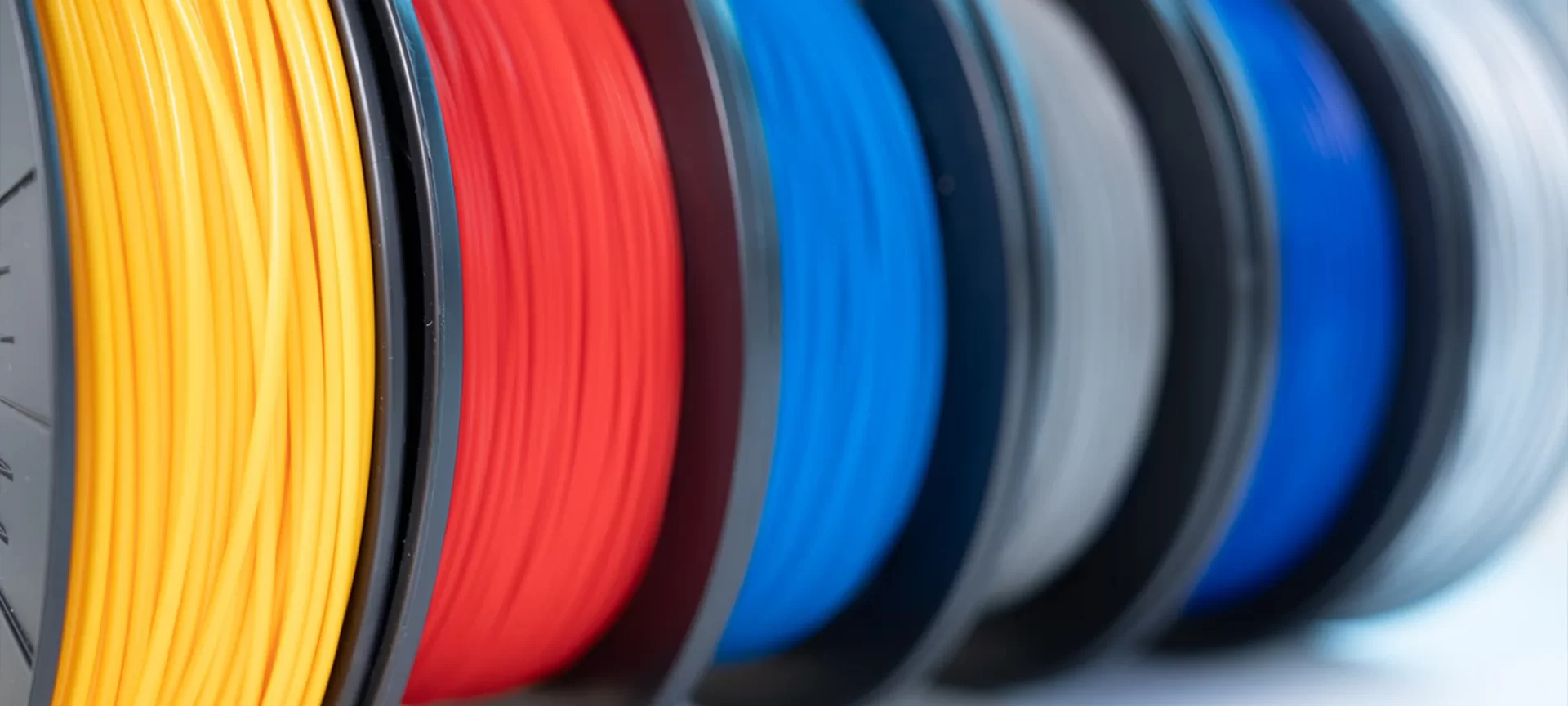

When it comes to materials used in 3D printing, you will find numerous options.

From flexible materials like plastic to the most expensive and toughest metals, you can choose from a plethora of options.

Designing with a particular material depends on a lot of things. And, no one is a better judge than you, yourself.

