3D printers serve different types of niches where each printer caters to specific applications. OA jewelry 3D printer helps you print out jewelry designs.

Jewelry making is a popular process involving a range of methods. Each method produces a different type of jewelry. For intricate and complex designs, you can use 3D printing technology.

With jewelry 3D printers, you can print difficult designs in a short span of time. You can replicate these designs easily without any room for error. The entire process gives the jewelry maker a creative hold over the design.

With a jewelry 3D printer, you can easily experiment and come up with something new and unique. You can even make jewelry with a variety of materials.

The rise of 3D printing opens up many opportunities when it comes to jewelry production. There are many options in the market for a jewelry 3D printer. However, choosing the best jewelry 3D printer can be a hard decision.

This guide will highlight the best jewelry 3D printing options. Each printer discussed below comes highly recommended, and we tried and tested each one. Read on to see which jewelry 3D printer works best for you.

What is a 3D Printer for Jewelry?

Generally, you can use 3D printers to make any type of model or item. You can also use a 3D printer, especially for printing accessories.

These 3D printers feature additive manufacturing technology. This technology is similar to other 3D printers but it allows you to work with various metals, including casting materials.

A jewelry 3D printer is ideal for accurate and complex jewelry design with ease. These machines ideally build layer by layer, without the need of going through time-consuming steps usually required with traditional methods.

For jewelry, resin 3D printers are also suitable. These printers use castable wax resin, which can easily transition from a gas into a solid-state, once heated.

FDM 3D printers are rarely used to print out jewelry, as they are not capable of the high resolution, accurate printing necessary for jewelry production.

A jewelry 3D printer should produce detailed and intricate designs in high printing quality. With high printer quality, less finishing will be required for the resulting jewelry piece.

