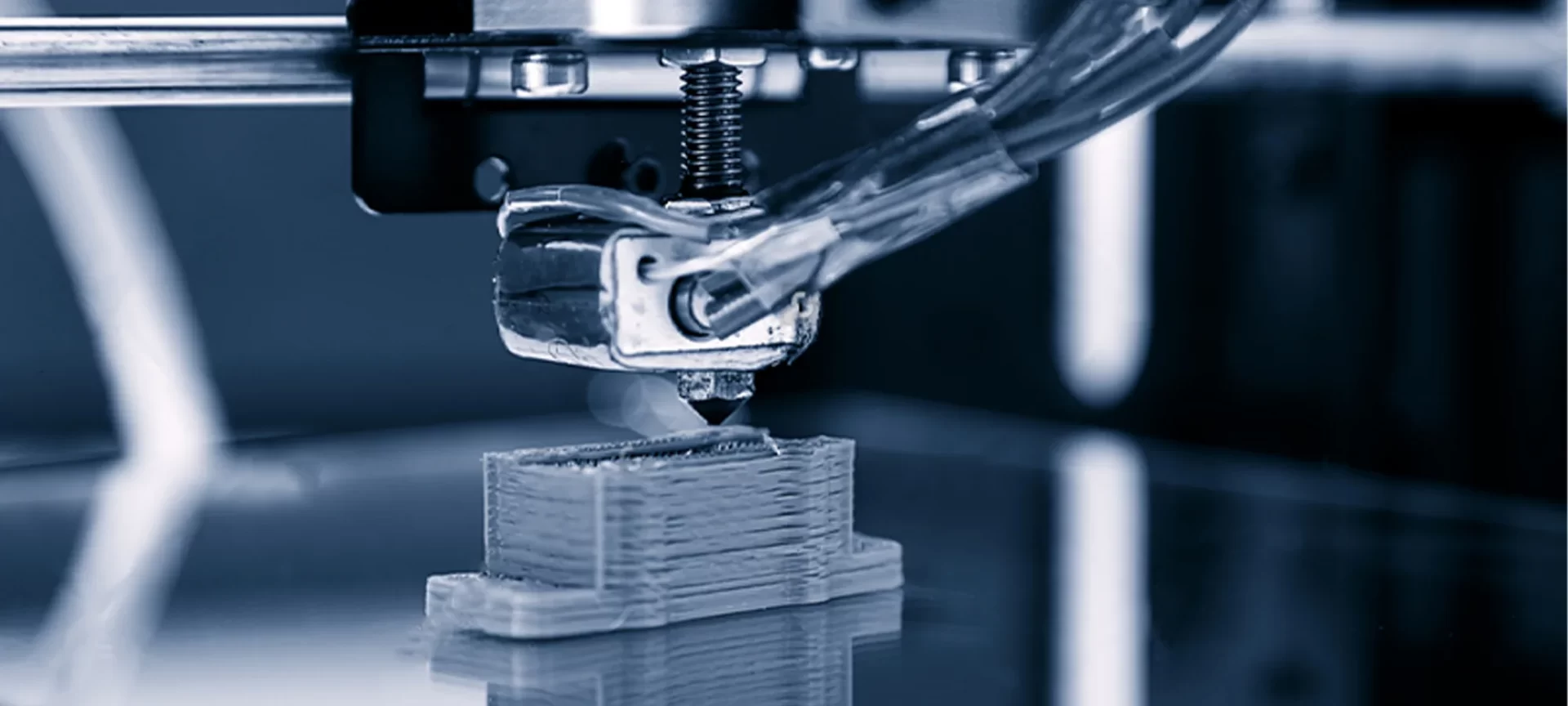

3D Printer is a whole made of many parts. Amongst those many parts that made up the complete 3D printer is the extruder.

The 3D printer extruder is a series placed together to handle the moving and processing of plastic filament.

A part of people thinks of the extruder as only the motor and associated parts that push and pull the filament.

There is another part of people that think the entire assembly includes the heated part that melts and deposits the filament.