While there are many materials and more are being added every now and then, few remain the most used ones for 3D printing.

The most widely used are plastics. These also come with different mechanical properties. Few are mainly used for engineering-grade purposes such as PEEK and others are for commercial use such as PLA.

Like plastics, resins are also very common as the SLA printers are. Resins are used with SLA printers. Then there are composites.

These are made from two materials to get the best of both worlds. We also have metals.

There is a huge range of selection you can make between various metals depending on their properties.

Which 3D Printing Material to Choose?

As there are many options, you must be feeling confused at the moment, which one to choose?

This is completely common for people who are 3D printing for the first time.

Because you have a set of reasons why are you printing 3D models, you will have different sets of requirements of materials too.

The first thing that determines which material to use is the purpose of your 3D printing.

For example, if you are printing containers for food, you must work with food-safe materials such as PETG.

If you are looking to create a prototype, why to use expensive metals when you can get the results with nylon printed prototypes.

To put it in the right way, one can decide about the material one wants to print with only after considering the reason for printing, the cheapest option available, the importance of quality of the objects 3D printed, characteristics and mechanical properties of the material and importance of appearance of the objects 3D printed, with of course the 3D printer material cost in mind. These are the basics to start with.

Once you narrow your selection, you can ask more questions to yourself. You can even try using different materials and see for yourself which one gets you the best output.

The truth is, it is because of the 3D materials that we can think of many designs that were only thinkable before.

The technology together with the 3D printing material options has given opportunities to print parts that are customizable at all levels, are inexpensive, have lower volume and weight and are easily printed.

3D Printing Material – Plastics

As you know that the most commonly used processes among all the 3D printing technology are FDM, let’s talk about the widely used filament in these machines. Plastics are available in many shades in terms of their properties.

ABS

ABS is one of the most commonly used plastic filaments. The perfect example would be Lego blocks. These Lego blocks were designed in ABS.

The colorful blocks with great strength have been a part of every house with children. These are affordable and lightweight.

One major thing that people printing with ABS are concerned about is the fumes it emits when heated.

However, there are many 3D printers that come with HEPA filters which reduces its effect to 99%, making it safe to be printed with inside homes.

The ABS 3D printing temperature may go around 220 degrees to 250 degrees Celsius.

Hence, must be used inside an enclosed build space and the heated bed is recommended for the best results. If your 3D printer has all these options, there won’t be any problem when printing with ABS.

This material can be utilized with FDM, SLA, PolyJetting and Binder Jetting.

The applications also include a lot of options. You can derive Architectural models, DIY projects, concept models and even use it for manufacturing.

PLA Filament

PLA filament is a corn starch derivative and that is why it is biodegradable.

Because it has a sweet pleasant smell after heating, it is mostly preferred over ABS. It also contracts less as compared to ABS which is a huge drawback with 3D printing with plastics.

It is, however, less durable than PLA. This material is also available in great numbers of colors similar to ABS.

3D Printers running on FDM, SLA, and SLS can utilize PLA for printing.

