3D printing has got a steep learning curve. And, individuals must expect to go through a lot of failed prints and constant frustration to start with. But it does lead to someplace better, isn’t it?

There are many factors that influence the way 3D objects are created. From the correct designing of STL files to the calibration of 3D printer, every smaller to bigger details matter.

These become even more challenging when we have to print smaller objects. Defining details in smaller parts is the real game. It starts from the designing phase and stays until the post-processing is finished.

Hence, we must discuss crucial parameters governing 3D modeling as well as 3D printing smaller parts. And, it would be better to find out if 3D Printing is at all apt for creating small objects. Otherwise, there is no point in even talking about it.

Can you 3D Print Small Objects?

Creating objects, even the smallest ones requires a lot of attention. And, when done using traditional methods, it can take a lot of effort.

It may happen that you do not even get the desired results that you are looking for. However, with 3D printing, not only you can minimize the efforts but can also achieve the impossible models for small objects.

Although 3D printing small parts come with its own share of difficulties, it is still rather easier to accomplish than with conventional means. And, you can do it in the best possible manner.

By realizing how small can a 3D printer print, you can assess the capabilities of a 3D printer. And, you sure would be astonished to know everything about 3D printing small objects.

You can definitely get better with time and by experimenting with different designs. However, patience is the key. Small objects need more care than larger ones.

But the results would be worth working for. The best part is that 3D printing can make everything smoother. And, with the time you will find it getting easier for you to create smaller objects, even when carrying intricate details.

Today, 3D printing is not limited to a large scale. However, it has already reached to individuals’ homes. People are using it to build bolt and nuts.

While that may seem easy, you can try other designs too. We will discuss a few examples later in the article. First, let’s focus on getting better with 3D printing small parts.

Is It Okay to Use 3D Printing Over Traditional Methods for Creating Small Parts?

Here we go. The first thing that we must come in agreement with is the choice. Do you even believe 3D printing smaller parts would get you better results? Or, you just want to go with the flow. While everyone is talking about it, what’s the harm.

Remember, you must get your head straight on this. So, let us help you understand the basics first. While there are many reasons for picking 3D printing instead of any traditional method, let’s find out the most crucial ones.

You must have heard that almost every design is possible with 3D printing. And, you have heard it right. With this technology, you can give shape to any design you can think of.

From smallest to the largest ones. You have got the flexibility to think out of the box and come up with your unique design.

It would never be excess even if we keep thanking Additive Manufacturing for the freedom of creation it has offered to humans. You can get through any level of complexity which was never possible using conventional methods.

Moreover, using 3D printing, you can actually decide what the item would be from inside. Hence, you can achieve lightweight yet durable parts.

Or, you can come up with the flexible parts as well, by changing the material for your project. There is a lot in store which you can uncover while 3D printing yourself.

3D printing creates a layer over layer. You can play around with the thickness of the layers and can achieve the surface finish as needed.

Plus, you can select between different materials and 3D printing processes to get the desired mechanical and aesthetic properties of the end product. Moreover, the technology is consistently evolving. Hence, it is a very exciting niche for keeping you engaged.

What to Consider When 3D Printing Small Parts?

As you must be all excited to find out the best tips to achieve the desired results, let’s dig in. A 3D part depends on a lot of things.

Starting from the 3D design to the way you post-process it later, everything matters.

And, in the midst of all that, taking care of a few crucial things could help you stay on the safer side when 3D printing smaller parts. You do not want to destroy your prints only by missing a few tricks.

So, here is what you must follow to keep your 3D prints intact.

3D Design Realistic Models that Function

First of all, it is surely true that 3D printing can get you almost every design in a matter of time. However, the 3D models must be realistic.

You must understand that the objects you plan to print would become a part of the real world. Hence, these must follow the laws of nature.

For example, you cannot think of designing an object that fails to justify the gravitational law. Also, you cannot think of eliminating an important wall or face from the structure thinking it would work. 3D Printer won’t be able to print it as it would form a hole in the print.

But the good news is that you can print parts with better precision. You can come up with huge complex designs, favoring the laws of nature, and you would be able to 3D print it.

