The talks about 3D printing do not seem to fade any sooner. It is all because of the plethora of benefits additive manufacturing offers. One can do things that were not possible before and it’s all because of 3D printing.

The benefits of 3D printing have led it to become a worldwide phenomenon. Starting from the gift shops to the high-end production of aerospace parts, 3D printing has booked its space in every niche.

The technology has been around since the ’80s, but wasn’t much heard until 2010. It is because additive manufacturing was mostly limited to the manufacturing of prototypes. But the applications have been widened.

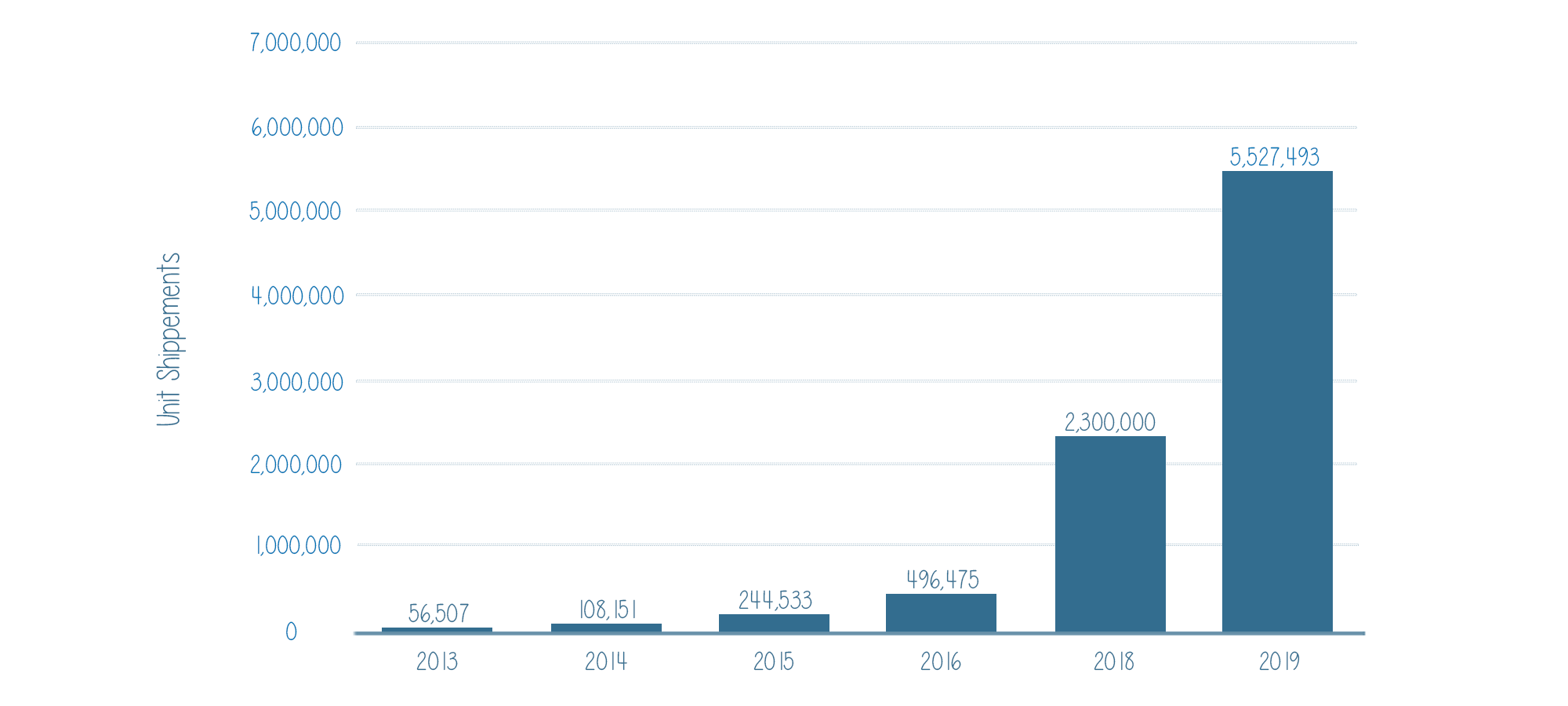

The far-fetched dream of researchers to make 3D printing accessible for masses seems around the corner. The low-cost 3D printers and a zeal to learn about this amazing technology has brought consumers closer to the trend.

