The quality of a part or functional prototype that you are 3D printing depends on a few factors such as the 3D design file, quality of the 3D printer you are using, and the quality of 3D printing filament.

The 3D Design file is a work of accurate playing with the software modeling tools. Buying the correct 3D printer for your application is based on the research that you do before buying and observing 3D printer features and matching them up.

But buying the correct 3D printing filament is a much tougher job because would not only have to research it out but also match it with your printer.

In this article, we are going to state and share facts and features of the Delrin 3D printing filament.

Reading this article would give you insight into this specific brand of filament, its use with the printers, the printer setting it recommends every user to keep, applications in which it is generally used, and where to easily get it from.

Let’s start with a little bit of an overview of this 3D printing filament.

Overview of Delrin 3D Printing Filament

Delrin is factually a trading name used by a renowned company named Dupont, for its range of Acetal Resin. And as far as Acetal resin is concerned, it is a pet name or a colloquial name for what is technically named Polyoxymethylene filament.

Apart from manufacturing 3D printing filaments, DuPont is manufacturing many kinds of products that fit into many industry verticals.

Making a significant claim on their About Us, Dupont has its own community of scientists, engineers, visionaries, and all their partners working day in, day out to transform industries and improve everyday life.

Polyoxymethylene filament is available in two kinds:

- Polyoxymethylene copolymer acetal.

- Polyoxymethylene homopolymer acetal.

For those who wish to know more exactly about Delrin, the closest scientific name of it is Polyoxymethylene homopolymer acetal.

What to Keep in Mind while Delrin 3D Printing?

Whether while 3D printing a part or functional prototype, or manufacturing a part or functional prototype using any traditional manufacturing method, one thing remains the same i.e. the attributes of the part are credited to the material used for making the part or functional prototype.

So it is important, whether you are dealing with this or any other manufacturing method to know the characteristics or basic properties in mind while manufacturing a part or functional prototype using that raw material.

Here, the raw material is Delrin which has the following properties.

- The company, DuPont claims Delrin as an ideal material in parts that are designed to replace metal. This the company reasons out, is because Delrin combines a low-friction and high-wear resistance with high strength and stiffness which applications of metal generally require. Delrin is also known to operate with a wide temperature range ranging from as low as -40 degrees Celsius to as high as 120 degrees Celsius. Offering excellent dimensional stability in precision molding, Delrin is known to mate easily with metals as well as polymers.

- When compared to Polyoxymethylene copolymer acetal, Delrin is known to offer higher tensile strength, with stiffness, creep, and fatigue resistance, additionally significantly higher impact resistance. And what does a combination of these mechanical properties give you as an outcome in the part or functional prototypes you are manufacturing? You get a single material that makes thinner weighing parts and functional prototypes, the material has shorter molding cycles and potential cost reductions.

Dupont also makes a claim “It’s more than acetal, it’s Dupont Delrin.” And what does it exactly mean by claiming so, is explained in the section below, derived from the company’s article about this claim.

It’s more than Acetal, it’s Dupont Delrin

Acetal copolymers are not as tough, light-in-weight, and durable as Dupont Delrin is. It inherently has low friction, wears, and moisture pick-up with excellent spring-back properties.

Delrin’s acetal homopolymer features a uniform backbone that has a larger crystalline block structure compared with acetal copolymers that provide a better chemical bonding.

Hence the parts or functional prototypes produced after Delrin 3D printing will be the stiffest and strongest.

Delrin has increased design flexibility, with thinner wall sections at the same physical part performance.

It is able to manufacture lighter parts and functional prototypes and enables less material usage. Mold filling is improved with shorter molding cycle times.

Compared to acetal copolymer, Delrin’s homopolymer has an 80 percent higher yield strain and a 65 percent higher flow rate.

Also over a 40 percent higher impact resistance particularly at low temperatures. More than a 1000 percent higher flex fatigue resistance is one of the most unique features of this material.

This particular combination of properties makes Delrin 3D printing then be used for a number of different purposes.

After having gone through these properties of Delrin, it would give you a nice idea about the kind of parts and functional prototypes one can manufacture using Delrin.

We hope that after reading this section of the article you can get an idea of where to use Delrin for. Let’s have a look at the applications of Delrin 3D printing.

