Did you ever think about 3D printed furniture? A lot of us often come across online designs of furniture created using AM technologies and wonder what if it’s possible at home.

Sometimes back, accomplishing such projects needed a large sum of money along with industrial 3D printers. However, with recent developments, these projects seem accessible and affordable as well. From small showpieces to a big chair, one can create a variety of different parts. That too, from the comfort of their homes.

Among the various techniques used for creating 3D Printed furniture, three of them are very popular. Check out how these work as well as what cost would each of the techniques incur when producing your favorite furniture.

How to Create 3D Printed Furniture

When it comes to designing beautiful parts, especially fully functional furniture, one must find the perfect settings to do it. Not only do the bigger designs need proper care to print but require enough space within 3D printers for completion in one go.

So, let’s find out the options that could help us finish our projects with utmost perfection.

Using Hangprinter to Create Furniture

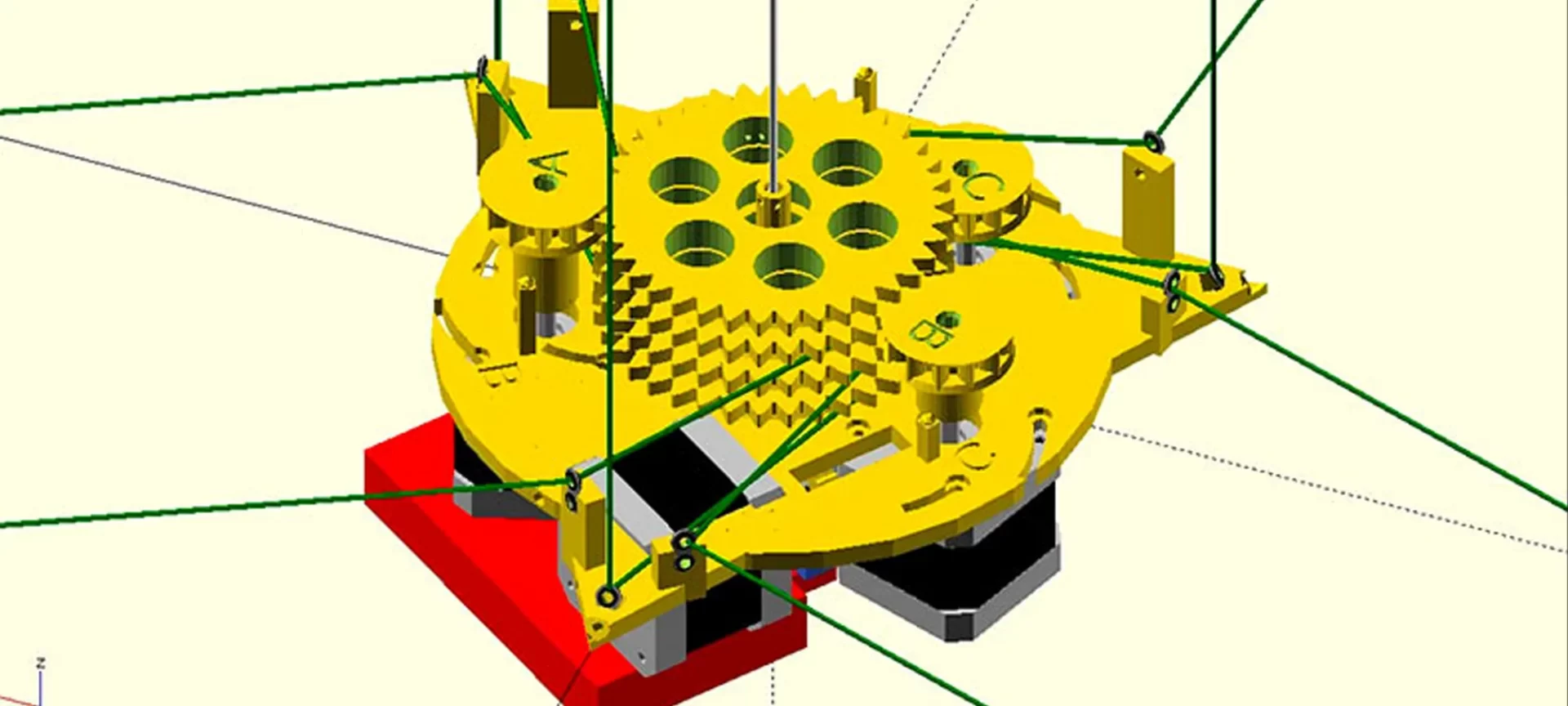

What is a Hangprinter? A lot different from the usual cartesian and delta 3D printers, these machines help in minimizing the cost of producing larger parts considerably. The technique was designed by Torbjørn Ludvigsen and soon became the talk of the town.

So, what differentiates Hangprinters from the usual AM machines? To start with, the Hangprinters aren’t housed inside cases as other 3D printers do. On the contrary, these mount on the ceiling of the room.

Hence, the restrictions of limited space that come along with enclosers aren’t the case with Hangprinters. Therefore, users can actually print volume with maximum space their rooms allow.

Not just that, the files of these machines are open-source. Hence, anyone wanting to replicate the machine at home can easily do it themselves. In addition, one can also update the design and sell as well.

What’s fascinating is that the majority of the components of the Hangprinters can be created using 3D printers while the cost of construction is around $250. Isn’t that quite affordable when compared to the price tag for industrial 3D printers?