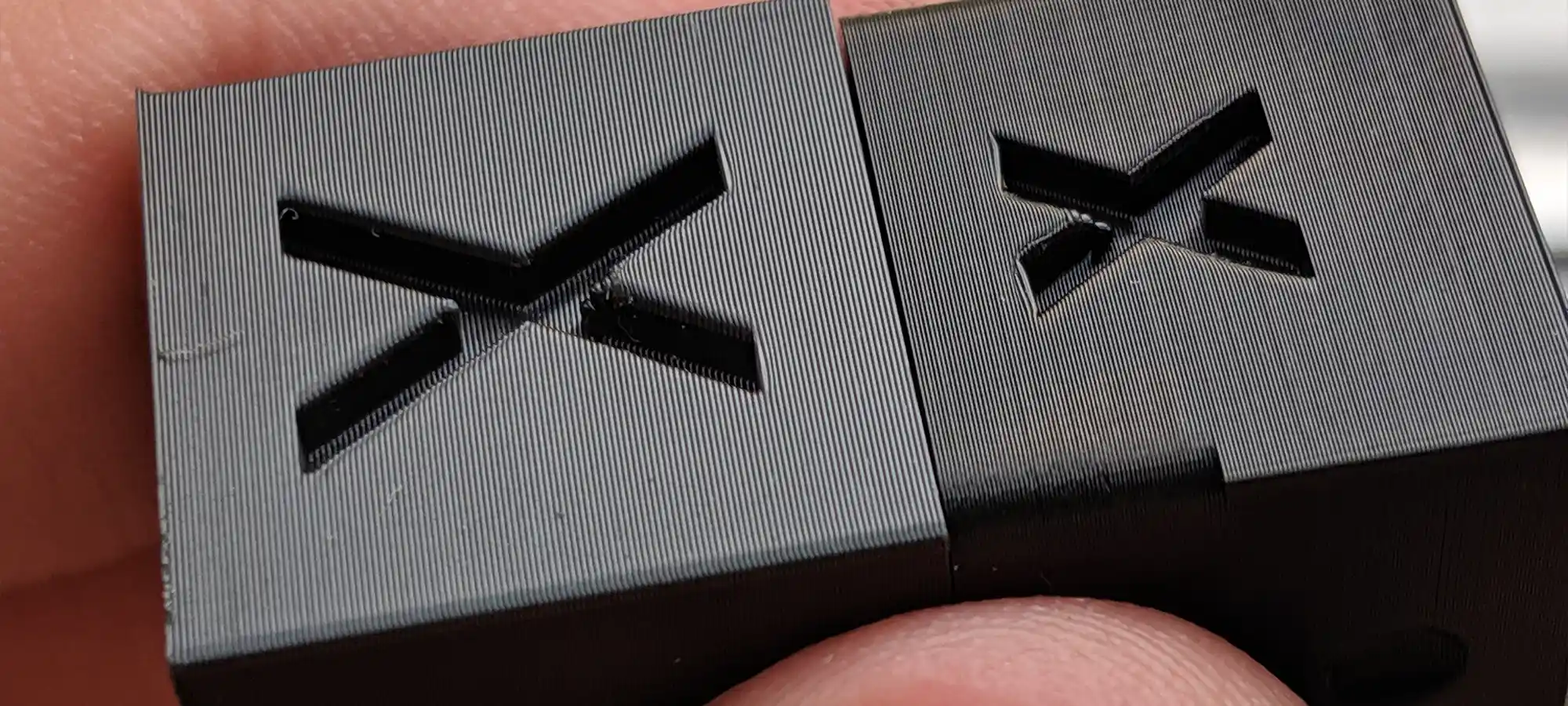

The people around the globe are using 3D printers to create amazing designs and items that were impossible to manufacture. The intricate design and finer details are well carved with the help of 3D printers without a need for too many hands.