Comparison Chart

| Name | Link | Nomination | Overall Rating |

|---|---|---|---|

| Creality Ender 3 Pro | Strong and Durable | 9.7 | |

| Elegoo Mars 2 Pro | Best Usage | 9.1 | |

| Anycubic Photon | Best Budget | 9 | |

| Formlabs Form 2 | Editor’s Choice | 9.8 | |

| Ultimaker 2 Plus | Strong and Practical | 9.5 | |

| Uniz Slash Plus | Most Reliable | 9.3 | |

| EnvisionTEC D4K Pro | Most Functional | 9.5 | |

| Peopoly Maoi | Best Value | 9.2 | |

| Solidscape S300 Series | Premium Pick | 9.6 | |

| Prodways ProMaker LD3 | Strong and Sturdy | 9.8 |

Best 3D Printer for Jewelry Making

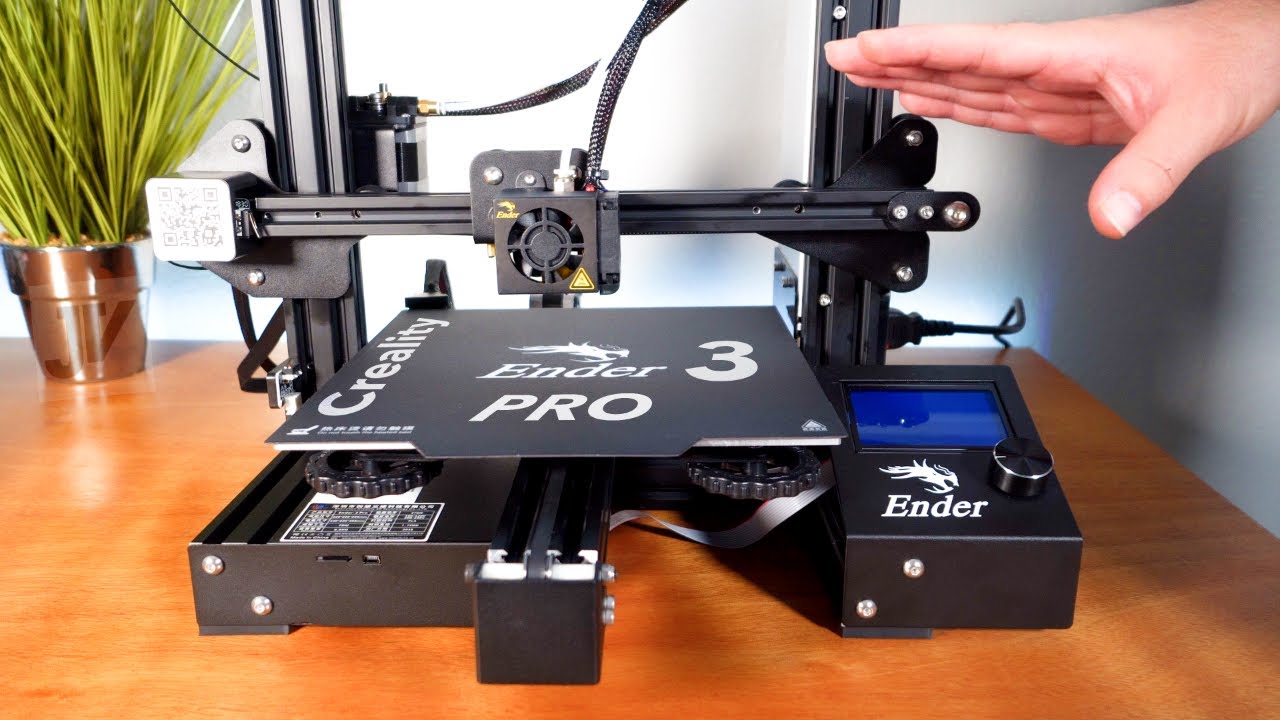

Creality3D Ender 3 Pro

|

Ender 3 Pro makes customizing jewelry an easy job. This jewelry 3D printer allows you to print accurate and high-quality jewelry designs. You can let your creativity loose while using this product. The printer allows you to enjoy more freedom than any other FDM printer. With a wide range of functions, the printer allows you to experiment with different designs.

The machine offers a print volume of 220 x 220 x 250mm. The 3D printer has a tight filament pathway that allows you to work with flexible material for a wide range of jewelry products. This printer is ideal for hobbyists and beginners in this field.

Salient Features:

- The jewelry 3D printer comes with a removable build surface plate that keeps the build plate safe and regulates temperature to keep it consistent.

- The UL Certified power supply is safe and protects your printer from voltage fluctuations. The hotbed heats up to 110o C in around 5 minutes

- In case of a power failure, the printer’s resume print function allows you to start from where you left off.

- It provides a one-year warranty and with its advanced software, this printer is definitely a steal.

- Provides fast printing with accuracy

- Easy to assemble

- Decent build volume

- Can be upgraded

- High-quality printing

- The print bed needs improvement

- Requires some additional adhesion materials

Elegoo Mars 2 Pro

|

In the increasingly competitive jewelry 3D printing market, the Elegoo Mars 2 Pro has made a name for itself as an easy-to-use machine that is highly functional.

The Mars 2 Pro includes an easy-to-follow User Guide that makes printing convenient. The printer has a build volume of 129 x 80 x 160 mm.

Its layer height ranges from .01mm to .2mm. You can connect the printer using a USB thumb drive. It also comes with a user-friendly color touchscreen LCD.

The Elegoo Mars 2 Pro offers precise jewelry printing using LCD printing to cure entire resin layers at once. This allows for a quick print speed of 30 to 50 mm/h. This sturdy printer is stable, thanks to its CNC-machined aluminum structure.

Salient Features:

- The latest heavy-duty, z-axis guide rod provides careful and accurate movement.

- It has Z-axis resolutions of up to 0.00125mm and XY resolutions of 0.05mm.

- The device also comes with new features, such as an LCD screen and button board. Both components work error-free.

- This machine is great for DIY projects or even professional use.

- Quick layer curing time

- Simple, easy-to-use workflow

- Offers Wi-Fi connectivity for easier control

- Loud cooling fans

Anycubic Photon

|

Anycubic is popular for its jewelry 3D printers. The Photon is one of the best jewelry 3D printers. Photon offers many high-quality features at a budget-friendly price.

With a solid and sturdy structure, this jewelry 3D printer offers a build volume of 97 x 54 x 150 mm. The Photon printer offers easy setup and operation. You can use these tools to loosen space, level the plates, and more.