There are two crucial components of the 3D printer extruder, the cold end, and the hot end.

In this article, we will state what happens when the 3D printer is not extruding and put in front of you some reasons for the same.

Because many parts are needed to work together, there is a possibility that a lot can go wrong in the printer.

So much so that, one of the most essential skills that are believed for someone who works with a 3D printer, is learning how to diagnose problems and troubleshoot them.

But learning those skills is not a straightforward process, it has its circular, spirally path. So finding the best solution requires a deep understanding of how 3D printers work.

This article focuses on solutions to one major problem i.e. what happens why when is a 3D printer not extruding? Some of the possible causes of a failure of extrusion and how can you solve them? We will start by stating what happens when an extruder stops extruding?

When a 3D Printer not Extruding

When every other part of the 3D printer is working great but there is no filament coming out of the extruder, that is when failure of the extruder is determined.

So, the first thing that you probably need to check is not on the extruder, but on all other parts, whether they are working fine or not!

One of the key signs, when such a problem should be diagnosed, is when the print head moves in the appropriate x-y directions, but no filament is being laid down on the build platform.

Failure of extrusion is a phenomenon that can not necessarily happen only when the 3D printing process starts, it can occur even before that! Also, in the middle of the project.

But as you can guess, if it happens so, that you come across this problem before starting to print, it is much less problematic than otherwise.

But this does not mean that if the problem occurs during the middle of printing, it cannot be solved.

But the final quality of parts and functional prototypes are not that good when the problem does not occur midway.

Now coming to the causes, there can be many, once you have come to encounter that it is the extruder which is not functioning as it should otherwise, that’s when you come to listing down the causes and figuring out which one might have happened.

Possible causes that led to the failure of extrusion

For a 3D printer to extrude, three things need to work together i.e. the extruders, the nozzle, and the filament of the material that you are 3D printing with.

Below mentioned are some of the reasons that you need to check if you have a 3D printer not extruding.

Filament is Over

This is a typical problem that is encountered by many 3D printers when they are in the middle of their project and their 3D printer stops suddenly.

Check whether there is a spool that is left in the filament or not.

Your filament shouldn’t have been ruined and you should still have time to load another spool of filament onto your 3D printer.

Extrusion Motor is Heated More than Needed

If your 3D printer not extruding, sand you are in the middle of your printing process, there are high chances that your extruding motor has gone beyond what it could withstand.

This can cause your extruder to stop working. Getting heated beyond the withstanding temperature is something that can occur if resistance from rotating comes in the middle of the rotating phenomenon as well as when the motor keeps on running for long period.

A simple solution to this problem is to stop the motors from running and let them cool down so much so their heat is normalized into room temperature.

The other way to do this is to keep a constant check-in in the manner in which the filament is being fed to the extruder.

It should be done freely and the printer should be allowed to have some of the other kind of break between two projects.

If the heating of the extruder motor is a problem even after the two things that are mentioned are checked, you need to install a cooling fan that directly cools the extruder.

