Looking at the 3D printer creating the layers, it may seem that the job is easy. However, do not be misled with the workflow that appears to be simple.

Because it is not. 3D printing is a difficult task and there are so many things that must be taken care of before letting the printing get on its job.

To ensure that a model does not fail, designers and experts take huge precautions. From 3D design to the post-processing of the parts, everything is precisely monitored. Otherwise, 3D printing mistakes can happen anytime leading to loss of efforts and material.

3D printing can help you get a lot of things done in the shortest possible time. However, a small mistake can make the time endless.

You may get caught up with mistakes that seem difficult to pin. In such cases, running through multiple failed prints will eat unnecessary time and effort of everyone involved in the 3D printing process.

You can even damage your 3D printer if you do not have the right skills to operate the same. And, most of the 3D printers that are used in industries or for professional setups are expensive.

A mistake can be minor or major, depending on your aim. If you are aiming to create a non-functional prototype, the strength may not matter much, but a minor error with the resolution or appearance of the prototype may ruin the entire hard work you just put in.

The errors could be many and different for dissimilar mistakes. But you can avoid most of these by understanding a few of the crucial guidelines of 3D printing.

So, what are the mistakes that one can fall prey to and how one can avoid them? Let us check out a few of the common mistakes and the ways to handle them before they make any harm to the 3D Printing projects.

Common 3D Printing Mistakes to Avoid

Here we are talking about the common mistakes. This means that you have been 3D printing and failing to get the desired results. Or, you are starting with your first print and want to ensure that everything goes well. If this is true, you must not worry.

Mistakes are a part of every new thing one tries for the first few times. However, staying vigilant definitely helps in recovering from those mistakes as early as possible.

3D printing mistakes are known to disturb users and few are problematic to deal with. With proper guidance and following best practices, one can certainly find a solution to all the existing problems. And, can even avoid those that may create issues when not considered beforehand.

Choosing the Wrong Printing Material

This is a very common mistake. Many beginners or even experts sometimes, fail to recognize the 3D printing material that could best serve the purpose.

This is because of the lack of proper material guidelines and a lack of intention of the user to learn more about different things associated with 3D printing.

For example, every material has its own properties. Some are stiffer and others are soft. Some can be used for high precision application and others may only be fit for serving jobs with fewer accuracy settings.

If you are planning to 3D print, you must know all the materials that your printer can work with. And, find out the one that suits the design you wish to print.

Materials have a huge importance in the world of 3D printing. They bring with themselves their unique properties and add that to the models you print. From physical to mechanical properties, your model takes most of what the material has to offer.

Hence, working your best to find the most suitable material must be the first priority when 3D printing. The output of the 3D print will depend a lot on the material that you choose.

