Carbon fiber filaments are made using tiny fibers infused into a base material. Doing so improves the properties of the material with which carbon fibers are mixed.

They are extremely strong and cause the filament to increase in strength and stiffness. Meaning that the 3D printed parts will be much lighter and more dimensionally stable because the fibers will help to prevent the shrinking of the part as it cools.

Among the several popular filaments that can be bought with carbon, fiberfill PLA has a special place.

Carbon Fiber PLA is demonstrably more rigid, provides excellent structural strength and layer adhesion with very low warpage. It also has a beautiful matte black finish with a slight sheen due to the embedded carbon that will definitely catch your eyes.

Common applications of carbon fiber filaments include R/C Vehicles, functional prototypes, decorative pieces, and lightweight props, states that Carbon Fiber PLA is ideal for any application which requires lightweight and rigidity.

Carbon fiber reinforced parts are designed to use less material and save weight. It is extremely popular in aerospace, civil engineering, the military, and motorsports. So, today let’s look in detail at this special mixture of strength instilling carbon fiber with flexibility like no other PLA.

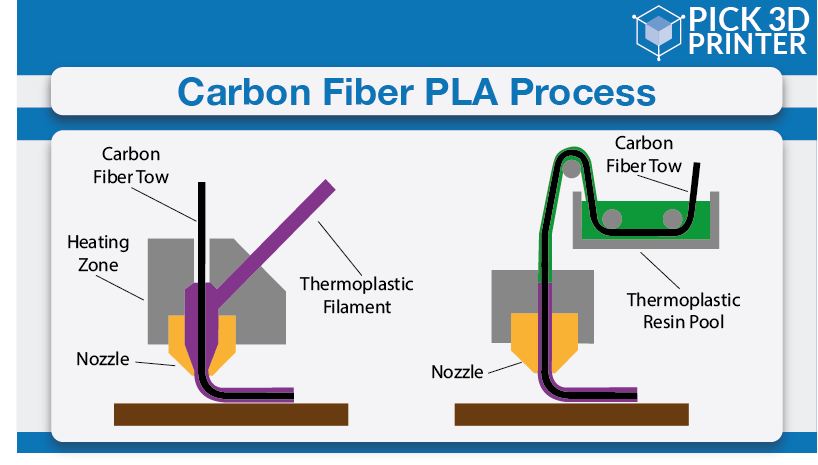

What is the Manufacturing Process of Carbon Fiber PLA?

Generally, every carbon fiber is produced with a six-step process. Starting with obtaining, PAN (polyacrylonitrile) as a byproduct of petroleum, the most preferred material for producing carbon fiber.

PAN is then mixed with other ingredients, after which it is spun into fibers that are as thin as 10% of the thickness of a human hair. These spanned fibers are oxidized for stabilizing the bond.

After that, they are made to go through the carbonization process. During this process, the fibers are heated to temperatures of 1000° C for removing impurities.

Then the surface is treated for improving bonding. In the final step of sizing, the fibers are coated and spun into different thickness yarns.

After carbon fiber is produced, its yarns can be further processed in a variety of ways depending on the final application.

They can be woven into sheets or, in our case of carbon fiber 3D printing, the yarn will be chopped into short fibers, mixed with a base polymer i.e. PLA, and then extruded into carbon fiber PLA 3D printing filament.

How Do You 3D Print With Carbon Fiber PLA?

Below mentioned tactics will reduce the chances of facing common 3D printing issues such as clogging and nozzle wearing down.

Upgrading to a Steel Nozzle

The carbon fibers in carbon fiber PLA can be extremely abrasive. In cases when the carbon fibers are actually harder than the brass nozzles, which are most of the time, printing with these materials with a stock nozzle will lead to damaging the printer.

Instead, it is wise to upgrade to a hardened steel hot end. These hot ends will resist the added wear from the fibers; also they tend to be less thermally conductive than their brass counterparts.

So, you may need to set the extruder temperature 40° hotter than usual. Doing so will help reduce the chance of a clog. Reducing the fan speed is also a way to prevent thermal issues with the steel nozzles.

Adjusting the Retraction Settings

Because the filament is full of non-melting small fibers, the chances of a nozzle clog are higher on the base material.

It is recommended to reduce your retraction distance or completely disable retractions. Because with an increase in retractions; there is a change of a buildup of fibers inside the extruder assembly.

Print at a Slower Speed

Printing at a slower print speed can be a huge benefit for carbon fiber PLA, as the extruder will be under less stress. Also, there is a higher chance of pushing small clogs via the nozzle if they start to form.