How Hangprinters Work?

Those who have worked with a usual 3D printer may not find it difficult to operate Hangprinters. Along with the knowledge of AM techniques, one also requires an understanding of electronics, as well as mechanics.

However, to help beginners as well as those not very equipped with similar techniques, can always find the detailed instructions available online handy. Additionally, the growing community of those working with Hangprinters is always there to help. If you are ready to test your skills by enduring trial and error, you certainly can master the art of printing using the technique.

Few Examples of Furniture Printed Using Hangprinters

Hangprinters were released in 2017. However, even being a relatively latest invention, there are a few designs of furniture printed using the machine that exists.

The most popular example is the lampshade printed by the maker of the Hangprinter in his first promotional video. There are other examples too. Such as the stool created using the same technique by Chris Riley.

Using Small 3D Printers to Create Large Furniture

Often large 3D printers aren’t the best choice for budget-friendly users. However, one still can print furniture using small and compact 3D printers. By preparing small parts separately and joining them together, it is possible to create larger furniture. And, there have been many projects that prove the same.

It might take a little more time to print multiple components separately. But the results are worth your efforts and time. When it comes to the cost of the machines, it’s cheaper and very much accessible.

The small format FDM 3D Printers are available for as little as $200. However, we would suggest spending some extra bucks and get a professional 3D printer. If you wish to keep the budget as low as possible, you can also turn up to DIY machines.

Few Examples of Furniture Printed Using Small 3D Printers

You must have come across Supermod, a 3D printed wall. The amazing design is the hard work of the founders of Simplus Designs. Specifically, Supermod is created as a storage module. The design is the best example of how joining different components together could still provide such an amazing structure.

In addition, the design is thoughtfully accomplished. The patterns, as well as opacities of this design, allow sunlight to fall into the contents of each module. Alongside, the glimmering effect that surrounds the room looks stunning.

Using affordable home 3D printers, one can also create some parts of the furniture if not the entire design. One such example is the wooden side table created using 3D printed joints by Youtuber and designer Alexandre Chappel. The project consisted of 3D printed joints while the remaining of the table was made using the conventional tools.

Those wanting to make something similar could easily access the STL files made by Alexandre, available for just $5 on his personal website. The detailed instruction for manufacturing the complete chair is also available with the file. Apart from the cost of the STL file, you may have to invest in the material cost, not more than $100.

Isn’t that a very budget-friendly way to create furniture using 3D printing technology? Although the design is not completely 3D printed furniture, but it does allow for efficient customizations. Those interested in creating complete furniture using AM technologies can always choose to print different components and joining them together.

Using Large Format 3D Printers for Creating Furniture

Obviously, furniture is a lot bigger than the usual desktop 3D Printers maximum build volume. Hence, leaving all barriers behind, how about including a much larger 3D Printer that does the job just right.

Although straightforward, it is not everyone’s cup of tea to get a highly expensive 3D printer to work with. Not only do these printers occupy a lot of space but would easily cost a few hundreds of thousands of dollars.

Therefore, it is difficult to find a lot of projects for 3D printed furniture created by individuals using large-format 3D Printers. Rather, these projects are usually venturing businesses with large budgets.

Few Examples of Furniture Printed Using Large Format 3D Printers

There are quite some projects that could easily awe you with their mystical designs and modern outlook. Wilkhahn Printstool One is one such artistic example produced by Wilkhahn and designed by Thorsten Franck. Created using an industrial 3D printer, the stool looks magnificent.

The Printstool One is among the few commercially accessible 3D printed furniture available for purchase. However, it is not easy to buy as the stools are produced as a limited-edition 500-piece run.

Not taking more than a few hours to print, along with assembly with non-printed parts, i.e., base and seat, the design is well crafted for ease and comfort.

Also, the stool is biodegradable. Using lignin which is an organic biopolymer to make the stool’s body, the company has come up with this eco-friendly 3D printed furniture. Consumers can also opt to customize the design as desired.

While the cost of the stools isn’t disclosed, these won’t be cheap. The price of usual furniture from Wilkhahn’s catalog often sits between $266 to $660. Hence, the 3D printed stools won’t come for any less price tag. Hence, making it unaffordable for most of the buyers.

Affordable Large Format 3D Printers

It is impossible to get hands-on a large format 3D printer for the price of a desktop machine. However, with some developments and companies trying to make industrial 3D printers accessible, there have been some models released recently costing as little as possible.

However, you can still expect these printers to cost around tens of thousands of dollars. Again, not suitable for individuals wanting to print a complete 3D Printed furniture in one go. The good news is that the price drop has actually favored designers along with smaller manufacturers to try 3D printing for the production of furniture.

“Manoveneer” finishing technique by a bunch of German designers to bring large-scale 3D printing to an affordable budget is a successful initiative. Their printer hosts a maximum build volume of 1005mm³ and is available for around $39,000 which is far less than the cost of industrial 3D printers.

The Conclusion

Now that you know the various techniques to 3D print furniture, which one would you choose? A lot depends on the price you are willing to pay and the quality you desire.

For instance, professional studios, as well as independent designers who have enough funds to invest in a large 3D printer, can certainly choose to pay and get a reliable machine for printing high-quality furniture.

However, if investing a large sum of money seems impossible, going with small 3D printers and choosing to print a few components of the furniture would be a wise choice.

Those who are willing to spend their time and effort in learning emerging techniques, and have the necessary skills, can use Hangprinters.