3D scanning helps in capturing object’s dimensions to further use it for editing and even processing it through 3D printer. One can easily create 3D modelling files using a 3D scanner.

Even when starting a print from scratch, 3D scanners stay an important tool. However, what is 3D scanning? And, how does it help in realizing the 3D digital files for printing it using 3D printers? All these questions must be visited to understand the technology in depth.

What is 3D Scanning?

3D scanning involves analyzing objects from the real world in order to collect data for reconstructing its complete appearance with the help of additive technology or other methods.

Because of 3D scanning, the object can be turned into a 3D model. The digital file can be used with CAD software and other modeling tools. You can even edit these files to make changes to the design.

Like 3D printing, there are various methods present for 3D scanning objects. Also, based on varied technologies, the 3D scanning machines also vary from one another.

If you haven’t researched much, it may be surprising to you that 3D scanning can be done using different methods. To have a brief picture of what 3D scanning looks like or is operated, let us discuss a few of the important methods of 3D scanning.

3D scanning is compatible with various modeling and designing tools. Hence, these can be added for use with 3D printers. The 3D scanners can capture not just the shape but also the texture and color of the objects, making it simple for 3D printing the objects as it is in the real world.

The process is also known as reverse engineering and is very helpful in many tasks.

What Things Can be 3D Scanned?

Anything that exists in the real-world can be 3D scanned. Although there are few limitations to the technology, however, apart from the size of the object, almost any factor is not much considerable. Most of the things can be 3D scanned.

Objects: Anything from a glass to a lamp can be 3D scanned using a 3D scanner. All you need to do is place the object steady and use a 3D scanner to scan the dimensions and the curves properly to create the digital file of the object.

Living Beings: 3D scanners can also be used for scanning humans or animals. This technology can help map the body dimensions and can be further printed using a 3D printer.

Surroundings: I did mention that the 3D scanner can scan almost everything. It is completely true for the surroundings you stay inside. For example, your living room or your office. You can scan those to create a digital file for printing it using a 3D printer.

How Does a 3D Scanner Work?

The different 3D scanners work in different ways. Depending on the methods 3D scanner use, the performance and capabilities differ. One can make use of any of the available methods that fit best for the desired application. Recreating shape is easy when using 3D scanners.

The technology depends on certain principles. Each making up for a different category of 3D scanning. Among various methods, few are used widely.

To name some, the ones that are usually found to be used across different verticals are Laser triangulation 3D scanning technology, Photogrammetry, Structured light 3D scanning technology, Laser pulse, and Contact-based 3D scanning technology.

What Are the 3D Scanning Technologies?

Let us discuss the major 3D scanning technologies in detail.

Laser triangulation 3D scanning technology

Laser triangulation 3D scanners make use of either a single laser point or a laser line for scanning the object across its dimensions. The 3D scanners cast the layer beam of the single laser point.

As soon as the laser light reflects back from the object needed to be 3D scanned, its initial trajectory is revised and noted by a sensor. The technology uses trigonometric triangulation along with the data from revision of the laser trajectory to obtain a specific deviation angle.

This angle is then connected with the distance between the object and the scanner. Once the scanner has collected almost all the necessary distances enough to map the object’s surface, the 3D scan is completed.

The advantage of this method is the high resolution that is very accurate and helps in mapping the object precisely. There is however a problem when scanning with laser triangulation technology.

The scanning is sensitive to surface properties. It may have problems scanning an object that are transparent or glossy.

Photogrammetry 3D Scanning Technology

The Photogrammetry is also known as photography. This technology uses photographs to measure the dimensions of the objects.

This helps in realizing the exact distances of surface points. Photogrammetry takes into account the power of computational geometry algorithms and the computer vision to come to the final digital file.

To do so, the method employs analyzing various photographs of a static object that needed to be scanned. These pictures must be taken from different angles.

This method automatically detects pixels equivalent to a similar physical point. The principle requires the user to mention the parameters of the camera. For example, the focal length, lens distortion, etc.

This technology is definitely impressive. However, it has its limitations. The major challenge comes when there is a need for analyzing lots of photos and hundreds and thousands of surface points taking accuracy into account.

Apart from the 3D scanner, one must own a high-end computer to run photogrammetry algorithms. The advantages include high precision and speed of acquisition. Photogrammetric technology can even recreate objects with varying scales.

