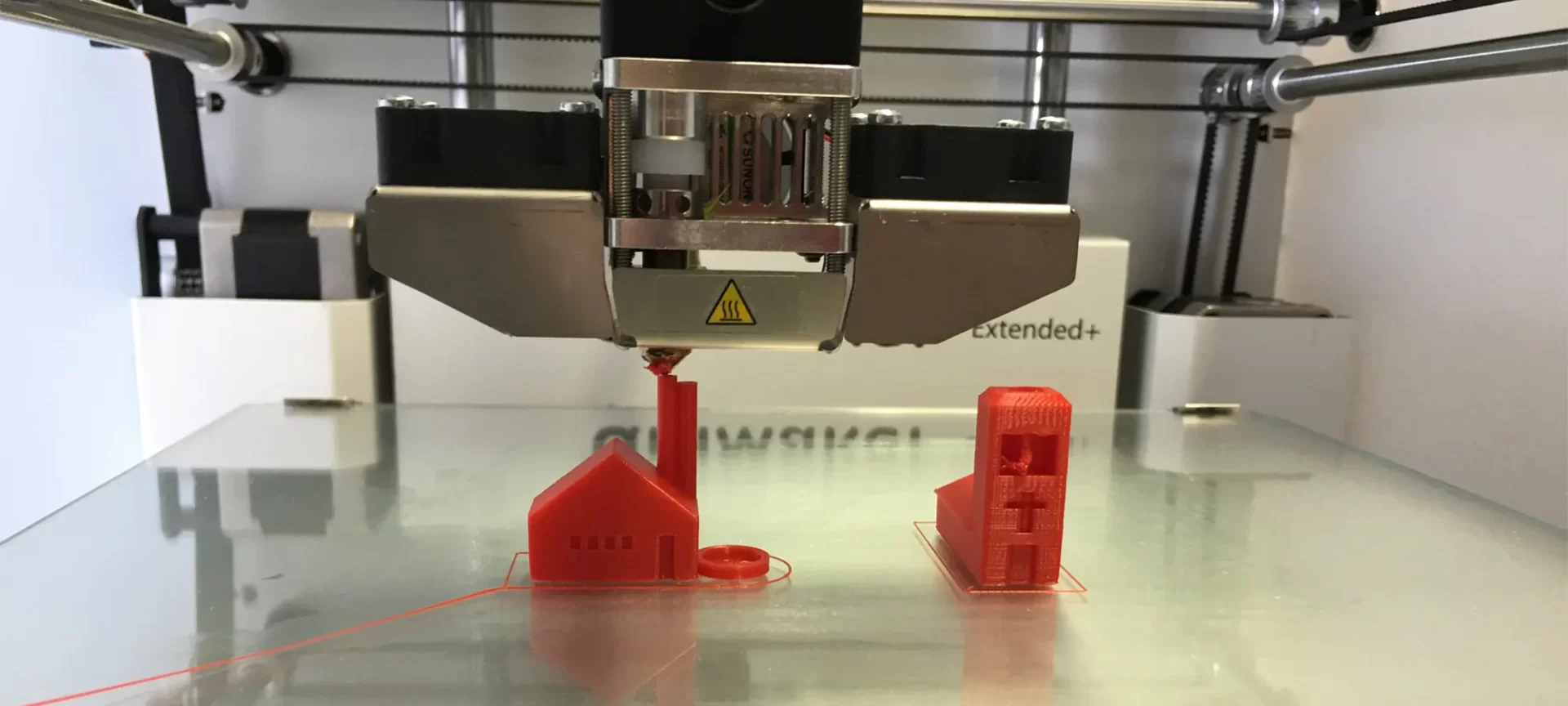

This is a crowded option. If you are looking to start a high-quality 3D printing service center, you must own 3D printers.

The competition lies within the turn around time and quality of prints you provide to your clients. You must own a printer than can print sophisticated designs with ease. It must be able to outline the finer details of the print clearly.

Moreover, as the competition is high, you may have to think of the niche that is less served.

There are many huge players already involved in serving niches like medical, e-commerce platforms and many others. In such a scenario, if you wish to step your foot, you must find a niche that is less engaged with 3D printing.

Software Development and Printer Manufacturing

Instead of printing or creating files, there are companies that manufacture such 3D printers to sell it to the customers.

These can range from consumer models to the ones used for making prototypes in industries and manufacturing units.

The cost to start such a business is very high. Most of those who are involved in manufacturing 3D printers or develop CAD software are from manufacturing, software design, and research field.

