Do you know that the perfect settings could help complete your 3D models faster than you are used to? Speed up your 3D printer and understand how fast it can go without compromising the quality.

Hence, getting you the best result, you have been looking for. A lot of the makers may not realize that they are not using the complete potential of their machine by running it at a lower speed.

This is due to the fact that they lack the curiosity to go beyond the achievable limits. However, there are many enthusiasts, who keep experimenting with their 3D print speed to know what their maximum limit is without sacrificing the print quality.

The question is: Is it even possible to speed up a 3D printer and not play around with the finish at all? Many individuals feel trying out different settings to achieve the goal.

However, it is not easier to succeed, especially if you are a beginner and have not much experience working with 3D printers.

The settings are fairly simple. And, these are mostly the secondary settings that ultimately works in favor of the print speed. So, if you know the parameters on which the speed depends, you can actually optimize those to achieve varying results.

What are the Different 3D Print Speed Settings?

As of now, you can find three different sets of printing speed available with the 3D printers. To start with, the most common 3D printers offer 40mm/s – 50mm/s of print speed.

However, another group of machines works at about 80mm/s to 100mm/s of print speed. Also, there are those that work with around 150mm/s speed. The good news is that you can even find printers that support a print speed of more than 150 mm/s.

But when choosing 3D printers that provide much faster speed, you may have to lose the quality of the prints. Hence, businesses and homemakers, often ignore falling for such high speed. Also, the filament may slip and create issues when 3D printing.

So, it is up to you to decide what you want from your 3D models. The perfect quality with considerate print speed or the fastest speed with improper surface finish and low print quality.

How to Change Print Speed Settings?

So, where are the settings for print speed available? You must know about the slicing software if you are thinking to speed up a 3D printer.

To change the 3D printing speed, you must know the settings of the slicing software. The slicing software is the application for preparing the 3D model you wish to 3D Print.

One of the most common slicing software is Cura. In this software, the print speed setting is available in the Basic tab.

You can change the speed by entering the value in the Print speed field. If you are not working with the latest version and using any of the former ones, you must switch to Advanced mode.

Here, you would find the Speed tab. Under this, you will find the Print Speed setting.

Most of the slicing software is smart enough to tell you the print duration based on your print speed. And, Cura does that too.

Right after you change the value in the print speed, Cura will recalculate the print duration. You can very much trust the time duration calculated by the software.

How to Speed Up Your 3D Printer?

Now that you have understood the basics of print speed settings, let us get some idea of how to optimize it for the best results.

Increase the Print Speed Value in Your Slicer Software

By increasing the speed value, you can actually find out how far you can stretch. Most of the time, you will find some room for improvement on the print speed, which certainly would impact the overall print duration.

When making the changes in the slicer software, you will have different speed setting options depending on the specific parts of your 3D model.

For example, the infill, support material, and other choices. You must play around with these settings to understand what your 3D printer is capable of accomplishing.

To be precise, you must set high infill speed. However, the perimeter and support material speed must be set to average. In the case of an external perimeter or bridges or gaps, the speed must below.

Usually, a 3D printer often warns users with the fastest speed it can work with. However, there is no harm is going a bit up and verifying the same for yourself.

Also, you can decrease the 3D printer’s wobble printer to increase the print speed. Make sure to eliminate vibrations by tightening the screws to make this possible.