The resin vat prevents spilling. The UV cooling system of this printer ensures a long useful life for the module. With a dedicated cooling system, you can work on a project with longer work hours.

Meeting your budget requirements, this jewelry 3D printer is ideal for beginners and entry-level jewelry design projects. For someone who wants to pursue 3D printing as a hobby, this is the perfect printer to start.

Salient Features:

- The printer also has slicing software that you can customize accordingly.

- The UV modules in the Photon perform various techniques that can help produce parallel UV rays. These rays are usually well spread across the LCD masking screen.

- This printer is quite small, which makes it easier to transfer from one place to another.

- The temperature of the printer during the printing process remains steady.

- Due to its small size, the printer takes around 2 and a half minutes to heat and begin the printing process.

- Comes fully assembled and does not require much energy for setting up

- Fully functional touchscreen user interface

- Comes with an easy to reach USB

- Linear Z-axis for precision

- Compact and lightweight

- Longer layer cure time

- Low-resolution prints

Formlabs Form 2

|

Formlabs Form 2 is an SLA printer recommended for jewelry production. This printer has a build volume of 115 x 65 x 155 mm, which is ideal for printing jewelry. This jewelry 3D printer is a desktop printer. It is compact in size and does not occupy much space.

The Formlabs Form 2 comes with a special SLA resin that is wax-castable. This allows you to work on different types and styles of jewelry.

Formlabs is a well-established company with programs that are sleek and easy to operate. The Formlabs Form 2 printer looks stylish while offering accuracy and ease of use.

The printer also works well with liquid resin so you don’t have to mess with it in the rough. You only need to put it in a canister and the machine with automatically operate it.

With multiple features, this jewelry 3D printer is a top pick for jewelry making.

Salient Features:

- Compact desktop design with a small footprint and an open frame design

- The printer uses a laser to solidify the resin

- The printer can automatically find the best orientation that works for you and the user interface is also easy to get the hang of

- Comes with a progress meter that displays the estimated remaining time

- This printer is compatible with many slicing software, such as Repetier-Host, Cura, Replicator G, and Simplify3D

- Formlabs Form 2 is versatile. Beginners can use it without any difficulty as it comes with an easy-to-use interface and a cooperative support team.

- Delivers consistent and reliable production

- Quiet to operate

- Easy resin loading feature

- Easy to set up and operate

- High functioning software

- Resin fill-ups can be expensive

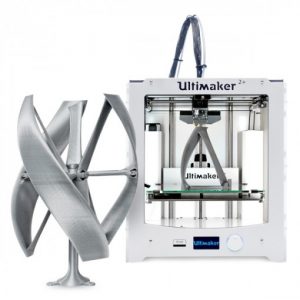

Ultimaker 2 Plus

|

Ultimaker made much advancement with its 2+ model. The jewelry 3D printer has a build volume of 223 x 220 x 205 mm. The printer connects to various devices using Wi-Fi or Ethernet cables, which allows remote printing.

You can also operate the printer with its 2.4-inch color touchscreen and a user-friendly interface. This model offers cutting-edge FDM printing with flexible support, making it a contender for the best jewelry 3D printers.

Ultimaker 2+ comes with swappable print cores. You can print with different filament types. It can support a wide range of printing materials, including PLA, ABS, CPE, nylon, and so on.

It can work with high-temperature materials easily as the print bed can reach up to 212o Fahrenheit. With a large build volume, the printer also allows you to utilize the space to print different jewelry types in one space.

Salient Features:

- Offers the finest and most consistent resolution for intricate jewelry designs

- Closed frame design

- If you run a jewelry printing business, this device should be your go-to choice

- Provides a large build area

- Precise extruder nozzles

- Compatible with other filament materials

- Does not offer auto-calibration

Uniz Slash Plus

|

Uniz Slash is known for its high-speed resin 3D printing. You can print high-quality jewelry using the Uniz Splash Plus, thanks to LCD Stereolithography.

The build volume of this 3D printer is 192 x 120 x 200 mm. The printer’s XY resolution is 75µm while it offers an accuracy of ±20µm.