This is not a business that can be thought of one day and could be started the next day.

It requires a high knowledge of working on printers and software. On top of that, a huge fund which isn’t easy for everyone to arrange.

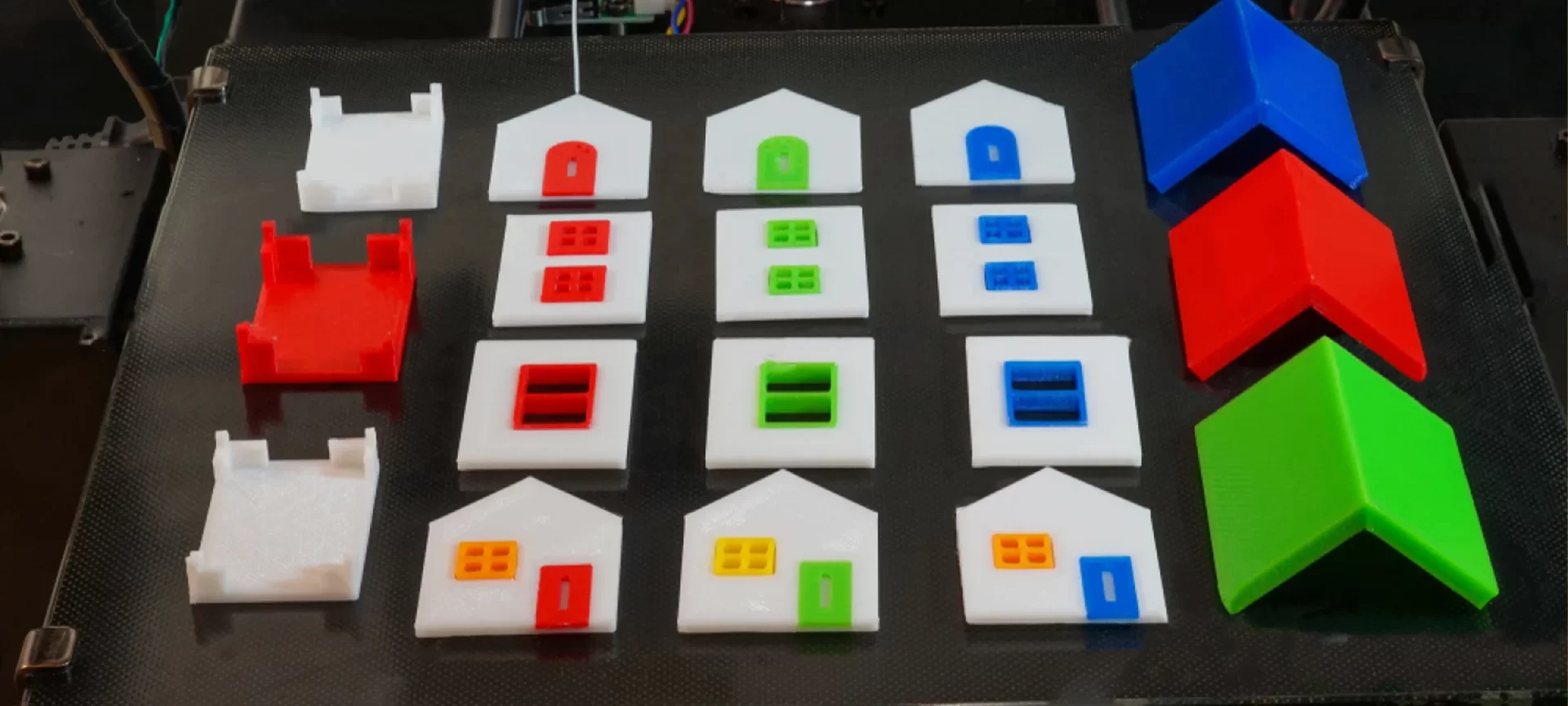

3D Printing Finished Items

A great option is to start 3D printing items that cannot be manufactured without a 3D printer. These items can be printed on demand.

For example, toys that are requested with some customization. This will restrict the mass production of these items, making it easier for you to print and sell.

Your creativity is the key to start such a business. You must think of which niche you would be targeting.

How about design schools? You can provide your 3D Printing services to fashion schools where students can see their designs 3D printed. There is a lot you can do when offering such services.

3D printing on demand would make it easier for you to be unique and have a firm hold of the market you are serving.

Selling 3D Printed Material or Supporting

Starting a 3D printing business that sells equipment and 3D printing materials is also a good option.

You won’t need much know-how about technology and can start the business right away.