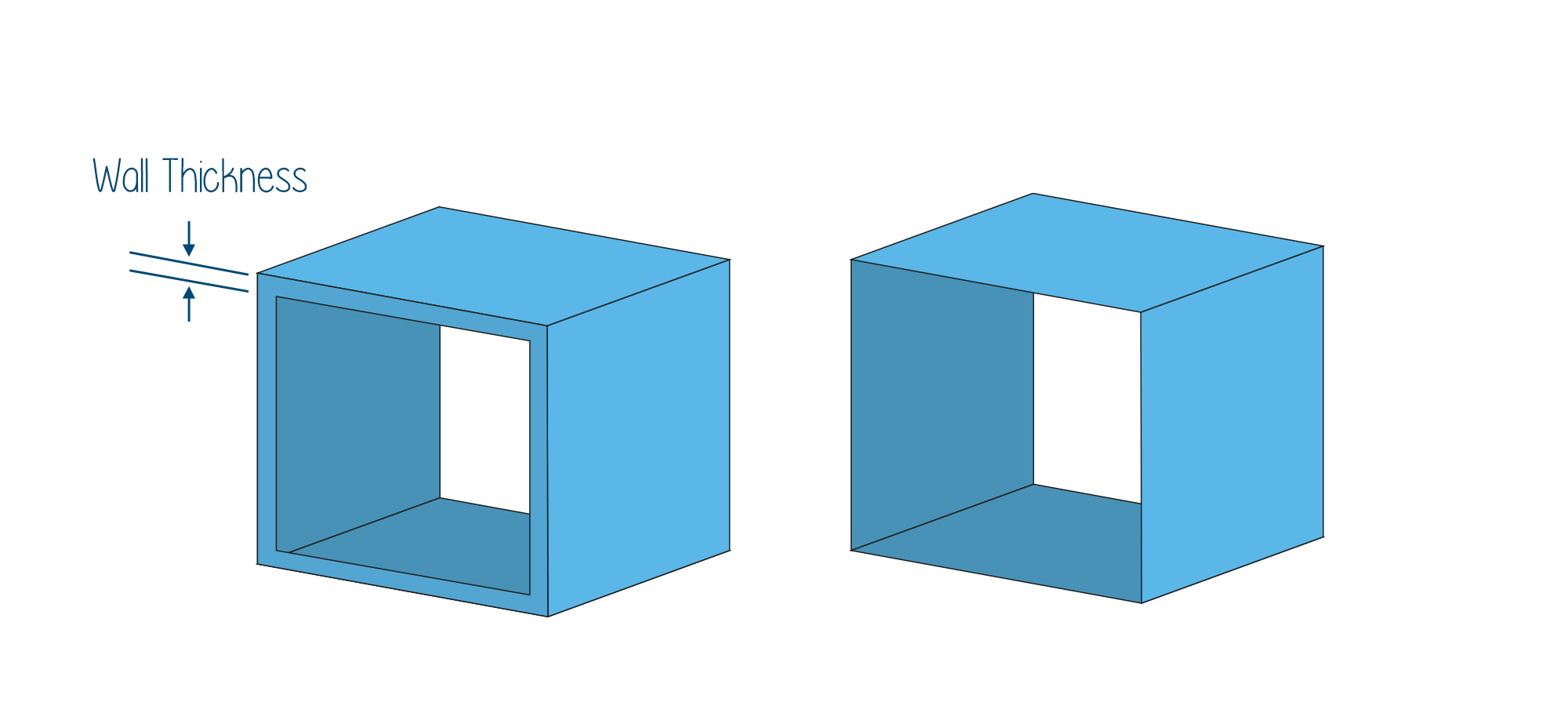

Not Emphasising on the Wall Thickness

The wall thickness is defined as the distance between the two surfaces of a model: the front and the opposite surfaces. When considering the wall thickness, one must calculate the minimum wall thickness that would be able to hold the model correctly.

Wall thickness depends on various factors. One must visit all of those to finally come to a conclusion. Starting from alignment, size to overall design makes up for finding the correct wall thickness of the 3D model.

One may fail to print the model in case of incorrect wall thickness. Even if printing happens, it may end up being too fragile or prone to cracks.

Trust this, wall thickness can be very decisive. You may think that the strength would increase with increased wall thickness. This is not true. Finding the minimum wall thickness to support your model is the key to a successful print.

You can work a little, find guides online, read about how to choose the wall thickness and then define the same in your 3D files. 3D printing could be challenging but won’t bother you when you know about things that may get your print wrong and tackle them properly.

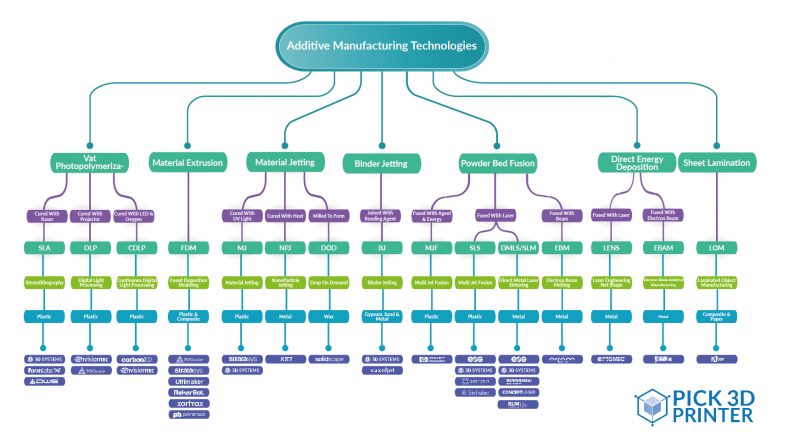

Not Able to Select the Correct 3D Printing Process

Sometimes we just choose the one that is easily accessible or the one which everyone else is using. Remember, this must not be the case with 3D printing.