This printer has a high printing speed, thanks to the manufacturer’s Smart Support technology, with speeds of up to 20 mm per hour. The resin vat floor of this printer is sturdy, comprising a polymer film, which enables it to last for 1,000 3D printing hours.

This jewelry 3D printer uses software named Uniz that is compatible with various devices, including Windows and Mac. The software allows you to make all the basic changes to your 3D model.

You can move, rotate, zoom and add specific media to your prototype, using this software. Different controls are available from the control panel while it also provides the information while you print. The software is extremely easy to use.

Salient Features:

- Auto-calibration system, which means less trouble when leveling the bed

- The printer arrives in a completely assembled form, so you can start printing right away.

- Durability is one of its key features, which makes it last long

- The print bed and extrusion nozzle can heat up to an extensive range of temperatures. This feature enables you to print with different kinds of materials.

- You can gift this printer to anyone and help them to start jewelry 3D printing. Also with a decent price range, it makes for a perfect gift.

- Uni-directional peel technology that allows for above-average print quality

- Unmatched printing speed

- Allows you to use various types of resins for printing

- Easy removal of media

- Durable steel and black anodized aluminum frame

- Can be printed from a computer using Wi-Fi

- Difficult to use for beginners as it has no control screen

EnvisionTEC D4K Pro

|

When it comes to industrial jewelry printing, EnvisionTEC D4K Pro is the best jewelry 3D printer in the league. The printer has a build volume of 148 x 83 x 110 mm.

Its key features include high print speed and accuracy, which are vital to jewelry production.

The 3D printer creates crisp jewelry designs at a high speed. With this 3D printer, you get 25-micron accuracy on the XY resolution and 1 micron on the Z-axis.

Though it’s an industrial 3D printer that is expensive, professional jewelers will find the D4K one of the best 3D jewelry printers.

Salient Features:

- If a power lapse occurs, this 3D printer will resume printing automatically.

- Works with all resins

- The printer is quick and easy to assemble

- The build platform ensures high-quality 3D printing for a variety of materials

- The D4K Pro possesses the ideal characteristics for jewelry production.

- User-friendly thanks to a super intuitive LCD interface

- Allows for mass production with repeatable designs

- Solid and sturdy build

- Expensive

- Not ideal for use at home

Peopoly Moai

|

Another jewelry 3D printer to consider is the Peopoly Moai. The printer has a build volume of 13 x 13 x 18 cm, along with a 70-micron laser spot. The printer is mechanically able to print up to 5-micron layer height resolution.

However, the print layer height depends on the type of resin you use for the printer. The printer prints via G-code and uses Cura for model slicing.

Printing with Peopoly Moai is relatively easier. You need to load a model in Asura while adding supports and hollows, if necessary. You can either use Cura for slicing or use Asura itself.

The printing process is extremely simple and easy to navigate through. The jewelry 3D printer has a tilt-motor mechanism that assists with level changes, softens the peel forces, calibrates, and does so much more.

Leveling the print plate is easy, as you only have to loosen and tighten the four bolts to achieve workable results quickly.

Salient Features:

- Allows 3rd party resins, which allows you to create various kinds of designs without any boundaries

- The Z-axis lead screw for the print plate is solid and sturdy with no room for error

- Peopoly Moai is a first-rate printer, which is quite popular in manufacturing. Its ability to produce quality prints using multi-materials makes it one of a kind.

- Super accurate and precise in function

- Quiet to operate

- Easy to use, which makes it beginner-friendly

- Easily print using a resin bath

- Comes with an accessory kit

- Requires assembly

- Messy printing process

Solidscape S300 Series

|

Solidscare S300 series printer is a professional-grade, top-of-the-line jewelry 3D printer. This printer comes with a ton of extra features that are ideal for professional use. The printer gets rid of any feature that you might hate about any other average SLA 3D printer.

The printer is mess-free as it does post-processing using dissolvable supports. The printer can be easily set up in no time and it’s just as easy to operate.

The machine is also able to automatically wax-cast your jewelry with accuracy and precision. The printer has a volume of 21.4 x 18 x 16 inches with a build space of 6 x 6 x 4 inches. The layer thickness for the printer goes down to 6 microns.