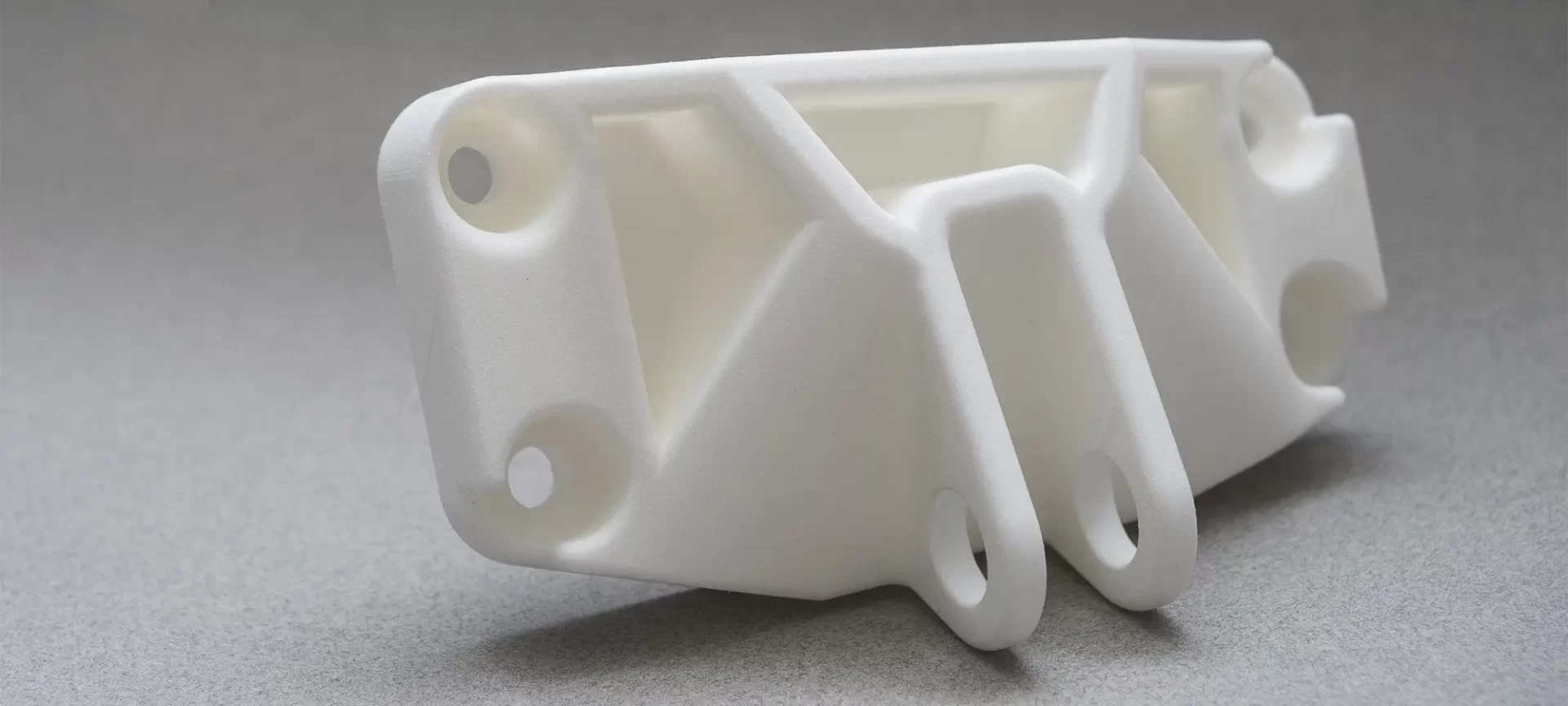

Nylon

Many refer to nylon as white plastic. It is a polyamide and is very flexible and strong. That is why its application ranges from arts to even engineering.

However, the parts that are printed by Nylon happen to have a rough surface. But you can always smoothen it during post-processing. The best part about nylon is its strongest layer bonding.

It provides great tensile and has strong mechanical properties. Like other plastic filaments, it is also susceptible to humidity. So, you better protect it and use it in a controlled atmosphere. The material can be utilized with FDM and SLS 3D printing technology.

PEEK

Another option from the family of plastics is PEEK. This is used for 3D printing high-performance parts. This 3D printing material is very much resilient to temperature, stress as well as chemicals.

The material is robust and can even stand X rays and gamma rays. However, to extrude PEEK, you require a temperature of 400 degrees Celsius. And hence, suitable for professional printers.

The material can be used with FDM and SLS 3D printers.

PET

This is a food-safe material and found usually for water bottle manufacturing. This is also a great alternative to ABS.

The good news is, it does not emit hazardous fumes. The material finish is glossy and it is strong more than it looks to be.

This material is highly utilized for consumer 3d printed products and is very popular. This material is only used with FDM 3D printers.