There are many processes for accomplishing 3D printing. Each of these processes is based on unique technology and work with a different set of materials.

For example, Fused deposition modeling works with filaments while Stereolithography works with resin.

Knowing each of these processes in detail would help you find out the reason they have been marked for different applications. Also, the resolution and model properties change when printed using different 3D printing processes.

Wondering which one to choose? While making the decision when choosing the right process, you must think of the model properties, its application, and overall use. The selection of material would also help you decide which process to go with.

There are other factors that would define the selection of the process you choose. Such as functionality of the model, visual appearance or its manufacturing capabilities.

Some 3D Process is fast but aren’t accurate. Few are precise but may not let you print in numbers. Others can get you decent accuracy and speed under one umbrella.

You may go through all those findings in detail before deciding which 3D printer you would pay for.

Using Incorrect File Resolution

One more common mistake that most of the users are not able to outline until the model is already destroyed. You may have come across pixelated prints or those not easy to handle while printing.

Every 3D printer has its own capabilities. For example, when you buy a 3D printer, you get the list of specifications that judge the overall performance of the machine.

File resolution is something that describes the smoothness and accuracy of your file. Each 3D printer is equipped with certain lower and higher resolution capabilities. If you make any mistake in choosing a setting that falls between these parameters, you may have to regret later.

Not just that, in terms of quality, choosing the wrong resolution, that even falls in between the set parameters could result in bad print.

Your printer does allow a low-resolution setting, but keeping it at the lowest side may speed up the printing process, but leave pixelated surface on the models. This means that the models would look uneven.

On the other hand, if the resolution is too high, the printer may not be able to print the model at all. To have the best results, one must choose a tolerance of 0.01mm for the STL file settings before exporting the 3D file to the 3D Printer.