A 3D printing machine with many capabilities is all you need when it comes to small scale production. You can make your imaginations come to life if you know how to operate CAD software and other design application.

So, isn’t it be best to start pointing out the benefits of 3D printing that we can reap by utilizing the technology for good?

What are the Benefits of 3D Printing?

‘The sooner the better’. It is imperative to know that a revolution can soon become part of the community without making much of a noise.

You may never know and you arrive at your production plant looking at your managers talking about getting 3D printers in few month tops. That would be shocking news.

A complete renovation of technology would mean the survival of those able to work around it. And, when this happens, you would like to be the first one to be chosen to operate the 3D printer with your preferred skillsets.

If you remember the computer age when a lot of workers had to either choose between learning to operate computers or leaving the company forever. This technology is no less than a similar revolution.

The question is: what are the benefits of 3D printing that make it so impressive?

The Fast Speed

3D printing is a boon for printing small parts at the fastest speed. Especially while prototyping, 3D printing is the best option. With traditional manufacturing, one has to create casts and molds to design a prototype.

These take time and also cannot guarantee that the prototype would pass all the specifications. This could take weeks and months to reach perfection with prototyping.

However, with 3D printing, one can design the 3D print and can use a 3D printer to print the part in a matter of hours or days. The changes are easy to incorporate. By changing the blueprint, one can implement the suggested changes to the prototype.

This all can happen in far less time than it takes with traditional methods such as injection molding. The production of functional parts from small to medium-sized volume can be done faster when manufactured with 3D printing.