PETG

PETG is a variant of PET. PET, when combined with glycol, gets you PETG and that is why the name for the material is coined. This 3D printing material was found to increase the effects of the already amazing material PET further.

These are also food safe and are resistant to weather. So, you can use this material to 3D print objects that can be used outside of the house.

This material can be extruded at a lower temperature. This means that the flow can be increased and thus the faster speed of 3D printing can be achieved when printing with this material.

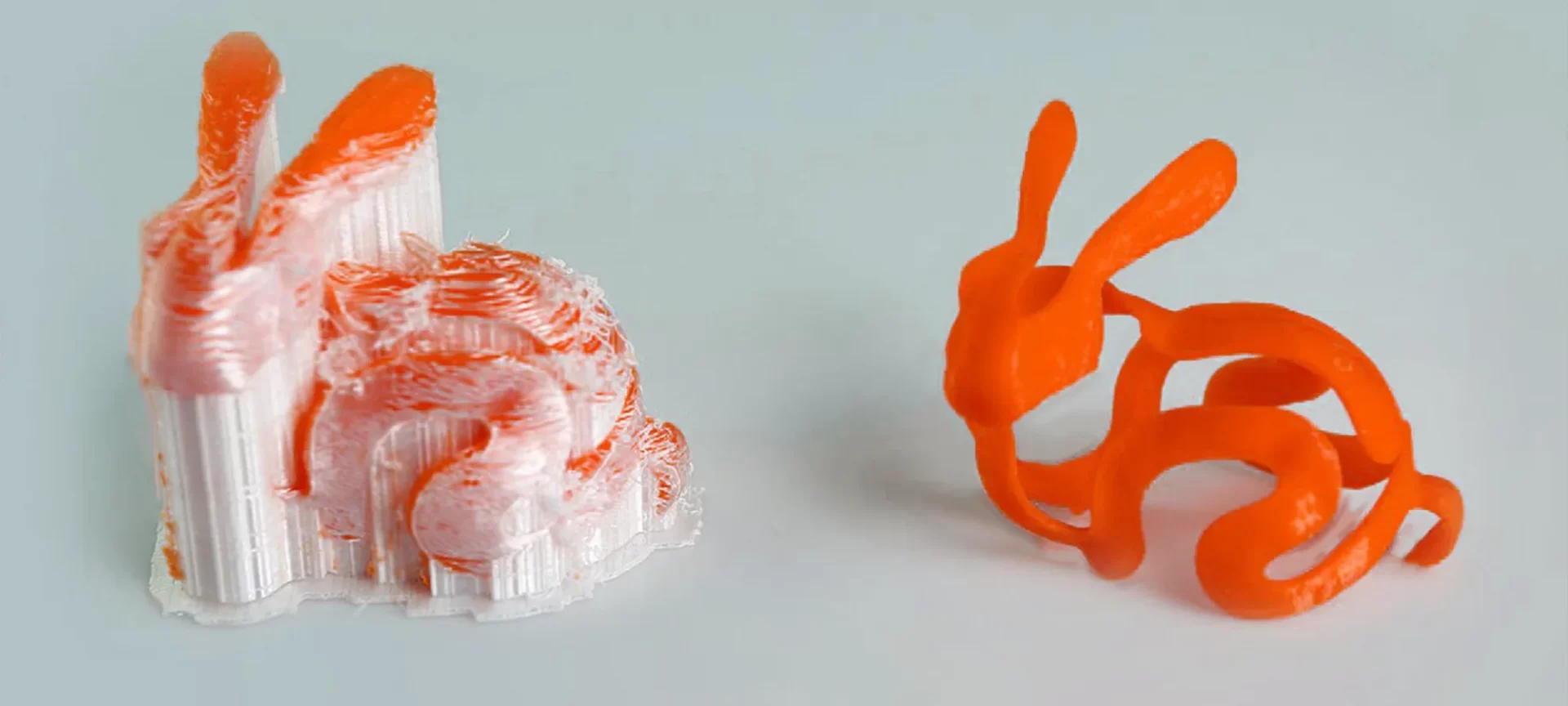

PVA

PVA is used mostly as soluble support material. Unlike many other variants of its kind, it is easily soluble in tap water.