The technology also has a problem with resolution sensitivity, hence, it can have problems with low-resolution photos.

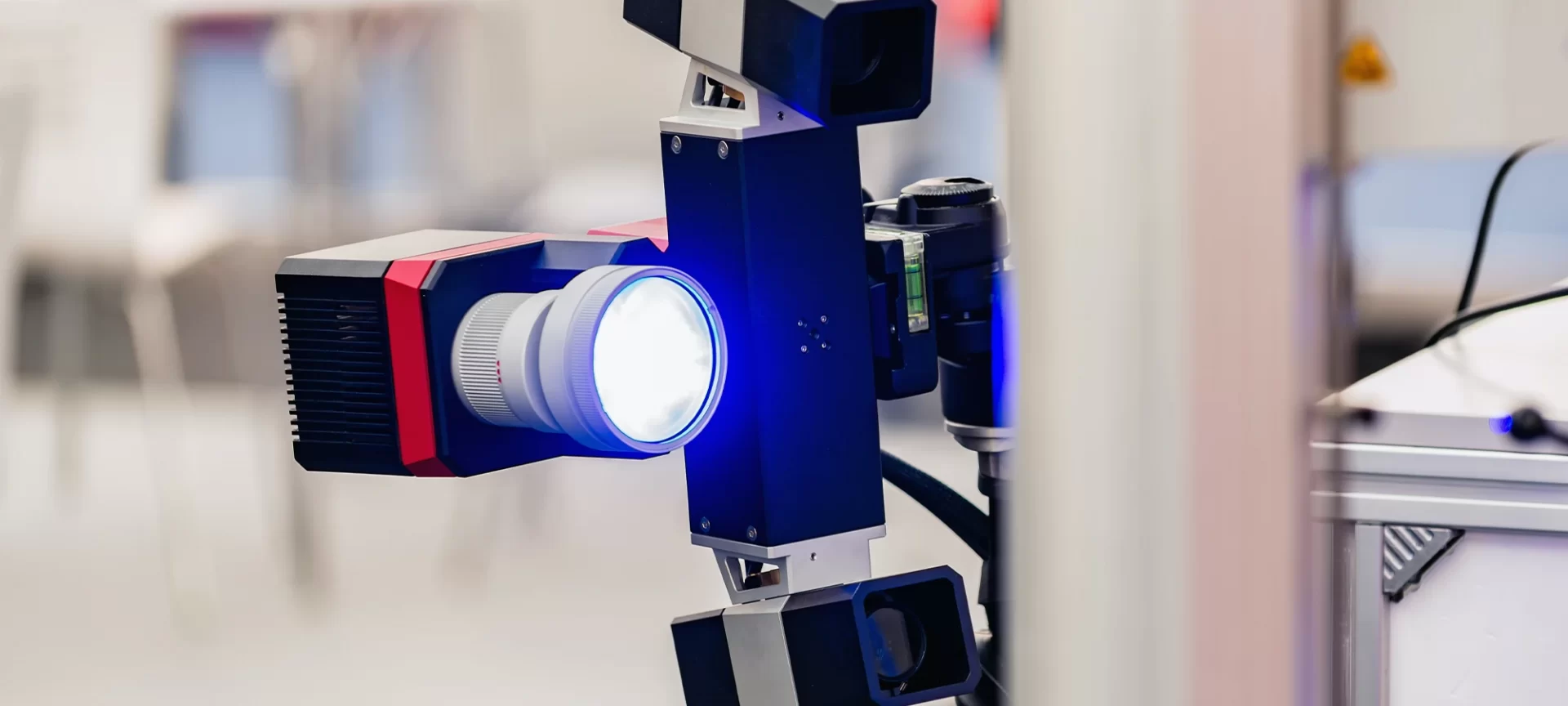

Structured Light 3D Scanning Technology

To better answer what is 3D scanning, it is important to talk about the various principles. Structured light 3D scanning technology is one such method for 3D scanning objects.

This principle is similar to laser triangulation methods as it used trigonometric triangulation. However, the method does not use a laser to capture the surface distances. However, it makes use of a series of linear patterns. By considering the ends of each line, the method takes care of calculating the distance of the surface from the 3D scanner.

There are various projectors that can be utilized for processing linear patterns or white or blue structured light. One such projector is DLP which is known as Digital light processing technology.

