If you are already in the field of 3D printing, you probably know about this debate that goes between the experts and intermediates about the 3D printing cost estimate.

Some are on the side of accurate cost calculation of 3D printing is impossible because of the uncertainties, while others are on the side that nothing is impossible.

Between these two kinds of extremist opinions, the wise have started taking into account the factors which determine the cost of 3D printing a part or functional prototype.

As it is generally in the case with the wise ones, the list that they’ve prepared is not complete and needs to be a lot more specific to be accurately able to claim ab numeric that summarizes the cost that one needs to pay for 3D printing.

But, the good news is unlike the other two extremist opinion holders, the list has started and can now claim some questions which are must to think while calculating 3D printing cost estimate.

And this estimation demands you to answer questions such as: What is the return on investment on the printer/ printers that our company owns? How much cost should one charge when a part or functional prototype demands loading only the half of tray for printing each part or functional prototype? And what about the labor time that is required for cleaning the parts after they’ve been printed?

Such and many more questions are needed to be answered for determining an accurate cost for 3D printing a part or functional prototype.

Companies like Xometry, Materialize as well as a lot more have a great tool for calculating and providing a quotation for their services, but when you have a printer in-house and wish to get a 3D printer cost estimate, nothing more helps than the knowledge of the factors. Click Here for more about How Much Does a 3D Printing Service Cost.

What to Consider for an Accurate 3D Printing Cost Estimate?

For explaining the coming parts of this article in a better manner we want you, readers to imagine a Josef from India who owns three 3D printers, Prusa i3 MK3S, Prusa Mini, and Prusa SL1.

Acknowledging his 3D printing service, a customer orders from him a test object and also asks for the price of the same.

She has a list of prerequisites that require her to print the part or functional prototype using Prusament PLA Orange and Prusa Orange Tough Resin SL1.

For providing the accurate cost, the following are the factors that Josef should consider.

Cost of 3D Printing Material

Assuming that after dealing all these years in 3D printing technology, Josef does know that the most expensive factors while 3D printing cost estimate is the cost of 3D printing material and manpower.

The 3D printing material mostly are filament or resins. The cost of 3D printing material depends on its manufacturer.

So, for example, a kilogram of Prusament PLA Orange costs $24.99. You can use your own slicer to tell you how much exact amount of filament or resin is needed for producing your part or a functional prototype.

For this example, in particular, let’s assume that the model can be printed using 6.27 grams. So that we can calculate the complete cost with in-depth accuracy.

So, what Josef would do is divided 24.99 by 1000 to know one gram cost of Prusament PLA Orange and then multiply it by 6.27 that is the quantity that your slicer has told it would need.

So a formula which you can then derive for finding a material cost that is one of the most important factors for 3D printing cost estimate is dividing the filament price by filament weight and multiplying it with the model weight.

After you are done with the cost of the material, you might want to note that somewhere down, because after we are done calculating all the factors, we would have to add them up.

Cost of Manpower Used in the Process of 3D Printing

This is a pretty subjective section for the simple reason that people according to different geographies have different rates per hour.

Let’s assume for the sake of simple calculation purpose that our Josef has rated himself at $9.5 per hour.

By experience, he knows that it would take him at least five minutes for preparing his printer and slicer.

Note that different printers take different times for preparation and we are here strictly assuming a hypothetical scenario.

So, let’s say it takes Josef five minutes to prepare the printer if he goes with Mini and 10 if he goes with SL1, then the cost of manpower for Josef would come down to $0.8 for MK3S mini and $1.6 for SL1.

After you have calculated the manpower cost, you need to note that down separately because we are going to need that while adding all the parameters in the end for the 3D printing cost estimate.

Operating Costs

These parameters involve taking into consideration many kinds of factors. The first and the foremost that should come to your mind is electricity because without that anything would not be possible.

And of course, there is no standardization in electricity costs. As in our case, Josef is from India, he would have to consider the local electricity costs per kWh. Let’s say his costs range anywhere from 0.07 USD to 0.09 USD and most of the time he knows that the printer consumes say a 100 to 150 Watts.

