Acrylonitrile Butadiene Styrene or ABS is one of the most popular thermoplastics in the world of 3D printing. Unlike others, ABS material is available at low cost, its sturdy in nature, can withstand high heat and wear.

The application is seen in a variety of consumer and industrial areas. Compared to the other materials for printing i.e. PLA, ABS is stronger and more durable.

In this article, we would be looking at the production process by which ABS is produced. Why printing with ABS is preferred? Limitations of printing with the material, Tips for 3D printing with ABS, and the main manufacturers that offer printing with ABS material.

One of the most striking features of ABS is the fact that this material is affordable. Very often in additive manufacturing, you see materials have got even more strength than ABS, but are less preferred because their cost is high.

Small businesses and especially, hobbyists cannot afford it. That is not the case with ABS. Because of this reason, ABS is the most preferred material by people in the field of 3D printing.

ABS is the most used material with FFM/FDM technology because of its physical properties. A high level of tensile strength, stiffness, and electrical properties make ABS withstand all the difficulties that come in the path of an FDM material.

However, if you are a newbie into the industry of 3D printing, it is natural for your mind to question,” why to print with ABS?” Especially after seeing that most of the people prefer this material. So to get an answer to this question, first let’s have a look at how ABS is made?

Because only after knowing about its production process, you can get to know why it possesses the properties that make the material perfect for 3D printing.

How is ABS Produced?

ABS is one of the first plastics that was used for 3D printing of parts and functional prototypes using an industrial-grade 3D printer. Produced in the year 1990, this thermoplastic polymer is also called as ‘terpolymer.’

ABS is produced by polymerization of acrylonitrile and styrene in the presence of polybutadiene. That’s exactly how ABS derived its name.

All these three materials are mixed generally in the proportions as 20 percent, 25 percent, and 55 percent of acrylonitrile, butadiene, and styrene respectively.

These three materials don’t typically mix and combine into a single product. This process of production is called emulsion.

Being a thermoplastic material, ABS has the quality to recycle itself whenever needed. One can also produce ABS from ABS itself. This is its special characteristics.

However, ABS’ characteristics can be changed by changing the proportions of all the three materials that make ABS.

For example, Styrene is responsible for giving ABS the rigidity and brilliance, so if you increase the proportion of styrene in its overall mixture, you will produce an ABS that is more rigid than general ABS.

Similarly, butadiene gives ABS its impact resistance and ability to survive at low temperatures. So, if Butadiene is used in more than 25 percent, you’ll be able to get an ABS that can survive at a lower temperature than normal ABS.

In the complete plastic injection industry, ABS holds the title of being the most used material, equivalent to PLA. Both, ABS as well as PLA are easy to print than other materials which are very technical and expensive.

After having looked at the printing process of ABS, let’s take a look at the benefits of printing with ABS or in other words, answer the curious question,” why to print with ABS?”

Why Print Using ABS?

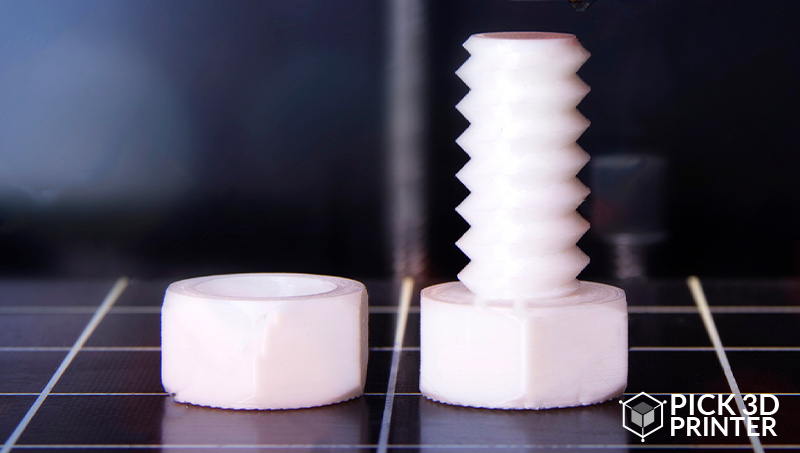

Used by FDM 3D printers, ABS comes in the form of a long filament that is wound around a spool. Operating this material on the printer is very simple, we need to keep this ABS strand into an extrusion head or extruder.