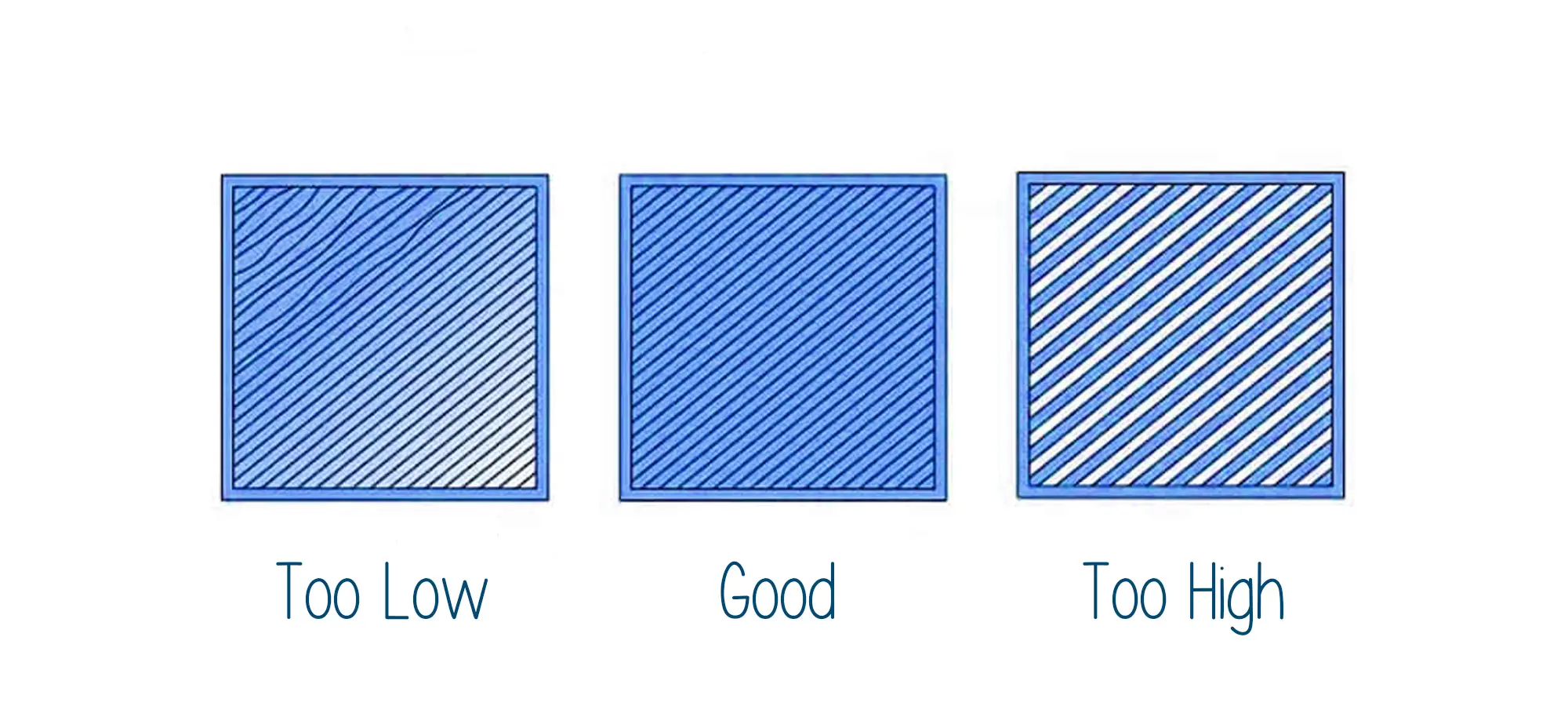

Bed and Nozzle are too Close

In conditions when the nozzle height of the printer is too low, the nozzle is considered too close to the print bed for allowing the molten filament to flow freely.

How can spot this phenomenon is, check if your 3D printer fails to extrude for the first two layers of the 3D printing process but starts extruding normally on the layers after that. For clearing this problem out, you need to set the initial nozzle height evenly.

The diameter of your opening nozzle is something that will come into play for setting the nozzle height properly.

Until you are satisfied with how the first layer looks, the best thing you can do is to adjust the nozzle height gradually.

If the nozzle that you have set is too low, it can still extrude but flatten the first layer of your print.

If such a thing happens, it can improve the first layer adhesion, but this doesn’t quite look as good as otherwise hence your measure may vary accordingly.