One does not need any chemicals to do the task. Used with FDM printers, this is the most common support material recommended by far.

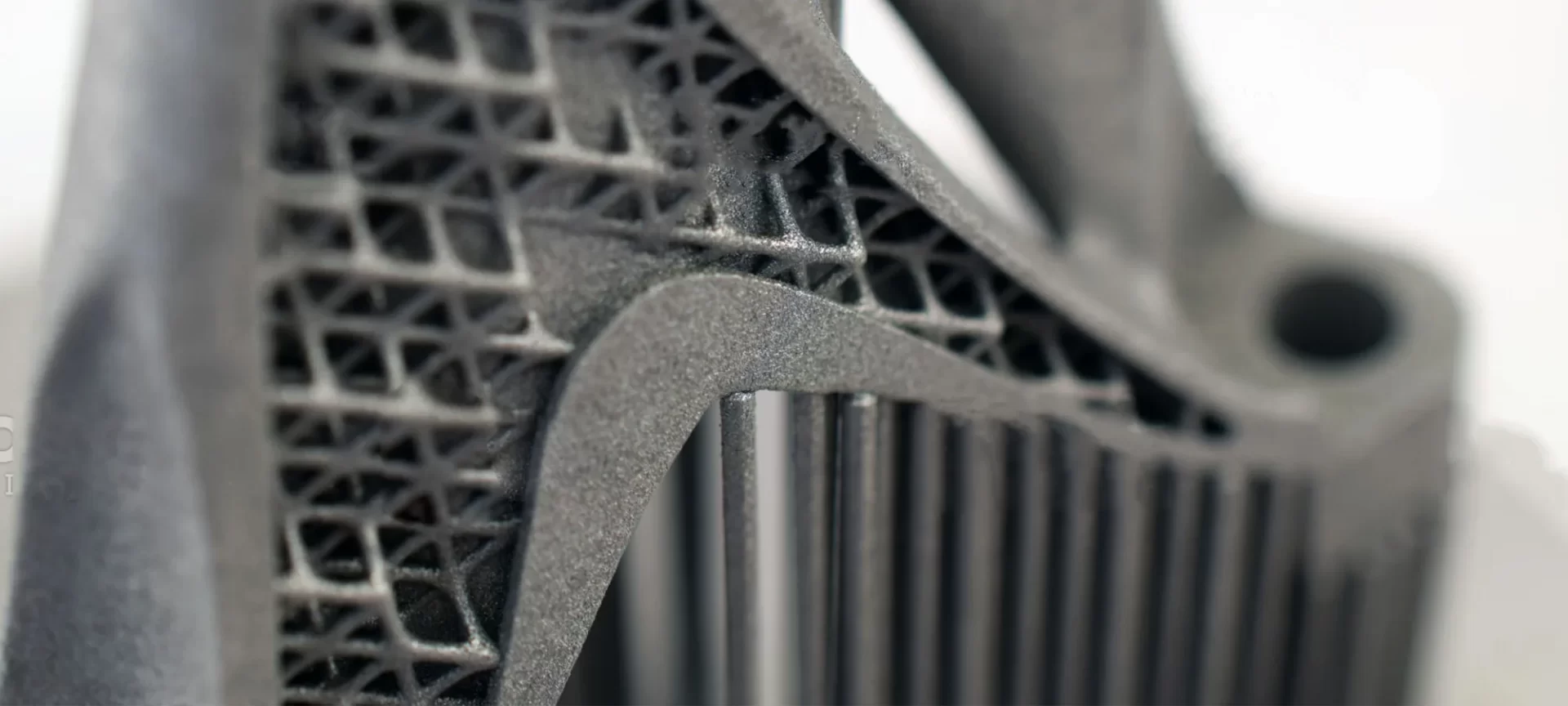

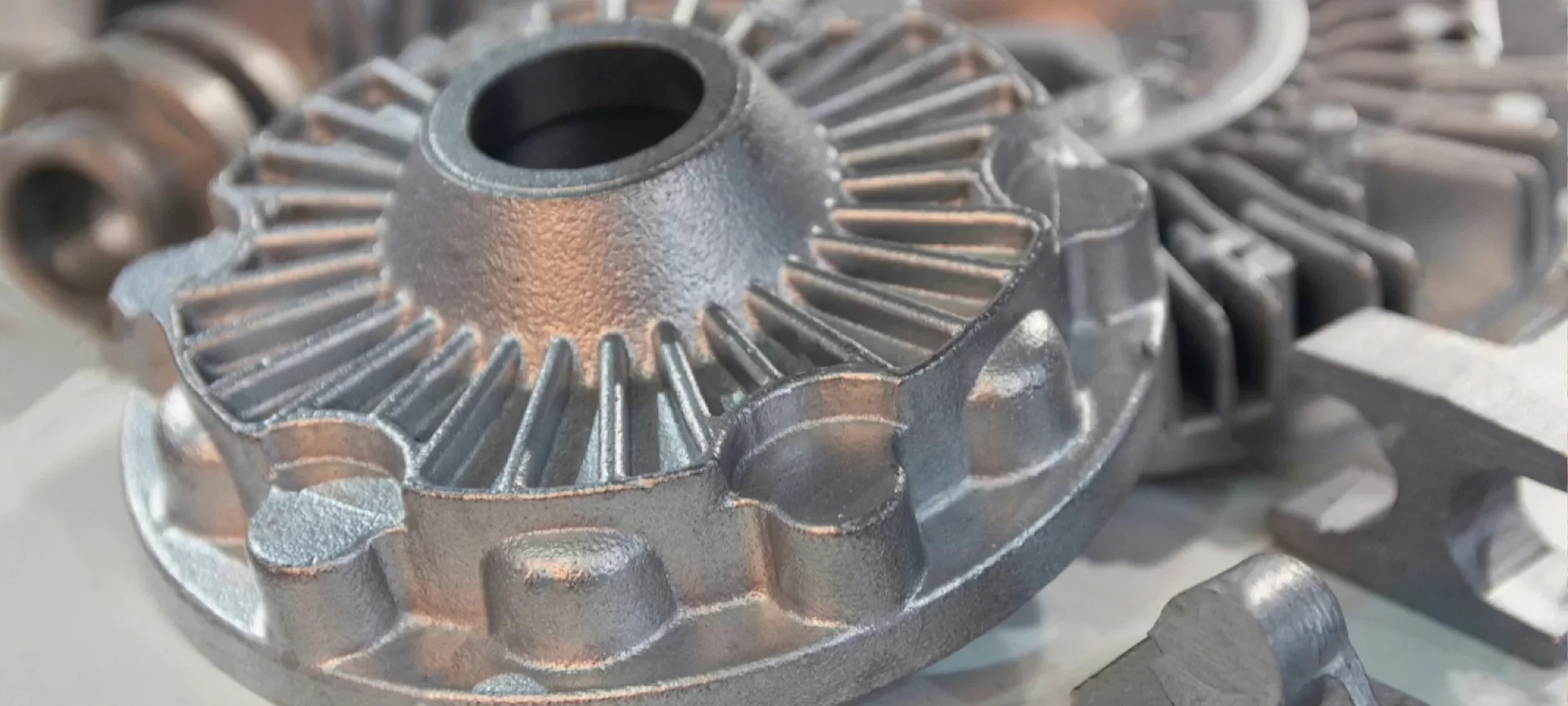

3D Printing Material – Metals

Metals are highly used in aerospace, medical and automotive industries. Hence, the 3D printers using metals as a 3D printing material is equally important as the ones using plastic and other materials are.

These materials are supposed to print complex geometrical designs and produces great details with finer designs.