This extruder heats ABS plastic to its melting point and makes a liquid form of this material. After ABS is liquefied, it’s deposited layer by layer as per the design of a 3D part or functional prototypes that’s to be printed.

The creation of plastic products by employing such a manufacturing process is very easy.

ABS material offers a very good surface finish. The reaction of ABS with acetone tends to produce a smoother and more polished surface than compared to other materials.

There is also ease in sanding ABS compared to PLA or other materials with which 3D printing is possible.

Another reason to use ABS is that it’s affordable. This change came in 2009. Before that, there were failures in many patents related to FDM 3D printing.

Which resulted in a significant decrease in the cost of 3D printers and their materials. Plastic materials like ABS filament are priced less than $80 per kg.

ABS has a lower melting point compared to other thermoplastic. Because of this property, it becomes easy for the manufacture to develop a printer.

Printer parts that can withstand lesser temperatures than parts that are costlier and can withstand higher temperatures. This decrease the overall cost of the printer and makes it available to small businesses and hobbyist that are still experimenting with 3D printing technology.

Moreover, ABS has amazing thermal and mechanical properties. This plastic does not tend to wear out soon and can withstand high temperatures.

It has high strength and flexibility. A very popular example of this material is the Lego bricks game. All the pieces of that game are manufactured using ABS.

Tips for 3D Printing ABS Plastic

There are specific things that one should keep in mind while printing with ABS filaments. No just ABS, but this goes with every material with which 3D printing can be done.

Keeping these things in mind would ensure that your overall journey of printing with that material would go smooth. The first amongst those things to take care of is the importance of the first layer.

While printing with ABS the two general problems that one will encounter are Warping and lift-off.

To ensure that the possibility of these two problems to exist in your 3D part of the prototype is minimal, it is important to have a very good print of the first layer.

This can be done by making sure that the build platform is nicely calibrated. Automatic calibration is preferred because manual calibration is generally known to achieve a lesser amount of precision, comparatively.

It is a known fact that the build plate material that is known to achieve excellent compatibility with ABS filament is PEI.

So, by ensuring the calibration and using the best compatible surface, you can make sure that warping and lift-off are no more of a concern for your 3D part.

The other tip deals with storing of ABS Plastic. It is important to store ABS in a manner that it has an overall impact on the quality of the print.

Expert’s advice on this issue is to store ABS in a container or a bag that is airtight and in case the filament has taken up some moisture, it’s possible to dry it.

Following these tips won’t consume much of your time and will have a good amount of impact on your print. Now let’s have a look at the limitations of ABS.

Limitations Of ABS Material

This material reports of getting damaged whenever kept for a long time in sunlight. If such a thing happens, it can negatively affect the overall quality of the print.

So, for products that are to be made with ABS, wherein they are to be exposed directly to UV light, a UV-resistant filament like ASA is suggested.

Temperature control is a big issue while printing with ABS material. This is to ensure that the print cools down slowly, by doing this, one can prevent chances of development of cracking in the 3D part.

Additionally, by managing the temperature a better layer adhesion is also achieved. But as mentioned above, temperature adjustments can be little time consuming and they involve trial and error.

ABS is a material that absorbs moisture from the air. So, if the filament of ABS is not stored properly, chances are that it can lead to poor quality of prints or even failure during the printing process.

When melted, ABS emits intensely smelling fumes which can cause irritation and headaches. This problem is not much of a concern while printing smaller amounts.

But, while printing parts and prototypes using industrial-grade printers, it’s better to have a ventilation and huge amount of working space.

Now let’s take a look at some of the industries that use ABS material.