Priming of the Extruder

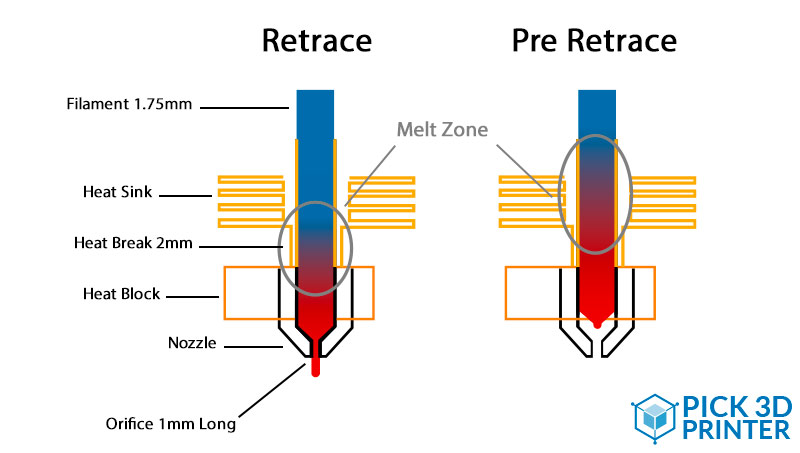

The molten filament can start to ooze out of the nozzle even the extruder is made to do nothing. This can result in a small section of the nozzle that is void of any filament material.

This in turn results in delaying extrusion to occur once you start the printing process.

Although arguably this problem is not seriously considered as big as others mentioned in the list, the solution to this problem is much easier than other problems, but it is still a problem when 3D printers not extruding.

For priming your extruder, the simplest way considered by many of the websites is to build a skirt around the first layer of your 3D printing project.

What this does is, it gives your filament the time and space that you need for establishing a smooth and constant flow before starting to print your first layer. And this is believed to get you consistent layers.

The important point to note here is, if one skirt does no good, you can add more than one skirt, but the only thing to worry about here is that you are consuming more filaments.