The S300 jewelry 3D printer can replicate the same design multiple times with no errors. You can operate the machine with a one-touch interface that is user-friendly.

The machine offers convenience and accuracy for anyone who wants to get into jewelry production.

Salient Features:

- The S300 comes with soluble support, which gets rid of the support material during the resin printer. This helps you achieve smooth and fine casting molds.

- The machine has an auto-fault detection system, which senses problems and restarts after interruptions.

- The machine comes with quick calibration in order to save material wastage

- Ender 5 is a great option for those who want to produce jewelry professionally.

- High print resolution

- Accurate designs

- Easy to set up and handle

- User-friendly interface

- Accompanying products are high-end and expensive

- Not compatible with Mac devices

Prodways ProMaker LD3

Prodways is known to make3D printers for dental and jewelry applications. Their recent product, the ProMaker LD3 is a compact but powerful jewelry 3D printer.

The LD3 uses MovingLight technology for detailed printing at high speed. This technology allows you to make large products without sacrificing quality. The LD3 has a build volume of around 64 x 120 x 130 mm.

The LD3 allows you to experiment with third-party products so you can produce a variety of high-quality jewelry. This printer is a well-rounded package for jewelers interested in working with 3D printing.

Salient Features:

- This printer is equipped with the latest technology, such as a touchscreen and Wi-Fi. These features make for easier operation.

- The 3D printer has a closed enclosure, which keeps the device dustproof.

- It is easy to assemble and it takes less than 30 minutes to put the printer together.

- The 3D printer has some latest technological advancements, which ensures an excellent user experience.

- Easy to assemble

- Compact footprint

- The printer bed heats up in 5 minutes

- Doesn’t have clear operation instructions

Buyer’s Guide

For jewelry production, you need to consider various factors when purchasing a jewelry 3D printer. Here are some of the key points that can help you make an informed decision while purchasing a jewelry 3D printer.

- Speed: With high-speed printing, you can print many products in a limited time. This process allows you to be faster than any other conventional jewelry production method. For this purpose, select a printer that allows high printing speed without compromising print quality, in order to get the best possible results.

- Resolution: A high-resolution 3D printer allows you to create jewelry with intricate details and designs. If you want your designs to be translated from the software as they are, you should look for a high-resolution printer. All the jewelry 3D printers listed above produce high-resolution jewelry.

- Compatibility: A compatible printer allows you to work with different types of printing materials. When it comes to jewelry production, the more options there are, the better it is. With a wide range of material compatibility, you can produce unique designs that also allow expanding your creativity.

- The Build Volume: You have to consider the dimensions of your printer as well. A build plate is usually shaped as a square or rectangle. If you are a beginner, a small printer will be suitable. However, if you are venturing into the jewelry-making business, you might need to look for a device with a larger build volume.

Frequently Asked Questions (FAQS)

What Do Jewelry 3D Printers Make?

A jewelry 3D printer usually prints molds for jewelry, for example, ring designs or chain links. These molds would often require you to set the stone or gems in yourself. You can also use the printer to make “fitting pieces” for testing purposes.

Is There A Limitation To What Shapes You Can 3D Print?

3D printing will allow you to work on any shape that you desire, depending on the scale. Some 3D printer models come with built-in model designs that you can use for printing. With a jewelry 3D printer, you can customize and design models.

Why Does Ventilation Matter While 3D Printing?

When your filament or resin heats up, it releases intense and reeking fumes, which may lead to irritation and headaches. Therefore, you need a properly ventilated room for 3D printing. However, some printers already have an enclosure or a fan, which will reduce your contact from the fume extraction.

Conclusion

There are different types of jewelry 3D printers available that offer unique features. From the printers reviewed above, Peopoly Moai is one of the most cost-effective jewelry 3D printers that offers useful features for jewelry production.

The Formlabs Form 2 proves to be the best of the best. It has multi-functional capabilities and comprises advanced engineered technology.

The device might be beginner-friendly but it has all the features that an advanced home 3D printer could have. All the jewelry 3D printers mentioned above are great for jewelry production, you just need to see which one best suits your needs.