Applications Of ABS Material In Different Industries

Compared to other materials, ABS is regarded as a top choice for pipes and fittings. Not only ABS is easier to install and lighter in weight, but also will it not suffer from corrosion or rotting.

This quality of the material is specially used when collecting waste. ABS has higher durability, more than PVC and because of its resistance to impacts, it has gained much popularity in the pipe fitting industry.

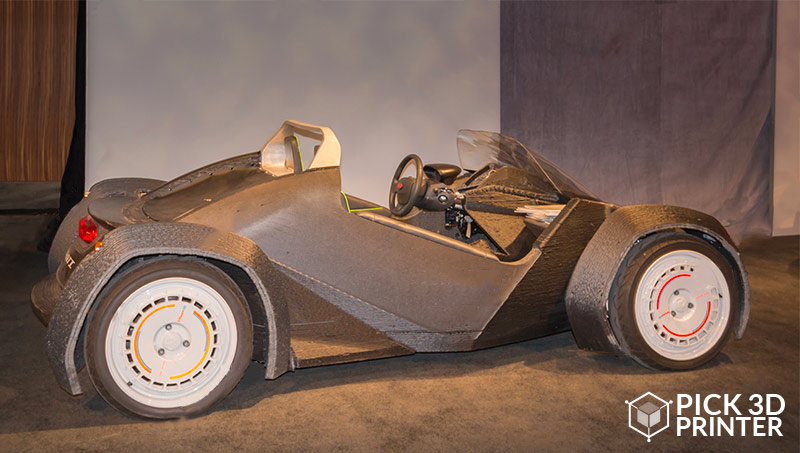

ABS material is light in weight. Because of this, it has found applications in the automotive industry. Vehicles have ABS plastic parts installed in them, which reduces their overall weight by 10 percent.

Some specific parts manufactured using ABS are dashboards, wheel covers, and body parts. These parts are built of ABS because they can resist low temperatures, they require more strength and good surface finish.

In 2014, Local Motors 3D printed an entire frame and body of the car with ABS reinforced with carbon fiber.

Another area that ABS material is found to be of tremendous use is household appliances. Vacuum Cleaners made of ABS have found their place in most of the homes. ABS is not just rigid and durable but is also found in many colors.

Remember our demands, while buying a household appliance? Even if it’s a vacuum cleaner, we want it to match the color shade of our furniture. It is because of this reason that ABS is used more compared to other plastics in this industry.

ABS has many mechanical properties like its stable, ductile, it has good machinability. It’s also a material that’s thermally stable. Apart from the industries mentioned above, ABS is used to make architectural models for engineers and in research departments.

In the medical field, it is used to make low-cost prostheses and tool handles. ABS material is also used to make plug holders for electric cars.

You can create electronics enclosures using ABS because of its excellent insulation properties and a lot more things.

The Conclusion

Main manufacturers of 3D printers are offering ABS filaments as a primary material to print. Amongst the main ones who are doing so, there is Stratasys, Ultimaker, FormFutura, and Innofil 3D.

ABS material is available in a wide range of colors. The prices of this range from $30 to $80 depending on the brand and the color you choose to go with.

There are also loaded filaments available in the market, where additives are added in ABS material. An example of one such loaded filament is called Kevlar.

This name is given to ABS based on carbon fibers or aramid fibers. Such a thing is done to increase the overall quality of the material for its application.

Kevlar reduces the warping phenomenon of ABS material and provides greater precision in printing. On the other hand, carbon reinforces the initial mechanical properties of the material.

However, these materials are on the expensive side of the market. They are not necessarily used only with FDM printing, but also with other methods like SLA, DLP, etc.

Overall, ABS is just like any other material that has its own pros and cons. But, one thing that cannot remain un-noticed is its wide existence in the additive manufacturing market.

Association of ABS material with two of the most widely used methods of 3D printing has made its place in homes of people. Whether the user is a beginner, an intermediate, or an expert in the field of 3D printing.