Applications of Delrin 3D Printing

Because of the high properties of Delrin, it is a favorite amongst engineers and designers. Below is the list of parts that one can manufacture using Delrin.

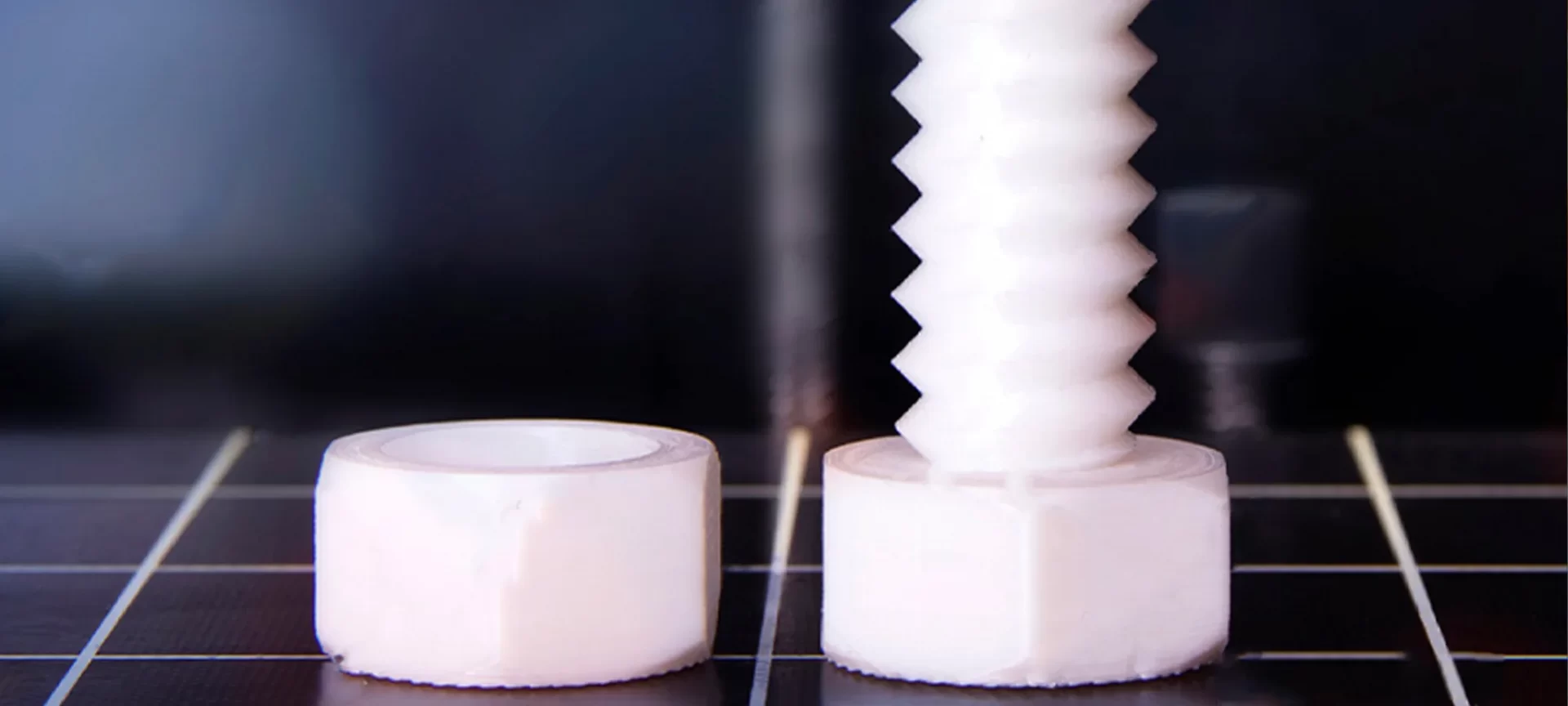

Gears and Bearings

Gears and Bearings as we all know are one of the key parts wherein most of the engineers and designers are interested.

Not only one has to deal with load and pressure, but also design gears in a way that will happen when they are subjected to wear!

Delrin is a 3D printing material with excellent resistance to wear, is an ideal material for such parts and functional prototypes.

Another property that a 3D printing material should have for making parts and functional prototypes like gears and bearings is the material’s coefficient of friction.