In short, you must ensure that the 3D design is printable. Or else, your efforts would be all wasted in the end.

Stick to the Guidelines

Do you know that every material is different and perform in its own unique way? Also, there are certain pre-requisites connected with every material you wish to print with.

And, the first job before you even start 3D printing is to go through the guidelines that come with your material.

You do not want to crib later only to know that your wall thickness wasn’t set as per the material’s instructions.

You must go through every single facts and guideline provided to you by the manufacturer. As you know the characteristics of materials differ widely.

Plus, the technology also makes things different in a lot of ways. 3D printers also have their own setting needs.

In order to successfully 3D printing smaller parts, you must check every related design guideline to stay away from any problem later. This will help you achieve precise 3D prints.

There are few settings that you won’t like to mess around with. From the wall thickness to minimum detail along with clearance and a lot of others would help achieve the best results.

While wall thickness would keep your model in one piece and won’t let it break in between, attention to details will get you the most accurate print.

You must consider the maximum as well as the minimum size of the models. The size will mostly depend on the build plate volume as well as the 3D printing process you choose. Keeping important factors in mind would always keep you on the safer side.

Ensure the Support is Apt

When 3D printing smaller parts, you may have to handle a lot of thin components in the design. And, these will require proper support to keep standing.

Supports are not the part of the models but are additions that you get rid of after the model is completed. These are only a means to keep your models straight up.

Now that’s another part of the story. We have to take off the support. Hence, 3D models must be thick enough to pain when you remove the support from the completed item.

Or else, it could break in the process of removal of support. The problem is more susceptible to smaller objects because they are already fragile because of their size.

Proper Layer Thickness

We have already talked about it a few times in the article. Layer thickness is measured in micrometers (µm). This is also termed as the height of the layers.

Different technology and 3D printers offer different capabilities when involving layer height. This means that some can get you finer layers than the others. And, you must have the knowledge of what your 3D printer could do.

Layer thickness defines the way your 3D model will look later. The minimum the layer thickness is, the higher is the resolution.

When building a small part, you may have to look at other specifications as well. Such as the time it would require to complete the print and many others.

Print Multiple Parts Together

If you are 3D printing small objects, you must have enough space left on your build surface. So, why not utilize it.

It would surely take a bit more time to complete the prints, however, it is helpful in providing more cooling time for the next layer to go over the previous one.

In other words, when you start printing with small parts, a layer is deposited in no time. Hence, the nozzle speed is reduced to provide more cooling time for the setting the next layer.

Sometimes, the time isn’t enough and the cooling isn’t satisfactory, leading to other problems in the resultant 3D models.

3D printing a few parts together would help increase the layer time difference, giving room for proper cooling of each layer.

Few Examples You Should Check

You are not the first one thinking of printing small objects. There already have been a lot of experiments by experts for finding out the worth of the technology when 3D printing tiny objects.