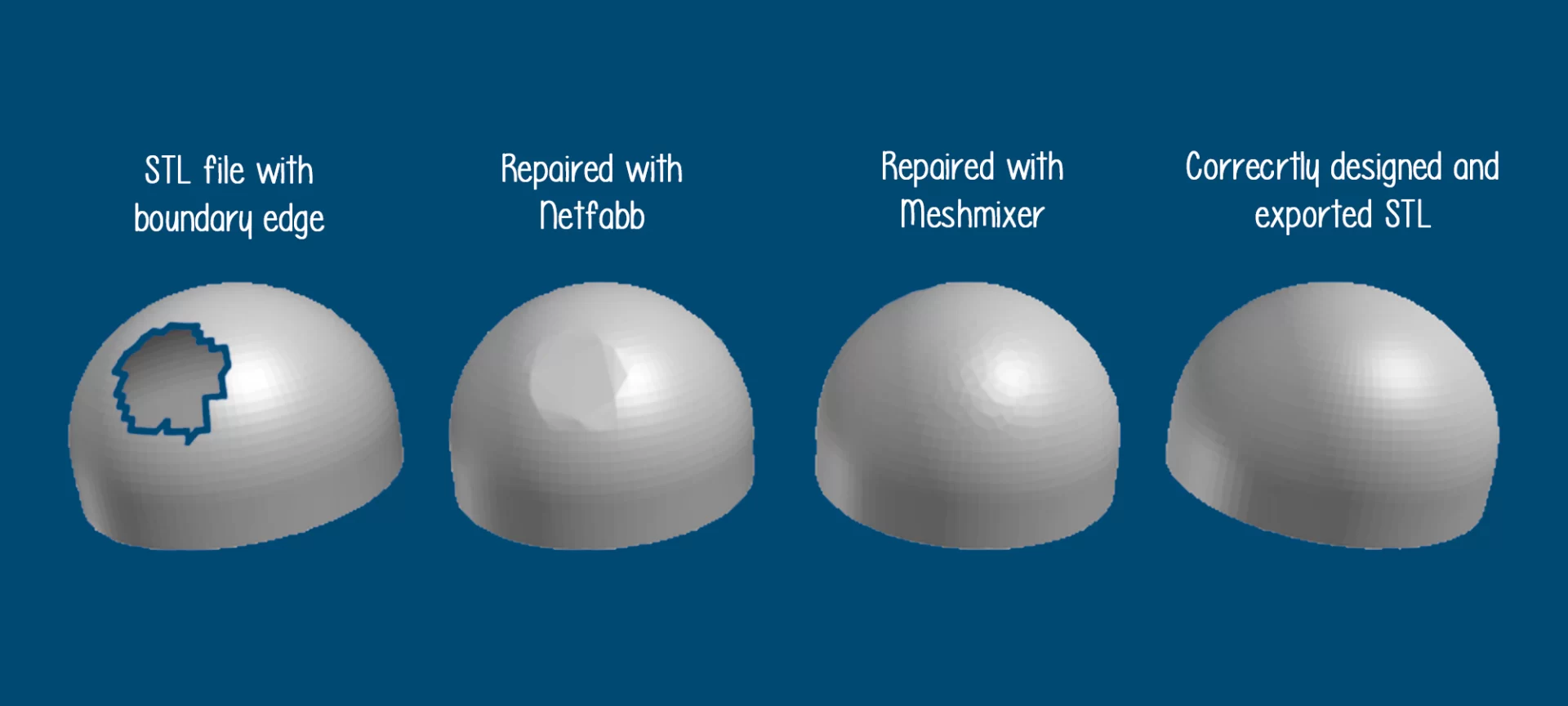

Improper STL Files

STL files are very important for every 3D print one creates. Without an STL file, it is impossible to print the models using 3D printers.

These STL files define the outer surfaces of the 3D model such as faces, edges, the mesh of points, as well as calculates the internal volume of the 3D model. STL files are the sole of 3D models and must be optimized precisely.

Any error in an STL file could lead to major issues. You won’t be able to cover up for 3D printing mistakes if you aren’t able to get the right STL file settings in action. Your models can end up having a poor resolution.

The problem does not end here. A small error in the STL file can lead to unnecessary headaches. You may have to deal with bad boundary edges, non-manifold edges, intersecting faces, over-refined mesh, and many such intolerable issues.

However, the solution is easy. When creating the STL files, ensure that these are fixed with the help of exclusive 3D printing software like Meshmixer.

To make things even more proper, ensure that the 3D file is repaired with the CAD software initially before exporting it to the STL file. Most of all, be watchful to ensure that the STL file is designed correctly.

Machine Handled Without Proper Setup

This is one of the silliest 3D printing mistakes. While this can be handled only by being attentive, most of the users ignore it taking these settings lightly.

And, finally, end up running the entire model. With each failed model, a lot of material, effort and time is wasted too. This is completely unreasonable, especially when the issues are generated because of human error or lack of attention.

When setting the machine for printing, taking care of the smallest things can help you carry the process smoothly. For example, a stuck nozzle, out of filament, etc can alter the printing process in between and would disturb the workflow entirely.

3D printers are capable of doing a lot of things by themselves. There are 3D printers that can detect the printer when it is out of filaments. But not every printer has that capability.

Even if they do, being a bit extra cautious won’t cost users any extra dime. These precautions would help restore the process on time.

These mistakes are the easiest to avoid. Before starting the actual print, users must test the printers for the setup and ensure that the 3D printer is good to print the next model.

The Conclusion

There may be a huge potential for 3D printing. However, everything can go worse, if not accomplished with care. 3D printing can be really challenging task if the mistakes are not discovered beforehand.

Those printing from long time may have experienced a lot of similar problems occurring with their prints. It is also true that those working to solve these problems find ways to ensure that they do not appear again. This helps in improving the process over time.

If you plan to learn about these silly mistakes initially, you can save yourself from a lot of pain later. Instead of learning after the problem has already occurred, you can be prepared beforehand. These changes could bring a huge difference to the quality of your models.

3D printing mistakes are bothering and can even distress users for long durations. Hence, keeping a closer eye on your models while it is being printed is very important.

Look for the leads that may signal you about the problems that may occur with the models and catch them as soon as possible. Once the printing starts, you may not be able to track the same once it has completed.

To avoid 3D printing mistakes, users must follow the best 3D Printing practices and understand the basics of 3D printing.

In addition, one must never leave improving their skills of 3D printing by accessing as many guides and learning materials available online.

With newer technological advancements, new signs of progress are being introduced in 3D printing. The new solutions and tools invested aim at easing the 3D printing process even further. And, helping users fight with the common 3D printing mistakes with better strategies and preparation.