So, try reducing your print speed at least by 25-50% for seeing what value works best for your specific brand of filament.

Using a Guided Filament Path

Carbon fiber PLA is far more brittle than the PLA filament. Meaning that it can snap easily when forced through tight corners, or rub on sharp edges of the printer frame.

So, ensure that the entire filament path, starting from the spool to the nozzle, comprises gentle curves, has no sharp turns or areas where the filament will be pushed forcefully along a surface.

A reduction in the chances of filament breaking can be done using a PTFE guiding tube, or by ensuring that the filament spool is in a strategic place.

Who Makes the Best Carbon Fiber PLA?

When it comes to buying carbon fiber PLA, there are many options. However, only a few are really reliable. And we have handpicked those few especially for you.

Proto-pasta

Made from NatureWorks 4043D PLA Resin, Proto-pasta Carbon Fiber PLA is compounded with 15% (by weight) chopped Carbon Fibers.

The filament is more brittle than standard PLA in its filament form, and so needs to be handled carefully to prevent breakage.

Printer Settings:

- Because of the chopped carbon, this filament may have trouble getting through smaller nozzles. However, the filament manufacturer has had good success using a 0.5mm nozzle and direct-drive spring loaded pinch-roll style extrusion head.

- Generally, the filament prints just like standard PLA on 3D printers i.e. at around 195-210° F. Also, there has been success a bit hotter around 220° F. So, you can experiment in this temperature range with your printer.

- The density of this filament is 1.3 grams per cubic centimeter. You are advised to keep the bed temperature at 50 degrees Celsius.

3DX Tech

This one’s an improved Carbon Fiber PLA 3D printing filament made using High-Modulus Carbon Fiber.

It is ideal for you while making structural components with high modulus, excellent surface quality, dimensional stability, and lightweight.

Made in the USA using premium Natureworks PLA, and high modulus carbon fiber, this filament is extremely easy to use.

Printer Settings:

- While printing with this 3D printer filament, your extruder temperature range should be around 190-220°C.

- The printer’s bed temperature should be around 23-60°C.

- For nozzle, the filament manufacturer recommends a hardened steel nozzle with a minimum diameter of 0.4mm.

- The heated bed preparation should be done with Magigoo Bed Prep Adhesive to achieve the best results. You require no heated chamber for printing this filament.

- For parts and functional prototypes in which you need supports, use Water-soluble AquaTek X1 USM.

- It is recommended to dry the parts manufactured by this printer at 65°C for 4 hours.

Filaments.CA

This Carbon Fiber reinforced PLA is made from Carbon Fibers infused with Standard PLA 3D printer filament. It is light in weight, stiff, and easy to print, just like normal PLA.

The filament is Abrasive so using a wear-resistant nozzle of 0.4 mm diameter or more is recommended.

As this is a mixture of carbon fiber and PLA, it is lighter compared to PLA and possibly more brittle or weaker because of the same properties.

Printer Settings:

- If possible use a heated print bed. And if you are doing so, set your print bed temperature to approximately 60°C for fine prints.

- The filament sticks well to Blue tape, PVA glue, and hairspray.

- Recommended extruder temperature range for printing with this printer is 190 to 230 degrees Celsius.

Matterhackers

PRO Series PLA is PLA infused with carbon fiber perfected by the team at MatterHackers. Manufactured in the USA, the filament has the tightest diameter tolerance on the market.

The filament combines the ease of printing PLA with the stiffness of carbon fiber, overall making it a high quality, reliable part.

Printer Settings:

- It is recommended to maintain the printing temperature range around 185-205°C.

- The spool dimensions of this filament are approximately around 200mm Total Diameter x 50mm Inner Hole Diameter x 70mm Height.

- Its dimensional accuracy is 2.85±0.05mm.

The Conclusion

Print settings, such as extruder temperature, speed, bed adhesion, and extrusion rates of carbon fiber PLA will be quite similar to the normal settings that are used for the base material which in this case is PLA.

However, due to the added carbon fibers, the filament is more likely to get clogged so you will require special hardware for avoiding damage done to the printer.

For ensuring you do not end up in any kind of unfavorable conditions with carbon fiber PLA, it is better to check out the suggestions given by the printer manufacturer.

Remember, this is the most eccentric mixture you will ever find in filaments. On one side it is high strength material carbon fiber and on the other, it is highly flexible material PLA. So, the parts produced by them would have combined properties and will stand out from parts manufactured by other filaments.