Delrin has a low coefficient of friction which makes it very smooth. So, for making rotating parts, Delrin is a very suitable choice.

High-Temperature parts and functional prototypes and Chemicals

Using Delrin 3D printing, one can manufacture piping because it has a low moisture absorption rate and is also chemically resistant to not only solvents but also hydrocarbons and neutral chemicals.

Delrin is a 3D printing material that delivers chemical as well as dimensional stability.

Rollers, as well as safety restraining materials, see the use of a Delrin 3D printing material which is more connected to Delrin’s application in traditional manufacturing techniques.

Delrin can withstand high temperatures as well as the part’s original dimensions which do not change even under temperature fluctuations.

After having seen some basic applications of Delrin material, let’s look at the few printing tips and tricks for manufacturing parts made from Delrin

How to 3D Print Using Delrin?

Every 3D printing material is compatible with one or the other specific type of setting which is more suitable while printing parts and functional prototypes using it.

Like most other 3D printing materials, Delrin too has problems with bed adhesion as well as warping. And this is because of Delrin’s property of low coefficient of friction.

Also as Delrin is a smooth material, users face some challenges with sticking the parts or functional prototypes to the print bed of the printer which is used for manufacturing it.

Most of the 3D printers are based on regular heating beds like glass or some other kind of textured surfaces.

But the bad news while Delrin 3D printing is those kinds of heating beds would not work as efficiently as they do with other 3D printing materials.

Instead, as suggested, you would need a wooden or cardboard surface on the top of the heated bed on which you can lay your printed part or a functional prototype.

A blue tape, hairspray, or methods like adhesives are advised because they are known to provide better results.

Another important point to note about Delrin is that it is a stiff material.

So, all you need is a metal hotend, but it should not get overheated, because then that leads to the production of formaldehyde fumes which are dangerous to inhale for any user dealing with the 3D printing of that part of a functional prototype.

A tip also suggests the user use a heated build chamber or a 3D printer with a closed body for decreasing the 3D printing time.