If you are ready to learn about the 3D printers and the technology, you can also start support business.

Helping 3D printing companies with your skilled knowledge in fixing the bugs or installing the printers would also be a good choice.

3D Printing of Items

The next key element that makes a huge difference in the way your business progresses is how efficiently you can handle your orders.

Every 3D printer has its own working style and they differ a lot in terms of material and other processes involved during printing.

Understanding the one you can using and applying the right methods to print would reduce the overhead of reprinting the items.

Clients do not like mistakes. If you are not versed in your 3D printer working, you may end up making errors.

Hence, increasing your turnaround time and affecting your quality. So, what mistakes you must avoid when 3D printing your items?

Not Checking the Material Properties and 3D Printing Processes

3D printing material comes in different properties. Some are flexible and some are brittle. Some can be light and some can be heavy.

Hence, you must know which material will suit the item you are planning to 3D print. Also, every material has its own recommendation of design and prints.

If you are using steel to print your item, checking the design recommendations such as corner round off, support for an overhanging part, etc is a must.

Once you have chosen your material, you must read about the design guidelines or your items won’t be printed correctly.

This will eat your time of processing as well as material cost. Most of the materials are not completely reusable. So, taking care of the design prerequisites will save you from a lot of problems later.

Before you pay for the 3D printer, you must know which one would suit your printing needs.

Every 3D printing process is different and so are the characteristics of the items printed using those technologies.

For example, the FDM 3D printing process can print interlocking parts that are not possible with it cannot be printed with Stereolithography.

Knowing which 3D printer would better serve the quality of your items, you would be able to make the right choice.

Moreover, spending on a 3D printer that may not fulfill your goals would be too expensive of an error you afford to make.

Even the bronze and silver will have differences in their appearance even when printed with the same 3D printing process, despite both being metals. So, carefully research what 3D process would better suit your business goals.

Improper Knowledge of Wall Thickness

There is always something more that remains to be learned when working around the wall thickness of the part you want to 3D print.

Either its too thick or too thin, both would be a problem for your design. A too thick wall will generate internal stress while the too thin wall will be fragile and will break easily.

You must know what wall thickness would help sustain your design and keep it away from being rejected by the client.

Learn about it and make the right use of information when designing your CAD file.

Errors While Exporting to STL File

To 3D print your item, you must export the CAD design to a printable format. The most common of which is the STL file.

In STL format, the designs are converted into triangles within a 3D space. When exporting the file to STL, it is vital to take care of the file resolution.

If the export is made in low resolution, your print will be pixelated. And, too high resolution may become difficult to handle.

In such a scenario, choosing the right tolerance for export is the key to good quality printing. It is recommended to use 0.01 mm to export your file to STL format.

Choosing the Software to Design 3D File

Not every 3D design software is used for creating 3D printable files. Some are used by 3D artists and will need additional changes to the file when used as the 3D printable file. Moreover, there are software available with fixed parameters for printing and is mostly used by beginners. For example, the set wall thickness and other settings.

There is certain software that is great for creating hollow designs while others would require extra efforts. Depending on your needs and skill set, choosing the right software for designing a 3D printable file is very crucial.

How To Sell 3D Printed Items?

Your 3D printing business is incomplete without clients. After you have figured out what you want to print and for whom you are printing, you must employ the promotional strategies to sell your 3D printed items to clients.

There are mostly two business selling setups and each should be handled with different promotional approaches.

You can check this article: 20 Coolest Things People 3D Printed

B2C Business Setup

If you are selling to the end customers, your promotional strategies would mostly compromise of online selling.

You can set up a website of yours and use social media or PPP strategies to create a buzz around the targeted audience.

You can also use online platforms such as Amazon or eBay to sell your products. Or, selling a motor and brick shop to target local customers would also help.

B2B Business Setup

When targeting businesses, there are a lot of things to consider.

If you already have competitors in your niche, you must come up with something that gets you an edge over others. You can beat the turnaround time or create better designs.

Before you go ahead and schedule meetings with the companies you want to provide your services to, have a proposal defined and the approach strategies. Only words do not work. They must have something to look at after you leave.

The Conclusion

3D printing is a promising technology and has provided many of its bread and butter.

Thinking of a 3D printing business is a good idea and must be executed with planning and commitment.

Unlike many other businesses, the field requires learning and skill set to properly run the business.

If you are deciding to start a 3D printing business, you must take care of all the key elements with utmost priority.

The journey wouldn’t be easy but certainly would give you an upper hand to succeed.