However, it is not easy to 3D print with these materials and one must be an expert in doing so. Hence, 3D printers utilizing these materials are often found in industries and large scale production houses.

One must own 3D printers that are large and which can withstand high temperature.

Aluminum

The lighter and versatile metals of all is Aluminium. Hence, its application is also wider. It is used with alloys to increase its strength and further improve its mechanical properties. Parts build with this material can be designed with thin walls.

One can achieve complex geometric designs using Aluminium. They also have a huge resistance to high temperature and stress. The metal can be used with 3D printers running with Direct Metal Deposition and Binder Jetting 3D printing technologies.

Cobalt-Chromium

This is also known as superalloy because of its amazing properties. The material is best for high-performance applications. Most widely used for medical and aerospace applications for making turbines.

Because of its strength and resistance to corrosion, the metal is very popular among 3D printing manufacturing companies. It is used with 3D printers with Direct Metal Laser Sintering and SLM technologies.

Inconel

This 3D material is again quoted as superalloy because of its unmatched strength to withstand high temperature and extreme environment.

This alloy is created by mixing nickel and chrome. The alloy is very popular among the aerospace industry. It is used to manufacture rocket engine parts. Isn’t that exciting?

Because of its great chemical and mechanical properties, Inconel is utilized for oil and chemical industries too.

However, its strength makes it difficult to be worked around with most of the 3D printing technology. The most preferred option is the Direct Metal Laser Sintering.

Nickle

Nickle is again used with other metal as alloys to make it available as 3D printing material. Parts printed using 3D printers are durable and stronger as compared to the ones built with traditional methods such as casting. The material is used with Direct Metal Deposition and Powder Bed Fusion 3D printing technologies.

Stainless Steel

Being the most affordable material among all the metals used with 3D printers, Stainless steel enjoys its share of popularity.

The metal strength is known worldwide and is best suited for various applications that require large and strong parts. From industrial to artistic designs, one can come up with various options when 3D printing with Stainless Steel.

The 3D printing material has excellent magnetic properties. If you wish to color, you can gold plate it to give a shiny appearance.

The metal can be printed with Direct Metal Deposition and Binder Jetting 3D printing technologies.

Titanium

Titanium is used in its pure form when powdered for 3D printing. The application of titanium includes high-performance medical usage.

It is best for manufacturing customized prostheses. It is also a good option for printing prototypes for aerospace, tooling and other industries.

However, one must be very cautious when printing with powder titanium as it is very reactive and can even explode.

The material can be utilized as 3D printing material with Powder Bed Fusion, Direct Metal Deposition, Binder Jetting 3D printing technologies.

3D Printing Material – Ceramics

The most common example of ceramics application in the 3D printing of kitchenware. From ceramic mugs to plate, everything looks so divine and useful when decorated on the kitchen shelves.

This material is very common among 3D printing experts and can be very well used inside homes as well. You will find much individual 3D printing with ceramics alone at their homes.

After the part is printed using ceramics, it requires quite a job of post-processing. The parts are made solid inside a kiln. This is done to increase the strength of the printed material and to let the particles blend even better.

One can use FDM or SLA or even binder jetting to build objects using ceramics. The properties of the parts include porous surface, fragility, heat resistance, etc.

3D Printing Material – Wood

Although wood is not used in its purest form, it is one of the best 3D printing materials to provide wood finish to the parts printed.

The wood fiber is mixed with plastic filament to provide it the necessary texture. You can use it like other filaments used in FDM printers.

You can even play around with the shade of brown with the changing temperature of the extruder. When working with low temperature, you will get a lighter shade.

On the contrary, when high temperature is used, one print in dark brown shade. It is fragile and used with FDM printers.