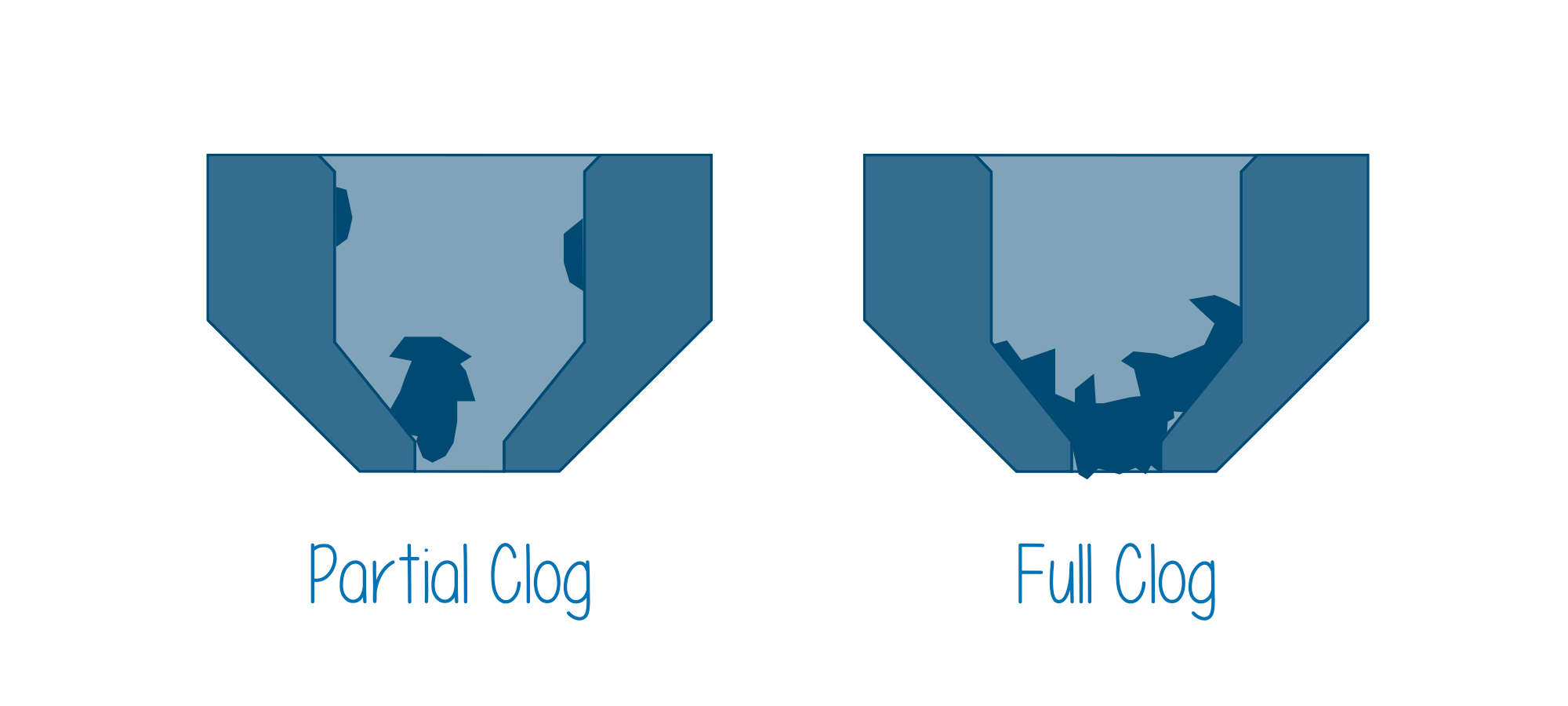

Nozzle is Clogged

If you are thinking that this can only be a problem before starting the printer and not during the printing process is on-going, that is not the case.

Even while the printing process is on, the nozzle can be clogged and can lead to a 3D printer not extruding.

You can check whether the nozzle is clogged or not by trying to feed a metal string, one such that typically is in the guitar up the opening of the nozzle.

The reason why it leads to the occurrence of a clogged nozzle can be many. Any nozzle that stays idle for very long inside an extruder can get cooled down and solidified inside the nozzle.

A filament with moisture can develop bubbles inside the heating element, which can then burst at the nozzle causing the plastic to stick to the nozzle’s inner surface.

Doesn’t matter how the nozzle has got clogged, the various options for you to unclog the nozzle is to have a brush with brass threads that will let you brush the inner surface of the nozzle and dislodge any and every hardened material.

In case if the clogged material is mostly plastic, there is also an option to use a heat gun and allow the plastic to melt out of the nozzle.

If all other option fails, the most reliable solution would be to disassemble the nozzle, and soak it in a suitable solvent, and then finally clean out the debris manually.