And if he prints the model on MK3S, it would take him an hour, wherein if he prints with Mini and SL1 it would take him an hour and a half and an hour and forty-five minutes.

The mathematical calculation of the above-mentioned scenario added with a fixed fee depending on the number of hours the printers have already been in operation makes up for the operating cost of 3D printing.

A general formula for calculating operation cost can be dividing the printer price with the required investment return multiplied by print time.

These are the three most standard costs that you should keep in mind with a 3D printing cost estimate. The next variable is the profit margin which varies from one manufacturer to the other.

Cost of Post Processing

As 3D printing technology is still in its development stage, it is very rare that parts or functional prototypes that are printed can be directly put on to the application.

So, you need to calculate the cost for polishing, painting, and heat-treating the part or functional prototype by knowing its application.

The post-processing would require you to know aspects such as surface finish and accuracy in the edges as well as other parts of the product that you wish to have in the end.

It is also reported in some cases, how the cost of post-processing exceeded the cost of printing the complete part or functional prototype by many times.

So, this is an important factor which should be considered. And it should be printer specific.

So, say for example in our case we are using either the i3 MK3S or Mini or SL1, so each of the printer’s Layer thickness should be considered and the cost of post-processing should only be calculated after knowing the required amount of layer resolution in the model.

Another way to consider this cost is by asking the customer, what kind of finish does she require.

But in all cases for considering the cost of post-processing a manufacturer must know all the aspects of 3D printing technology and should be familiar with all the equipment that he or she has on hand.

For if in our example, Josef does not know the layer resolution that any of our 3D printers provide, he would not be able to accurately determine the cost of post-processing and ultimately lead to providing an inaccurate 3D printing cost estimate to his client.

Profit Margin

A print failure is a very normal scenario to occur especially when 3D printing is not done by experienced hands.

There could be a loss of filament or any other uncertainty in the way of the complete 3D printing process.

A possible issue is with print quality, like warping, adhesion issues, etc. So, calculating a price by taking into account all of these parameters is a herculean task.

Combine with this the manufacturer’s experience in making the part or functional prototype that he has manufactured before or is doing for the first time, makes up a calculation of profit margin which is actually the risk of making a part for the first time or having made a part or functional prototype before.

Profit margins are generally set on the basis of raw material that is to be used in the making of the part or functional prototype.

For the sake of calculation let’s say Josef in our example sets a margin of 30 percent, so the profit comes out to be $1.3 in the case of MK3S, $1.16 in the case of Mini, and 3.15 in the case of SL1 3D printer.

However, we would like to emphasize the subjectivity of this section particularly because the mindset of the manufacturer plays an important role and there is no generalization in this parameter like it was in say the manpower section or the 3D printing material section, or even the operating costs section.

And lastly, one needs to include the taxes which are again going to vary as per the geography of the manufacturer.

So, our complete formula would be the addition of the cost of the 3D printing material with manpower cost, operation cost as well as margin and tax.