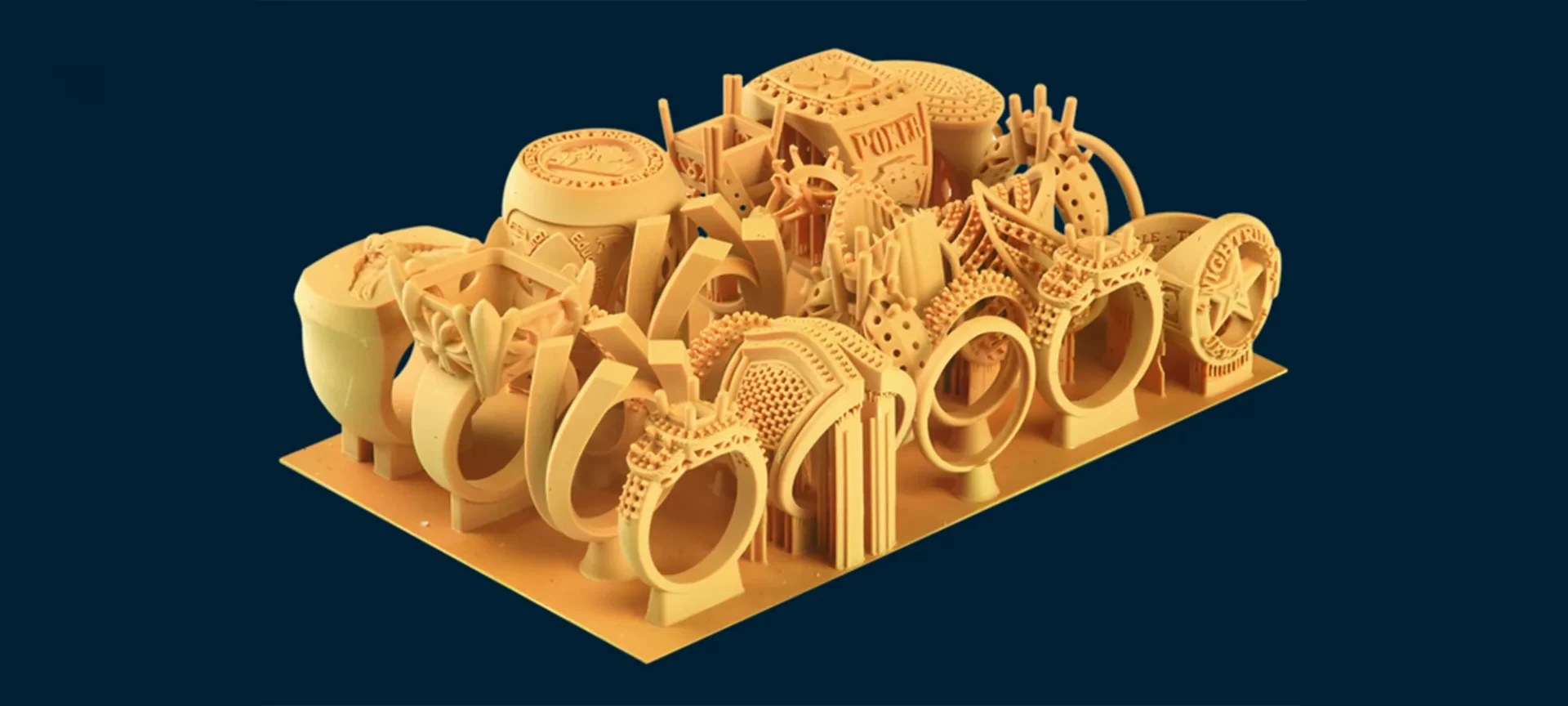

3D Printing Material – Wax

Wax isn’t used as the final 3D printing material. However, they are utilized to make molds with great resolution.

Mostly used for lost wax casting methods, these materials are very important. The best use of wax comes in when creating customized pieces of jewelry.

The Conclusion

There are various other 3D printing materials available and one can certainly add them to their list.

However, you must enquire about the material before printing it. Or, the order in a small amount if you want to test the results.

Either its 3D printer plastic or any other 3D printer filament, you must be cautious about what you choose.