If you wish to scan the body, you can use these methods without any doubt. The technology is faster and very precise in terms of capturing the dimensions of the subjects.

The limitations are still there, apart from all the great things it offers. It is sensitive to lighting effects and can have problems when working with bright light in outer space.

Laser Pulse 3D Scanner

The Laser pulse-based 3D scanners can also be cited as Lidar or Time-of-Flight scanner. It works by measuring how much time laser takes when projected on an object to come back.

The speed of light is known and the time is calculated which ultimately provides the distance traveled by the laser. With the help of the distance, speed and time formula, one can easily conclude the distance between the object and the 3D scanner.

The laser scanner is capable of measuring millions of laser distance in a picosecond.

To work properly, the 3D scanner must the laser 360 degrees around one point. To ensure this is taken care of, the 3D scanners are equipped with mirrors which helps in changing the orientation of the laser.

There is another type of 3D scanner technology known as Phase shift laser 3D scanners. These are the sub-category of a laser pulse. The difference between a pulse shift laser and laser pulse is that the phase shift system modulates the laser beam’s power as well apart from pulsing the laser.

And, the phase shift lasers provide better and accurate results as compared to the laser pulse 3D scanners.

The laser pulse 3D scanners, though, are useful when it comes to scanning bigger objects such as an entire room. Although they are slow, this advantage over other 3D scanners makes laser pulse a 3D scanner popular among many users.

Contact-based 3D scanner

Another name for Contact-based 3D scanning is digitizing. As the name suggests, the technology uses contact or physical touch to collect 3D data on the subject.

The method accomplishes when the 3D scanner investigates the subject through physical touch. During the scanning, for perfect accuracy, the object must be held firmly in one place.

The 3D scanner touches the surface of the object at various points and records the 3D information. The touch is initiated with the help of an articulated arm. This arm is capable of collecting all the respective angles and details of the object for providing precise specifications.

This kind of scanning is usually helpful after the fabrication of parts and during the quality control steps. These are also used during the maintenance process.

The 3D scanners are highly accurate and precise which makes these 3D scanners a great aid for many applications. Even the transparent surfaces can be scanned with the help of Contact Based 3D scanner.

However, the scanner does have some limitations. The major of which is slow speed and the inaccuracy to scan free-form objects or parts with complex geometric surfaces.

Applications of 3D Scanner

The 3D scanner can be used for various applications. Here are a few of the major areas where 3D scanning is widely utilized for precise results.

Industrial Design: Before 3D scanning came into the picture, the measurement of parts for designing new products used to take many days of hard work. However, it is very easy to complete the task with the help of 3D scanners. There are many 3D scanners that are capable of measuring the smallest to larger parts with high precision. These specifications can be exported to different CAD tools for further making necessary changes to it. Or, processing it through 3D printing or other manufacturing methods.

Reverse Engineering: If you are looking to recreate anything, you can start by scanning the subject. For prototyping, this method is highly beneficial and speedy.

Healthcare Services: Do you know that medical science has gone too far when it comes to designing artificial prosthetics. Thanks to 3D scanner that has made it easy to take measurements with accuracy depending on the specific anatomy of every patient. It can scan precisely the body parts and can help in creating prosthetics that fit correctly without any room for mistakes.

Articulating Designing: There are many ways to create amazing designs. However, nothing gives more freedom as compared to 3D scanners. 3D scanners can be used for realizing a variety of art forms in the simplest way possible.

Movie Industry: Movie industry isn’t behind when using 3D scanners for creating stunning visual effects and stunts. Movies like Terminator, World War Z, and many others used the technology to provide their viewers with the best cinema experience. A lot of things could be done by 3D scanning which isn’t possible without it at all.

Education Industry: 3D scanners are being used by education and research institutions for learning about artifacts accurately and with great precision without even causing any harm. The 3D scanners are also helpful in museums where one can check out the scanned copies of the real artifacts from every angle.

The Conclusion

3D scanners are getting involved in many applications and with time, the possibilities are being widened. Today, with the help of 3D scanners, a lot of work can be accomplished in a matter of time which used to take days for completion. This has paved the way for a well organized and simple workflow.

More and more people are looking for an answer to the question: what is 3D scanning. It is because of its immense benefits that are not limited to just a few applications, but a bunch of users that spread across many niches. Utilizing 3D scanners, one can make many things possible.