Filament is Stripped

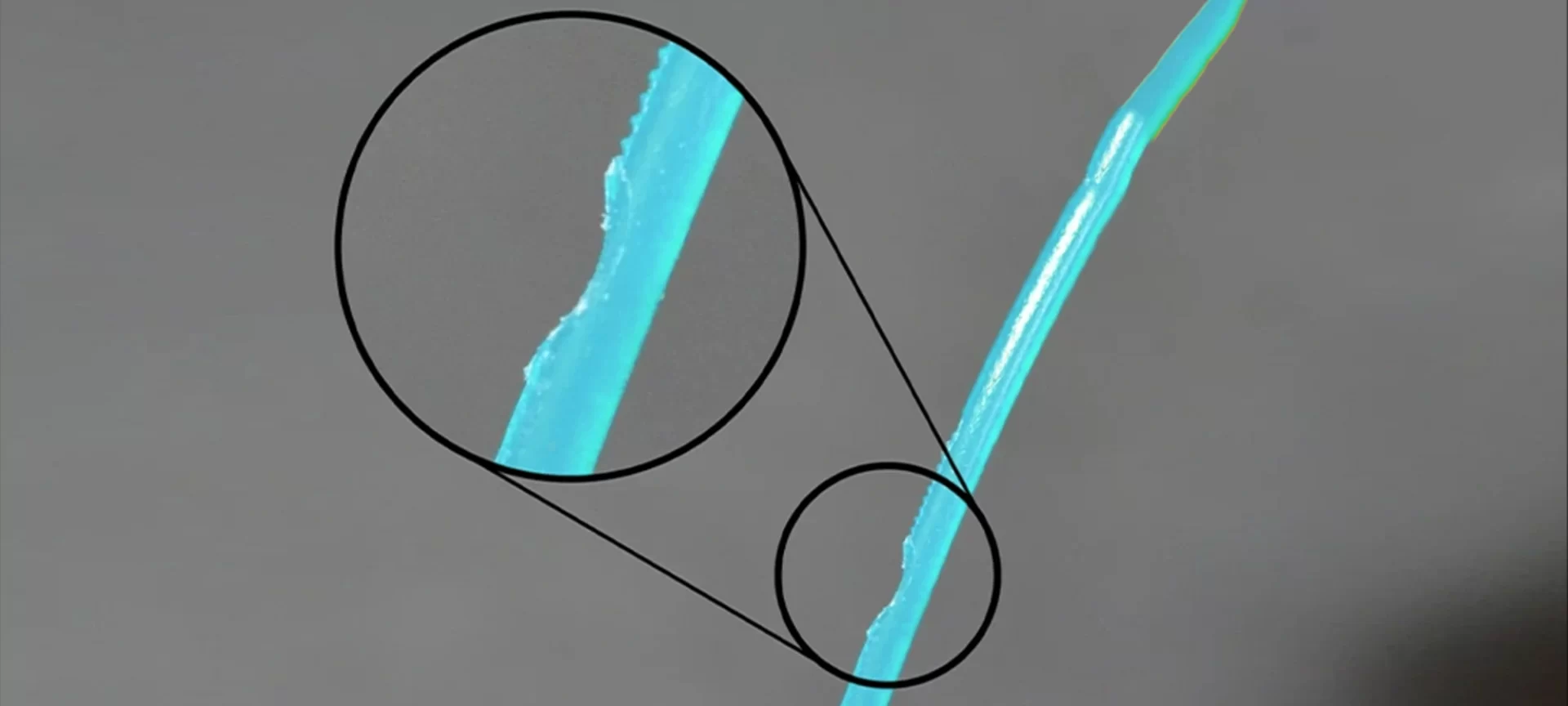

When the gears of a filament hold the filament very firmly, the plastic of the filament gets worn out.

This thins out the filament which is in contact with the extruder, as well as the extruder gear gets filled with the plastic material.

Stripping of the filament can happen because of several different reasons starting with, if there is too much tension on the filament spool, the extruder gears may over-exert against the filament.

It can also occur if the printing temperature settings are set either too high or too low, the increased resistance of the filament against the extruder gears can also cause the filament to get stripped.

A filament getting stripped is one of the main reasons for the 3D printer not extruding.

The thing that you need to worry about a stripped filament is that you will almost certainly have to open up the entire extruder assembly which takes a lot of effort, forgetting your 3D printer to work normally again.

If you are wondering, for another way to remove the stripped plastic material from the extruder gears, all you can do is to poke them out from the hobs manually using a steel brush or any small pointed tool.