Choosing the Correct Infill

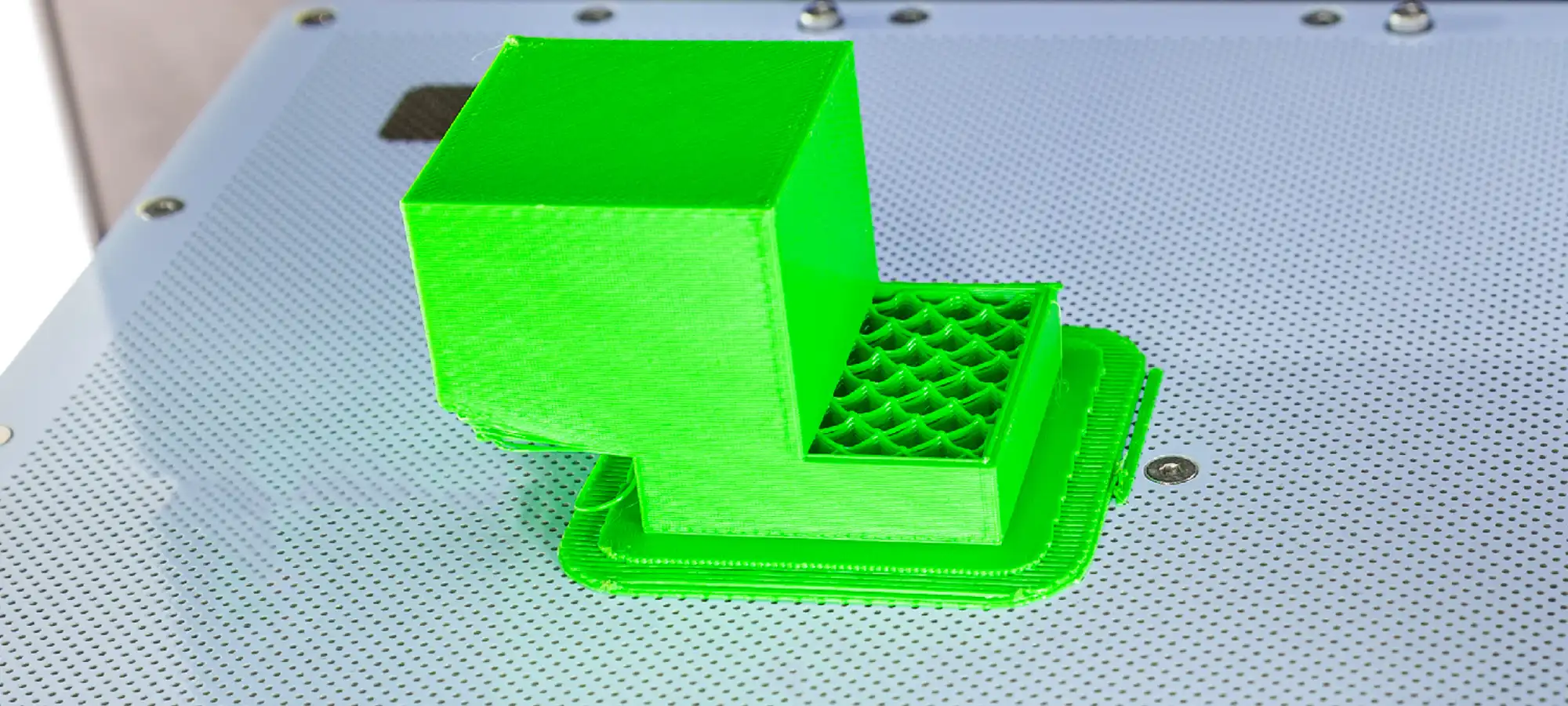

If you have been working with 3D Printers for quite some time now, you must have explored the various infill patterns.

All these patterns have their own strengths and weaknesses. Also, there are certain infill patterns that offer high print speed. These 3D Print faster, hence, results in less print time. Ultimately, helping users to speed up a 3D printer.

Think you can trade off strength when seeking high speed, you can choose the ‘lines’ pattern. This infill pattern is simple to print and requires fewer movements when compared with other choices.

Hence, offering users 25% higher print speed, definitely depending on the design of the 3D model.

Again, when talking about the best 3D printing practices, you must not miss on the strength of the parts completely. On the contrary, you must find a balance between speed and strength. In doing so, you can choose to print with triangle patterns or even grid patterns.

If all you want is strength, you better choose to go with a honeycomb pattern. This pattern is highly detailed and makes a lot of turns to complete the print. So, the speed won’t be as fast as it would be with lines or triangles.

Infill Density Also Counts

It is easy to gaze that higher infill density will result in excess print time. A 3D model with 0 percent infill density is hollow from inside. Hence, taking less duration to print.