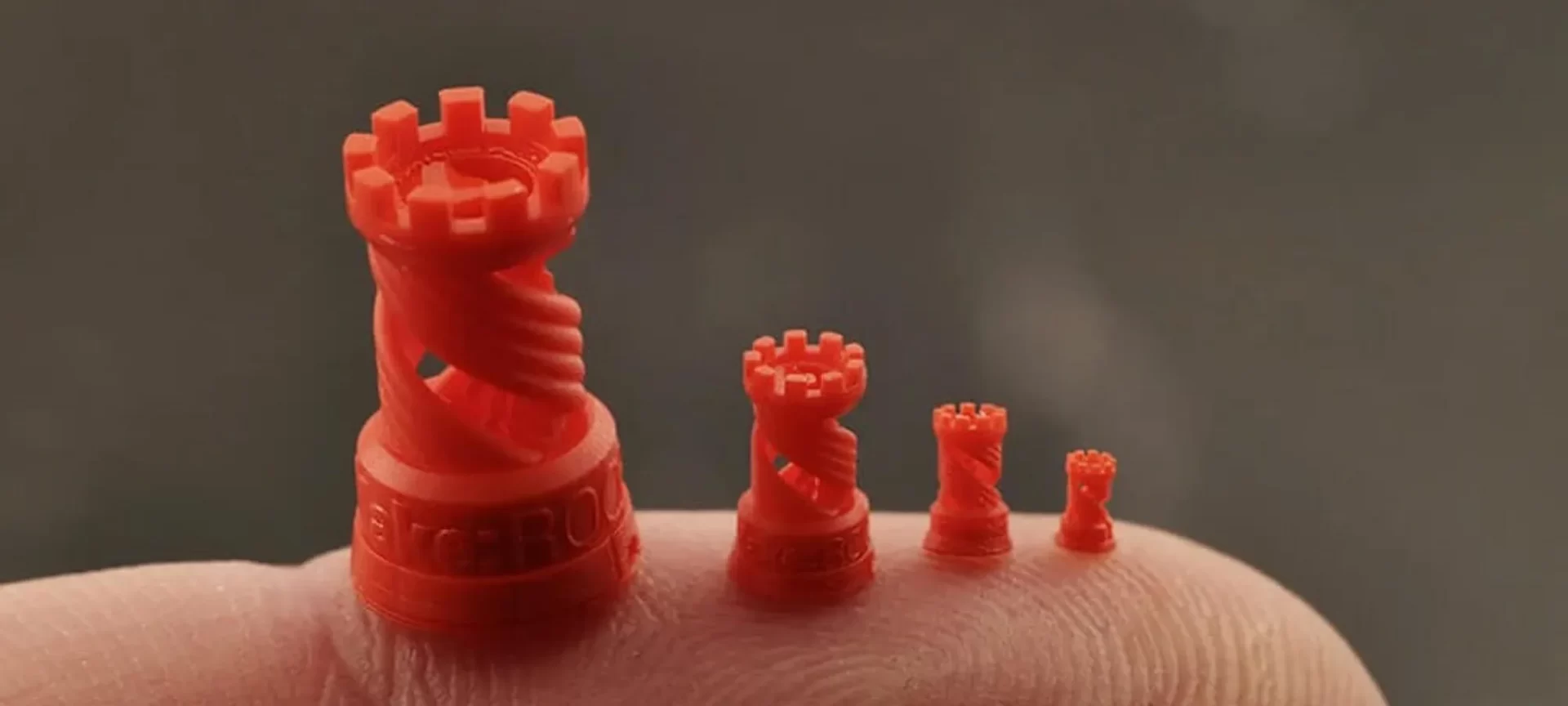

Tiny Towers

Here is a 3D printer, The Solus, which is capable of printing extra small pieces. The DLP based 3D printer is very amazing and produces impressive results, not only with bigger objects but with smaller ones too.

The tiny tower with 3mm high may not fit any useful application, but that’s just an example to show how small the printer can go. It can print highly precise small objects. How about printing some jewelry and rings?

There could be a hundred of applications when you know you can go small. And, this 3D Printer lets you do that smoothly.

Miniature Saw

The man who came up with the smallest working drill was able to create a lot of buzz around the 3D printing community. And, the job was accomplished using the Ultimaker 2 3D printer.

The saw was created in four different parts which were combined together to create the working saw.

It has a tiny hearing aid battery alongside a tiny motor that concluded the entire design and made it work. It was measured at 1.5 CM. The design was completed in an hour.

Marvin Miniature

3D printing small parts help you find out how far the technology can go with bringing the specified details perfectly created on the small parts.

The job happened with the Solidscape T76+ 3D printer. And, it was the Hungarian 3D printing service Basilikus 3D that made it possible.

The Conclusion

You must have thought about it and we all do: Why is it so important to go through all the math when 3D printing small parts? And, why not.

If you have tried hands with a 3D printer and wanted to create something really small, you would know the answer. While it seems like an easy job, it isn’t.

The good part is, it could be. All you have to do is, find the right way to proceed. Take care of the right settings and do not overlook guidelines.

Check your 3D model twice and if possible, multiple times, unless you are sure about it. And, do not forget to keep trying because that is what leads to good memories.