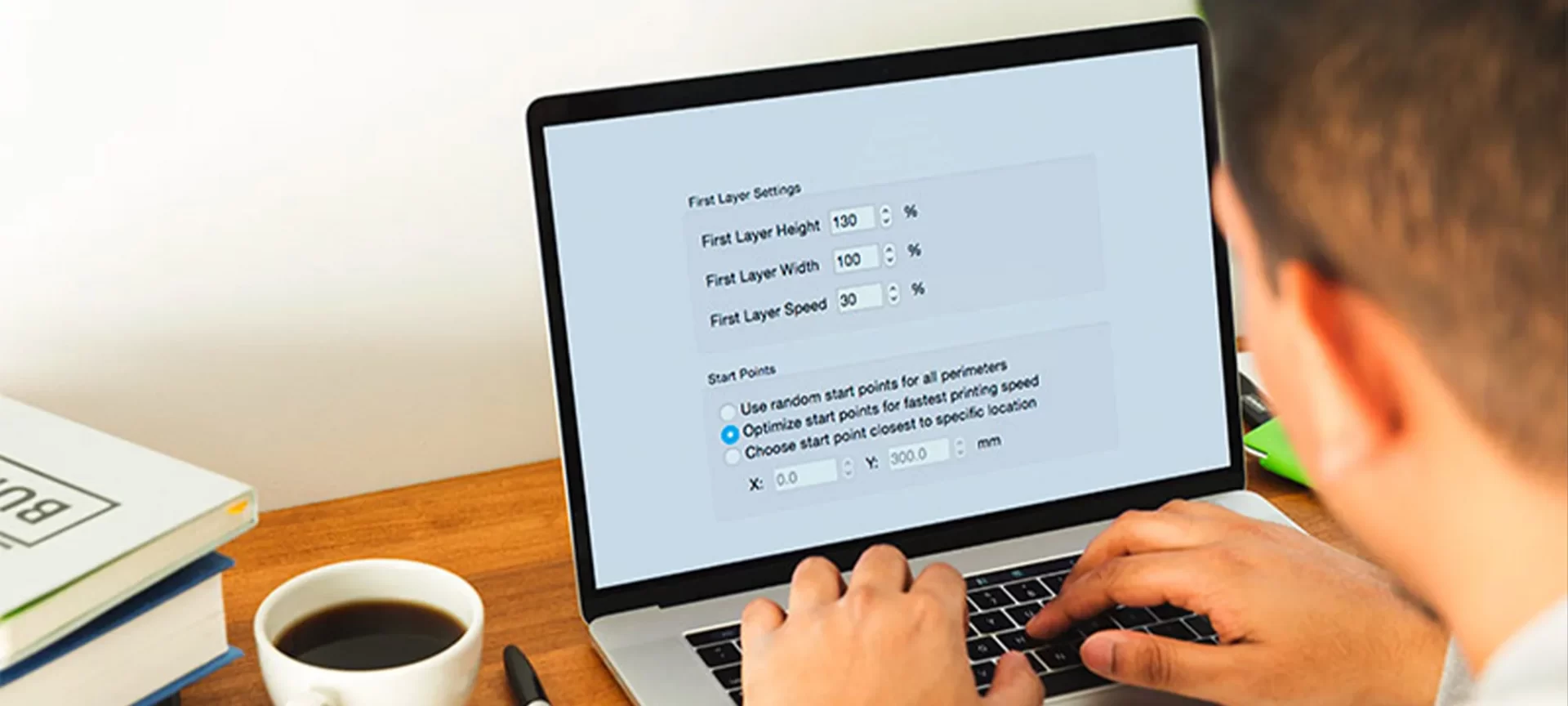

What are the Best Printer Settings while Printing Delrin?

The suggested hotend temperature while Delrin 3D printing is in the range of 210 to 230 degrees Celsius.

Going above 230 degrees Celsius, you would overheat this material and ruin the 3D printing of part or functional prototype and put yourself in danger of inhaling unwanted fumes in the atmosphere.

Normally the printer with which you are 3D printing should have a temperature ranging from 120 to 150 degrees Celsius, but apart from this advice, experts also recommend trial and error yourself before deciding what’s best for you.

As far as the print speed of the printer is concerned, you are recommended industry-standard i.e. 30 millimeters per second.

This print speed is known to help in ensuring the layer bonding of top quality.

In case the print head moves faster than the mentioned speed, the stiff material as such as Delrin 3D printing would not get enough time for achieving good adhesion onto the previous layer of the part or functional prototype that has been printed.

After having gone through the printer settings which you need to take care of while Delrin 3D printing, let’s look at the pros and cons before concluding this article.

Pros and Cons of Delrin 3D Printing

- Compared to other 3D printing materials, Delrin has a high fatigue resistance.

- A higher creep resistance, as well as toughness combined with higher tensile strength and stiffness, makes these materials good enough to replace metal in the application of parts or functional prototypes.

- Using Delrin you can make thinner, lighter parts as well as reduce part production costs.

- You can see the application of Delrin in Gears, Safety resistant components, door system components, conveyor system components, medical delivery devices, ski bindings, as well as zip fasteners.

- Because of lower bed adhesion, parts printed using Delrin are advised to print under an experienced hand on 3D printing. Otherwise, there are high chances of a bad adhesion in the printed parts and functional prototypes, due to the use of which, application failure can be a very likely outcome.

- Delrin requires a higher printing temperature range. So, 3D printers that offer a lower printing temperature range, which is often cheaper in price are not recommended for Delrin 3D printing.

- The cost of this filament as per GIZMODORKS, which is one of the many websites that offer this filament is $26.95 for a 1.75 mm diameter filament spool which is either black or white in color. ABS on the other hand costs $19.95. So, while you are doing a batch production of parts or functional prototypes, it would cost you much higher.

The Conclusion

Because of the increase in awareness of 3D printing technology, many websites have started offering 3D printing filaments, so you can easily find Delrin for Delrin 3D printing on GIZMODORKS as mentioned above.

Apart from that website, you can also find Delrin’s spool on 3D printers online store, 3D printing shop, and hobby king.

At each of these websites, you can get Delrin for Delrin 3D printing at varied prices such as $45, and $20 as well.

Hope that the aim with which we started presenting this article has been closely achieved and while you are busy doing your research for which filament to buy for your next metal 3D printing project, you consider Delrin as one of those.

And that it does suit your 3D printer and you have a safe and journey using this 3D printing material. We wish you good luck with 3D printing metal type parts and functional prototypes.