Subsequently, resulting in high speed. On the other hand, the 100 percent infill density would mean a completely solid part. This is usually not needed ever unless there is a reason for it.

This only increases the print time without justifying for the material and time used in the process. If you can find a balance between infill density and the print requirement, you would know what infill density would suit your settings.

You cannot always use a 0 percent infill density even if it prints faster. You can speed up a 3D printer but what if you are printing a functional prototype or an end part aimed at holding weight?

Most of the models with a balance of speed and infill density can be accomplished between 20% and 35% settings.

Hence, you do not have to compromise on print speed if you know how much infill density would help keep your part together.

For instance, when printing a showpiece or figurines, you can even go below the balanced infill settings. Some models can also be printed with o percent infill. So, the settings would depend mostly on the purpose of your 3D print.

Work with Adaptive Layers Settings

Have you ever used the adaptive later settings or the dynamic layer settings in Cura? If not, you are missing a lot. With this setting, you can optimize the layer heights which changes as per the angle of the layer.

And, the process happens on its own while the 3D model is progressing inside the 3D printer. That is why the name. It changes automatically as and when required depending on the layer angle.

Hence, you can speed up a 3D printer considerably when choosing it over the traditional layer settings. The setting works by determining the areas that have significant curves and variations.

Depending on the same, the 3D printer optimizes the layer height to thinner or thicker values. For curved surfaces, a 3D printer chooses to print with thinner layers. Hence, providing a smoother finish.

On the contrary, the 3D printer would use thicker layers when not necessary. Hence, helping users to speed up 3D printer speed considerably.

Instead of working on a common layer height setting, the machine would adapt as per the need. Providing a balance between speed and final finish.

The Correct Wall Thickness

Are you ready to work with wall thickness? If you have found out the relationship between infill density and wall thickness, sure you are. These two parameters depend on each other and users must find out how before changing the wall thickness of the 3D model.

Maintaining a correct ratio between infill density and wall thickness would help instill the structural capabilities with successful print results.

You must work with patients to find out the best ratio for your 3D printer settings. You must take note of the ratios you use for the different 3D prints and stay vigilant to find out which setting provides the best results.

You must aim at attaining the balance between print speed and the quality of the final model. Settings using low infill density alongside low wall thickness would put your print at risk.

These settings would only work if the end-product does not need strength to be called a successful print.

When concerned about the print speed, you would find the results surging with a decrease in the number of shells or perimeters of your 3D models.

Once again, you must find out with trial and error the numbers that provide a fair amount of strength, while staying as low as possible.

Use as Less Support as Possible

It does not need much explanation. The lesser material your printer extrudes, the faster it completes the 3D print. Keeping the support low would also allow for a smoother finish. In other words, you can save a lot of time and maintain the quality of your print at the same time. You can check the different orientations to find out which one needs less support.

You can find out ways to keep your support requirements as low as possible. However, at the same time, you must include it wherever necessary. Or else, your 3D print will fail to print at all.

3D Print Multiple Parts

Do you think that your 3D printer can take up more parts at once? If that is so, do not waste the space by keeping it empty. Besides, you must print multiple parts at once. Utilizing the build space as much as possible will help complete the job in less time.

To do so, you can use the center as well as arrange a function in your slicer. You will find a significant change in the print speed.

Moreover, it would also help avoid settings such as reset then reheat your printer. The settings won’t be possible with larger parts that take up most of the space. But if you are 3D printing small objects, you can duplicate the models and 3D Print those at once.

Once again, you can play a little bit with the orientation of the models to see which one gets you the maximum fit for multiple 3D models. However, at the same time, avoiding the orientation that increases the need for support in your prints.

In short, you must find a way that helps you print multiple parts in one go without compromising on other parameters on the top.

The Conclusion

3D printing is a vast niche. Every day you get to learn through your experiences. Every project gives you a different outlook towards what could be the best settings for your 3D models.

And, with time, you realize that additive manufacturing is never becoming short of surprises. Similarly, when wanting to speed up 3D Printer, you must follow your instincts and try new settings, every now and then.

This would help find more about what is best for your 3D models. And, settings that suit your specific requirements.