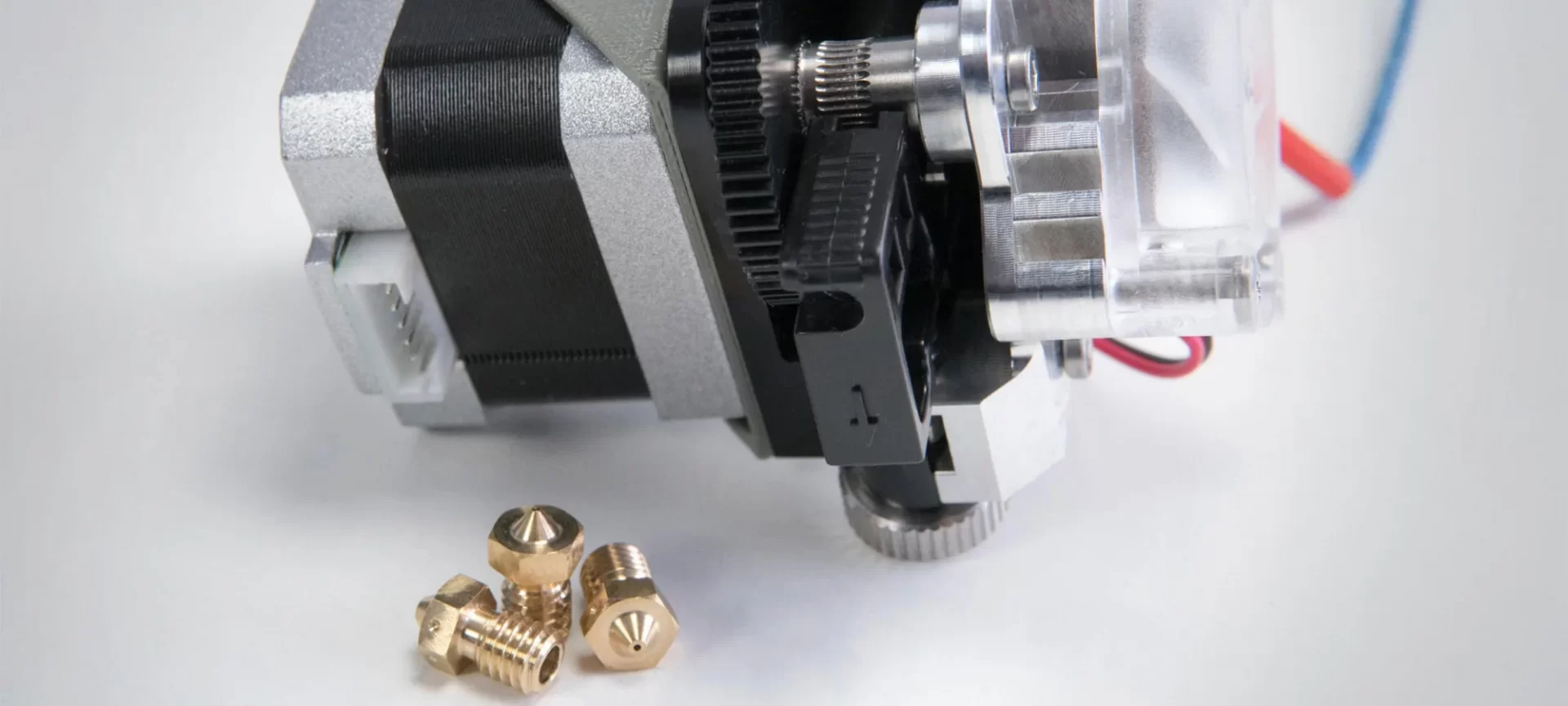

PTFE tube is Worn Out

When you have a 3D printer not extruding, you need to look at two major components in the extruder:

- The drive gear.

- The idler.

The latter acts as the surface against which the drive gear pushes the filament. In a way that it allows the gear to get a hold of a certain section of filament that sits between the gear and the idler.

The idler, because of its function, needs to be made of a rigid material as well as the material should have low-friction that will contribute minimal resistance to the extrusion of the filament.

The idler is therefore made of either rubber wheels that rotate with the drive gear, or a PTFE tubing. This is also a very important part when a 3D printer not extruding.

For those who have already disemboweled their extruder assembly, you should be easily able to spot out the worn-out PTFE tubing.

The best indicator for this problem is a visible “brim” on the surface of a PTFE tubing.

This is the part that is asking out to be replaced. Every time disassembling and putting together the complete extruder assembly is a lot of work, so the best is to replace the PTFE tubing of your extruder when you clean the drive gear.

The Conclusion

Patience is something that you will need when your 3D printer not extruding properly. To check through each of the parts mentioned in this article, you will at least need a few minutes of your printing time.

And you will have to also make sure, things are diagnosed in the way they should be, otherwise, there are chances that even after you have felt, to solve the extrusion problem, it is not for real.

And then this whole scenario would take up more time than it should have.

Dissembling of parts and cleaning them up again and then putting them back to work is something not excessively complex for someone with experience with the printer, but it is definitely complex for those who are new and hence should take care of.