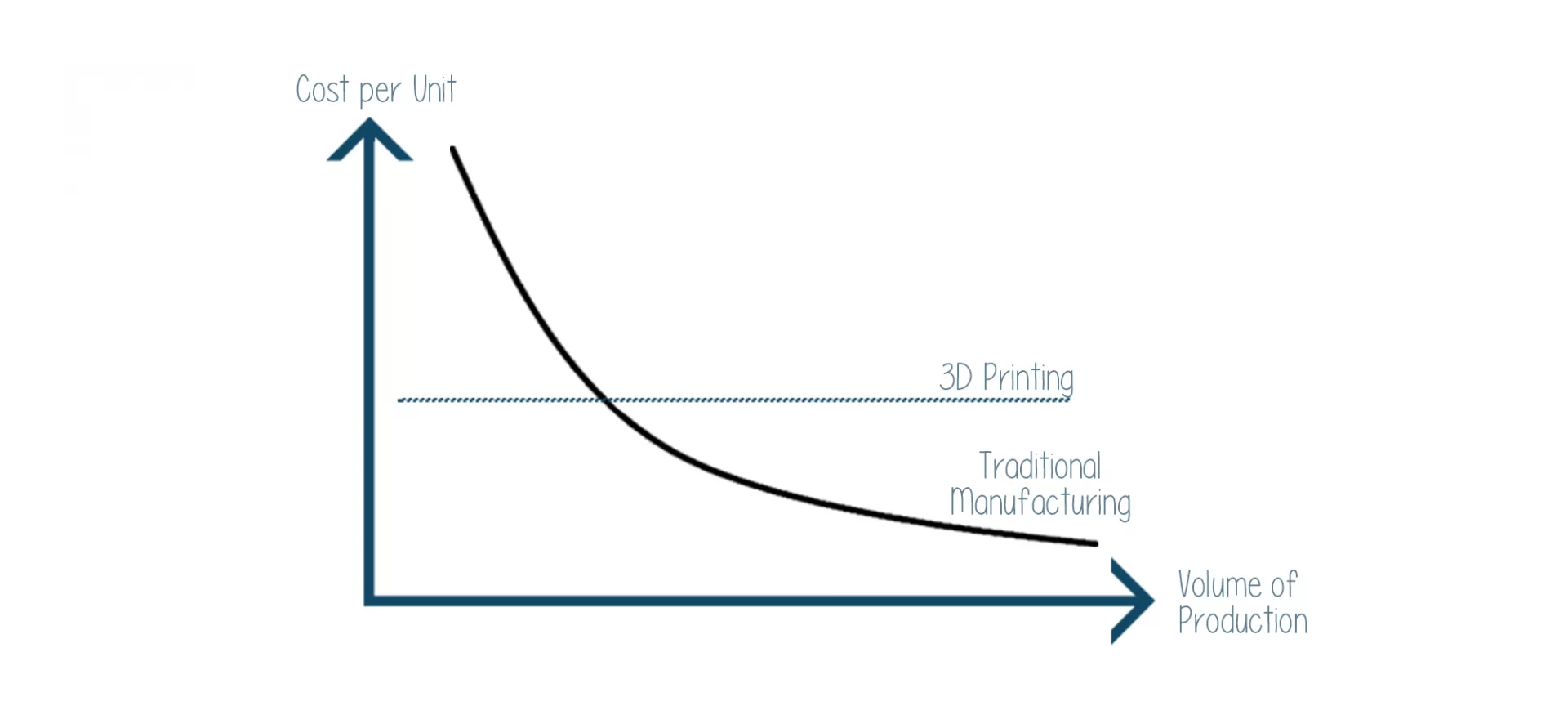

Lower Cost as Compared to Traditional Manufacturing

The cost is broken down into three main factors: operation, material and labor cost. When it comes to print the low volume items, 3D printing has no competitors.

The energy consumption is being reduced exponentially with the introduction of new machines and technology. This is making 3D printing even more sustainable.

The desktop 3D printers are economical in terms of energy consumption. The industrial 3D printer though uses high energy for operation, the ability for producing efficient and complex geometric designs makes their use indisputable for many applications such as healthcare and aerospace.

The material cost varies a lot. While the PLA and ABS come cheap, the metals are pretty expensive. If you are building parts with nylon or PLA, you can complete the part at a cheaper cost.

It will also depend on the design of the part and how much material you would need for those parts. Check out our 3D Printing Materials Guide.

In short, the introduction of cheap and variety of material choices is making 3D printing beneficial and more competitive.

One-Step Manufacturing Solution

When it comes to manufacturing, the major concern that bothers everyone is the involvement of multiple steps to efficiently manufacture a part.

Even a simple looking steel bracket has to go through a lot of stages to finally conclude as completed. Traditional manufacturing also requires a lot of tools and different machines for manufacturing certain parts.

However, with 3D printing, one 3D printer can add layer one over another to print the part directly from the 3D printers.

There may be certain post-processing requirements based on the 3D printing process used and the design of the part. However, these are nothing when compared to the steps involved in traditional manufacturing.

After the CAD file is prepared which is also a requirement for traditional manufacturing, the 3D printer does the remaining job.

Instead of cutting the steel, preparing it for welding, building jig, welding, grinding, drilling holes and various other steps, 3D printer print the steel bracket layer by layer using the preferred material.

And, labor cost is nothing when compared to traditional manufacturing. One can reduce the dozens and hundreds of labors involved to few tens when working with 3D printers.

Freedom to Design Whatsoever

There was a time when the complexity of design used to be a huge issue within the manufacturing industry. This does not apply to 3D printing.

Instead of thinking about the design and if it could be possible with traditional manufacturing, one has to concentrate on orientation and minimum size restrictions. And, everything can be printed using 3D printers.

Most of the major limitations of design that existed with traditional manufacturing has been easily removed with 3D printing.

Additive manufacturing gives freedom to the designers to think about whatever they wish and come up with the best orientation and no to less support required for successful printing.

The complex geometries are easy to create and fun to make with 3D printing.

3D Printing is Highly Sustainable

Subtractive methodologies for manufacturing required a lot of parts to be wasted from the initial block.

This resulted in a loss of material which was not able to be employed during the next production phases. The wastage of a high volume of material was not economical and very unsustainable.