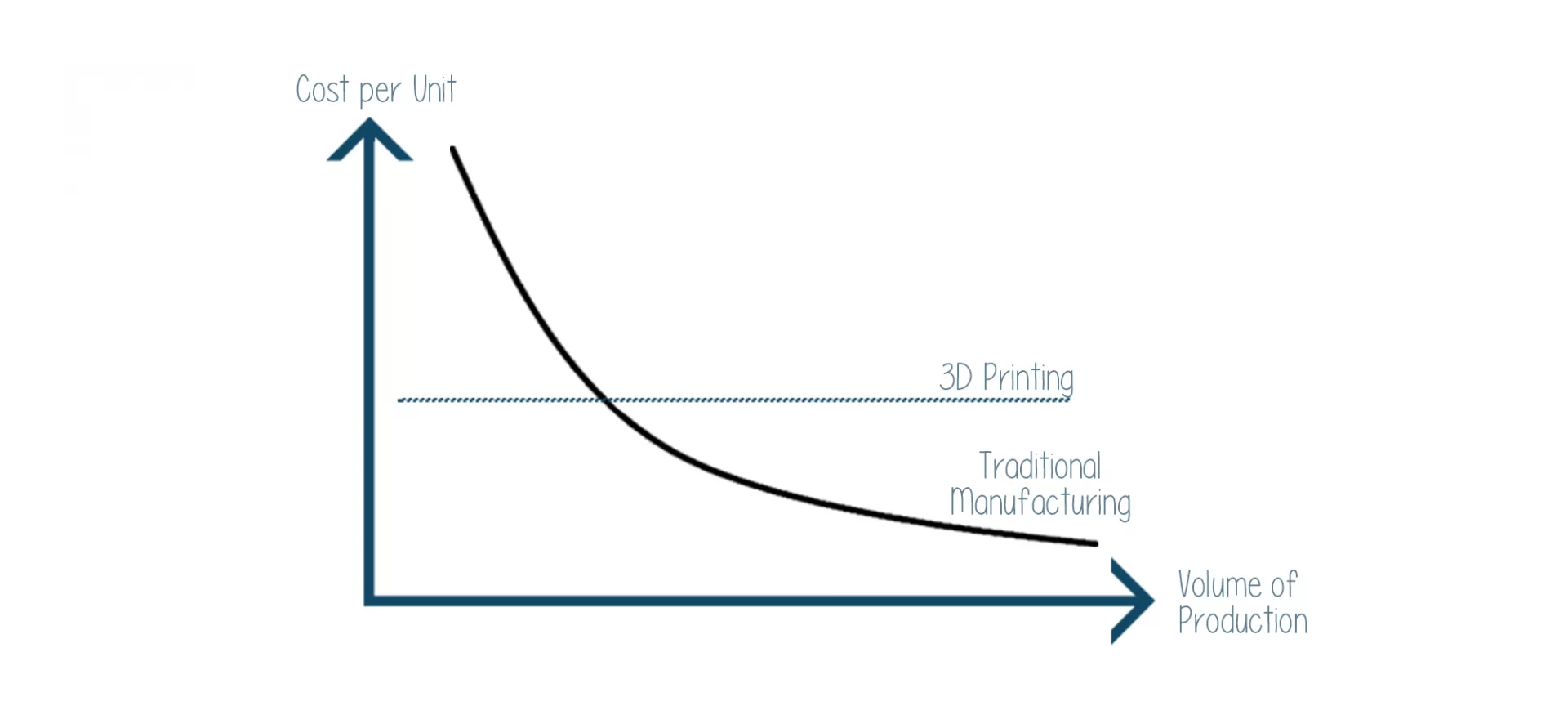

In case when the customer wishes to buy any part or functional prototype in bulk, the price is going to fall than the one that you’ve calculated.

Because one of these factors, namely, the operating cost factor is going to be decreased by a significant amount, depending on the number of pieces that the customer requires.

The greater number of pieces needed, the lower the prices are. The smaller number of pieces needed, the higher the prices are. And this is no law of 3D printing technology, but a law of any product in general.

The 3D Printing Cost Calculators

To ease out the work of manufacturers there are tools available online which take from your specific inputs and calculate to you the cost of printing a complete part or functional prototype.

But an important thing to note here is that these cost calculators or tools do not necessarily take into account all the parameters.

They are created to operate differently based on different types of algorithms and mathematics.

So, one must check before giving and input to such calculators and taking the output from them about the list of parameters they use for calculating the cost.

And after checking and acknowledging the list of parameters to one’s own, can one decide whether or not the cost calculated by that calculator is close enough to what it is according to his or her requirements.

The Conclusion

What does appear to be simple in this above article is much more difficult when put into application.

3D printing cost estimate with accuracy is the most difficult task which every manufacturer is subjected to, every time a client asks for a quote.

Although there are online calculators available, not all of them subscribe to the inclusion of every criterion that a manufacturer wishes to accommodate.

It is to be understood that a 3D printing cost estimate is a task that one should do in a customized way for every printing project.

There is no standard way and there should not be one. Because every design of the object is different, every project quantity is different and there are so many minor parameters to look out for in each and every project.

The Discovery of each and every of such minor parameters leads to a closer approach for calculating 3D printing cost for a part or functional prototype.