3D printing has eliminated such problems. There are raw materials that can be processed again for rebuilding or reusing it for more than one production.

Moreover, there is no cutting of material to start with. The material is constructed one layer at a time using the amount of material needed.

The small-scale productions are possible with minimum space requirement and no need for expert’s involvement in the manufacturing steps. For this reason, the service stations are settled in parts where the cost of land is higher as well.

This has facilitated closer shipping distances and lesser shipping cost. Isn’t that one of the greatest benefits of 3D printing so far?

Manufacturing Customizable Parts

As additive manufacturing has been best utilized when building one part at a time, complete customization of designs is completely possible.

Instead of dresses that were manufactured in standard sizes, one can change the size after every print. It is most helpful in industries like medical and dental niches.

One can easily build customized prosthetics, dental aids and implants using 3D printing for best fit according to the variable sizes of the individuals.

For single-run productions, 3D printing is the most cost-effective solution. From sports gear to fashion items, customized products are needed in various industries. 3D printing seems to be the ultimate solution for such requirements.

Visualize the Touch and Feel During Product Testing Phase

There are times when we design a product but are unsure about its efficiency or looks.

Apart from manufacturing it and verifying the design alongside all the desired preferences, we do not have much of a choice. But is that economical or feasible option when done with traditional manufacturing.

Building single parts are not just costlier but result in wastage of time and efforts.

However, with 3D printing, designers can actually verify the touch and feel of the design and decide which material could be the best option for printing the parts. One can make minor to entire changes to the design without much of a hassle with 3D printing.

Reduction of Risk to Failure

When thinking from a designer’s perspective, the failure of designs is a huge setback for the complete production cycle.

When trying to introduce a new feature to the existing product, a company has to go through many tests and trials.

Every time a prototype is prepared, it is tested against its appearance and efficiency.

If it is a functional prototype, the challenges even raise quite higher. Hence, it is very important to ensure that the designs are perfect and well-implemented through the production methods for proper streamlining of the next phase of production.

But does it sound possible every time? As long as there is the involvement of human error, the probability of mistakes never fades. This is not a case with 3D printing.

Not just that one can design the prototypes faster, one can print is exactly as designed in the first go itself without involving much cost and effort. And, in lesser time.

Even in need for design change, there won’t be much loss in terms of cost and time. This significantly reduces the risk of failure.

The Ease of Access

3D printing is being used by individuals around the world for various tasks. The cheaper and smaller desktop machine has a smaller learning curve and can be used inside houses as well.

This has led to its increase in accessibility to consumers and hobbyists. People are even using desktop 3D printers for learning technology better.

As the demand is growing, the cheaper machines with better functionality are being introduced. And, it will further increase the accessibility of 3D printers for individual use.

Achieve Best Quality

It is no brainer to understand that less labor-intensive jobs are much more successful.

As the human error is reduced, the quality increases anyway. 3D printers are working for the complete automation of designs.

For example, the old 3D printers required a lot of setups such as bed leveling, axis setups, etc. But, the 3D printers now available could be used directly after plugging out of the box with few minor network settings.

Isn’t that a huge leap in the benefits of 3D printing that it offers? It clearly is.

The Conclusion

It is very lucid to see through the various advantages of additive manufacturing. One can do a lot of things when involving 3D printing technology to its best use. Many milestones have been already set and many more would soon surface.

The array of jobs that 3D printing can accomplish makes it imperative to include the technology within some of the major inventions of all time.

A technology that started with the goal of easing the task of prototyping soon became an integral part of much-finished product manufacturing.

Industries are understanding the success that is connected with 3D printing and researchers are working round the clock to make the technology more efficient. All these contribute to the better future of 3D printing technology that we will soon witness.

While we are talking about the benefits of 3D printing, there are others who are actually reaping its benefits.

And, many more already setting up plans to include 3D printing into their manufacturing routine.

Although technology will take some time to remove traditional manufacturing from its roots, the trend has already begun. With more companies joining hands with 3D printing, the trend is supposed to further rise.